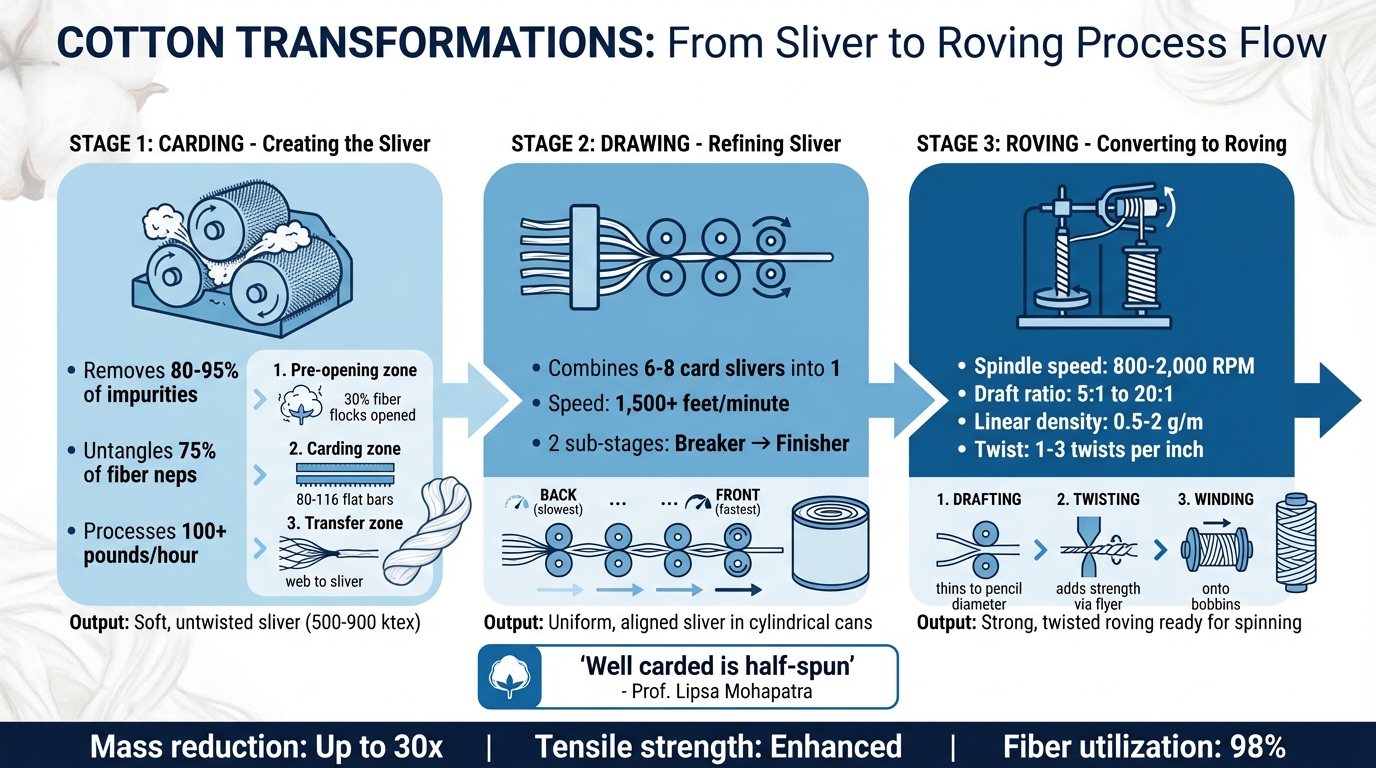

The journey of cotton fibers into yarn involves two critical stages: sliver and roving. Sliver is a soft, untwisted strand formed during carding, where fibers are cleaned, untangled, and aligned. Roving, a thinner strand with a slight twist, strengthens the fibers for spinning. These processes ensure fiber quality and consistency, which are essential for producing high-quality yarn.

