Shipping cotton in containers is challenging due to theft, contamination, delays, and fluctuating freight rates. Here’s how to address these issues effectively:

- Prevent Theft: Cargo theft costs the U.S. cotton industry billions annually. Partner with reliable carriers and use secure packaging to reduce risks.

- Avoid Contamination: Use approved materials like polyethylene (PE) film for moisture protection and avoid metal fasteners that can damage packaging.

- Reduce Delays: Plan shipments early, use data-sharing tools like FLOW, and consider alternative ports or transport modes to sidestep bottlenecks.

- Control Costs: Maximize container space, consolidate shipments, and choose the right container size to save on freight expenses.

Practically Cotton Bales Export container Stuffing by Paresh Solanki Start your Export Business

How to Prevent Moisture Damage and Contamination

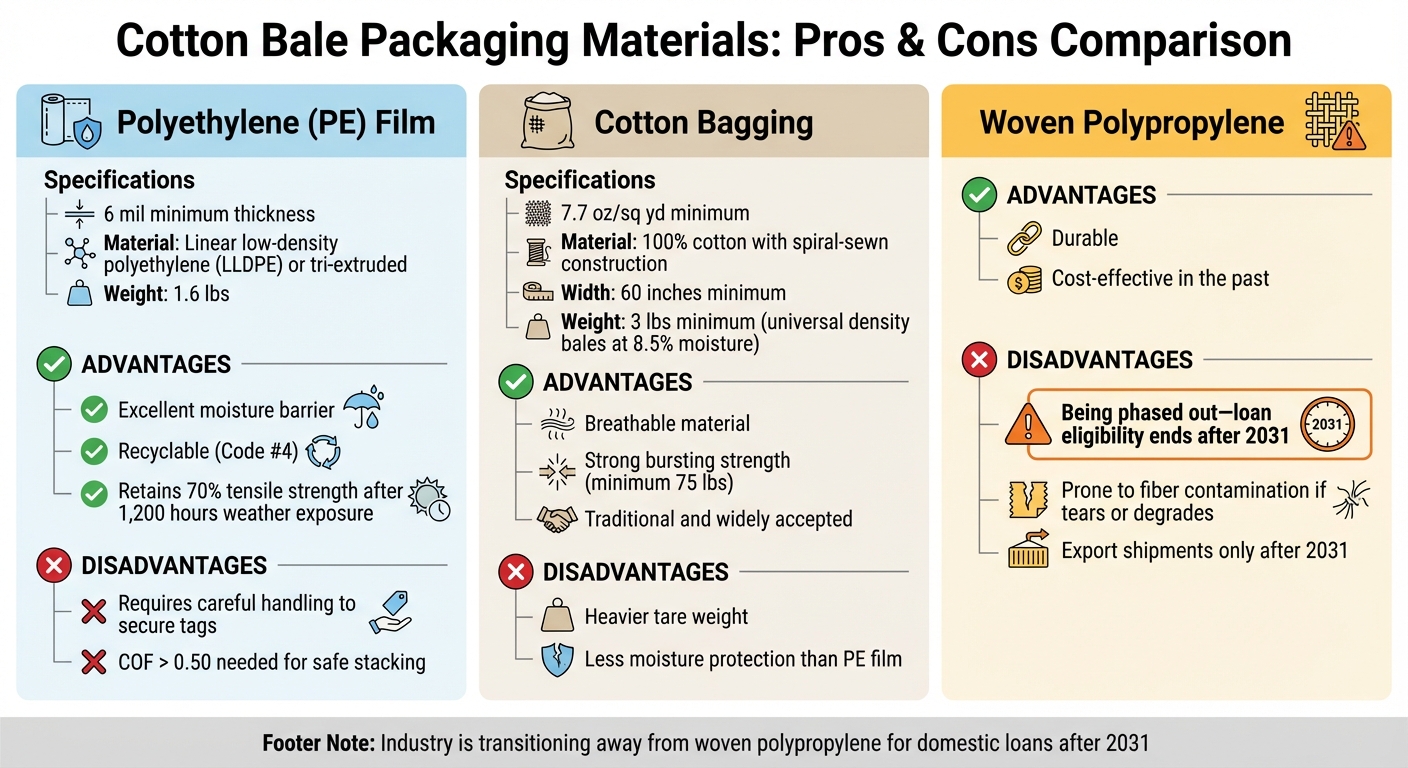

Cotton Bale Packaging Materials Comparison: PE Film vs Cotton Bagging vs Woven Polypropylene

When moisture levels exceed 7.5%, mold and bacteria can thrive, which puts cotton fibers at risk of damage and can lead to shipment losses.

