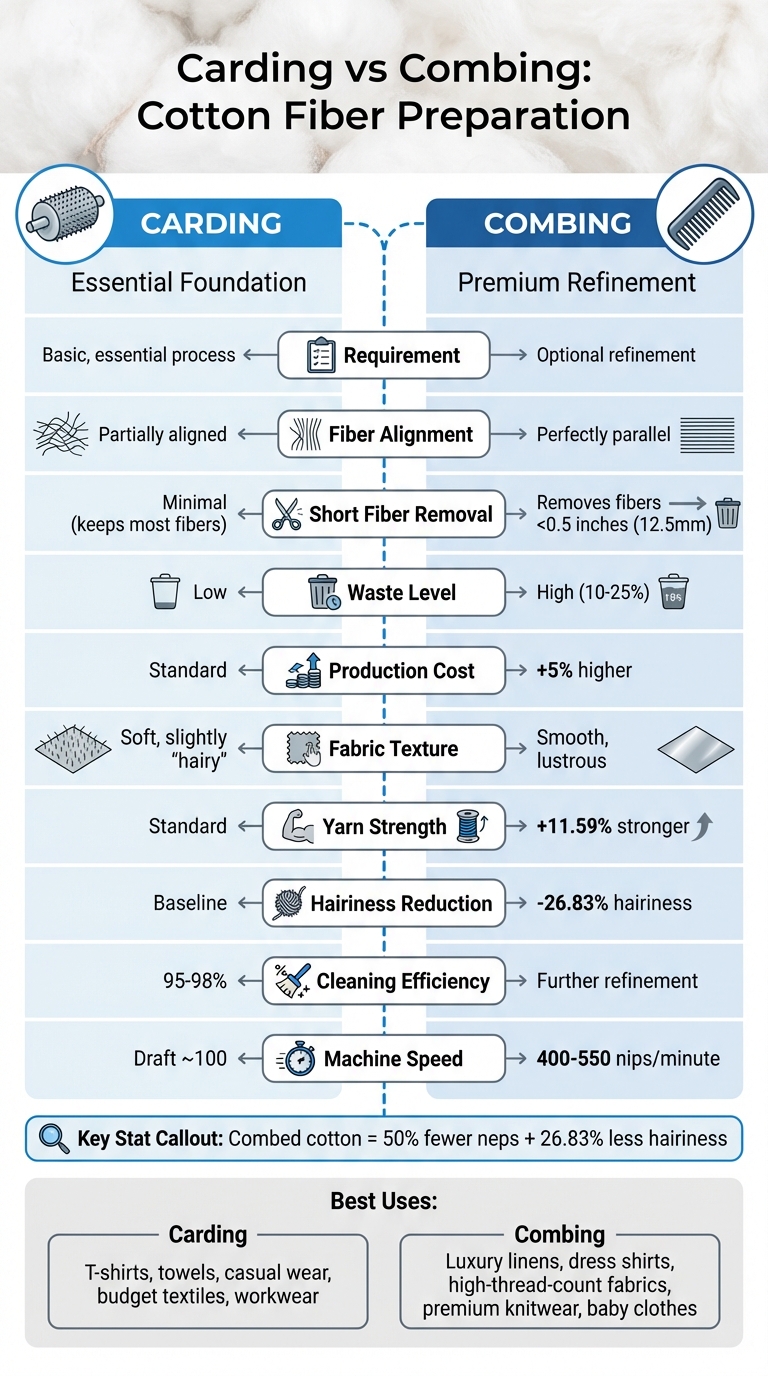

When preparing cotton fibers, the choice between carding and combing significantly impacts fabric quality and production costs. Carding is the initial step that untangles and aligns fibers into a continuous strand, suitable for everyday fabrics like t-shirts and towels. Combing, a secondary process, removes shorter fibers and ensures smoother, stronger yarns, ideal for premium items like luxury linens and dress shirts.

Key Differences:

- Carding: Basic process; partially aligns fibers, retains most short fibers, cost-effective, slightly rougher texture.

- Combing: Advanced refinement; removes short fibers, creates smoother, stronger yarns, increases costs by ~5%.

Quick Comparison:

| Feature | Carding | Combing |

|---|---|---|

| Fiber Alignment | Partially aligned | Perfectly parallel |

| Short Fiber Removal | Minimal | Removes fibers <0.5 inches |

| Waste Level | Low | High (10-25%) |

| Production Cost | Standard | ~5% higher |

| Fabric Texture | Soft, slightly "hairy" | Smooth, polished |

| Durability | Standard | Superior |

Bottom Line: Use carding for cost-efficient, everyday items. Opt for combing when smoothness, strength, and durability are critical for premium products.

Carding vs Combing Cotton Fiber Preparation Comparison Chart

Process of Carding & Combing

sbb-itb-0e617ca

Carding: Process and Benefits

Carding is the first and most crucial step in preparing cotton fibers, transforming raw, tangled cotton into organized strands ready for further processing. It’s often referred to as the backbone of the spinning process.