Key processes include:

- Carding: Removes impurities, aligns fibers, and forms sliver.

- Drawing: Combines and stretches slivers to improve uniformity.

- Roving: Reduces thickness, adds twists, and prepares fibers for spinning.

Modern machinery, automation, and sensor technologies have improved efficiency, reduced waste, and enhanced fiber quality. For example, advanced roving frames now offer energy savings, automated features, and real-time monitoring. These innovations ensure better yarn production while balancing quality and cost.

Cotton fiber transformation is all about precision. Proper handling at each stage - from sliver to roving - directly impacts the final yarn’s strength and texture.

Cotton Fiber Transformation Process: From Sliver to Roving in 3 Stages

Yarn Manufacturing: Preparation for Spinning

Carding: Creating the Sliver

Carding is where raw cotton begins to take its first steps toward becoming a textile. This process untangles clumps of fibers, removes impurities, and forms the first rope-like strand known as a sliver. As Prof. Lipsa Mohapatra from the National Institute of Fashion Technology explains:

"Well carded is half-spun".

It's no wonder this stage is often referred to as the "heart" of the spinning mill.

Modern carding machines are impressively efficient, removing 80% to 95% of impurities that earlier cleaning stages missed. They also untangle about 75% of all neps - those pesky knots of fibers that can lead to defects in the finished product. With the ability to process over 100 pounds of cotton per hour, today’s machines combine speed and precision.

How Carding Machines Work

Carding machines operate through three main zones:

- Pre-opening zone: This stage uses a feed roller and a taker-in (a roller with saw-tooth wires) to open up around 30% of fiber flocks and remove coarse trash.

- Carding zone: Here, the heavy lifting happens. A large cylinder covered with wire teeth works alongside 80 to 116 flat bars (30 to 46 of which are active at any time) to separate fibers and untangle them individually.

- Transfer zone: A doffer collects the individualized fibers, forming them into a thin web.

This delicate web is then funneled through a "trumpet", which condenses it into the sliver form. To ensure uniformity and stability, calendar rollers compress the sliver before it’s neatly deposited into a rotating cylindrical can, ready for the next stage.

Why Carding Matters in Fiber Processing

Carding doesn’t just clean the cotton; it transforms it. By removing trash, dust, and short fibers, it aligns the remaining fibers into a partial longitudinal orientation. This process also ensures transverse mixing, which creates consistency throughout the production lot . Weak or excessively short fibers are filtered out by the card clothing, resulting in stronger, less hairy yarn.

The input material - usually a compressed batt weighing between 500 and 900 ktex - emerges as a uniform sliver, perfectly prepped for the next step in the process. From here, the sliver moves seamlessly into the drawing stage, where its uniformity is further enhanced.

Drawing: Refining Sliver for Roving

Once carding creates the initial sliver, the drawing process steps in to refine it. This involves combining six to eight card slivers into a single strand. By blending multiple slivers, the process evens out inconsistencies, resulting in a more uniform product.

The next step, drafting, stretches this combined mass using rollers that increase in speed progressively. The back rollers move the slowest, while the front rollers move the fastest, restoring the material to the weight of a single sliver. This stretching not only thins the sliver but also straightens and aligns the fibers, which is crucial for creating strong yarn. Drafting frames are equipped with paired rollers designed to ensure consistent stretching and alignment throughout the process.

How Drawing Frames Operate

After passing through the front rollers, the fiber web is funneled into a compact, rope-like sliver using a trumpet-shaped device.

Modern drawing frames can operate at speeds exceeding 1,500 feet per minute. The process is typically carried out in two stages: breaker drawing and finisher drawing. The first stage blends the fibers, while the second stage refines the sliver further, preparing it for the roving frame. Once refined, the sliver is coiled into cylindrical cans, ready for the next stage of production. This careful refinement ensures the sliver is in optimal condition for efficient processing in the roving frame.