The National Cotton Council's Quality Task Force emphasizes this point:

"The NCC's Quality Task Force urges diligence be exercised to minimize the possibility of fiber quality deterioration due to excessive water and concentrated wet spots."

Preventing moisture issues begins at the gin. Liquid spraying systems can create concentrated wet spots that become breeding grounds for mold and rot. Once bales leave the gin, using approved packaging ensures protection from external moisture during both transport and storage.

Proper Baling, Packaging, and Container Preparation Methods

The Joint Cotton Industry Bale Packaging Committee (JCIBPC) enforces strict standards for bale packaging to maintain fiber quality. Only use approved bagging and ties to safeguard cotton fibers.

Polyethylene (PE) film bagging is the most effective moisture barrier. This film must be at least 6 mil thick and made entirely of linear low-density polyethylene (LLDPE) or tri-extruded material. Such specifications ensure the film retains 70% of its tensile strength even after 1,200 hours of weather exposure. The bagging should fit snugly and completely cover both bale heads to block any moisture from seeping in.

Cotton bagging is a breathable option that works well in controlled storage settings. This material must weigh at least 7.7 ounces per square yard and be made from 100% cotton with spiral-sewn construction. It must also be at least 60 inches wide for consistent coverage. While it doesn’t offer the same moisture protection as PE film, it’s a trusted choice in environments where humidity is less of a concern.

Avoid using metal fasteners, as they can puncture the wrap and lead to contamination. If bagging is cut for sampling, it’s crucial to patch it promptly with approved materials before shipping.

Before loading containers, check that they are dry, clean, and well-ventilated to reduce the risk of moisture transfer.

Packaging Options: Pros and Cons

| Packaging Material | Advantages | Disadvantages |

|---|---|---|

| Polyethylene (PE) Film (6 mil minimum) | Excellent moisture barrier; recyclable (Code #4); retains 70% tensile strength after prolonged weather exposure | Requires careful handling to secure tags; COF > 0.50 needed for safe stacking; lightweight (1.6 lbs) |

| Cotton Bagging (7.7 oz/sq yd) | Breathable; strong bursting strength (minimum 75 lbs); traditional and widely accepted | Heavier tare weight (3 lbs minimum for universal density bales at 8.5% moisture); less moisture protection than PE film |

| Woven Polypropylene | Durable and cost-effective in the past | Being phased out - loan eligibility ends after 2031; prone to fiber contamination if it tears or degrades during handling |

The industry is moving away from woven polypropylene, which will no longer qualify for domestic loans after 2031. It will remain an option only for export shipments.

How to Prevent Damage from Shifting Loads and Poor Stowing

When cotton bales shift during transport, they can collide with container walls and with each other. This movement can lead to punctures, especially if the container floors or walls have sharp edges, protruding nails, or splinters. Even the toughest packaging materials can fail under these conditions. Empty spaces, or voids, in the container only make things worse by giving the cargo room to move, which is a common cause of damage during sea, rail, and road transport.

Another issue is broken bale ties. When ties fail, the bales expand, making them harder to secure and increasing the risk of movement. Avoid using metal fasteners, as they can introduce contamination and fire hazards.

To minimize these risks, it’s important to use effective loading and securing techniques.

Best Loading and Securing Methods

Controlling load movement starts with proper weight distribution and protective barriers. Heavier bales should always go at the bottom to create a stable base. Adding a layer of cardboard or plywood between the cotton bales and the container walls can help prevent punctures from sharp edges.

For filling voids, dunnage bags are a reliable solution, but they need to be chosen based on the mode of transport. Here’s a quick guide:

- Truck shipments: Use two-ply bags that can handle up to 18,000 kg.

- Sea containers: Opt for four-ply to six-ply bags, which support 27,000 kg to 45,000 kg.

- Railroad cars: Use six-ply to eight-ply bags, designed to handle 45,000 kg to 54,000 kg, as they face stronger impacts from end-to-end movement.

To avoid punctures, keep dunnage bags off the floor, where nails or moisture could damage them. Also, position these bags away from container doors to prevent dangerous pressure build-up when the doors are opened.

Rubber friction mats can be another effective tool, especially for ocean and rail transport, as they reduce both lateral and end-to-end shifting. Make sure dunnage bags are aligned with the height of the cargo to prevent them from "ballooning", which reduces their effectiveness.

