The U.S. cotton industry is at a turning point. Climate change, supply chain vulnerabilities, and labor inequities are creating significant challenges in scaling cotton sourcing. But solutions exist. Here's a quick summary of the key issues and actionable steps:

- Climate Challenges: Rising temperatures, erratic rainfall, and water scarcity threaten cotton yields. Solutions include climate-resilient farming methods like precision irrigation, no-till practices, and regenerative agriculture.

- Supply Chain Transparency: Cotton's journey is hard to trace due to blending, manual documentation, and inconsistent regulations. Digital tools like blockchain, DNA markers, and RFID tags are improving traceability.

- Labor Issues: Unsafe conditions, low wages, and lack of protections persist for many cotton workers. Fair trade certifications and direct sourcing initiatives support equitable practices.

- Collaboration: Industry programs like the Better Cotton Initiative and Cotton Trust Protocol are helping align standards and promote sustainable practices.

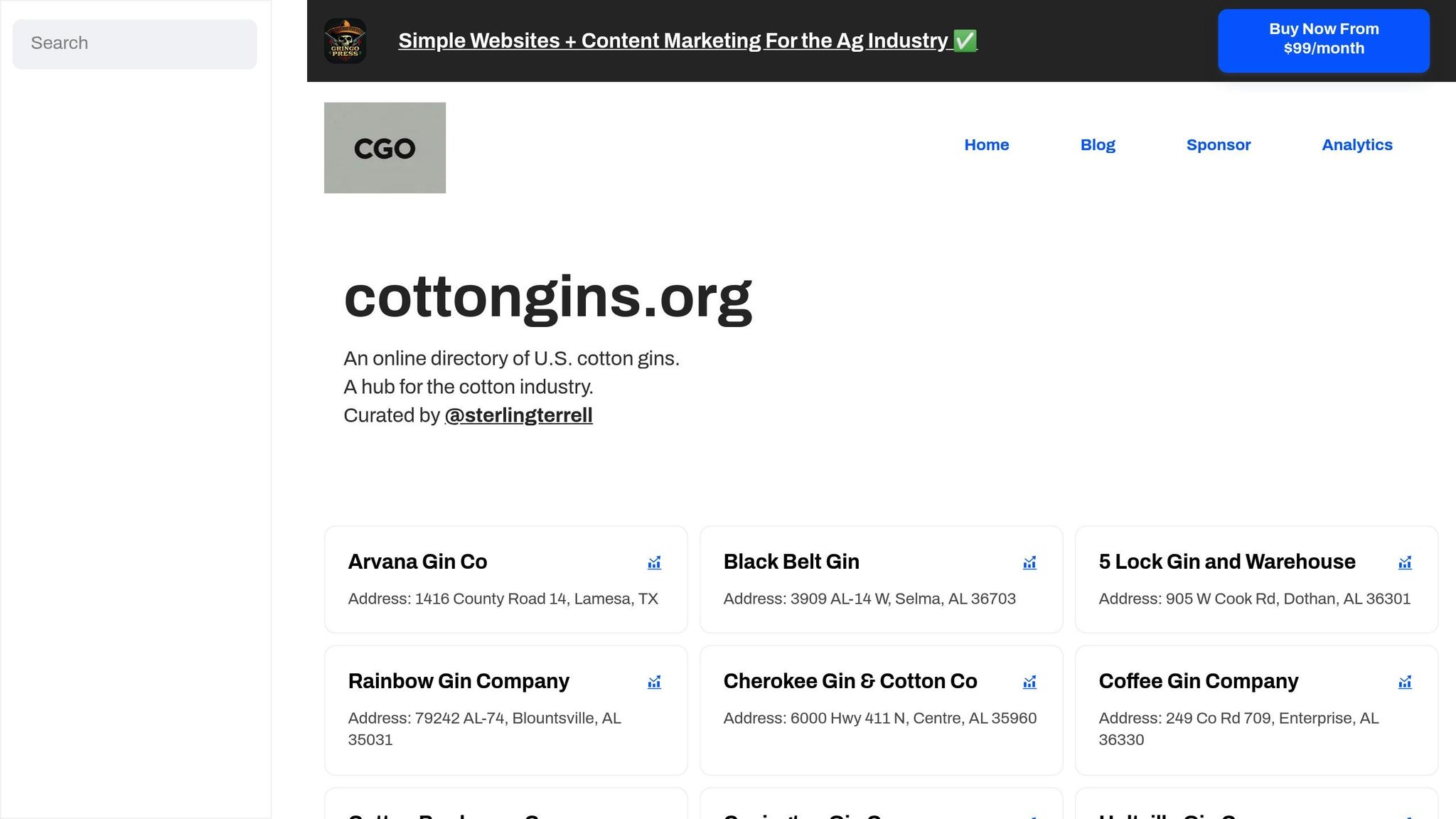

Quick Tip: Tools like cottongins.org aid traceability by mapping cotton gin locations, ensuring supply chain integrity.

Scaling sustainable cotton sourcing requires collaboration, innovation, and transparency. By addressing these challenges, the cotton industry can build a more resilient and equitable future.

From Dirt to Shirt; A Sustainable Apparel King w/ TS Designs Founder Eric Henry

Climate Change Effects on Cotton Farming

Cotton farmers across the United States are facing mounting challenges due to climate change. Rising temperatures, erratic rainfall, and severe droughts are making it harder to sustain consistent cotton yields. For instance, drought stress alone can slash cotton crop yields by as much as 67%.

Water scarcity is one of the biggest hurdles. Despite covering just 2.6% of the world's cultivated land, cotton farming consumes up to 10% of global agricultural water. Producing a single kilogram of cotton can require anywhere from 7,000 to 10,000 liters of water, depending on conditions. Cotton plants typically need 24–31 inches (600–800 mm) of water during the growing season, leaving them vulnerable when rainfall patterns shift.

