Cotton traceability is transforming how the industry ensures transparency and accountability. With growing consumer demand for ethically sourced products and stricter regulations, brands need reliable systems to verify the origins and sustainability of their cotton. Blockchain technology and certifications like Better Cotton Initiative (BCI) and Global Organic Textile Standard (GOTS) are stepping in to solve long-standing challenges in cotton supply chains.

Key Takeaways:

- Blockchain creates tamper-proof records across the supply chain, ensuring data integrity and transparency.

- Certifications like BCI and GOTS provide clear standards for tracking cotton from farms to retail shelves.

- Challenges include data accuracy at entry points, connectivity issues for small farmers, and privacy concerns.

- Solutions involve combining blockchain with physical tracers like DNA markers and adopting user-friendly platforms for data sharing.

Why It Matters:

- Consumer Trust: Over 50% of fashion consumers now prioritize ethical sourcing.

- Regulations: Laws like the EU Green Claims Directive require proof of fiber origins.

- Market Value: Traceable cotton earns higher prices and avoids risks like supply chain fraud.

This shift is more than a trend - it's becoming essential for brands to stay competitive. From blockchain pilots in Uzbekistan to certifications like the U.S. Cotton Trust Protocol, the industry is embracing tools that ensure cotton is traceable, compliant, and ethically sourced.

How Blockchain Technology Improves Cotton Traceability

Core Blockchain Features for Supply Chains

Blockchain creates a tamper-proof record of transactions, ensuring every step in the cotton supply chain - from farm to retail - is permanently documented. With smart contracts, processes like verification between supply chain partners are automated. For instance, when a gin operator logs a bale's Permanent Bale Identification (PBI) number, a smart contract can instantly cross-check it with USDA records. The system also uses standardized data models, such as EPCIS standards, to capture the essential details (who, what, where, when, why) in real time. This standardization allows everyone in the supply chain - whether small-scale farmers or large global brands - to share and access data securely, based on their permissions.

To combat fraud, blockchain systems often pair digital records with physical tracers. One method involves spraying DNA markers onto raw cotton at the gin, which can later be verified through PCR testing. This creates a physical-to-digital link, ensuring the cotton matches its recorded data. These features make blockchain a practical tool for improving cotton traceability.

Blockchain Tools for Cotton Tracking

In July 2021, the UNECE launched a blockchain pilot project in Uzbekistan, the sixth-largest cotton producer globally. The initiative aimed to trace T-shirts from cotton fields to retail shelves. Partners like Indorama Agro, Indorama Kokand Textile, and Nil Granit integrated Ethereum blockchain with Haelixa DNA markers, showcasing how complex supply chains can achieve full traceability.

On a larger scale, the U.S. Cotton Trust Protocol uses its Protocol Consumption Management Solution (PCMS) to track cotton at scale. The PCMS platform records each bale's unique PBI number and gin weight, verifies this data against USDA master lists, and creates a token for every kilogram of verified fiber. These tokens act as digital twins of the cotton, enabling precise tracking. Aaron Barcellos explains:

"The Trust Protocol allows everyone to see where and how their cotton is made. With third party verification, we're able to be transparent about the growing process".

During the 2024/25 season, the PCMS platform helped brands and retailers trace thousands of tons of fiber. Transparency maps allowed users to follow cotton's journey from shipment to ginning, confirming it as "Protocol Cotton". While these tools are promising, blockchain technology still faces critical challenges.

Blockchain Limitations and Challenges

Although blockchain ensures data integrity, it cannot guarantee the accuracy of the information when initially entered. Fraudulent data recorded at the farm or gin level becomes a permanent part of the blockchain. Additional challenges include ensuring accurate data entry, addressing connectivity and digital literacy issues among smallholder farmers, coordinating across the 15+ nodes in the supply chain, and managing data privacy concerns. Many participants hesitate to share sensitive details, such as supplier identities or pricing, on a distributed ledger.

Experts suggest combining blockchain with forensic tools like DNA markers to ensure the physical cotton matches its digital record. They also recommend adopting standardized frameworks like UN/CEFACT or EPCIS for smoother data exchange and creating mobile-first solutions that enable farmers to input data directly from the field. These strategies can help overcome the hurdles and maximize blockchain's potential in cotton traceability.

