Cotton combing transforms raw cotton into smoother, stronger, and more aligned fibers, making it essential for producing premium yarns used in luxury textiles. Here's what you need to know:

- Purpose: Removes short fibers, impurities, and neps, improving fiber quality for yarns rated Ne 40+.

- Benefits: Combed cotton is softer, more durable, resists pilling, and retains color better than carded cotton.

- Efficiency: Modern combing machines process up to 600 kg/hour, with advanced models achieving 20% higher output.

- Challenges: Combing increases costs by 5% due to 10-25% fiber waste, but the quality boost justifies the expense for high-end markets.

- Key Components: Feed system, nipper assembly, combs (circular and top), detaching rollers, and noil removal systems work together for precise cleaning and alignment.

For U.S. cotton producers, combing adds market value by upgrading medium-staple fibers into premium products. Collaboration between gins and mills ensures optimal fiber quality and reduced waste, supporting the production of high-quality textiles.

Combing Process Explained - Yarn Manufacturing

Main Parts of a Cotton Combing Machine

A cotton combing machine is designed with five key systems that work together to eliminate short fibers and impurities while aligning longer fibers. This process is crucial for producing high-quality yarn. Let’s break down how each component contributes to this precision.

Feed System and Lap Preparation

The feed system manages how cotton enters the machine. Card slivers are combined to create a lap, which can be as thick as 80 ktex. A feed plate and feed roll then move this lap into the combing zone in small, precise steps. This measured feeding ensures the fibers are consistently presented for combing, setting the stage for uniform results throughout the process.

Nipper Assembly and Clamping Zone

The nipper assembly consists of two main parts: a top nipper and a bottom cushion plate. Together, they clamp the lap securely during combing. Modern designs feature an eccentric mechanism that applies pressure gradually through a "soft-closure" system. These nippers oscillate up to six times per second, moving backward to position fibers for combing and forward to deliver them to the detaching rollers. For instance, Rieter nippers improve efficiency by increasing output up to 15% and reducing noil content by as much as 2% compared to older models.

"High-precision clamping of the lap in combination with the optimized motion of the circular and top combs results in ideal combing action across the entire range of nip rates." - Rieter

Circular Comb and Top Comb

The circular comb, or bottom comb, works with the top comb to separate short fibers from longer ones. As the nippers hold the fiber fringe in place, these combs pass through the cotton, removing fibers shorter than 12.5 mm along with neps and trash. The top comb focuses on cleaning the trailing ends of the fibers, ensuring they are neatly aligned. This dual action creates a parallel fiber arrangement, giving combed cotton its signature smoothness and shine.

Detaching Rollers and Sliver Formation

Detaching rollers play a crucial role in pulling the cleaned fibers together to form a uniform sliver. During this step, drafting ensures the fibers are straightened and perfectly aligned, preparing them for efficient spinning.

Noil Removal and Waste Handling

Short fibers and impurities, collectively known as noil, are continuously stripped away and collected during the combing process. Removing noil is essential for producing stronger and more uniform yarn. The collected waste fibers are then sent to specialized systems where they can be repurposed for lower-grade textile products.

The Cotton Combing Process Step by Step

Cotton Combing Machine Process: 3-Stage Workflow from Raw Cotton to Aligned Sliver

To appreciate why the combing process is key to producing high-quality cotton fibers, it helps to understand how raw cotton is transformed into a clean, aligned sliver ready for spinning. This process takes place in three main stages, each carefully designed to build on the previous step.

Feeding and Nipping

The journey begins with feed rollers advancing the cotton lap in small, precise increments, typically 4.3–6.7 mm per cycle. During this initial phase, the nippers remain open. Once the lap reaches the correct position, the nippers close, gripping the fibers firmly to create a controlled fringe that extends beyond the nipping point. This secure hold minimizes the loss of long fibers, reducing waste. The amount of cotton fed per cycle plays a crucial role - it directly affects the noil percentage, sliver quality, and production rate. Lower feed amounts generally yield higher-quality sliver, especially when adjusted to match the fiber length. These precise feeding steps lay the groundwork for effective combing.

Combing Action

With the fibers securely clamped, the rotating circular comb gets to work. Its saw-teeth or needle rows sweep through the exposed fiber fringe, removing short fibers, neps, and impurities that aren’t held by the nippers. These unwanted materials are carried away as noil. Next, the top comb - equipped with fine teeth (like 25 teeth per inch) - engages the fiber fringe. As the clamped fibers are pulled through the fine teeth, the trailing portion undergoes additional combing. This step straightens any hooks, removes remaining short fibers (typically those shorter than 21–25 mm), and catches contaminants that may have been missed by the circular comb. The amount of noil removed determines the combing intensity: 5–10% for semi-combing, 10–20% for standard combing, and over 20% for super combing. After this meticulous cleaning, the fibers are ready to be formed into a continuous sliver.