Temperature extremes are another critical issue. When temperatures rise above 90°F (32°C), cotton crops suffer, especially during the reproductive stage when flowers and bolls develop. The Intergovernmental Panel on Climate Change notes that global land surface temperatures increased by 1.4°F (0.78°C) between 1850–1900 and 2003–2012, with projections suggesting an additional rise of up to 8.6°F (4.8°C) by 2100. These conditions demand new approaches to farming.

"A major limitation to yield is root exploration failing to keep up with boll growth. This imbalance between root and shoot activity affects the ability of the plant to fill bolls."

– Sruthi Narayanan, Associate Professor of Crop Ecophysiology

Unpredictable weather patterns are also disrupting traditional farming schedules, complicating irrigation and increasing the risk of crop failure. Hardpans, compacted soil layers caused by extreme weather, can reduce yields by up to 50%. Combined with drought-induced stunted growth, fewer bolls, and lower fiber quality, these challenges are putting the financial stability of cotton farmers at risk.

Using Climate-Resistant Farming Methods

To tackle these challenges, U.S. cotton farmers are turning to climate-resilient strategies. One promising avenue is improving root systems. Research shows that certain root traits in Upland cotton varieties, such as Deltapine 14, Station Miller, and Southland M1, can significantly boost water-use efficiency.

"These traits will be valuable in developing the next generation of water-use-efficient Upland cotton varieties."

– Sruthi Narayanan, Associate Professor of Crop Ecophysiology

Precision irrigation and soil moisture monitoring are also proving to be game-changers. Frank Rogers, a grower in South Carolina, emphasizes the importance of data-driven water management:

"You can't manage what you don't measure. Knowing exactly what's in our soil lets us give our crops what they need, where they need it, when they need it."

Drip irrigation systems, for example, can reduce water use while increasing yields by up to 30% and cutting costs through better fertilizer efficiency.

Conservation practices are gaining traction as well. In the Cotton Trust Protocol program, 56% of farmers have adopted no-till or conservation tillage methods, and 62% are using cover crops. These techniques improve soil health, enhance water retention, and help farms withstand extreme weather.

