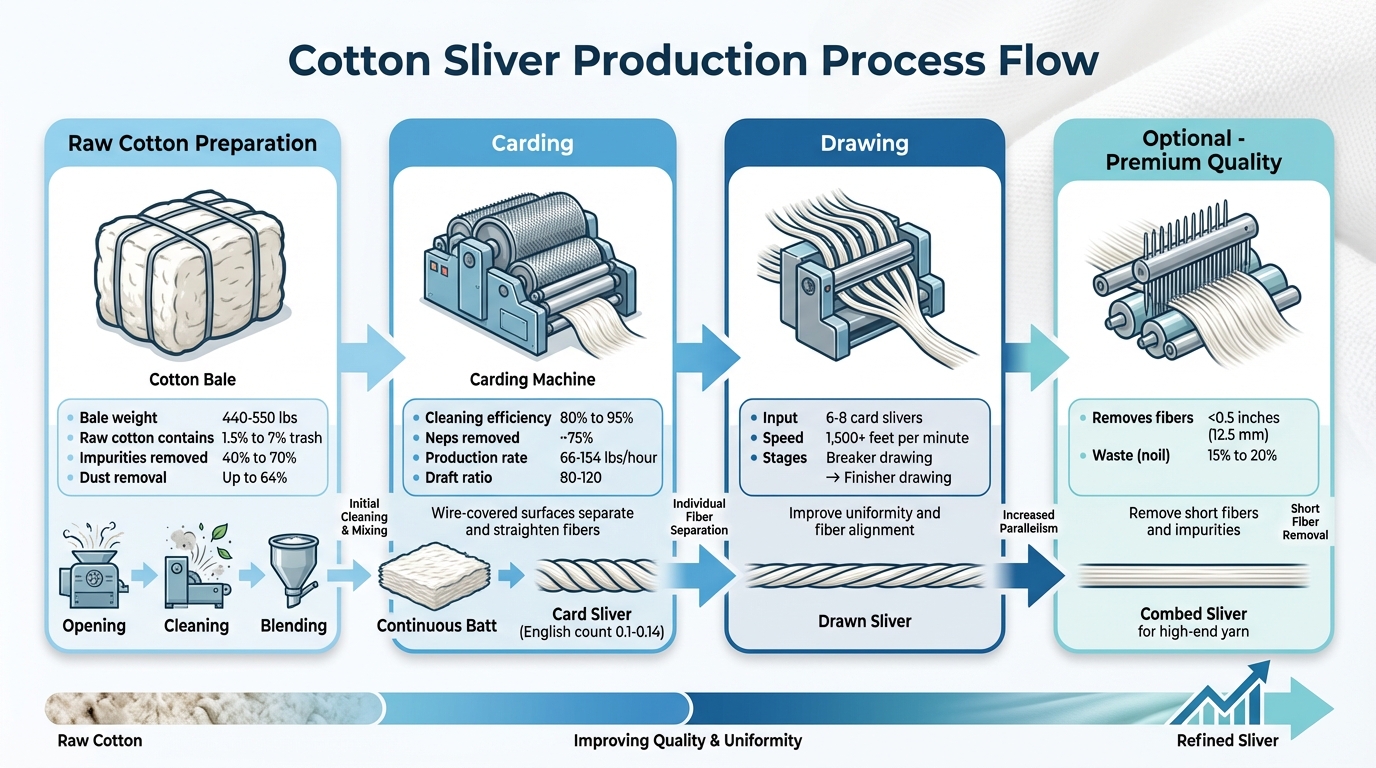

Cotton sliver production is the first step in turning raw cotton into yarn. A sliver is a soft, untwisted strand of aligned cotton fibers, formed during the carding process. Its quality directly impacts yarn strength, consistency, and waste levels in spinning mills. Modern machinery ensures efficient sliver production, but achieving consistency requires careful preparation, blending, and refinement through processes like drawing and combing.

Here’s a quick breakdown of the process:

- Raw Cotton Preparation: Cleaning and blending fibers to remove impurities and ensure uniformity.

- Carding: Separating, straightening, and forming fibers into slivers.