7. TextileGenesis: Creating transparent supply chains with Blockchain

Certifications That Set Standards for Cotton Traceability

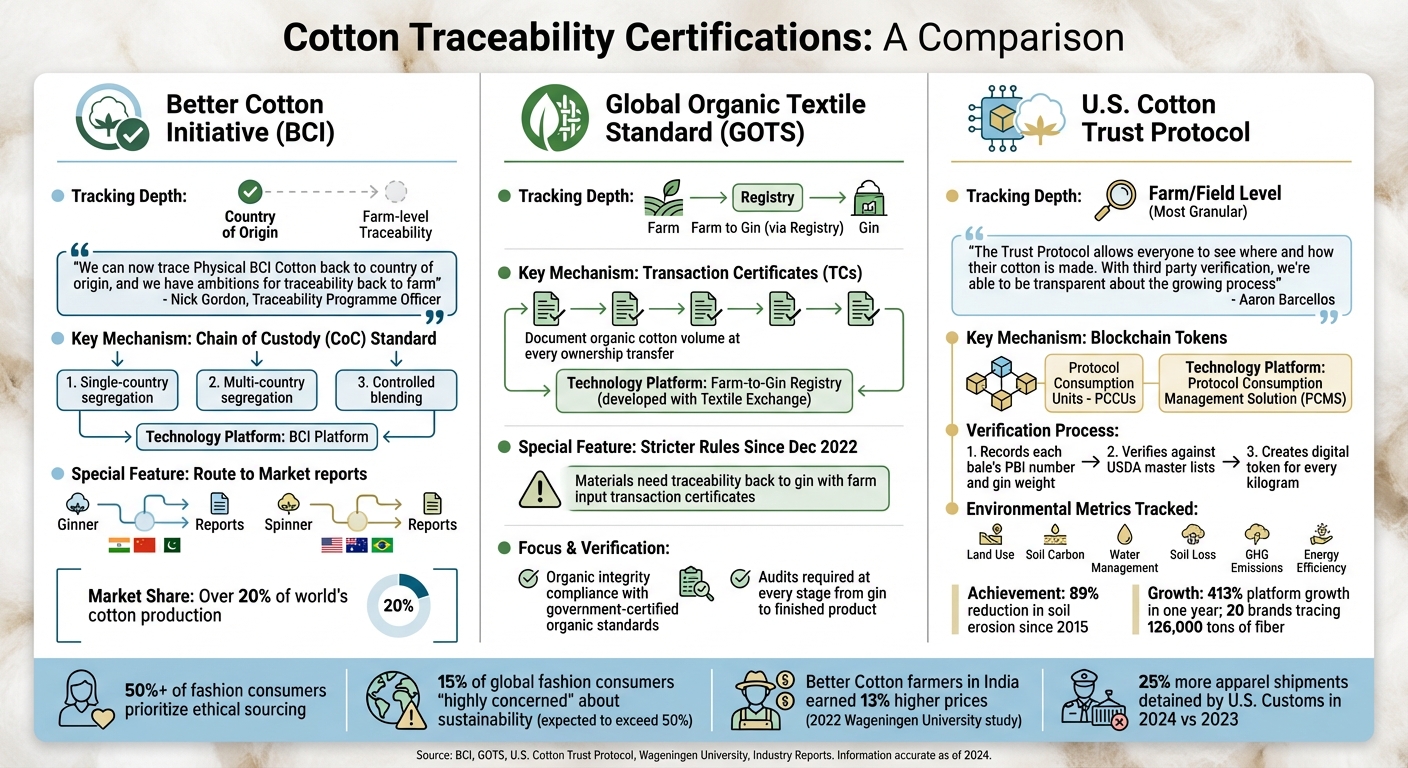

Cotton Traceability Certifications Comparison: BCI, GOTS, and U.S. Cotton Trust Protocol

Blockchain may offer the technical backbone for tracking cotton, but certifications lay down the rules of the game. These programs establish the frameworks that ensure cotton can be followed from the field to the final product, giving brands and consumers confidence in their claims. By working alongside blockchain, certifications provide clear and auditable standards that enhance traceability.

Better Cotton Initiative (BCI)

BCI has taken a major step forward in traceability by combining blockchain technology with well-defined standards. In late 2023, BCI introduced a program that moves beyond the mass balance approach, enabling the tracking of "Physical Better Cotton" back to its country of origin. This is made possible through a Chain of Custody Standard, which offers three models: single-country segregation, multi-country segregation, and controlled blending. All of this is managed on the BCI Platform.

Nick Gordon, the Traceability Programme Officer at Better Cotton, highlighted the program’s ambitions:

"We can now trace Physical BCI Cotton back to country of origin, and we have ambitions for traceability back to farm".

BCI’s Route to Market reports already provide traceability to the ginner in countries like India, China, and Pakistan, and to the spinner in locations such as the U.S., Australia, and Brazil.