"Carding is considered as the heart of the spinning process." - TextileEngineering.net

How Carding Works

The carding machine uses cylinders covered in wire-wound pins, known as "card clothing", to comb through the raw cotton. These pins, arranged on rotating cylinders and stationary or moving "flats", work together to separate and straighten the fibers. The cylinders move at different speeds, creating a carding action that breaks apart fiber clumps and aligns the individual strands.

This process involves a draft of around 100, ensuring the output is much finer and more organized than the raw input. As the fibers pass through the machine, they are straightened, aligned into a parallel formation, and condensed into a continuous strand called a sliver. Modern carding machines are highly efficient, reducing trash content in the sliver to less than 0.2%. This alignment is critical for spinning or further refinement, such as combing, for higher-quality applications.

Benefits of Carding

Carding cleans, organizes, and aligns fibers in one efficient step. Modern carding and blow room systems achieve a cleaning efficiency of 95% to 98%, a significant improvement over older systems that managed only 80% to 88%. Additionally, about 75% of fiber knots (neps) are disentangled during the interaction between the cylinder and flats.

This process is cost-effective, combining cleaning and alignment in a single pass. For manufacturers producing everyday cotton goods - like workwear, basic apparel, or household textiles - carded yarn offers adequate quality at minimal cost. However, carding can result in fiber hooks (bent ends), which may slightly reduce fiber length. These hooks can be corrected in later drawing stages if necessary.

"Well carded is half-spun." - Prof. Lipsa Mohapatra, Assistant Professor, National Institute of Fashion Technology

Combing: Process and Benefits

Combing is a secondary process that comes after carding when manufacturers aim to produce high-quality cotton yarns. While carding is essential for all cotton processing, combing refines the fibers further by removing shorter ones and creating smoother, more uniform bundles.

How Combing Works

In a combing machine, carded sliver is passed through fine metal teeth that act like a mechanical filter. The process starts with nippers holding the fiber bundle in place while a circular comb removes protruding fibers. A stationary top comb then aligns the trailing ends of the fibers. During the "piecing" step, freshly combed tufts are joined with the previous web, forming a refined sliver.

Modern machines operate at speeds of 400 to 550 nips (cycles) per minute. Cotton is moistened to about 8.5% during this stage, which reduces static and improves fiber flexibility. The combing process specifically removes fibers shorter than 12.5 mm, as these contribute to yarn hairiness and lack mechanical strength. The waste material, known as "noil", accounts for 10% to 25% of the input and is a byproduct of this precision process.

Benefits of Combing

Combing significantly improves yarn quality by eliminating imperfections and aligning fibers more precisely. Compared to carded yarns, combed yarns show an 11.59% increase in tensile strength and a reduction in hairiness by up to 26.83%. Additionally, combing reduces mass variation and neps by as much as 50%.

The result is a smooth, lustrous yarn with parallel fibers that reflect light beautifully. This makes combed yarns ideal for high-thread-count fabrics, premium shirting, and fine knitwear. The removal of short, rough fibers also enhances softness, making combed cotton perfect for baby clothes and apparel for the elderly.

However, combed yarns are about 5% more expensive than carded yarns due to the extra processing time and material waste. Still, the waste (noils) isn’t discarded - it’s increasingly repurposed into nonwoven products like insulation, filtration materials, or lower-grade yarns.

Carding vs Combing: Main Differences

Both carding and combing are crucial steps in preparing cotton fibers, but they serve different purposes. Carding lays the groundwork by untangling and partially aligning fibers, while combing takes it further, refining fibers to achieve a premium quality. Choosing between just carding or adding combing impacts the fiber's quality, production costs, and the final fabric's characteristics.

Comparison Table: Carding vs Combing

| Feature | Carding | Combing |

|---|---|---|

| Requirement | Basic, essential process | Optional refinement for higher quality |

| Fiber Alignment | Partially aligned | Perfectly parallel and straight |

| Short Fiber Removal | Minimal; keeps most fibers | Removes fibers shorter than 0.5 inches (noils) |

| Waste Level | Low | High (up to 25%) |

| Production Cost | Standard | About 5% higher than carding |

| Fabric Texture | Soft but slightly "hairy" | Smooth and lustrous |

| Durability | Standard | Superior (stronger yarn) |

| Equipment | Carding machine (cylinders/flats) | Comber machine (fine metal teeth) |

These differences highlight how each method shapes the fabric's final qualities.

How Each Method Affects Fabric Quality

The way fibers are processed directly influences the fabric's texture, durability, and appearance. Carded cotton includes more short fibers, which gives the fabric a softer feel and a slightly textured surface. This makes it a great choice for everyday items like t-shirts, casual clothing, and budget-friendly home textiles. However, the "hairy" surface of carded cotton can lead to pilling over time, especially with frequent washing and use.