- Drawing: Combining multiple slivers into one for better alignment and uniformity.

- Combing: Removing short fibers for premium yarn quality.

- Machinery: Carding machines, draw frames, and combers play key roles in sliver production.

Key challenges include dealing with short fibers, maintaining equipment, and controlling contaminants. Solutions like preventive maintenance, stable processing conditions, and advanced contamination detection systems help mills produce high-quality slivers efficiently. This process forms the backbone of yarn production, influencing the final product's quality and profitability.

Cotton Sliver Production Process: From Raw Cotton to Refined Sliver

Yarn Manufacturing: Preparation for Spinning

Raw Cotton Preparation: Starting the Sliver Production Process

Raw cotton bales typically contain 1.5% to 7% trash, which is partially removed during the blowroom process - eliminating 40% to 70% of impurities. This step sets the stage for producing high-quality sliver. The process begins with two essential steps: opening and cleaning, followed by blending to ensure consistency.

Opening and Cleaning

Cotton arrives in tightly compressed bales, each weighing between 440 and 550 pounds. Automated bale pluckers methodically release fiber tufts, making them easier to clean in the subsequent steps. As textile researcher Mazadul Hasan Shishir explains:

"The first operation required in the blowroom line is opening. Tuft weight can be reduced to about 0.1 mg in the blowroom."

The cleaning process involves a combination of mechanical beating, air currents, gravity, and centrifugal force to separate trash like seeds and leaf fragments from usable fibers. Cleaning machines use adjustable grid bars to ensure heavier impurities fall through, while lighter fibers continue through the line. Modern suction units enhance this process by removing up to 64% of dust from raw cotton. Additionally, advanced contamination detection systems equipped with high-speed cameras identify non-cotton materials, which are then ejected using air jets before reaching the carding stage. After cleaning, the fibers are formed into a continuous batt to maintain consistent material weight for the carding process.

Blending for Uniformity

Blending is critical for achieving consistency. Differences in fiber length, strength, and micronaire across bales can result in uneven yarn if not addressed. Himanshu Fogla, Director of Jumac Manufacturing, highlights the importance of blending:

"Through careful blending, variations and inconsistencies in the yarn are minimised, and overall homogeneity is enhanced."

To achieve this, mills use computerized bale management systems that group bales based on fiber properties determined by USDA classing data. Bale pluckers then remove small amounts of fiber from each bale, ensuring an even mix from the outset. Multi-cell blenders further randomize and homogenize the fiber tufts by filling and emptying multiple chambers. This uniform blend ensures that fibers entering the carding stage are consistent, directly impacting the quality of the sliver produced.

Carding Process: Converting Cotton into Slivers

Once cotton is uniformly blended, the next step is the carding process, which transforms the fibers into a continuous sliver. This step is crucial in spinning, as it turns cleaned cotton into individual fibers that can be formed into a sliver. Modern carding machines are incredibly efficient, cleaning up to 80% to 95% of remaining impurities and untangling about 75% of neps (tiny knots of tangled fibers) that may still be present.

How Carding Machines Work

Carding machines use wire-covered surfaces moving in opposite directions to separate and straighten the fibers. The process begins when cotton is fed into the machine via a roller, which passes the material to a taker-in equipped with saw-tooth wire. This combs the cotton into small clusters or flocks. These fibers are then transferred to the main cylinder, where they interact with a series of flat bars - typically between 80 and 116 - that rotate above the cylinder. This interaction is the heart of the carding process, breaking apart fiber clumps, removing dust, short fibers, and leftover debris.

The machine operates with two key actions: the carding action, which separates and individualizes the fibers while removing neps, and the stripping action, which moves fibers between different surfaces. These mechanical actions prepare the fibers for sliver formation. Modern carding machines are highly productive, with output rates ranging from 66 to 154 pounds per hour, and some high-speed models exceeding 100 pounds per hour.

Breaker Carding and Sliver Formation

After the fibers are carded, they are collected by the doffer, which removes them from the cylinder and condenses them into a sheet-like web. This web is then fed through crush rollers and funneled into a trumpet-shaped device that compresses it into a rope-like strand. This strand, known as a sliver, has an English count between 0.1 and 0.14 and is coiled into metal cans for easy transport to the next stage: the draw frame.

