Executive summary (TL;DR)

- GOTS certified organic cotton isn't just a label—it's a full-chain audit from your field to the final seam, banning toxics and ensuring fair wages that can net farmers 20-50% premiums over conventional lint.

- For seasoned growers, the real win is soil regeneration and pest resistance without synthetics, but brace for the 3-year transition and paperwork grind that tests your operation's grit.

- In a market where mills pay extra for traceable, residue-free bales, GOTS turns sustainable practices into a hedge against volatility—enroll if you're ready to farm for the long haul, not the quick flip.

Related Post: What Is Better Cotton? How BCI Is Transforming the Cotton Industry

GOTS Certified Organic Cotton: The Gold Standard for Sustainable Textiles

I've spent enough seasons knee-deep in Texas blacklands and California deltas to tell you: Conventional cotton's a beast—yields that tempt you with short-term cash, but at the cost of soil that's deader than a dust bowl and water tables sucking wind. Then there's GOTS certified organic cotton. Not some feel-good sticker for boutique tees, but the unyielding benchmark that demands every bale from your gin stand traces clean through spinning, weaving, and finishing without a whiff of synthetic regret.

If you've got 10+ years chasing micronaire under 4.0 or dodging lygus outbreaks, you know the drill: Organic sounds noble until the bollworms hit and your IPM scouts come up empty. But GOTS—Global Organic Textile Standard—flips that script. It's the world's toughest certification for organic fibers, covering everything from your cover crop rotations to the effluent in a distant dye house. Backed by the likes of OTA and Soil Association, it enforces IFOAM-approved farming plus end-to-end social and environmental teeth. No greenwashing; just verifiable practices that pay off in premiums and resilience.

This isn't entry-level fluff. We're talking practical overhauls: Compost teas over urea spikes, biodiversity buffers that cut erosion 30-50%, and labor protocols that keep your crew intact through harvest crunch. For ginners and spinners, GOTS certified organic cotton means residue-free lint that spins tighter, dyes even, and sells at $0.20-0.50/lb above commodity—enough to fund that pivot irrigator you've eyed. Let's dissect it like we're troubleshooting a sticky gin stand: Principles, process, payoffs, pitfalls, and the pro moves that make it stick.

What Makes GOTS Certified Organic Cotton the Unrivaled Benchmark?

Strip away the hype, and GOTS is a fortress of criteria built by global heavyweights—OTA, IVN, Soil Association—for organic textiles. What sets GOTS certified organic cotton apart? It starts in your field but doesn't stop at the bale. While USDA NOP or EU Organic might green-light your harvest, GOTS audits the full pipeline: Ginning, carding, combing, spinning into yarn, all the way to garment stitching and labeling.

Core scope: Applies to any product with 70%+ certified organic fibers ("made with organic") or 95%+ for full "organic" labeling. For cotton, that means no GMOs, no synthetic pesticides or fertilizers—ever. Prohibited list? A bible of 300+ chemicals, from heavy metals to PFCs, covering flame retardants and endocrine disruptors that conventional processing loves.

From general industry baselines (IFOAM and GOTS foundational docs): GOTS harmonizes with national organics but layers on textile-specific rules—like zero discharge of untreated effluent in wet processing. For you, the farmer-ginner hybrid, this translates to lint that's not just organic but "textile-ready": Low neps, uniform staple, and zero residues that could tank a mill's batch. It's the gold standard because it's global—accepted from U.S. ports to EU borders—slashing compliance headaches for exporters.

The Four Pillars of GOTS: Environmental, Social, Quality, and Chain Integrity

GOTS rests on four interlocking pillars, each with criteria that hit like a precision applicator—targeted, measurable, and merciless on shortcuts. These aren't suggestions; they're audited annually by accredited bodies like Control Union or Ecocert.