Finally, using volumetric weight calculators can help ensure that the load is evenly distributed and stays within safety limits. Proper planning and securement are key to keeping your cargo safe and damage-free.

sbb-itb-0e617ca

How to Handle Supply Chain Delays and Cost Problems

U.S. exporters are grappling with challenges like port congestion, container shortages, and chassis scarcity. These issues often lead to shipment delays that can stretch from days to weeks. Port congestion is largely due to outdated infrastructure, labor shortages, and a surge in cargo volumes. On top of that, "equipment dwell time" - the period customers hold onto chassis and containers - has, in some cases, doubled, putting additional strain on the equipment needed to move cotton from warehouses to ports.

Container shortages continue to be a major hurdle. With 30 ocean common carriers handling 98% of containerized freight for international trade in the U.S., any disruption in their operations ripples through the entire supply chain. The American Cotton Shippers Association emphasizes that the party responsible for freight bookings must ensure containers are available for transport and loading within the agreed shipping month.

"With freight so volatile, it's important to have a contingency plan in place that considers rising rates, port delays, disruptions, and other obstacles." - David L. Buss, CEO, DB Schenker USA

Chassis availability has seen some improvement in certain areas due to targeted investments. For example, in 2025, DCLI (Direct ChassisLink Inc.) redeployed resources to support agricultural shippers, adding 4,000 more chassis in Houston and boosting availability by 40% in Chicago and Kansas City. In Memphis, chassis availability was doubled to assist agricultural exports during periods of heavy congestion.

Addressing these delays requires careful logistical planning.

Practical Logistics Solutions

Planning shipments in advance can help mitigate delays. The Freight Logistics Optimization Works (FLOW) program, introduced by the U.S. Department of Transportation in March 2022, allows participants to share container demand data up to 90 days ahead of arrival. This public-private initiative helps companies anticipate how current capacity aligns with future demand, making it easier to take proactive measures to reduce delays and fees. The Bureau of Transportation Statistics ensures the confidentiality of data shared by cargo owners and carriers.

Rerouting shipments through alternative ports can also ease delays. Instead of congested hubs like New York or Miami, consider using ports such as Philadelphia, Wilmington, Mobile, Oakland, or San Diego. Some chassis providers offer off-dock equipment at ports like Oakland and Seattle/Tacoma, which can also help avoid bottlenecks. Staying updated with the Bureau of Transportation Statistics can give you valuable insights into port dwell times, anchored containerships, and truck speeds, helping you time your shipments better.

Leverage real-time tracking tools and supply chain visibility platforms to monitor shipments end-to-end. These tools allow for quicker responses to potential issues. For urgent shipments, consider air freight or intermodal options when ocean ports are overwhelmed. Diversifying transport modes and maintaining relationships with multiple carriers can provide critical alternatives when primary routes are disrupted.

Warehouse compliance is another crucial factor. Regularly review weekly cotton flow (BMAS) reports to identify warehouses that may be falling short on mandatory reporting standards, as this could signal delays at the origin. Implement electronic warehouse receipt (EWR) protocols and use "Update Shipping Order" features to better manage shipping schedules. Double-check all Bill of Lading and packing list details to avoid customs holds.

For additional leverage, consider applying for an Export Trade Certificate of Review (ETCR). This allows you to legally collaborate with other cotton stakeholders, strengthening your negotiating position with ocean carriers and potentially lowering shipping costs through shared economies of scale. Diversifying warehouse locations can reduce risks from single points of failure, and maintaining "safety stock" levels provides a buffer against unexpected delays.

How to Increase Profits Through Cost-Effective Methods

Focusing on efficient shipping practices is a great starting point, but incorporating cost-effective strategies takes profitability to the next level. For instance, fewer damaged bales mean fewer insurance claims and disputes, while faster deliveries improve cash flow. On top of that, optimizing container space can significantly lower per-unit costs, directly impacting profit margins. A good next step? Take a closer look at container space and packaging choices to uncover more savings.

One of the quickest ways to cut per-unit costs is by maximizing container space. With around 90% of global trade relying on ocean containers, every cubic foot matters. Here’s an interesting fact: a 40-foot container costs only about 30% more than a 20-foot container but offers nearly double the capacity (67.7 m³ vs. 33.2 m³). This is a big advantage for bulky shipments like cotton. Standardizing bale packaging helps avoid bulges and wasted space. For dense loads, 20-foot containers are ideal, while 40-foot containers work better for bulkier shipments, allowing you to take full advantage of the extra capacity at a modest price increase.