Detaching and Piecing

In the final stage, detaching rollers take over, forming the cleaned fibers into a continuous sliver. The overlapping tufts bind together, creating a uniform strand. Initially, the combed sliver might be weak and require additional gilling to correct fiber alignment and improve spinning performance. However, the detaching process ensures that the fibers remain untangled and aligned throughout. Maintaining consistent machine speeds, proper roller pressure, and smooth table conditions is essential for producing a uniform sliver with controlled unevenness percentages (U%). This stage ties everything together, delivering a sliver that supports stronger, more consistent yarn production.

Machine Settings That Affect Performance

Once the combing process is understood, fine-tuning machine settings becomes essential for improving fiber quality. These adjustments transform raw cotton into high-quality combed sliver. Three critical settings - feed distance, nipper timing and pressure, and top comb depth - play a key role in determining how many short fibers are removed as noil, how well fibers align, and the overall quality of the resulting yarn.

Feed Distance and Fiber Length

Feed distance directly impacts the combing ratio, which determines which fibers remain in the sliver and which are removed as noil. Essentially, feed distance acts as the cutoff point for fiber retention. For instance, studies on Egyptian cotton varieties G70 and G75 have shown combing ratios ranging from 11% to 19.9%. Interestingly, research reveals that middle-length fiber loss peaks at a 15.7% ratio before declining. Since longer fibers are less likely to end up as noil, aligning the feed distance with the fiber length profile is essential for achieving maximum efficiency. This adjustment works hand-in-hand with precise nipper operations to protect valuable long fibers.

Nipper Timing and Pressure

The nipper assembly, operating at speeds of up to 500 nips per minute, must be perfectly synchronized with the feed rollers, circular comb, and detaching rollers. Proper timing and pressure are critical for maintaining fiber integrity. Correct nipper pressure ensures that long fibers are securely clamped while allowing the circular comb to effectively remove short fibers, neps, and impurities. If the pressure is too low, valuable fibers may escape into the noil stream; if it’s too high, fibers risk breaking. Equally important, the timing of the nipper’s movements - when it opens, closes, and shifts - ensures fibers are presented to the combs at the right moment. Poor timing can lead to premature release or improper clamping, which damages fibers, reduces combing quality, and increases waste.

Top Comb Depth and Speed

The depth of top comb penetration is another crucial factor in the combing process. Deeper penetration generally improves combing efficiency and reduces yarn defects, but pushing it too far can disrupt the combed fringe, leading to more classimat long faults and uneven fabric. Mill technicians frequently adjust top comb settings to balance the noil percentage with quality standards. When calibrated correctly, the top comb efficiently removes short fibers without disturbing the fringe. On high-speed machines, which can operate at 600–700 cycles per minute, precise top comb settings are vital for maintaining performance.

sbb-itb-0e617ca

Why Cotton Combing Matters for U.S. Producers

Improved Fiber Length and Alignment

Cotton combing plays a key role in enhancing the quality of U.S. cotton by improving fiber length and alignment. This process removes fibers shorter than 0.5 inches and arranges the remaining fibers into a neat, parallel bundle. For U.S. producers, this step is particularly important for the two dominant cotton types: Upland and Pima cotton. Upland cotton, which makes up about 97% of U.S. production, has fiber lengths between 1 and 1.25 inches. Meanwhile, Pima cotton, known for its extra-long staple fibers of 1.375 inches or more, relies on combing to maintain the integrity needed for its premium pricing. Proper alignment of fibers not only enhances inter-fiber friction and mechanical interlocking but also significantly improves yarn quality. The result? A cleaner, finer, and more lustrous fiber compared to cotton that’s only carded. This refined quality gives U.S. cotton a competitive edge in luxury textile markets.

Stronger Yarn and Better Fabric Appearance

Combed cotton offers substantial advantages over carded cotton, particularly in strength and appearance. By eliminating weak, short fibers, combing produces yarn that is 20% stronger. This process also creates a smoother and more uniform yarn surface, reducing pilling by 50% and making the cotton 30% softer. These qualities are critical for high-end fabric applications, including digital printing, screen printing, and heat transfers. The enhanced strength and texture ensure that the finished fabrics meet the high standards demanded by premium markets.

Balancing Quality and Waste

While combing improves fiber quality, it does come with some trade-offs, particularly in terms of waste. For U.S. producers, finding the right balance between quality and efficiency is essential to maintain profitability. This is especially true for extra-long staple varieties like Supima®, where preserving fiber integrity through combing is crucial for supporting the premium pricing of luxury garments. By carefully managing the combing process, producers can achieve both superior fiber quality and economic viability.

