Big data is transforming cotton farming by improving efficiency, reducing costs, and addressing critical challenges like water scarcity and rising input expenses. Farmers now use advanced tools like GPS, drones, and IoT sensors to optimize irrigation, fertilizer use, and pest control. These technologies deliver measurable benefits, such as:

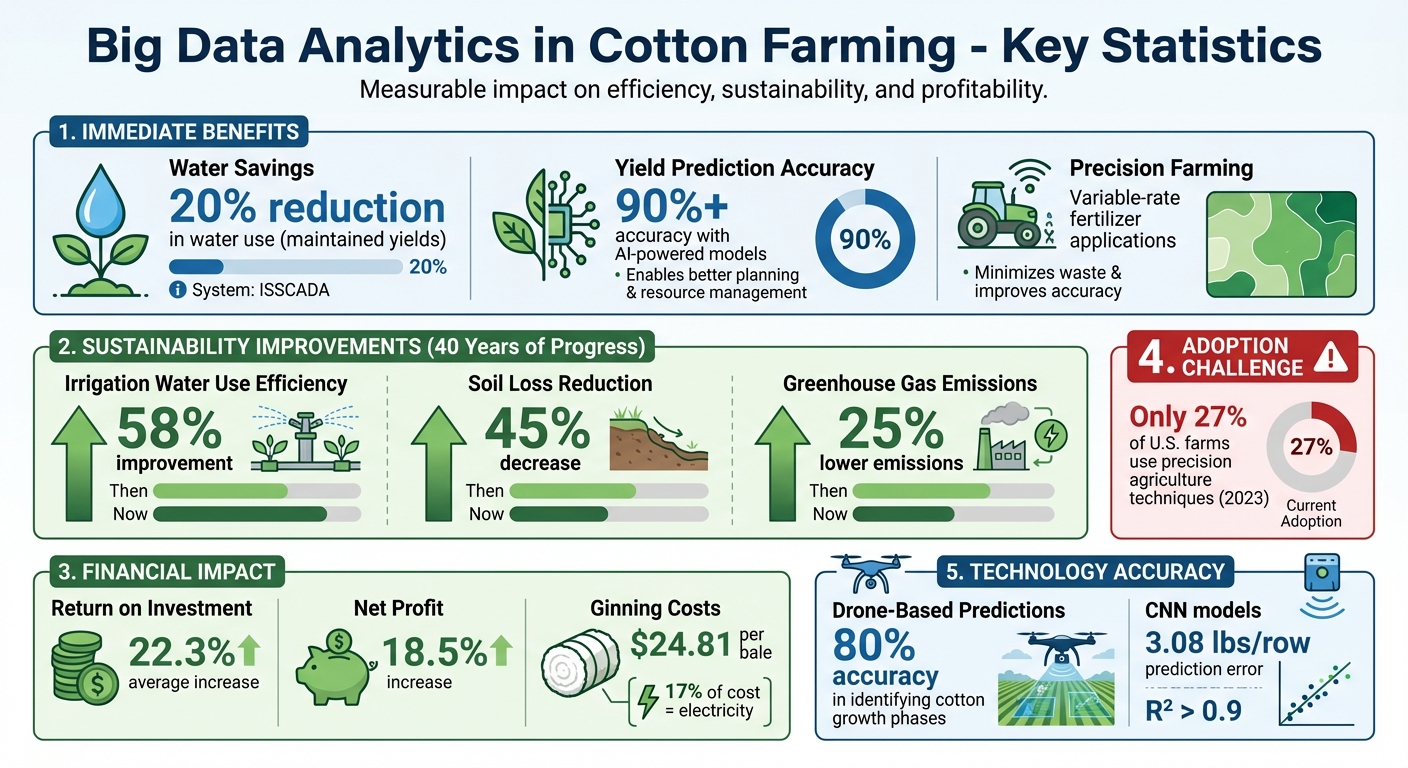

- Water savings: Systems like ISSCADA reduced water use by up to 20% while maintaining yields.

- Precision farming: Variable-rate fertilizer applications and seed variety analysis minimize waste and improve accuracy.

- Yield prediction: AI-powered models predict yields with over 90% accuracy, enabling better planning.

Beyond the farm, data analytics enhances ginning processes, cuts energy costs, and ensures supply chain traceability. Despite adoption barriers like high costs and data ownership concerns, emerging technologies like AI and IoT are making these tools more accessible. Cotton farmers who embrace data-driven methods can improve profitability and adapt to future challenges.

Big Data Analytics Impact on Cotton Farming: Key Statistics and Benefits

Revolutionizing Cotton Farming: How Satellites and AI are Changing the Game

How Big Data Is Used in Cotton Farming

Big data has become a cornerstone of cotton farming, shaping every stage of the process, from planting all the way to harvest. Farmers now depend on advanced tools - like soil sensors and drones - to gather essential data that guides smarter decisions throughout the growing season.