Why Sliver Uniformity Matters

Uniformity in the sliver is critical for producing quality yarn. Any irregularities in the sliver’s mass can become more pronounced during the roving and spinning stages, leading to weak spots, uneven thickness, or increased hairiness in the finished yarn. Since the roving process significantly reduces the fiber mass, even minor inconsistencies in the sliver can result in yarn breakage or defects. A consistent sliver is key to avoiding these issues and ensuring a smooth production process.

sbb-itb-0e617ca

Roving Frame: Converting Sliver into Roving

The roving frame, often called the speed frame, plays a key role in bridging the gap between drawing and spinning. The sliver produced during the drawing process is too thick and delicate to be directly spun into yarn, particularly in ring spinning. To address this, the roving frame transforms the sliver into a thinner, stronger strand known as roving.

This process builds on the uniformity achieved during drawing, fine-tuning the fibers to prepare them for efficient spinning.

How Roving Frames Work

Roving frames operate by drafting, twisting, and winding the sliver into roving. Here’s how it works:

- Drafting: A sequence of rollers, each moving faster than the one before, stretches and thins the sliver to a pencil-like diameter.

- Twisting: To make the strand strong enough for handling, a component called a flyer introduces a slight twist, creating what’s often referred to as "green yarn."

- Winding: The twisted strand is then wound neatly onto bobbins, ready for the next stage of spinning.

This precise combination of actions ensures the fibers are prepared for high-quality yarn production in subsequent processes.

Why Roving Formation Is Important

Roving formation is a critical step for both spinning efficiency and yarn quality. The twist added during this stage provides the mechanical strength needed for the roving to withstand high-speed unwinding from the bobbin without breaking. This step is especially important in ring spinning, where the refined fiber properties contribute directly to superior yarn quality.

Although modern systems like rotor and air-jet spinning skip the roving stage and convert sliver directly into yarn - achieving production speeds up to 10 times faster than ring spinning - the roving process remains indispensable for ring spinning. It ensures the fiber refinement needed for producing premium-quality yarn, a hallmark of this traditional spinning method.

Machinery and Recent Developments in Sliver-to-Roving Processing

Main Machines in Fiber Transformation

Transforming sliver into roving relies heavily on three key machines, each playing a distinct role in the process. Carding machines are responsible for disentangling fibers and removing impurities like trash and dust. Next, drawing frames combine and stretch multiple card slivers - typically six to eight - enhancing fiber alignment and minimizing thickness inconsistencies. Finally, roving frames take the drawn sliver, reduce its diameter, add twists for strength, and wind it onto bobbins for further processing. These roving frames operate at spindle speeds ranging from 800 to 1,500 RPM, with some advanced models reaching up to 2,000 RPM. They typically use draft ratios between 5:1 and 20:1 to achieve a sliver linear density of approximately 0.5–2 g/m, adding 1–3 twists per inch to strengthen the roving. With the integration of digital technologies, these machines now deliver even greater efficiency and precision.

Recent Developments in Roving Technology

The evolution of roving technology has been marked by the integration of digital controls and automation, significantly refining production processes. Digital monitoring systems have revolutionized mill operations, offering unparalleled oversight. For instance, Rieter's ESSENTIALmonitor provides real-time production data across entire facilities, helping reduce labor needs by up to 10%. Similarly, advanced sensor systems like the Uster Quantum 4.0 and Loepfe YarnMaster PRISMA use dual-measurement technologies - combining capacitive and optical sensing - to detect foreign materials, color variations, and irregularities with remarkable accuracy. These advancements directly enhance fiber uniformity, operational efficiency, and energy conservation.

Take, for example, a 2025 case study from a Brazilian textile mill. The mill adopted a high-speed roving frame by Rieter to process recycled cotton into Ne 40 roving for T-shirt production. Thanks to features like automated doffing and energy-efficient drives, the mill reduced energy consumption by 12% and fiber waste by 10%, ultimately earning GOTS certification. Similarly, a European wool mill leveraged compact roving technology for organic wool processing, cutting water usage by 25% while improving yarn quality for premium knitwear.