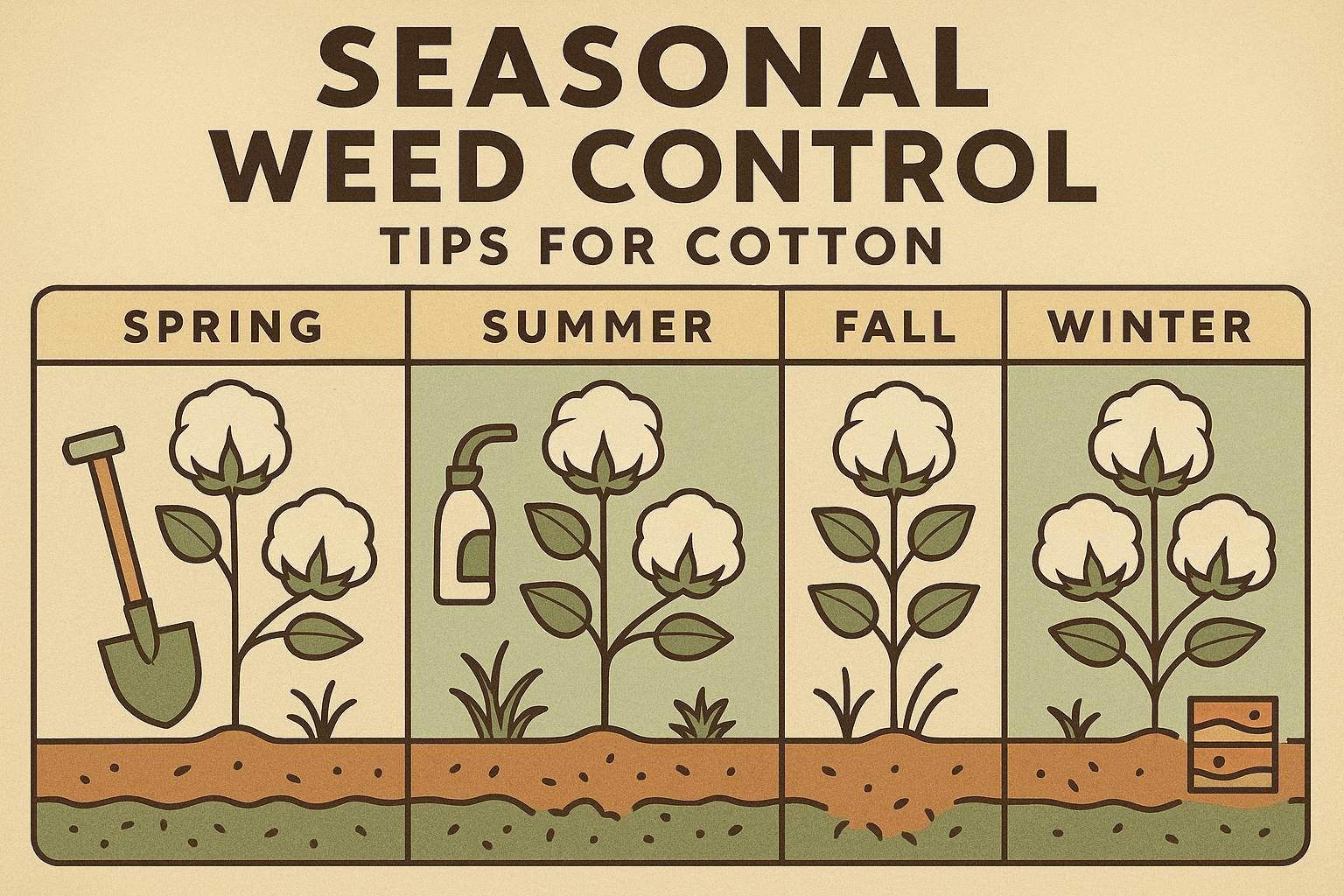

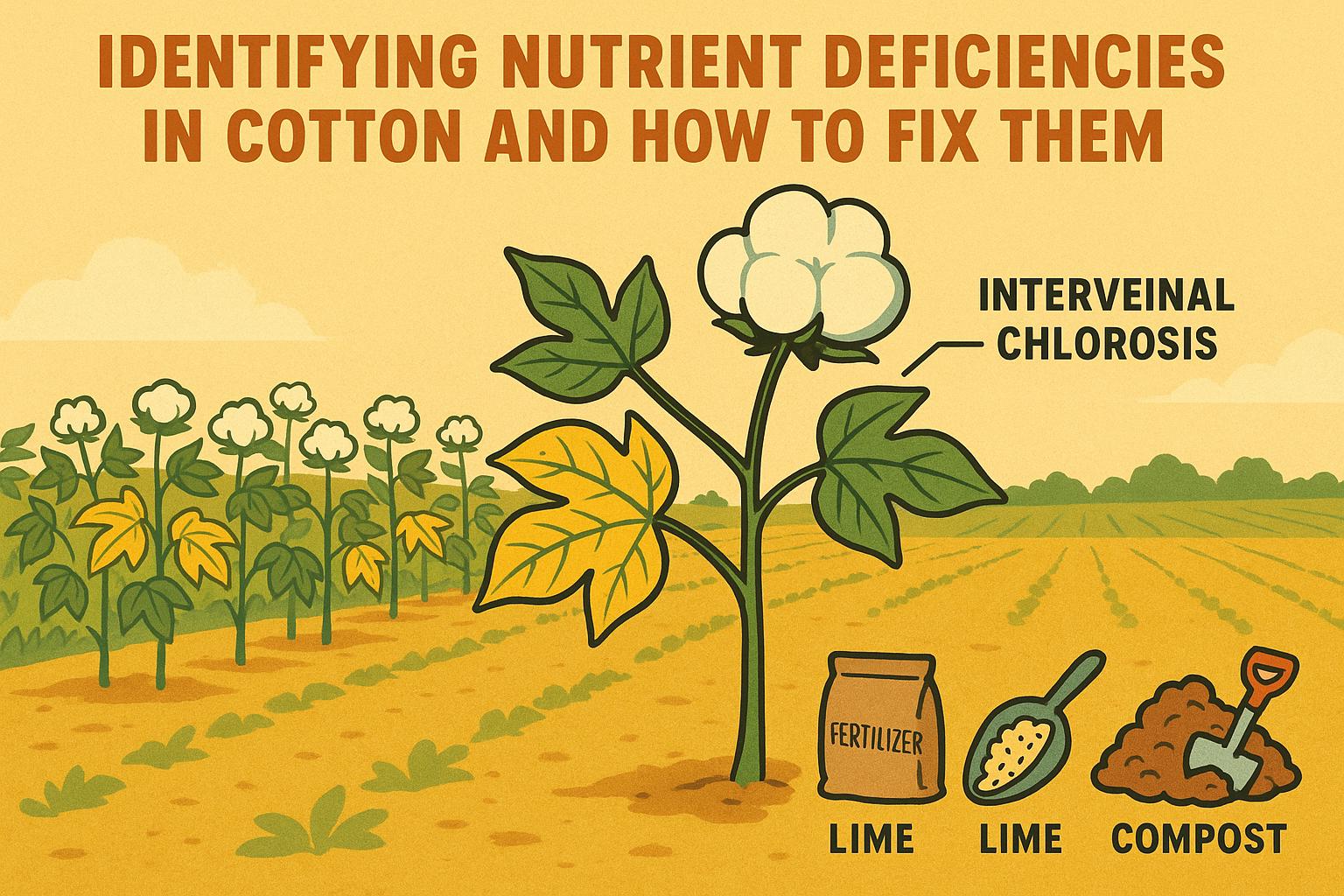

- Environmental Criteria: From Soil to Spinning Effluent Farming: Organic methods only—compost, green manures, crop rotations to build soil organic matter 1-2% over cycles. Water? Efficient stewardship: Drip systems over floods, recycling 90%+ in processing. In spinning, no toxic auxiliaries; only low-impact scouring agents. Result? Biodiversity jumps—pollinator habitats via hedgerows, cutting insect pressure 20-40% naturally. For fiber processing, GOTS mandates energy audits, slashing carbon footprints 15-25% versus conventional mills.