How Combing Connects to Ginning and the U.S. Cotton Supply Chain

The efficiency and quality of combing are deeply tied to what happens upstream in the ginning process. A well-executed ginning operation can make or break the performance of combing later in the supply chain.

How Ginning Quality Affects Combing Efficiency

Combing isn’t a standalone process - it heavily depends on the quality of fiber coming from the gin. If gin operators push their equipment too hard, like using excessive cleaning passes or running saws at high speeds, fibers can suffer mechanical damage. This leads to more neps and short fibers, forcing mills to remove more noil, which increases waste and production costs. On the other hand, when gins use carefully calibrated settings, they can remove seed-coat fragments and trash without over-processing. This results in cleaner, more uniform fibers that allow mills to run combers faster and with less aggressive settings, improving productivity while keeping waste in check.

The impact of ginning adjustments can be seen in real-world cases. Take, for instance, a mill producing 60s combed ring-spun yarn. Despite using high-quality U.S. upland cotton, they were dealing with 18% noil and nep defects. Lab analysis revealed that the problem stemmed from a local gin that was over-processing cotton with too many lint-cleaner passes and high drying temperatures during a wet harvest. Once the gin cut back on lint cleaning, lowered drying temperatures, and reduced saw speeds, the mill adjusted its combing settings. The results? Noil dropped from 18% to 14%, yarn evenness improved, and fabric appearance claims decreased. This example highlights how fine-tuning gin operations can significantly enhance combing performance.

This direct relationship between gin settings and combing underscores the importance of collaboration between mills, growers, and gins.