Another effective approach is shipment consolidation. Combining smaller orders into a single Full Container Load (FCL) is much more economical than shipping partial loads, especially if your cargo exceeds 20 cubic meters. Consolidated shipments, paired with efficient freight management, can reduce total freight costs by up to 10%. In fact, broader logistics optimizations can lead to savings of 3% to 12%.

Using Cotton Gin Directories to Find Partners

Finding dependable partners is key to streamlining operations, and regional cotton gin directories can be a valuable resource. Platforms like cottongins.org help cotton producers and exporters connect with U.S. cotton gins in various states and counties. These directories provide detailed addresses and even allow new entries, making it easier to identify partners near your warehouses or ports.

The cotton gin directories on cottongins.org also offer sponsorship opportunities to boost your business’s visibility in the industry. For $200 per month, Official Sponsors receive perks like logo placement, footer backlinks, and one free Sponsored Post annually. Featured Sponsors, at $400 per month, enjoy top directory placement and two Sponsored Posts annually. These posts not only stay pinned for one day but are also shared on social media and archived, ensuring long-term exposure to industry stakeholders actively looking for shipping partners and logistics solutions.

Conclusion: Main Points for Reducing Risks and Increasing Profits

To safeguard your cotton shipments, stick closely to JCIBPC standards. Use approved materials like 6 mil polyethylene film with a static coefficient of friction ≥0.50 to keep bales secure and free from contamination or shifting. Avoid using metal fasteners, and make sure any bale sampling cuts are repaired quickly to prevent moisture damage. These packaging steps are the backbone of a reliable shipping process.

For stable loads, focus on proper stowage and low-slip packaging. Leverage the Permanent Bale Identification (PBI) system to track each bale from gin to mill, ensuring compliance with international standards and simplifying warehouse operations. These practices not only protect your cargo but also help you meet global requirements.

Stay ahead of industry changes: remember that woven polypropylene bagging will no longer qualify for CCC loans after 2031, and wire ties will be restricted to export use. Automating BMAS reporting can also help you streamline processes and avoid unnecessary delays.

Finally, build strong partnerships by exploring cottongins.org, where you can find U.S. cotton gins that meet industry benchmarks. Sponsorship options are also available to enhance your visibility among key players.

FAQs

What are the best ways to prevent moisture damage when shipping cotton?

Managing the moisture content (MC) of cotton is crucial to prevent moisture damage during shipping. From the moment cotton is harvested to when it reaches its destination, maintaining the right MC levels is key to preserving its quality and value. Tools like reliable moisture meters and sensors can help keep an eye on these levels and ensure they stay within the ideal range.

Beyond monitoring, storing and transporting cotton in controlled environments plays a big role. It's important to shield cotton from rain, high humidity, or any damp conditions. Using protective packaging, such as certified round module wraps, adds an extra layer of protection, keeping moisture and contamination at bay. By combining effective moisture monitoring, proper storage conditions, and secure packaging, you can greatly reduce the chances of moisture-related issues and ensure your cotton arrives in top-notch condition.

How can I secure cotton bales in shipping containers to prevent damage?

To keep cotton bales safe during shipping, using durable packaging materials is a must. These materials help protect the bales from damage caused by weather conditions or physical impacts. It's equally important to stack and secure the bales properly within the container. This often involves using tie-downs, straps, or dunnage to keep them from shifting or getting crushed during the journey.

Selecting the right container also plays a big role. Opt for containers that are either climate-controlled or well-ventilated. This helps manage humidity and temperature changes, which can otherwise affect the quality of the cotton. By sticking to these steps, you can ensure the cotton reaches its destination in top-notch condition.

What are the best ways to avoid shipping delays and control costs when exporting cotton?

When exporting cotton, staying on top of logistics and cost management is key to avoiding shipping delays. Leveraging advanced tracking tools - like IoT or blockchain - can help you monitor shipments in real time and quickly address any hiccups along the way. Choosing the right transportation method is also crucial. For larger shipments, full container load (FCL) is often the best choice, while less-than-container load (LCL) works well for smaller volumes, offering a good balance between cost and speed.

Partnering with dependable shipping companies and ensuring all paperwork is accurate and submitted promptly can prevent unnecessary customs delays. It's also important to properly pack and secure cotton shipments to reduce the risk of damage or contamination. Keep an eye on container usage to avoid extra charges, like detention or demurrage fees, by efficiently scheduling pickups and returns. By following these steps, you can ensure your cotton gets delivered on time without breaking the bank.