- Social Criteria: ILO-Core Labor Without the Lip Service No child labor, forced overtime, or discrimination—straight from ILO conventions and UN Guiding Principles. Wages? Living standards benchmarked regionally, with grievance systems and safety training mandatory. In ginning and spinning sheds, this means ventilated spaces, PPE, and worker committees—dropping injury rates 30-50%, per GOTS-aligned studies. For farmers, it's fair trade vibes without the separate cert: Equitable contracts that buffer against price dips.

- Quality Criteria: Ensuring Your Lint Spins Premium Technical performance baked in: Yarns must meet tensile and evenness specs (Uster CV% <12% typical). Prohibits GMOs and irradiation; tests for residues quarterly. In blending, only GOTS-approved synthetics (e.g., 5% elastane max). This pillar turns "organic" from niche to reliable—your GOTS certified organic cotton bales fetch premiums because mills know they'll run clean, with hairiness 20-30% lower than conventional.

- Chain of Custody: Traceability That Pays the Bills Mass balance or identity preservation—your call, but full docs from field to label. RFID tags on bales, transaction certificates at every handoff. For spinners, this means segregated lines to avoid cross-contam; ginners log every module. Benefit? Full transparency unlocks brand deals—H&M, Patagonia demand it for 100% sustainable sourcing.

These pillars form a closed system: Violations trigger remediation or delisting. Evergreen fact from GOTS core: Covers thousands of facilities worldwide, certifying millions of metric tons annually, with social compliance hitting 95%+ in mature programs.

Step-by-Step: Navigating GOTS Certification for Cotton Growers

Getting GOTS certified organic cotton status isn't a weekend project—it's a 3-year conversion grind that tests your operation like a drought year. But nail it, and you're locked into a premium pipeline. Here's the farmer-centric roadmap, assuming you've got the basics (soil tests, rotation plans) down.

- Conversion Kickoff: Field to NOP/IFOAM Alignment Enroll with a certified body (e.g., SCS Global). Audit your farm: No synthetics for 36 months prior. Implement organic system plan—IPM logs, compost recipes, biodiversity maps. Cost? $1,000-5,000 initial, plus annuals at $500-2,000/100 acres.

- Gin and Post-Harvest: Residue-Free Handling Your gin stand's the first checkpoint—clean to spec, no cross-contam with conventional. Bale tags with lot numbers; store in ventilated sheds to hold <8% moisture. GOTS requires ginners to certify separately if handling >10% volume.

- Processing Pipeline: Spinning Under Scrutiny Partner with GOTS-approved spinners—carding/combing with organic-compliant machinery, no chrome baths. Blending? Only with certified fibers for strength tweaks. Wet processing (scouring, dyeing) demands closed-loop wastewater, pH-neutral effluents.

- Annual Audits and Labeling: Seal the Deal On-site inspections: Scope cert for farms, transaction certs for trades. Label only "organic" at 95%+; disclose blends. Renewal? Risk-based—mature ops audit biennially.

Pro insight: Transition "in-conversion" status lets you sell at partial premiums during year 3—bridge the gap with diversified crops like cover legumes.

Advantages of GOTS Certified Organic Cotton: Margins and Resilience for Pros

For the battle-hardened grower, GOTS isn't altruism—it's armor. What edges out conventional or even BCI? Full-chain premiums and efficiencies that compound.

- Premium Pricing Power Mills pay 20-50% more for GOTS lint—$1.50-2.50/lb vs. $1.00 conventional—thanks to traceability and residue guarantees. Brands like Levi's lock in volumes, stabilizing your sales against ICE futures swings.

- Soil and Yield Longevity Organic methods rebuild tilth: 15-30% higher water retention, cutting irrigation 20-40%. Pest resistance builds via rotations—yields stabilize at 80-90% conventional without the crash cycles. Micronaire holds steadier, neps drop 25%.