Combed cotton, on the other hand, delivers a smoother, more polished fabric with added strength and resistance to pilling.

"The result of combing cotton is that you get a stronger yarn, which ultimately means a stronger and more breathable fabric. It's also a lot smoother and has a less hairy feel than non-combed cotton".

This refinement makes combed cotton perfect for high-thread-count bed linens, dress shirts, and luxury garments where both appearance and durability are key. Additionally, the combing process allows manufacturers to produce finer yarns that carding alone cannot achieve.

How to Choose Between Carding and Combing

Factors to Consider

Deciding between carding and combing comes down to balancing fiber quality and cost efficiency. Start by evaluating the short fiber content (SFC) in your cotton. If the SFC is high, relying on carding alone can result in yarn that's too hairy and visually unappealing, making combing a necessary step. On the other hand, if the short fiber content is already low - below 18% by number - carding alone might deliver acceptable results.

Fiber count also plays a big role. For finer yarns (35–60 count), combing is essential because carded slivers lack the strength and consistency needed for these delicate threads. Coarser yarns (28–34 count), however, can often be produced with just carding. Combing becomes worth the extra expense when the final product demands smoothness, shine, and durability - qualities prized in luxury items like high-end bed linens or dress shirts. Everyday items like t-shirts, towels, or casual wear can perform well with carding alone, keeping costs lower.

"Finding the right balance between the appropriate fiber quality and processing costs is critical to maintaining profitability." - CottonWorks

It's also important to account for waste. Combing removes a significant amount of material as noil, which increases production costs. To mitigate this, many manufacturers recycle comber waste into lower-count yarns or nonwoven products. The trick is to remove just enough waste to meet your quality goals - removing even 1% more than necessary can dent your profits. A smarter approach is to control neps during the carding process by running the machines at lower speeds, reducing the need for excessive combing later.

These considerations directly impact how you choose your processing method.

Application Examples

Different industries approach these decisions based on their product goals. Take luxury bedding, for example. Manufacturers producing high-end bed linens often choose combing to achieve the smooth, lustrous finish their customers expect. While combing adds about 5% to production costs, the enhanced softness and durability justify the higher price tag.

On the other hand, producers of budget-friendly t-shirts or everyday clothing stick to carding. This method delivers a slightly hairier texture but keeps costs low, allowing for competitive pricing in the market.

Premium dress shirt manufacturers have no choice but to use combing. Fine yarn counts (40–60) required for crisp, professional fabrics depend on the strength and quality that only combing can provide. Meanwhile, for products like bath towels or kitchen linens, carding is usually sufficient. These items prioritize absorbency and durability over the refined texture and sheen that combing offers.

At the end of the day, the choice between carding and combing boils down to what your target market values - and whether they're willing to pay for the extra refinement combing provides.

Conclusion

Choosing between carding and combing comes down to your product goals and target market. Carding is the essential first step that turns raw cotton into a usable sliver, while combing is an optional refinement that removes short fibers and aligns the remaining ones for a smoother, more polished result. Carded cotton, with its slightly rougher texture, works well for everyday items, while combed cotton delivers sleek, strong fabrics with better resistance to pilling.

Combing adds to production costs and generates more waste, but it’s a must for making premium products where customers expect - and are willing to pay for - top-tier quality. For budget-friendly basics like casual t-shirts or standard bedding, sticking with carding helps keep costs in check without sacrificing functionality. Striking the right balance between quality and cost is key to meeting the needs of different market segments.

"Finding the right balance between the appropriate fiber quality and processing costs is critical to maintaining profitability." - CottonWorks

Align your fiber preparation method with your brand’s positioning and price point. Use combing for products that require smoothness, durability, and higher thread counts - think premium dress shirts, luxury linens, or high-end undergarments. For high-volume, cost-conscious production, carding is the way to go. By tailoring your approach to your market, you can maintain healthy margins while delivering the quality your customers expect.

FAQs

Is combed cotton always worth the extra cost?

Combed cotton is often worth the extra cost because it produces fabric that’s stronger, softer, and longer-lasting. By removing shorter fibers during the combing process, it minimizes pilling and creates a smoother, more refined finish. This makes it a great choice for high-quality products where durability and comfort truly matter.

How can I tell if a fabric is carded or combed cotton?

You can tell carded cotton apart from combed cotton by looking at its texture and finish. Combed cotton feels smoother, looks shinier, and is more durable because its fibers are carefully aligned in the same direction. On the other hand, carded cotton has a rougher surface and a less uniform texture. This contrast comes from the extra step in processing combed cotton, which removes shorter fibers and impurities, resulting in a finer end product.

What happens to the waste (noil) from combing?

Noil, the waste produced during the combing process, consists of short fibers, neps, and traces of foreign material. This material is removed to improve the overall quality of the fiber, resulting in smoother, more refined yarn. By eliminating noil, the cotton becomes suitable for producing finer textiles.