Global Organic Textile Standard (GOTS)

GOTS takes a more rigorous route to traceability, requiring audits at every stage - from the gin to the finished product. The system relies on Transaction Certificates (TCs), which document the volume of organic cotton as ownership changes hands. Each transfer must include a new certificate, ensuring an unbroken record.

In December 2022, GOTS introduced stricter rules: materials certified under the Organic Content Standard (OCS) now need traceability back to the gin, supported by farm input transaction certificates. The Farm-to-Gin Registry, developed with Textile Exchange, collects farm-level data to verify volumes and detect any substitution or fraud. GOTS stands out by focusing on organic integrity, a term that requires compliance with government-certified organic standards.

U.S. Cotton Trust Protocol

The U.S. Cotton Trust Protocol blends certification with blockchain through its Protocol Consumption Management Solution (PCMS). Each bale of cotton is verified using its Permanent Bale Identification (PBI) number, which is cross-checked against USDA master lists. Verified fiber is then converted into digital Protocol Consumption Units (PCCUs).

The program also measures six environmental metrics: land use, soil carbon, water management, soil loss, greenhouse gas emissions, and energy efficiency. By the 2024/25 season, growers participating in the Trust Protocol had already met or exceeded five of six national sustainability goals, including an 89% reduction in soil erosion since 2015.

The PCMS transparency map allows brands to see the names and locations of every mill and manufacturer involved in production. Companies like Carhartt, Inc. and Engelbert Strauss have joined the program to track their cotton supply chains and increase their use of responsibly grown cotton. In 2025, the Trust Protocol also launched a pilot program to trace regenerative farming practices, offering brands new options for sourcing cotton grown with these methods.

| Certification | Tracking Depth | Key Mechanism | Technology Platform |

|---|---|---|---|

| Better Cotton (BCI) | Country of Origin (moving toward farm) | Chain of Custody (CoC) Standard | BCI Platform |

| GOTS | Farm to Gin (via Registry) | Transaction Certificates (TCs) | Farm-to-Gin Registry |

| U.S. Cotton Trust Protocol | Farm/Field Level | Blockchain Tokens (PCCUs) | PCMS |

sbb-itb-0e617ca

How to Implement Traceability Systems

Setting up a traceability system starts with a clear plan. Producers, gin operators, and partners need to understand the steps, tools, and strategies required to ensure a positive return on investment (ROI). The good news? Traceability can often build on existing systems without requiring a complete overhaul of operations.

Collecting Data Across the Supply Chain

Accurate data collection is the backbone of any traceability system. At the gin, operators record each bale's PBI number and weight, creating a "digital twin" for the cotton. This information is verified instantly against official databases like the USDA master list through the U.S. Cotton Trust Protocol's PCMS system, which generates a Protocol Consumption Unit (PCCU) for every kilogram of verified fiber. This process aligns with the peak marketing period, as over 50% of the U.S. cotton crop is sold between November and January.

Choosing the right Chain of Custody (CoC) model is another critical step. Options include:

- Segregation: Keeping cotton from specific origins separate.

- Controlled Blending: Mixing certified and non-certified cotton under strict ratios.

- Mass Balance: Tracking volumes without physical separation.

Verification systems typically include three levels: facility audits, digital certificates, and physical checks. As Nick Gordon points out, tracking cotton through multiple handoffs is challenging, but consistent data collection at every stage helps close visibility gaps. These foundational steps ensure that digital solutions can be integrated smoothly.

Adopting Digital Platforms

Digital platforms simplify traceability by automating data collection and minimizing manual input. The key is leveraging existing identifiers - like the PBI number and gin weight - so workflows remain familiar and efficient.

Integration becomes seamless with tools like API and SFTP connections, which allow current software to communicate directly with traceability platforms. For example, Textile Exchange's eTrackit platform, launched in September 2024, uses "eTransactions" to provide real-time inventory updates and peer-to-peer validation within a closed-loop supply chain.

Training is essential to ensure these systems are accessible to all users, regardless of their digital literacy levels. As Nick Gordon explains:

"When introducing a digital traceability system, we need to consider varying levels of digital literacy, and make sure any system we introduce is readily understandable and easy to use, while also fitting the needs of users."

User-friendly platforms like the BCI Platform and dTrackit are designed specifically for the cotton industry, consolidating essential data like scope and transaction certificates in one place. This reduces paperwork and simplifies the entire process. By automating data validation, these platforms make traceability more efficient while paving the way for measurable ROI.