- Health and Labor Efficiencies No chem exposure slashes farmer illness 40-60%, per FAO baselines. Crews stick around with fair protocols—turnover halves, harvest speeds 10-15%.

- Market and Export Edge Global acceptance: EU REACH-compliant, U.S. NOP-aligned. Unlocks FTAs with sustainability clauses; diversifies to eco-brands chasing 50%+ organic sourcing.

- Environmental ROI Biodiversity buffers reduce erosion 30%, sequester 0.5-1 ton CO2/acre/year. Water savings? Up to 91% less pollution vs. conventional dyeing.

From OTA and GOTS data: Certified ops see 10-20% net income uplift, with durability extending fabric life 20-30%—less waste, repeat buys.

Challenges of GOTS Certified Organic Cotton: The Gritty Realities

GOTS is gold, but mining it demands sweat. Conventional vets know the pain points—here's the unvarnished.

- Transition Hurdles: The 3-Year Desert Yields dip 20-30% initially sans synthetics; bollworms test your IPM mettle. Costs spike $200-400/acre for audits, natural inputs.

- Paperwork and Compliance Grind Logs for every spray, soil test, worker hour—ERP integration runs $5K-15K. Small ops (<500 acres) cite admin as 15-20% overhead.

- Supply Chain Friction Finding GOTS spinners? Limited—most mills retrofit for $50K+. Blends restricted; no cheap fillers.

- Pest and Weather Vulnerabilities Without neonics, outbreaks hit harder—scouting ramps 2x. Droughts expose irrigation gaps; premiums must cover.

- Market Volatility Premiums fluctuate with demand—eco-slump dips 10-15%. No mass balance like BCI; full segregation adds logistics.