Regenerative agriculture is another approach showing measurable benefits. Some programs report up to a 41% reduction in greenhouse gas emissions and a 21.9% decrease in water consumption compared to traditional farming methods. Farmers using techniques like intercropping and natural inputs have seen yields jump from 700 kg/acre to 1,000 kg/acre.

Collaborations are amplifying these efforts. Since 2005, WWF and IKEA have trained over 4,500 cotton farmers in practices such as mixed cropping, composting, and using crop residues like cotton stalks to improve soil and water management. These initiatives aim to cut greenhouse gas emissions per unit of cotton by up to 30%.

"We have seen first-hand the impact of climate change on some of the most vulnerable in the supply chain, and the time for action has never been more urgent. We now have data that shows the significant potential of our farm level programs in climate change mitigation. We hope to encourage and help others in the textile industry to work on increasing responsible production by supporting smallholder farmers in adopting our REEL practices."

– Alison Ward, CottonConnect CEO

The U.S. Cotton Trust Protocol is also stepping in to support farmers. Texas grower Alyssa Cain highlights the importance of this initiative:

"It's not always easy to take risks when you're a farmer, especially financial risks. This program gives us the support to try new things, to build a better system for the long haul. That not only provides peace of mind but a farm with healthier soil, cleaner water, a system that works with nature, not against it."

Better Supply Chain Tracking and Transparency

The path cotton takes from the farm to becoming a finished product is anything but straightforward. Along the way, tracing its true origin can become a daunting task. One major hurdle? Cotton from various sources is often blended together, and the process relies heavily on manual documentation, which is prone to errors.

Adding to the complexity is the patchwork of regulations across different countries. While some nations enforce strict rules to document cotton origins, others barely monitor the process. This inconsistent oversight creates gaps in tracking. In many regions, outdated paper-based systems make collecting and verifying data unreliable at best.

Economic pressures further complicate things. Suppliers, aiming to cut costs, sometimes replace certified cotton with cheaper alternatives. Considering that the global retail market for processed raw cotton products surpassed $18 billion in 2021, the temptation to take shortcuts is significant.

Trade disputes also muddy the waters. Cotton often passes through intermediary countries to obscure its true source - a growing issue that makes transparency even harder to achieve.

The lack of visibility across supply chains is striking. A Deloitte survey revealed that only 15% of Chief Procurement Officers have insight beyond their tier-one suppliers. Meanwhile, just a third of the top 100 clothing companies actively track their supply chains. This creates blind spots in an industry where consumers are increasingly demanding transparency.

To tackle these challenges, companies are turning to digital innovations to simplify and secure supply chain tracking.

Using Digital Tracking Tools

Digital technology, especially blockchain, is reshaping how cotton traceability is managed. Blockchain creates tamper-proof records for every transaction and movement in the supply chain. These platforms centralize supplier data, transactions, and compliance records into one digital hub.

In 2020, the United Nations Economic Commission for Europe launched a pilot project aimed at developing a blockchain-based system to trace cotton from the field to the shelf. This initiative, part of the UNECE-UN/CEFACT framework, ran from 2019 to 2022 with European Union backing. It provided participating governments and companies with tools such as policy recommendations, implementation guidelines, and pilot projects to test blockchain applications.

Real-world examples show the potential of these technologies. LVMH developed AURA, a blockchain platform that assigns digital certificates to luxury items, ensuring an unchangeable record from production to sale. In Africa, Bext360 uses blockchain to track cotton production while also ensuring fair payments to farmers and combating exploitative labor practices.

| Technology | Advantages | Limitations |

|---|---|---|

| Blockchain | Secure, transparent, tamper-resistant | Expensive to implement, requires broad adoption |

| DNA Markers | Highly accurate, unique identification | Costly testing, specialized equipment needed |

| QR Codes/RFID | Affordable, easy to use | Prone to fraud, limited data capacity |

A digital traceability system can map supplier relationships across all tiers (1-3+) and assign unique identifiers to every supplier. This approach allows companies to follow cotton’s journey from farms through ginning, processing, and manufacturing stages.

