Long-staple cotton stands out in textile production for its longer fibers, which lead to stronger, finer, and smoother yarns. Compared to short-staple cotton, it produces fewer imperfections, offers better durability, and supports high-quality applications like luxury bedding and premium clothing. Key advantages include:

- Stronger Yarn: Up to 32.3% higher "work-to-break" values.

- Fewer Imperfections: Up to 46 fewer thick and thin spots per kilometer.

- Enhanced Durability: Longer fibers reduce breakage during spinning.

- Fine Yarn Production: Enables high-count yarns like 80-Ne and above.

- Smoother Textiles: Fewer exposed fiber ends mean less pilling.

These benefits make long-staple cotton a preferred choice for premium textiles, albeit at a higher cost due to its rarity and careful processing. Proper preparation, such as combing and selecting high-uniformity fibers, ensures maximum performance during spinning.

Quick Overview of Long-Staple Cotton Benefits:

- Fiber Length: 1.3–2.5 inches (vs. under 1.2 inches for short-staple cotton).

- Applications: Luxury sheets, premium shirts, embroidery threads.

- Processing: Roller ginning preserves length and quality.

For textile producers, sourcing high-quality long-staple cotton and optimizing spinning techniques are essential for achieving top-tier yarn and fabric quality.

What Is Long-Staple Cotton and Why Does It Matter?

Defining Long-Staple Cotton

Long-staple cotton stands out for its longer fiber length compared to standard Upland cotton. Premium types like Pima and Egyptian cotton measure around 1.5 inches, whereas typical Upland cotton falls below 1.125 inches. While Upland cotton (G. hirsutum) makes up about 90% of the global cotton market, long-staple and extra-long staple (ELS) varieties, such as U.S.-grown Pima and Egyptian Giza cotton, belong to the G. barbadense species.

Fiber length is largely determined by the plant variety, though factors like water shortages, extreme weather, or rough ginning processes can reduce it. Supima cotton, a trademarked ELS variety grown in the U.S., is particularly rare, accounting for less than 1% of global cotton production.

In addition to length, fiber fineness, measured as micronaire, is a key quality metric. Finer fibers allow for more fibers in a yarn's cross-section, which strengthens the yarn. Another important factor is the length uniformity index, which compares the average fiber length to the upper-half mean length. Higher uniformity ensures consistent fiber lengths, which is critical for efficient processing.

These characteristics make long-staple cotton fibers highly valued for spinning.

Main Advantages for Yarn Spinning

The extended fibers of long-staple cotton provide more surface area for twisting, leading to improved spinning efficiency and smoother, more even yarns. This allows manufacturers to create very fine, high-count yarns - such as 80-Ne or even 140-Ne - without compromising strength. In contrast, short-staple cotton is better suited for coarser yarns.

"Fiber length affects yarn strength, yarn evenness, and the efficiency of the spinning process. The fineness of the yarn that can be successfully produced from given fibers also is influenced by fiber length." - Cotton Incorporated

Additionally, the longer fibers produce yarns with fewer exposed ends, creating textiles that are softer, smoother, and more resistant to pilling. This makes long-staple cotton the go-to choice for luxury sheets, premium shirts, and embroidery threads. On the other hand, short-staple cotton is typically used for denim, budget apparel, and low-cost home textiles. However, the superior quality of long-staple cotton comes at a higher price due to the meticulous growing and processing required.

How Long-Staple Cotton Improves the Spinning Process

Better Fiber Alignment and Consistency

Longer fibers naturally align more efficiently during the drafting process, which helps reduce imperfections in the yarn. This is largely due to the lower short fiber content (SFC) in long-staple cotton, minimizing irregularities like "thin places" and "thick places" in the yarn structure. Additionally, long-staple cotton has a reduced tendency to form fiber hooks during the transition from card sliver to drawing sliver. This smoother transition ensures consistent fiber alignment.

"Modifying fiber length distribution can improve multiple yarn properties."

- Eric F. Hequet and Jane K. Dever, Researchers

A better fiber length distribution also results in a lower coefficient of variation (CV) in the yarn, which is a clear indicator of improved uniformity throughout production. This precise alignment not only reduces imperfections but also lays the groundwork for producing stronger yarn.