At this stage, the fibers are not yet perfectly aligned. About 50% of the fibers have trailing hooks, 15% have leading hooks, 15% show double hooks, and less than 20% are fully straightened. This partial alignment is fine-tuned during the drawing stage, which follows. The draft applied during carding - ranging from 80 to 120 - ensures the output sliver is much finer and more uniform compared to the input material.

Refining the Sliver: Drawing and Combing

Once carding is complete, the sliver undergoes further refinement to ensure precise alignment. Two key processes - drawing and combing - prepare the material for the production of high-quality yarn.

Drawing Process: Smoothing and Aligning Fibers

The drawing process combines six to eight carded slivers into a single, uniform strand through a technique called doubling. This step helps smooth out inconsistencies present in individual slivers, creating a more even base.

Next, the sliver is fed through rollers that gradually increase in speed - a mechanism known as drafting. This stretching action restores the strand's mass to that of a single sliver while improving fiber alignment. Drafting also eliminates residual hooks, ensuring a consistent fiber structure. Modern draw frames operate at impressive speeds, often exceeding 1,500 feet per minute. Typically, drawing involves two stages: breaker drawing (the initial pass) and finisher drawing (the final refinement before the sliver moves on to roving or spinning).

Once the fibers are aligned and smoothed, the sliver is ready for combing, a process that takes refinement to the next level.

Combing for Premium Quality

Combing builds on the work of drawing by removing short fibers and impurities, producing slivers suitable for high-end yarn. While drawing aligns fibers, combing eliminates fibers shorter than 0.5 inches (12.5 mm), which can weaken the yarn and affect its appearance.

"Short fibers of length less than 12.5 mm do not contribute to the mechanical properties of the yarn but increase yarn hairiness, which adversely affects the yarn and fabric appearance."

- Mazharul Islam Kiron, Founder & Editor, Textile Learner

The combing machine uses needle-covered surfaces to extract short fibers, neps, and impurities. The waste material, known as noil, typically accounts for 15% to 20% of the input material. While this noil cannot be used in premium yarns, it is often recycled into lower-grade yarns or nonwoven products, helping mills reduce waste and manage costs effectively.

| Feature | Drawing Process | Combing Process |

|---|---|---|

| Purpose | Improve uniformity and fiber alignment through doubling and drafting | Remove short fibers, neps, and impurities for superior quality |

| Techniques | Doubling (blending) and drafting (stretching) | Nipping, combing (half-lap), and piecing |

| Waste Removal | Minimal; primarily removes dust | Significant; extracts noils for recycling |

| Impact on Yarn | Standard strength and evenness | Enhanced strength, smoothness, luster, and fineness |

| Usage | Essential for all spinning systems | Optional; used for fine-count or high-end yarns |

Combing is often reserved for producing fine-count yarns used in premium clothing and upscale home textiles. The process not only enhances the softness and drape of the fabric but also improves the parallel alignment of fibers, giving combed yarns a distinct sheen and a luxurious feel.

sbb-itb-0e617ca

Machinery Used in Sliver Production

Main Machines: Carding, Draw Frames, and Combers

Once slivers are refined through processes like drawing and combing, specific machines ensure these improvements are carried forward seamlessly. Three key machines play a pivotal role in sliver production: the carding machine, draw frame, and comber. Among them, the carding machine is the cornerstone, tasked with separating fibers and forming the initial rope-like sliver. Modern carding machines can handle impressive workloads, processing cotton at rates of up to 485 lbs/hour (220 kg/h). This efficiency bridges the gap between raw cotton and a refined fiber mass.

"The card is the heart of the spinning mill and well carded is half spun."