Digital tools also help businesses meet regulatory requirements. With laws like the EU Deforestation Regulation, Food Safety Modernization Act, and ESG reporting standards, companies must prove their products are ethically and sustainably sourced. These technologies provide the documentation and audit trails necessary to meet such demands.

How cottongins.org Supports Supply Chain Tracking

As digital tools improve traceability, accurate data on cotton gin locations becomes essential. This is where cottongins.org steps in. The platform offers a comprehensive directory of U.S. cotton gins, helping brands pinpoint key processing sites and confirm supplier legitimacy.

By addressing a key challenge - identifying where cotton is processed - cottongins.org makes it easier for companies to map their supply chains. Brands sourcing U.S. cotton can ensure their suppliers are working with verified gins rather than unregulated facilities.

For supply chain managers using digital tracking systems, cottongins.org provides the foundational data needed to build reliable traceability programs. When combined with technologies like blockchain or RFID, accurate gin location data enables companies to create detailed, trustworthy supply chain maps.

The platform also aids compliance efforts. By documenting gin locations and supplier relationships, companies can demonstrate due diligence and maintain credibility in the face of increasing regulatory scrutiny. Additionally, the directory’s submission system ensures that gin data stays current, giving businesses the confidence that their traceability efforts reflect real-world conditions.

sbb-itb-0e617ca

Social Equity Issues in Cotton Sourcing

Addressing inequities among cotton workers is a critical step in building sustainable supply chains. Cotton farming involves millions of workers who deserve fair treatment and equal opportunities, yet the reality often paints a different picture.

The statistics are sobering. Agriculture is one of the most dangerous industries globally, with a fatal accident rate twice as high as the average across other sectors. Cotton workers frequently endure unsafe conditions, and a staggering 99% of the world’s cotton farmers live in developing countries.

In the United States, the challenges are distinct yet equally pressing. Between 2020 and 2022, 42% of crop farmworkers lacked work authorization, leaving them vulnerable to exploitation and without the protections enjoyed by workers in other sectors. These workers often face exclusion from basic labor rights, compounding their precarious situations.

The relentless demand for cheap cotton, fueled by fast fashion, exacerbates these issues. When brands prioritize low costs, the pressure passes down the supply chain, leading to reduced wages and unsafe conditions for workers. Common issues include child labor, forced labor, discrimination, and hazardous working environments. These challenges underscore the urgent need for stronger standards and fair practices throughout the supply chain.

"Laws without enforcement are empty promises", says Gerardo Reyes Chavez of the Coalition of Immokalee Workers.

This lack of enforcement leaves 60% of the workforce without proper protections, according to Daniel Costa from the Economic Policy Institute.

| Key Labor Issues in Cotton Farming | Impact on Fashion Supply Chain | Actions |

|---|---|---|

| Forced Labor | Ethical risks, lack of supply chain transparency | Implement transparency measures, enforce due diligence laws |

| Child Labor | Human rights violations, long-term social costs | Social certification programs, NGO oversight |

| Hazardous Conditions | Health risks, environmental damage | Promote organic farming, improve safety standards |

| Low Wages | Perpetuates poverty | Support fair trade, enforce minimum wage laws |

Supporting Fair Trade and Labor Standards

Fair trade certification offers a tangible way to address these inequities. By focusing on systemic change, fair trade benefits entire communities. For example, sales of Fairtrade-certified cotton products in India surged over 270% in 2023, reflecting growing consumer demand for ethically sourced goods. Additionally, 80% of Fairtrade shoppers are willing to pay more to ensure fair compensation for producers.

The financial benefits are substantial. In 2021, over 10,900 metric tons of cotton lint sold under Fairtrade standards generated $1.3 million in Fairtrade Premium. These funds were reinvested into community projects such as education and healthcare. Environmental gains also accompany these efforts: Fairtrade organic cotton produces 45% fewer greenhouse gas emissions than conventional methods, and 96% of Fairtrade farmers avoid chemical pesticides, compared to 60% of non-Fairtrade farmers. Fairtrade organic farmers also achieve 20% higher water efficiency and earn nearly 5% more than their non-Fairtrade counterparts.