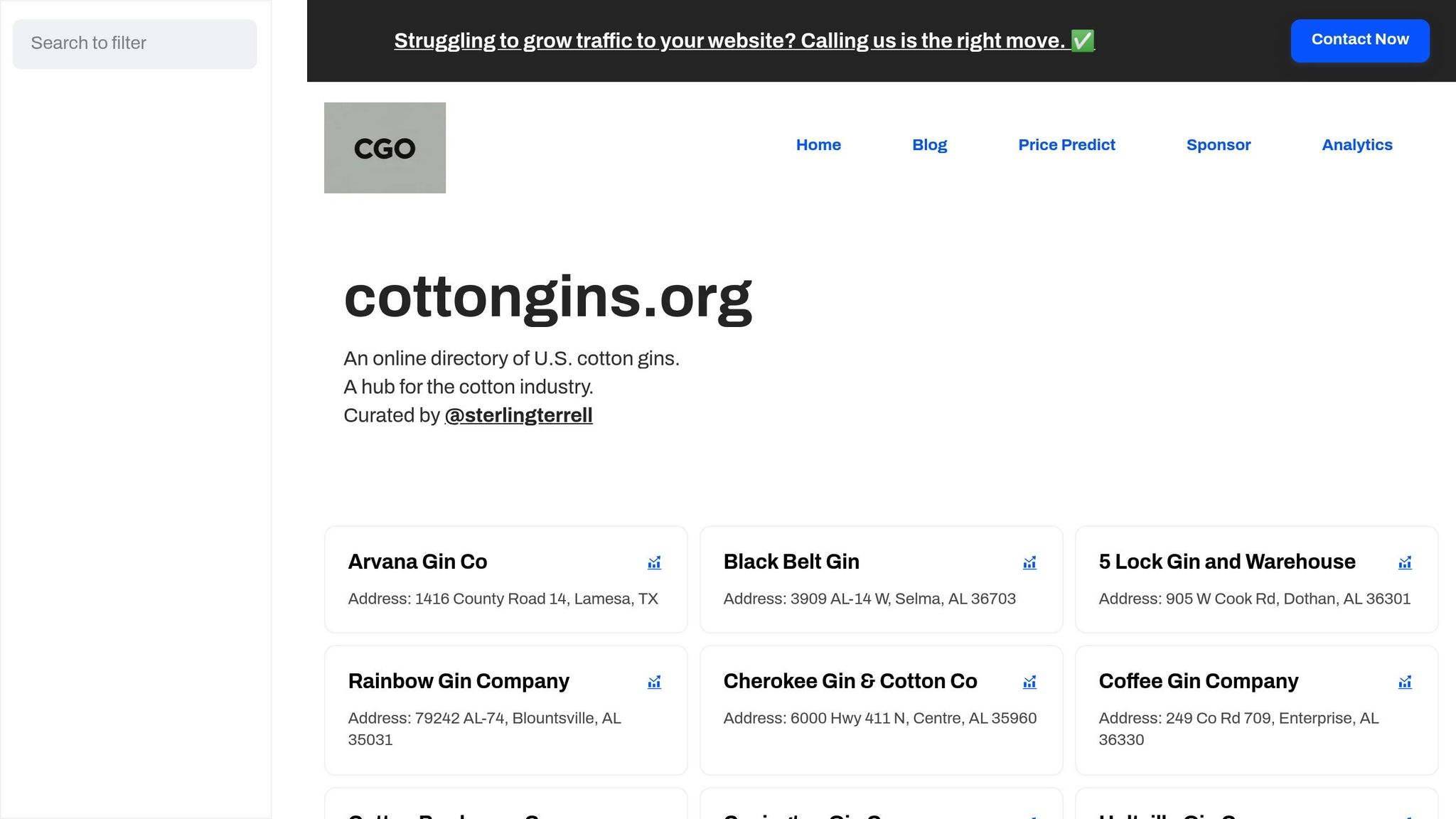

Using cottongins.org to Find Regional Gin Capabilities

For mills and growers focused on combed-yarn markets, finding the right gins is crucial. That’s where cottongins.org comes in. This online directory lists U.S. cotton gins across 15 states, allowing users to search by region and access contact details. By pairing this information with regional classing data and advertised quality programs - like low-damage roller ginning for Pima or long-staple cotton - mills can identify gins capable of delivering combing-ready fiber. Similarly, growers aiming to secure contracts for premium combed yarn can use the site to connect with gins willing to customize cleaning settings and bale management for high-end programs.

Aligning Ginning and Spinning Targets

For combed-cotton programs to succeed, seamless communication between gins and mills is essential. Mills need to clearly outline their requirements - such as yarn count range, target noil percentage, and Uster limits - so gins can adjust their processes accordingly. This might include tweaking drying temperatures, adjusting cleaner sequences, or fine-tuning saw speeds to meet fiber specifications while maintaining acceptable grades and turnout.

Regular reviews of classing data, noil percentages, and yarn test results help both parties refine their settings. For instance, if over-cleaning is damaging staple length, gins can scale back. Conversely, if excessive trash is causing issues during combing, additional cleaning may be necessary. This kind of collaboration not only ensures consistent quality but also supports dedicated combed-cotton programs. It creates a win-win scenario where growers and gins can justify premium pricing by delivering exactly what mills need for high-quality combed yarn production.

Conclusion

Getting the hang of cotton combing can give both growers and gin operators a real advantage. By filtering out short fibers, neps, and impurities, the combing process takes raw cotton and turns it into high-quality fiber. The result? Stronger, smoother, and shinier yarns that stand out in the market. In fact, combed yarns often fetch about 5% more in price compared to carded yarns.

For U.S. cotton producers, syncing up ginning and combing processes is crucial. When ginning operations fine-tune their cleaning methods to maintain fiber quality, the cotton sent to combing mills is easier to process, with less waste and more value added.

On top of that, the numbers back up the benefits. Modern combing machines can handle up to 600 kg per hour while recovering 80–90% of noils for reuse. These machines are key to producing the fine yarns (Ne 40 and higher) needed for luxury clothing, premium bed linens, and high-end technical textiles.

FAQs

What are the key advantages of using a cotton combing machine?

Using a cotton combing machine brings several key advantages to the cotton industry. By precisely aligning fibers and eliminating shorter or less desirable ones, it helps create smoother, stronger, and more uniform yarns. This process enhances the quality of the fiber, leading to softer, longer-lasting fabrics with reduced pilling and a more polished appearance.

On top of that, these machines boost production efficiency by cutting down on waste, which translates to added value for producers and manufacturers. Cotton combing technology is essential in crafting high-quality textiles while making the most of resources for both growers and manufacturers.

What does the combing process do to improve cotton yarn quality?

The combing process improves the quality of cotton yarn by removing short fibers, impurities, and small knots known as neps. This results in a yarn that is smoother, more uniform, and stronger, making it both durable and visually pleasing.

By refining the fibers, combing not only enhances the spinning process but also produces fabrics with a softer feel and improved performance. It's an essential step for manufacturers looking to create premium cotton products.

Why is it important for cotton gins and mills to work together during the combing process?

Collaboration between cotton gins and mills plays a key role in ensuring a consistent supply of high-quality, long-staple fibers. These fibers are crucial for the combing process, which eliminates impurities and shorter fibers, ultimately producing stronger, more uniform yarn and higher-quality fabrics.

By working together, gins and mills can synchronize their processes to minimize waste, boost efficiency, and maintain consistent fiber standards. This teamwork not only elevates the quality of the final cotton products but also helps farmers and manufacturers get the most value out of their cotton.