- Dr. Artzt, Research Institute in Denkendorf

After carding, the draw frame takes over, combining multiple card slivers to improve uniformity and align fibers more precisely. These machines operate at speeds exceeding 1,500 feet per minute, ensuring consistency in the sliver. For high-quality yarns, the comber steps in to remove fibers shorter than 0.5 inches, further refining the sliver and enhancing its quality.

| Machine Type | Primary Function | Production Rate | Key Quality Impact |

|---|---|---|---|

| Carding Machine | Separates fibers, removes trash and neps | Up to 485 lbs/hour | Achieves 80% to 95% cleaning efficiency |

| Draw Frame | Combines slivers and aligns fibers | 1,500+ feet per minute | Improves uniformity and fiber alignment |

| Comber | Removes short fibers (under 0.5 inches) | Varies by model | Enhances evenness and strength for premium yarns |

These machines work together to ensure slivers meet high-quality standards. The cost of this equipment reflects their advanced capabilities. For instance, in India, cotton carding machines are priced at around ₹1.45 million (approximately $17,400), while specialized fiber carding machines cost about ₹1.65 million (roughly $19,800). Over the years, advancements in these machines have significantly boosted efficiency. Carding production rates, for example, have surged from just 11 lbs/hour (5 kg/h) in 1965 to the impressive levels seen in modern systems.

Quality Control in Sliver Production

Parameters for Sliver Quality

After the refinement process, maintaining consistent sliver quality hinges on strict quality control measures. Key parameters are monitored throughout production to ensure each sliver meets precise standards. Among these, short fiber content (SFC) plays a pivotal role, as it directly affects drafting force and the overall efficiency of spinning operations. Another critical factor is linear density, which must be closely tracked to ensure the sliver drafts to the correct yarn count. Additionally, fiber alignment and uniformity are essential - misaligned fibers can create weak spots and defects in the final yarn.

"Short fiber content has the greatest impact on drafting force." - D. D. McAlister, III, J. D. Bargeron, and L. C. Godbey

To optimize production, modern mills rely on computerized systems that group cotton bales based on fiber characteristics like micronaire and length. These systems, combined with drafting force measurements, help predict processing waste and enhance efficiency. These parameters provide the foundation for the testing methods outlined below.

Testing and Monitoring Techniques

Quality control involves thorough testing at multiple stages. For instance, count (Hank) is checked regularly, and drafting force is measured using untwisted fiber bundles to quickly identify and address any issues. Sliver samples are prepared by running them through a drawbox 5 to 10 times, aligning the fibers before evaluating their length, maturity, and strength.

Environmental factors are also tightly controlled, as cotton's electrical resistance decreases drastically with humidity - a 13% rise in relative humidity can reduce resistance tenfold. Advanced tools, like high-speed cameras, now identify and remove contaminants such as plastics or off-color fibers. Additionally, specialized equipment ensures high-quality sliver production:

- Uster Tester: Measures evenness.

- Fibrograph: Evaluates fiber length.

- Micronaire: Assesses fineness and maturity.

Challenges in Sliver Production and How to Address Them

Common Challenges in Sliver Production

Spinning mills face a range of recurring issues that can hinder sliver production. One major problem is dealing with short fibers - those shorter than 0.5 inch (12.5 mm). These fibers weaken yarn strength, increase hairiness, and raise drafting force requirements. The result? Higher waste levels and reduced overall efficiency.

Equipment wear and tear is another common challenge. Worn drafting rollers, dull half-lap needles, and improperly functioning nippers can harm sliver uniformity. On top of that, environmental factors like temperature and humidity fluctuations can lead to increased fiber breakage during processing. Contaminants such as plastic, organic debris, and dust further complicate matters. These not only disrupt high-speed machinery but also lead to defects in the final product. Addressing these issues requires a combination of regular maintenance and strategic upgrades.

Practical Solutions for Better Production

To tackle these challenges, spinning mills can implement several practical solutions aimed at improving efficiency and ensuring consistent quality.

- Preventive Maintenance: Regularly buff drafting rollers and replace worn half-laps to maintain sliver quality. For mills processing over 100 pounds of cotton per hour, proactive maintenance is essential to avoid costly downtime.

- Environmental Control: Keeping temperature and humidity stable helps minimize static buildup and reduces fiber breakage.

- Operator Control Points: Operators should verify nipper settings, roller pressure, and trumpet dimensions against established norms to ensure smooth operation.

- Contamination Detection: Camera-based systems can detect and eject foreign materials by analyzing their color, shape, and transparency, significantly reducing defects caused by contamination.