"Buying a fairly traded garment is not giving to charity, but is much more a positive statement of fulfilling one's commitment towards all the people who are ultimately responsible for the garment", explains G S Rao, state coordinator for Fairtrade-certified Chetna Organic in India.

In the U.S., the Cotton Trust Protocol enforces criteria like fair treatment, legal wages, and safe working conditions, while prohibiting child and forced labor. Federal laws such as the Migrant and Seasonal Agricultural Worker Protection Act and the Fair Labor Standards Act also aim to safeguard labor practices. Beyond compliance, fair trade standards empower farmers by fostering more democratic organizations and giving them a stronger voice in the supply chain.

Supporting Women and Minority Farmers

Fair trade principles also help address representation gaps among producers. For instance, women-owned cotton farms in the U.S. account for just 3% of the total, while minority-operated farms remain underrepresented as well. Globally, women make up 43% of agricultural workers but own only 20% of the land. This imbalance not only perpetuates inequality but also reduces productivity. Women in developing countries perform nearly half of the agricultural labor yet produce 20–30% less than men, largely due to limited access to land, markets, and resources.

Direct sourcing initiatives can help level the playing field. For example, Victoria’s Secret & Co. began purchasing cotton directly from four Alabama family farms - three of which are women-owned and one Black-owned. In 2023, 43% of the company’s cotton came from these farms, ensuring that producers received a larger share of the revenue.

Training programs also make a difference. A study from Maharashtra, India, found that only 33% of women cotton farmers had attended training in the past two years. However, when training was provided, adoption of improved farming techniques rose by 30–40%. Similarly, the Better Cotton Programme has led to success stories like Almas Parveen in Punjab, whose training resulted in an 18% increase in yields, a 23% profit boost, and a 35% reduction in pesticide use.

Financial services further empower marginalized farmers. The Cargill Cocoa Promise, for instance, has established 660 Village Savings & Loan Associations, mobilizing nearly $800 million in savings for income-generating activities. USDA programs also support underrepresented farmers through loans, disaster aid, and conservation assistance.

"With the challenges our industry is facing now, we can't afford to leave anyone on the sidelines. Everyone deserves a seat at the table", says Ruth Kimmelshue, Senior Vice President at Cargill.

"Uplifting women is not only the right thing to do; it's essential for understanding and meeting the needs of our diverse customer and supplier base", adds Thamys Carvalhais, Global Lead for Cargill's Women Network.

Women’s health and safety also require specific attention, such as ensuring that pregnant or nursing workers are not exposed to chemical pesticides. Upholding decent work principles means creating opportunities for productive, secure, and dignified employment while eliminating wage discrimination. Preventing child labor is equally vital to allow both boys and girls access to education, paving the way for generational progress in cotton-producing communities. Empowering diverse producers is essential to advancing sustainable cotton practices in today’s competitive markets.

Working Together Through Industry Programs

Industry programs are playing a key role in advancing sustainable cotton sourcing by building on digital traceability and supply chain transparency. Despite sustainable cotton making up 30% of global production, less than 20% of this is sourced by companies - a gap that industry programs aim to address.

These programs provide a structured framework to tackle this shortfall. They establish shared standards, offer training resources, and enhance communication between farmers, brands, and retailers. By distributing responsibilities across the supply chain, they help tackle the challenges of scaling sustainable cotton sourcing without overburdening any single participant.

For example, in 2019 and 2020, the Cotton 2040 Impacts Alignment Working Group united key organizations such as BCI, Cotton Connect, Cotton Made in Africa, Fairtrade, MyBMP, the Organic Cotton Accelerator, and Textile Exchange. Facilitated by Forum for the Future with support from the Laudes Foundation, these groups signed a Memorandum of Understanding to standardize impact measurement and reporting for sustainability in the cotton industry. This collaboration introduced consistent reporting metrics, simplifying progress tracking and communication, and laid the groundwork for unified practices moving forward.