Costs and Return on Investment

Implementing traceability systems comes with costs, including the additional workload for documenting transactions, investing in digital platforms, and providing training to bridge digital literacy gaps. However, the benefits far outweigh these initial expenses.

One immediate advantage is regulatory compliance. Traceability offers the documentation needed for laws like the EU Green Claims Directive and the Corporate Sustainability Reporting Directive (CSRD), helping brands avoid penalties and reputational risks. It also mitigates the risk of sourcing from restricted regions or using forced labor, ensuring compliance with U.S. import laws.

Financial benefits are also compelling. For example, a 2022 study by Wageningen University found that Better Cotton farmers in Nagpur, India, earned 13% higher prices for their cotton compared to conventional farmers. This demonstrates how traceability can directly boost market value.

Consumer demand is another driving factor. A 2022 Bain & Company study revealed that 15% of global fashion consumers are "highly concerned" about sustainability - a number expected to exceed 50% in the coming years. Brands that can prove their sustainability claims through traceability build stronger consumer trust and loyalty.

Operational efficiency is another major benefit. Traceability systems enhance supply chain visibility, allowing stakeholders to identify bottlenecks and improve resource allocation. Farmers, for instance, can use traceability data to monitor water and energy use, making adjustments that improve both efficiency and environmental outcomes. As Aaron Barcellos, a Trust Protocol farmer, explains:

"The Trust Protocol allows everyone to see where and how their cotton is made. With third party verification, we're able to be transparent about the growing process."

| Key Area | Business Benefit / ROI |

|---|---|

| Regulatory Compliance | Provides proof for EU directives; avoids fines |

| Risk Mitigation | Lowers risk of sourcing from restricted regions |

| Consumer Trust | Builds loyalty as sustainability becomes a priority |

| Operational Efficiency | Improves visibility; identifies bottlenecks |

| Market Value | Enables price premiums and access to "Impact Marketplaces" |

Emerging financial incentives, such as "Impact Marketplaces" and carbon insetting frameworks, further strengthen the case for traceability. These systems reward farmers for sustainable practices by using traceability data to calculate environmental impacts, offering direct financial benefits alongside operational improvements.

Case Studies in Cotton Traceability

Real-world examples show how blockchain and certification systems are reshaping cotton traceability, offering transparency and accountability across supply chains. Let’s dive into some key pilot projects that highlight their impact.

Organic Cotton Traceability Pilot

Fashion for Good spearheaded a yearlong project to trace 75 metric tonnes of organic cotton from Indian farms to retail shelves. This initiative combined Bext360's blockchain technology with physical markers such as DNA from Haelixa and fluorescent tracers from Tailorlux. Major brands like C&A, Kering, PVH Corp, and Zalando took part in this effort.

While digital records are useful, they alone can't prevent cotton substitution. To address this, the project embedded DNA markers into cotton fibers, enabling forensic verification at every step. Managing Director Katrin Ley emphasized the significance of this approach:

"The success of the organic cotton traceability pilot provides a positive impulse towards traceability and transparency in the value chain".

The project also made data collection more accessible for smallholder farmers by adopting mobile-friendly tools. Its success has paved the way for broader scalability tests in diverse environments.

UNECE Blockchain Pilot

In July 2021, the United Nations Economic Commission for Europe (UNECE) launched a blockchain project in Uzbekistan, the sixth-largest cotton producer globally. This initiative tracked T-shirts from cotton fields to retail shelves, involving players like Indorama Agro (farming), Indorama Kokand Textile (spinning), and Nil Granit (manufacturing).

The pilot achieved end-to-end visibility across 15 supply chain nodes. Using an open-source Ethereum blockchain and standardized data models based on UN/CEFACT and EPCIS frameworks, it ensured seamless cross-border communication.

Another UNECE-led pilot, in partnership with Stella McCartney and Turkish supplier SÖKTAS, ran from September 2022 to June 2023. This project focused on regenerative cotton practices, recording a carbon capture rate of 18.94 tonnes of CO₂ per hectare annually in the top 45 centimeters of soil. Elisabeth Türk, UNECE's Director of Economic Cooperation and Trade, highlighted the consumer benefits:

"Once we know the provenance of the clothes that we buy, and the path they have travelled in global value chains, then we can make informed decisions as consumers about the sustainability claims of those goods".

These pilots underscore how blockchain can verify sustainability claims and incentivize better practices.

BASF Smart Contracts for Farmers

In October 2022, BASF Agricultural Solutions introduced the "Seed 2 Sew" pilot in Komotini, Greece. This project partnered with five local farms, Thrakika Ekkokkistira ginning mill, and fashion brand Athos Pallas to track FiberMax® cotton from seed to retail. Using Bext360's blockchain platform, which consumes 99.95% less energy than older blockchain systems, the pilot covered 5,000 cotton bales - enough for over 6 million T-shirts.