Compact roving technology has become a game-changer for mills aiming to enhance fiber smoothness and strength. By incorporating compacting devices directly into the roving frames, mills can produce roving with reduced hairiness. Energy-efficient drafting systems with variable speed drives further contribute to sustainability by lowering power consumption by 10% to 15%. Additionally, automated features like doffing and sliver feeding systems can cut labor costs by around 20%. Modern digital control systems also play a crucial role, reducing yarn defects by up to 15%. Automated stop-motion sensors ensure immediate detection of sliver breaks, maintaining an impressive 98% fiber utilization rate.

Conclusion

Precision at every stage - carding, drawing, and roving - is the backbone of quality yarn production. The journey from sliver to roving plays a critical role in determining the final yarn's characteristics, with each step directly influencing the outcome.

Carding sets the stage by removing impurities and aligning fibers into a uniform sliver. Drawing follows by blending multiple slivers, evening out variations, and further straightening the fibers for consistency. Finally, roving reduces the sliver's linear weight while introducing a controlled twist, ensuring the material holds together during the ring spinning process.

The relationship between fiber preparation and yarn quality cannot be overstated. When each stage is optimized, mills achieve higher throughput without compromising quality. However, balancing fiber quality with processing costs is vital. Overinvesting in unnecessarily high-quality fibers can hurt profitability, while using subpar fibers can result in production inefficiencies and losses. Remarkably, the drawing and roving stages can reduce fiber mass by up to 30 times while enhancing tensile strength, showcasing how precision at each step adds up to significant improvements in the final product.

"Finding the right balance between the appropriate fiber quality and processing costs is critical to maintaining profitability." - CottonWorks

Advancements in automation and sensor technology have further emphasized the importance of precise fiber handling. These innovations not only boost efficiency but also elevate the standards for yarn production across the industry.

Whether your operations rely on traditional ring spinning or newer methods that bypass the roving stage, mastering these foundational processes is essential. A deep understanding of these steps ensures the production of yarn that aligns with today’s rigorous quality requirements and market expectations. These continuous refinements drive progress in yarn manufacturing.

FAQs

How does carding improve the quality of cotton yarn?

Carding plays a key role in cotton processing by cleaning and aligning fibers into a smooth, uniform sliver. It works to remove impurities and straighten fibers, which helps create stronger, more consistent yarn with fewer flaws.

By improving the quality of the fibers, carding not only boosts the overall durability of the yarn but also enhances the efficiency of the spinning process. This makes it an indispensable step in producing high-quality cotton products.

How do modern technologies improve the cotton roving process?

Modern advancements have transformed the cotton roving process, making it more accurate, efficient, and dependable. Today, advanced sensors play a key role by tracking critical factors like fiber tension, draft ratio, speed, and moisture levels in real time. This data is then processed by intelligent systems that automatically fine-tune machine settings, ensuring consistent roving quality while minimizing breakage.

On top of that, the latest roving frames come equipped with precision drafting rollers, computer-controlled motors, and automated take-up systems. These features enable machines to adjust themselves, work seamlessly with various fiber blends, and produce finer, more uniform roving. Thanks to these innovations, manufacturers can now deliver higher-quality yarns while boosting both production speed and overall efficiency.

Why is it important for sliver to be uniform in yarn production?

Consistency in sliver is key to producing high-quality yarn. It ensures even fiber distribution, minimizes defects, and allows for smoother processing during spinning. A uniform sliver also performs exceptionally well with advanced spinning technologies, like air-jet systems, which demand precision.

By reducing fiber irregularities, a consistent sliver leads to stronger, more durable yarn while boosting the efficiency of production. This approach not only elevates the quality of the final product but also cuts down on waste and lowers operational costs.