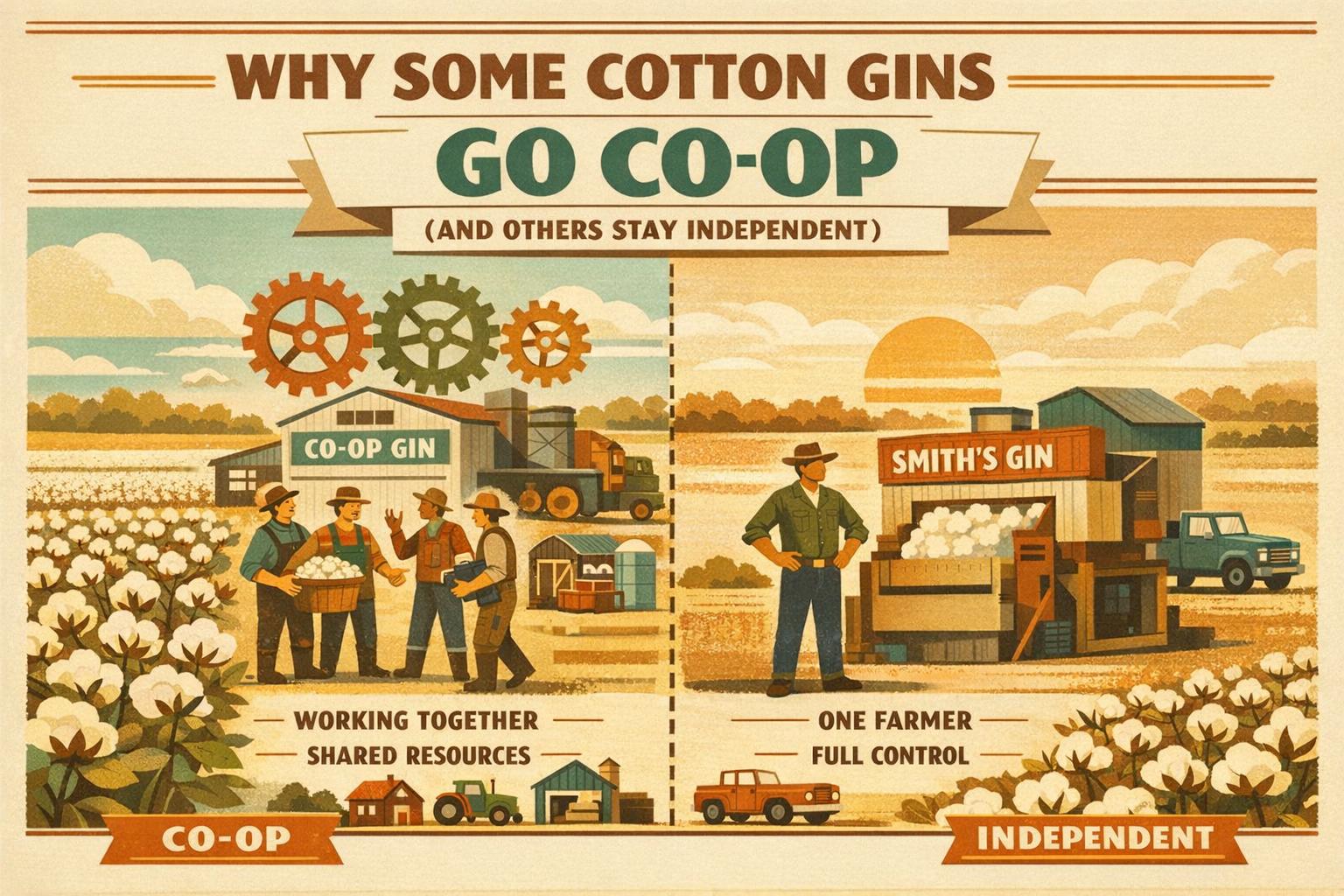

Mitigate: Stack with crop insurance riders for organics; join co-ops for shared audits (cuts costs 30%).

GOTS in Fiber Processing and Spinning: Seamless from Bale to Bobbin

Your lint's journey under GOTS? Meticulous. Ginning: Seed removal sans chemicals; baling at 7-9% moisture to prevent mold. Carding/combing: Mechanical only—no optical cleaners with toxics. Spinning: Ring or open-end with organic lubes, twist multipliers tuned for low hairiness (S3 <150). Blending? Up to 30% non-organic for "made with," but full organic demands purity.

Quality specs: Yarn CSP >1,800 for Ne 20; fabrics withstand 50 washes sans shrinkage >5%. Wet processing: Biodegradable dyes, no AOX discharges. For spinners, this means 10-15% less ends-down from cleaner fibers—efficiency gold.

Pro Tips: Thriving with GOTS Certified Organic Cotton

- Field Hacks: Rotate with nitrogen-fixers like vetch—boosts next crop 15-20% without ferts. Scout weekly; neem-based IPM holds lygus under 5% damage.

- Gin Tweaks: Dedicate lines for organic—cross-contam fines hit $10K. Log HVI per bale for traceability.

- Partner Smart: Vet spinners via GOTS database—prioritize those with compact spinning for finer counts.

- Financial Buffer: Hedge premiums via forward contracts; diversify 20% acreage to organics for risk spread.

- Crew Buy-In: Train on social criteria early—empowered workers spot issues, cut defects 25%.

Actionable Takeaways for Cotton Veterans

- Audit Your Acres: Map soil health this off-season—target 1% organic matter gain via compost trials; enroll in conversion for partial premiums.

- Certify Strategically: Pick a body like Ecocert; budget $3K initial for 200 acres—ROI in year 4 via 30% yield rebound.

- Blend for Bucks: Source GOTS spinners for 50/50 organic-poly blends—stretch elastane without quality dips.

- Market Muscle: Bundle GOTS with HVI certs in bids—$0.30/lb edge on export lots to EU mills.

- Resilience Build: Install basin-level water meters—slash use 25%, qualify for carbon credits at $15/acre.

GOTS certified organic cotton isn't the easy path—it's the enduring one. In fields where margins fray like old denim, it weaves sustainability into profit, turning your lint into legacy. You've tilled the dirt; now claim the standard that elevates it.