Smart contracts played a key role by automating payments to farmers who followed the Certified Sustainable FiberMax® (CSF) protocol. These farmers earned financial rewards for adopting sustainable practices, such as improving water use and soil health. Emmanouela Kouroudi, Vice President of Thrakika Ginning Mills, explained:

"We give financial premiums to CSF farmers for quality cotton and strict adherence to sustainability protocols!".

The program, involving about 1,600 farmers, also delivered environmental benefits. These included reducing CO₂ emissions by 5–15% and increasing soil organic carbon by 60–80 kilograms per hectare annually. Blockchain further ensured that claims about origin, chemical use, and labor standards were backed by irrefutable evidence. Maria Karamba, Head of Sales at Athos Pallas, emphasized the added trust:

"Certifications are not always reliable in the textile industry and a blockchain that sources cotton will take the trust to another level".

Together, these initiatives show how blockchain and certification systems can drive transparency and accountability, fostering trust across global cotton supply chains.

Conclusion: Building a Transparent Cotton Industry

The cotton supply chain is undergoing a transformation, thanks to blockchain technology and certification systems. These innovations are replacing traditional mass balance tracking with physical traceability, where actual cotton fibers are monitored from farm to finished product. This shift isn’t just a choice - it’s becoming a requirement under new regulations.

Every player in the supply chain stands to gain. Farmers can tap into premium markets and earn direct financial rewards through Impact Marketplaces, which compensate them for adopting sustainable practices. Gin operators benefit from faster verification of cotton bales using PBIs (Physical Bale Identifiers), allowing them to market certified cotton quickly, especially during the critical three-month post-harvest period. Marketers, on the other hand, get access to real-time data and compliance tools, catering to the 70% of consumers who prioritize ethical production.

Consider this: Better Cotton now accounts for over 20% of the world’s cotton production, making large-scale traceability possible. The U.S. Cotton Trust Protocol’s digital platform saw a staggering 413% growth in just one year, enabling 20 brands to trace 126,000 tons of fiber. Meanwhile, U.S. Customs detained 25% more apparel shipments in 2024 compared to 2023, highlighting the growing demand for verifiable origin documentation.

"Traceability at scale for cotton will drive a seismic shift within our industry's supply chains. Better Cotton's traceability solution is poised to help the industry deliver that shift."

– Alan McClay, Chief Executive Officer, Better Cotton

Alan McClay’s words emphasize the transformative potential of blending technology with established practices.

FAQs

How does blockchain help track cotton through the supply chain?

Blockchain technology is changing the game for cotton traceability by securely logging key information at every step of the supply chain. Details like location, timestamps, and verification records are stored on a digital ledger that can't be tampered with.

This approach boosts transparency and accountability by offering real-time access to reliable, unchangeable data. It equips cotton producers, manufacturers, and retailers to address the increasing consumer demand for ethical and responsibly sourced products.

What challenges come with implementing cotton traceability systems?

Setting up cotton traceability systems comes with a host of challenges, largely due to the intricate nature of global supply chains. These supply chains often involve numerous players spread across different regions, making coordination and reliable data collection both time-consuming and resource-heavy. On top of that, verifying claims tied to farming practices or labor conditions requires systems that are not only thorough but also capable of ongoing, detailed monitoring.

Integrating technologies like blockchain into these processes introduces another layer of difficulty. It often requires considerable investment, technical know-how, and overcoming pushback from those accustomed to traditional methods. Ensuring the accuracy of data and avoiding mislabeling becomes even more critical as misleading claims continue to surface within the industry.

Adding to the complexity are the varying regulations and standards across different countries. These inconsistencies make it harder to establish uniform traceability practices. Overcoming these obstacles demands a mix of collaboration, technological advancements, and a strong commitment to transparency throughout the entire supply chain.

How do certifications like BCI and GOTS improve transparency in the cotton supply chain?

Certifications such as the Better Cotton Initiative (BCI) and the Global Organic Textile Standard (GOTS) play a key role in promoting transparency. They ensure cotton is sourced and processed following strict ethical and environmental guidelines. These programs create traceable systems that track cotton's journey from farms to finished goods, verifying compliance at every stage.

For consumers, these certifications offer peace of mind, signaling that the cotton in their products aligns with high standards for environmental responsibility, worker rights, and ethical sourcing. For businesses, they serve as a way to build trust and credibility while addressing the increasing demand for responsible practices.