Stronger and More Durable Yarn

The enhanced alignment of long-staple cotton fibers directly contributes to stronger, more durable yarn. For instance, increasing fiber-bundle elongation from 6% to 10% significantly boosts both yarn strength and elongation. Fibers with greater toughness and lower tensile stiffness are better equipped to handle higher spindle speeds - up to 1,000 rpm for high-twist 30/1 and 40/1 yarns - without causing an increase in breakage.

Moreover, the longer upper half mean length and higher uniformity index of extra-long staple (ELS) cotton provide superior yarn quality compared to standard upland cotton varieties.

"Better fiber that contributes to the construction of stronger yarns is desirable and allows the more efficient production of fabric."

- Robert L. Long, CSIRO Materials Science and Engineering

More Efficient Spinning Operations

Long-staple cotton significantly boosts spinning efficiency by reducing operational interruptions. Its superior fiber alignment minimizes "ends down" events (yarn breakages) that disrupt production and require manual intervention. This consistency allows spindles to run at faster speeds without increasing breakage rates, ultimately improving throughput. In experimental trials, enhanced fiber length distribution has led to yarn work of rupture values as high as 743.8 gf/cm.

The benefits of long-staple cotton are particularly evident in ring spinning, which is highly sensitive to short fibers. The maturity of long-staple fibers also ensures that their length is preserved during high-speed processing, maintaining reliable performance throughout the operation.