Using Industry Programs and Standards

Three major certification programs dominate the sustainable cotton landscape, each offering a distinct approach:

- Better Cotton Initiative (BCI): Representing 20% of global cotton production and active in 26 countries, BCI focuses on improving environmental, social, and economic standards. It allows the use of genetically modified (GM) seeds in some regions.

- Cotton made in Africa (CmiA): Operating exclusively in sub-Saharan Africa, CmiA supports smallholder farmers, promotes rain-fed agriculture, and prohibits GM seeds. Its emphasis lies in ethical and environmental benefits.

- Organic Cotton: Although it accounts for less than 1% of global cotton production, organic cotton adheres to the strictest standards, eliminating synthetic chemicals and requiring audits by GOTS-accredited certifiers.

| Program | Global Reach | Key Focus | GM Seeds Policy |

|---|---|---|---|

| Better Cotton Initiative (BCI) | 26 countries, 20% of global cotton | Environmental, social, and economic improvements | Permitted in some regions |

| Cotton made in Africa (CmiA) | Sub-Saharan Africa only | Smallholder farmers, rain-fed agriculture | Banned |

| Organic Cotton (GOTS/OCS) | Global, <1% of market | Chemical elimination, soil health, biodiversity | Banned |

To effectively engage with these certifications, companies should first define their sustainability goals. Early discussions with supply chain partners about traceability, availability, and costs can help ensure that the chosen certification aligns with their objectives.

Thirty-six major brands have committed to sourcing sustainable cotton by 2025, recognizing certifications such as Organic, Fairtrade, BCI, Cotton Made in Africa, and recycled cotton. This collective effort is creating market demand, encouraging more farmers to adopt sustainable practices.

"The industry is awakening to the necessity of sustainably grown cotton. It is great to see additional brands joining this initiative to accelerate the momentum of cotton production in a way that will positively impact smallholder farmers, water quality and soil health."

- La Rhea Pepper, Managing Director at Textile Exchange

These certifications not only unify practices but also foster stronger, longer-term collaborations within the supply chain.

Building Long-Term Supplier Partnerships

Strong partnerships between buyers and suppliers are essential for improving product quality, supply chain efficiency, and overall competitiveness. With the cotton industry supporting around 22 million households across 75 countries, stable relationships are crucial for ensuring its sustainability.

Take Swedish fashion brand Lindex, for instance. In 2010, the company committed to sourcing 100% of its cotton from more sustainable sources by 2020. To meet this goal, Lindex established direct relationships with yarn and fabric suppliers and strengthened its internal alignment on sustainability initiatives.

Similarly, Eileen Fisher began sourcing organic cotton in 2004 and has since transitioned nearly all its cotton-based materials to certified organic. The brand also supported farms during their conversion to organic cotton, committing to buy transitional cotton during the three-year conversion period - a critical step in increasing organic cotton availability.

"We will never increase the amount of organic cotton available unless we support farmers during the three-year conversion period."

- Megan Meiklejohn, Sustainable Materials and Transparency Manager at Eileen Fisher

Volcom's Farm to Yarn program highlights the power of comprehensive partnerships. By working with CottonConnect, Volcom traces certified organic cotton back to farms in India, while also providing social and professional education for farmers and women in nearby villages. Although restructuring their supply chain was challenging, long-term relationships made the transition possible.

"Long-standing relationships with manufacturing partners have made our transition to programs like Farm to Yarn much easier than they might have been. This is because we have built trust and solid relationships that have helped as we transitioned to this and other programs. Patience and commitment (on both sides) have been crucial to making the program a success."

- Derek Sabori, Sustainability Advisor at Volcom

Strong partnerships also ensure fair wages, reasonable prices, and equitable payment terms across the supply chain. As Annemiek Smits from Solidaridad notes:

"Equality in partnerships is a precondition to ensuring a living wage for workers, fair prices, no disproportionate burden on one party in the supply chain, and fair payment terms."