Additional processing methods can also make a big difference. For instance, incorporating combing into the production process removes short fibers, improving both yarn strength and appearance. As Mazharul Islam Kiron, Founder & Editor of Textile Learner, explains:

"The setting between the machine elements in the comber machine plays a critical role in deciding the quality as well as processability of the material"

Another effective measure is using chute feeds (batt formers). These ensure that the carding machine receives a consistent weight of material, leading to more uniform sliver output. By adopting these strategies, mills can streamline production and meet the high standards required for efficient spinning.

Conclusion

Cotton sliver production plays a central role in the success of yarn manufacturing. In advanced spinning systems like open-end, air-jet, and Vortex, yarn is created directly from sliver, skipping the roving stage entirely. This means the quality of the sliver becomes the ultimate factor in determining the integrity of the yarn.

Production metrics highlight just how critical sliver quality is. High-capacity machinery and faster drawing speeds are essential, as they allow six to eight sliver strands to blend seamlessly during the drawing process, ensuring uniformity. This uniformity influences yarn strength, consistency, and durability - all key factors in a mill's ability to remain competitive.

These technical considerations directly shape decisions about quality and cost management.

"Balancing fiber quality and processing costs is crucial for profitability." - CottonWorks

Maintaining strict quality control is essential to minimize downtime and enhance efficiency. By monitoring drafting force, mills can assess processing performance and anticipate potential waste. Additionally, maintaining suitable environmental conditions, using well-matched equipment, and employing contamination detection systems help safeguard both product quality and production speed.

As discussed, choices around fiber selection and machine upkeep affect every step of the production process. Decisions like balancing fiber quality with cost, perfecting blending techniques, or incorporating combing for higher-end markets all contribute to the overall success of the operation. By mastering these essential production practices, spinning mills can meet rigorous quality demands while achieving the efficiency necessary to excel in today’s competitive textile industry.

FAQs

What are the key challenges in producing cotton slivers, and how can they be resolved?

One of the key hurdles in producing cotton sliver is preserving fiber quality during critical steps like carding and combing. If machinery settings are too loose or poorly aligned, fibers can become tangled, forming neps - those tiny lint balls that disrupt sliver uniformity and ultimately compromise yarn quality. On top of that, leftover short fibers and impurities can cause uneven drafts, leading to sliver breakage and higher energy usage.

To tackle these challenges, focus on precise alignment and maintaining tighter gaps between the carding cylinder and components like flats or the doffer. Fine-tuning parameters such as feed rate, roller speed, and wire tension can help minimize short fibers and impurities. In the combing process, removing a controlled portion of short fibers - usually between 5% and 25% of the feedstock - enhances sliver smoothness. While this step might slightly increase costs (about $1 per kilogram of yarn), the improvement in quality is worth it. Lastly, regular equipment maintenance and thorough operator training are indispensable for maintaining efficiency and ensuring consistent, high-quality production.

What role does carding play in ensuring high-quality yarn?

Carding plays a key role in the spinning process, where raw cotton fibers are cleaned, untangled, and arranged into a continuous, untwisted strand known as a sliver. This step eliminates up to 95% of impurities, including dust, seed fragments, and short fibers, while aligning the fibers in a parallel manner to ensure greater uniformity.

The quality of the sliver has a direct effect on the yarn produced. Effective carding helps reduce defects like neps (tiny fiber tangles) and uneven areas, which results in yarn that is stronger, smoother, and more consistent. A properly carded sliver not only minimizes irregularities but also reduces breakages during spinning, leading to superior yarn quality and improved performance in the final product.

Why is blending raw cotton important before sliver production?

Blending plays a crucial role in preparing raw cotton for sliver production, ensuring a consistent and uniform mix of fibers. By combining fibers from multiple bales, variations in properties such as length, strength, fineness, and impurity levels are balanced out. This process helps reduce inconsistencies and enhances the overall quality of the sliver.

A properly blended feedstock is vital for subsequent steps like carding, drawing, and roving. It helps prevent problems like uneven thickness, neps, or fiber breakages. The result? Higher-quality yarn and smoother production with less waste and fewer interruptions.