Growing, Spinning and Weaving Cotton

sbb-itb-0e617ca

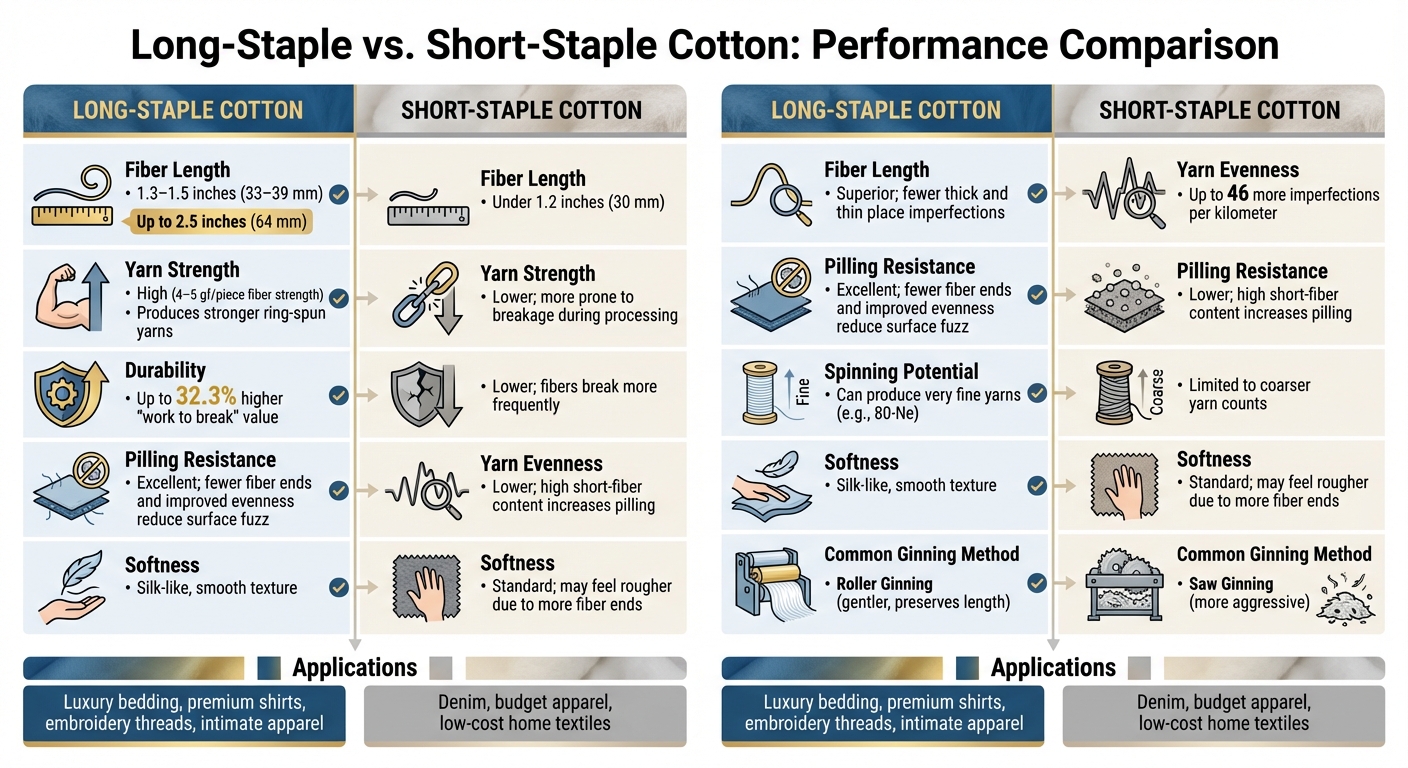

Long-Staple vs. Short-Staple Cotton: A Direct Comparison

Long-Staple vs Short-Staple Cotton: Performance Comparison

When it comes to yarn production, the differences between long-staple and short-staple cotton are hard to ignore. Fiber length plays a major role, influencing everything from spinning behavior to the final quality of the textile.

Long-staple cotton fibers typically measure between 1.3 and 1.5 inches, with premium varieties reaching up to 2.5 inches. In contrast, short-staple cotton fibers fall below 1.2 inches in length. This variation directly affects how the fibers perform during spinning, ultimately shaping the quality of the yarn produced.

One key metric to consider is fiber strength, measured in grams per tex. Long-staple cotton consistently produces stronger ring-spun yarns compared to standard upland cotton. This added strength translates into durability; textiles made from long-staple cotton can have up to 32.3% higher "work-to-break" values, meaning they hold up better after repeated use. The table below highlights these and other critical differences.

Comparison Table: Long-Staple vs. Short-Staple Cotton

| Metric | Long-Staple Cotton | Short-Staple Cotton |

|---|---|---|

| Fiber Length | 1.3–1.5 inches (33–39 mm), up to 2.5 inches (64 mm) | Under 1.2 inches (30 mm) |

| Yarn Strength | High (4–5 gf/piece fiber strength); produces stronger ring-spun yarns | Lower; more prone to breakage during processing |

| Durability | High; up to 32.3% higher "work to break" value | Lower; fibers break more frequently |

| Yarn Evenness | Superior; fewer thick and thin place imperfections | Up to 46 more imperfections per kilometer |

| Pilling Resistance | Excellent; fewer fiber ends and improved evenness reduce surface fuzz | Lower; high short-fiber content increases pilling |

| Spinning Potential | Can produce very fine yarns (e.g., 80-Ne) | Limited to coarser yarn counts |

| Softness | Silk-like, smooth texture | Standard; may feel rougher due to more fiber ends |

| Common Ginning Method | Roller ginning (gentler, preserves length) | Saw ginning (more aggressive) |

Yarns made from long-staple cotton are smoother and more consistent, which means they maintain their appearance even after extended use. This makes them a favorite for high-end products like luxury bedding, premium shirts, and intimate apparel.

Practical Tips for Working with Long-Staple Cotton

How to Source Quality Long-Staple Cotton

To ensure you're working with top-tier long-staple cotton, focus on Gossypium barbadense varieties like American Pima, also known as "Extra-Long Staple" (ELS) cotton. These fibers range from 1 1/4 inches to 1 9/16 inches in length, which is significantly longer than standard American Upland cotton, typically measuring between 7/8 and 15/16 inches.

For precise quality data, check the 12-digit PBI tag through the USDA AMS Cotton and Tobacco Program's database. This system provides detailed measurements of fiber length, uniformity, strength, micronaire (fiber fineness and maturity), color, and trash levels using High Volume Instruments (HVI).

Choose roller-ginned cotton whenever possible. This method helps protect the fiber length, ensuring more uniformity, fewer neps, and reduced short-fiber content.

After sourcing, proper preparation is critical to maintain the superior qualities of long-staple cotton.

Preparing Fibers for the Spinning Process

Preparation is key to optimizing spinning performance. Start by using a bale plucker to blend fibers from multiple bales. During the cleaning process, adjust the beaters' grid bars to remove trash effectively without harming the long fibers. Combing is a must when working with long-staple cotton. This step eliminates short fibers (typically 0.5 inches or less), allowing for finer yarn counts, enhanced sheen, and greater durability.

"In the opening, cleaning, and carding processes, low-micronaire or fine-fiber cottons require slower processing speeds to prevent damage to the fibers."

– Cotton Incorporated

For fine-fiber or low-micronaire cotton, slow down processing speeds during opening, cleaning, and carding to avoid fiber damage. After carding, merge six to eight slivers and pass them through rollers operating at varying speeds. This straightens trailing fiber ends and ensures consistent weight across the slivers.