- Annemiek Smits, Corporate Partnerships Manager Cotton & Textiles at Solidaridad

Building these partnerships takes time, but the investment pays off. Companies can encourage transparency by visiting farms, understanding their needs, and exploring direct sourcing opportunities. Certified suppliers can help ensure environmentally friendly materials, while close collaboration allows for quick problem-solving and continuous improvement.

As Volcom’s Derek Sabori puts it:

"We've had to undo the way that business was done - unravel our supply chain, as we like to say. This took time and constant discussion, constant commitment, and it wasn't always the easy way."

- Derek Sabori, Sustainability Advisor at Volcom

The effort is worth it, resulting in more resilient supply chains that benefit everyone involved while advancing sustainability goals.

Conclusion

Scaling sustainable cotton sourcing requires a united effort across the entire supply chain. The fashion industry’s sheer size - and the environmental strain caused by cotton production - makes it clear that action is urgently needed. But challenges persist, including a limited supply of sustainable raw materials, inconsistent management commitment, and a lack of supply chain transparency. Even though 59% of apparel industry chief procurement officers see responsible sourcing as a strategic priority, only 1% of new items marketed by major fashion retailers carry sustainable labels.

Collaboration and transparency are essential to overcoming these hurdles. Climate-resilient farming practices can help address environmental concerns, while digital tools for tracking and improved transparency allow for better oversight of sustainable initiatives. Industry-wide programs have shown that collective efforts can create meaningful change throughout the supply chain.

"We believe collaboration is key to driving meaningful change and achieving our shared sustainability goals." – CottonToday

Addressing social equity is another critical piece of this puzzle. Fair trade standards and support for women and minority farmers, as previously discussed, bring a human-centered approach to sustainable cotton sourcing. Long-term partnerships with suppliers also create the stability needed for lasting progress across the supply chain.

For stakeholders in the U.S. cotton industry, platforms like cottongins.org offer valuable tools to enhance supply chain mapping and traceability. By providing a directory of cotton gins, opportunities for sponsorships, and the ability to submit new entries, this resource strengthens the network of relationships needed to scale sustainable sourcing effectively.

Ultimately, success depends on increasing the supply of sustainable raw materials, securing stronger management commitment, and achieving greater transparency throughout the supply chain. As these efforts align, tools and platforms that improve connectivity and traceability will play a growing role in driving progress. Together, these steps can help the cotton industry move toward a more sustainable and resilient future.

FAQs

How does blockchain technology improve the traceability of cotton supply chains?

Blockchain technology is transforming the cotton supply chain by offering secure, transparent, and tamper-resistant records of every transaction and movement. This means every step - from cotton farming to the finished product - can be verified and tracked in real time.

With blockchain, companies can crack down on illegal practices, verify the origins of cotton, and support ethical sourcing. It also gives consumers the ability to make more informed and responsible decisions by providing clear insights into the cotton's journey and sourcing practices. By boosting transparency and accountability, blockchain plays a crucial role in advancing sustainable cotton sourcing efforts.

How do programs like the Better Cotton Initiative support sustainable cotton sourcing?

Programs such as the Better Cotton Initiative (BCI) are key players in shaping more environmentally friendly and responsible cotton sourcing. They focus on educating farmers about sustainable farming techniques, ensuring transparency and traceability throughout the supply chain, and motivating brands to choose cotton that is grown with care for the planet.

The BCI is dedicated to reshaping the cotton industry by enhancing farming practices, uplifting cotton-growing communities, and boosting the global demand for cotton produced sustainably. These initiatives aim to foster a cotton sector that's both kinder to the environment and fairer to the people involved.

How does climate change affect cotton farming, and what strategies are farmers using to adapt?

Climate change is creating tough conditions for cotton farming, with rising temperatures, erratic rainfall patterns, and more frequent extreme weather events. These shifts can interfere with key growth stages, lower crop yields, and make water resources scarcer.

To tackle these challenges, farmers are turning to climate-smart practices. This includes cultivating drought-resistant cotton varieties and improving how efficiently water is used. Technologies like gene editing and advancements in root development are playing a crucial role in helping cotton plants endure heat and water stress. These efforts are designed to safeguard cotton production as the environment continues to evolve.