Once the fibers are prepped, the focus shifts to spinning techniques that maximize the quality of long-staple cotton.

Best Spinning Techniques for Long-Staple Cotton

For producing fine, high-quality yarns from long-staple cotton, ring spinning is the go-to method. This technique can handle yarn counts as fine as 50-Ne and 80-Ne. Use HVI data to assess fiber length, uniformity, and strength, ensuring the best bale selection and machine settings.

Keep an eye on micronaire levels with airflow instruments. When working with low-micronaire cotton, reduce machinery speeds during opening and carding to prevent fiber damage. Cotton with a high uniformity index is also essential, as it reduces short-fiber content, which can otherwise lead to processing challenges and lower-quality yarn.

Another critical factor is fiber elongation. High-elongation fibers are more resistant to breaking during mechanical processing, while low-elongation fibers can cause up to 46 additional thick and thin spots per kilometer of yarn. Selecting cotton with good elongation properties will help minimize imperfections and maintain consistent yarn quality throughout the spinning process.

Conclusion

Long-staple cotton enhances yarn spinning by providing stronger, more uniform fibers that align better during processing, resulting in superior finished products. High-elongation long-staple fibers can significantly reduce yarn imperfections - cutting as many as 46 thick and thin places per kilometer compared to lower-quality options - while also increasing work-to-break values by up to 32.3%. These advantages lead to faster spinning speeds, fewer interruptions, and premium textiles that fetch higher market prices.

"The upland ELS trait contributes to significantly improved upland yarn quality." - C. Wayne Smith, Department of Soil and Crop Sciences, Texas A&M University

These proven quality improvements guide best practices in sourcing and processing. Whether you're a cotton grower looking to enhance market appeal or a textile manufacturer producing finer yarn counts like 50-Ne or 80-Ne, prioritizing Extra Long Staple (ELS) varieties is critical. Benefits include reduced fiber breakage during processing and smoother spinning operations, producing textiles that meet the high standards of today’s discerning consumers.

For those seeking reliable sources of long-staple cotton, cottongins.org provides a detailed directory of cotton gins throughout the United States, organized by state and county. This resource connects you with suppliers and partners who understand the care required to maintain the quality of long-staple fibers from harvest to yarn production. The key to fully leveraging the advantages of long-staple cotton lies in careful selection, precise preparation, and optimized spinning techniques. By considering fiber elongation alongside traditional strength metrics and utilizing HVI data for informed choices, you can tap into the full potential of this premium material.

FAQs

Why is long-staple cotton ideal for creating high-quality textiles?

Long-staple cotton is prized for creating top-tier textiles, thanks to its longer fibers. These fibers produce yarns that are stronger, smoother, and more consistent, resulting in fabrics that feel softer, last longer, and resist pilling or tearing.

Because of its strength and uniformity, long-staple cotton is ideal for spinning into fine, high-thread-count yarns. This makes it a go-to material for luxury items like premium bedding, high-end clothing, and other refined textiles. Its exceptional quality ensures a polished, sophisticated finish, making it a favorite in the textile world.

Why is fiber length important for yarn spinning and quality?

Fiber length plays a crucial role in yarn spinning and greatly influences the quality of the final product. Longer fibers, often referred to as long-staple cotton, produce stronger and smoother yarns with fewer flaws. These fibers bond together more effectively, need less twist during the spinning process, and enhance production efficiency while delivering higher-quality yarns. On the flip side, shorter fibers can result in weaker yarns with noticeable imperfections, such as thick spots, increased fuzz, and a higher likelihood of pilling - issues that can compromise both durability and appearance.

The uniformity of fiber length is just as important. When fibers are consistently longer and more uniform, they spin more smoothly and yield yarns of consistent, superior quality. Selecting the appropriate cotton variety and employing proper ginning methods are key to preserving fiber length and uniformity, which are vital for producing top-tier textiles.

Why does long-staple cotton cost more than short-staple cotton?

Long-staple cotton comes with a higher price tag because its longer fibers create yarns that are stronger, smoother, and more consistent. These fibers need less twisting during the spinning process, which leads to textiles that are softer to the touch and more durable over time. This makes it a go-to choice for luxury items like high-end bedding and premium apparel.

The added cost also stems from the specialized cultivation and harvesting techniques needed to grow long-staple cotton. Its ability to produce superior-quality products makes it an appealing option for manufacturers focused on delivering top-tier goods.