Precision Agriculture Tools

High-tech tools like GPS and autosteer systems have streamlined fieldwork, making operations smoother and more efficient. Modern cotton pickers are equipped with yield monitors that provide real-time data on harvest weight and volume. As Cotton Incorporated explains:

"The fact cotton yield monitors are now standard on pickers allow cotton producers the chance to map yield variability in their fields and see firsthand if within-field variability is an issue on their farms."

When properly calibrated, these yield monitors generate detailed maps that highlight areas of varying productivity within a field.

Drones have become another essential tool for data collection. Between 2016 and 2021, researchers at Texas A&M AgriLife Research used DJI Phantom 2 and 4 drones to capture RGB images of 30 to 42 cotton varieties. These images were transformed into Digital Surface Models to measure canopy height and identify the "time of onset of steady phase" for cotton genotypes with an impressive 80% accuracy. Variable-rate technology then uses this spatial data to fine-tune fertilizer applications, ensuring nutrients are delivered only where they’re needed, based on grid soil sampling and nutrient models.

These precision tools also play a crucial role in optimizing irrigation practices.

Water Management and Irrigation

Modern irrigation systems rely on a network of IoT devices, including soil moisture sensors and weather stations. These tools monitor key factors like soil water content, temperature, and electrical conductivity, while weather stations track rainfall, solar radiation, and wind speed. Together, they provide a clear picture of water availability and crop requirements.

Systems like ISSCADA have shown they can significantly reduce water usage without sacrificing yields. These systems allow farmers to set stress thresholds, enabling automated adjustments to irrigation schedules based on real-time data.

Beyond water management, big data is proving invaluable for tackling pest and disease challenges.

Pest and Disease Detection

Predictive analytics has transformed pest management, shifting the focus from reactive spraying to proactive prevention. By analyzing remote sensing imagery, weather patterns, and soil conditions, these systems can forecast potential pest outbreaks - like bollworms, red spiders, Fusarium wilt, and Verticillium wilt - before they happen. This approach not only reduces chemical use but also minimizes environmental impacts. As CottonToday highlights:

"Data analysis plays a crucial role in informing IPM strategies, enabling growers to make more informed decisions about pest control."

Another tool, Degree Day 60 (DD60) models, tracks heat units above 60°F and combines this data with real-time weather conditions to predict cotton growth stages. This helps farmers precisely time pest control efforts, maximizing their effectiveness and efficiency.

Improving Yield and Quality with Data Analytics

Data analytics is reshaping how cotton farmers monitor crops and prepare for harvest. By leveraging precise measurements and predictive models, farmers are not only improving yields but also enhancing fiber quality. This data-driven approach ensures better yield predictions and smarter resource management.

Crop Monitoring and Growth Tracking

With advancements in sensors and drone technology, data analytics has taken crop monitoring to a new level. Farmers now rely on drone imagery and logistic growth models to track development stages, from root establishment to boll maturation. For example, a Texas A&M study conducted in 2016 and 2021 used DJI Phantom drones to predict crop maturity with 80% accuracy. The study highlighted how rainfall variations - 24.4 inches in 2021 compared to 11.6 inches in 2016 - play a significant role in growth patterns.

One key metric derived from drone data is the maximum growth rate (Rmax), which shows a strong correlation with final yield (R² of 0.68 overall, reaching up to 0.82 in wetter seasons). By closely monitoring Rmax, farmers can fine-tune inputs during the exponential growth phase, optimizing production potential.

Yield Prediction and Resource Planning

In 2022, USDA-ARS researchers demonstrated the power of UAV imagery combined with convolutional neural network (CNN) models to predict yields with a mean error of just 3.08 pounds per row (R² > 0.9). This level of precision helps farmers plan resources more effectively. Haoyu Niu from the Texas A&M Institute of Data Science emphasized:

"Integrating UAV-derived imagery and CNN regression models is a potent strategy for advancing precision agriculture, providing growers with a powerful tool to optimize cultivation practices."

Machine learning models, such as Artificial Neural Networks, have further enhanced early yield predictions. With R² values between 0.85 and 0.89, these models can forecast yields as early as 70 days after planting by analyzing factors like canopy volume, boll counts, irrigation levels, and the Excessive Greenness Index.

When it comes to fiber quality, farmers focus on the T5 parameter, which signals the transition from vegetative growth to boll maturation. This timing is critical for decisions such as applying harvest aids and managing irrigation to prevent water stress, which could harm fiber characteristics. To ensure long-term accuracy, onboard yield monitors like the John Deere CP 770 are calibrated regularly, providing reliable data for future planning.

sbb-itb-0e617ca

Big Data in Cotton Ginning and Supply Chain

Once cotton leaves the field, data analytics takes center stage in refining ginning operations and optimizing the supply chain. The data collected during harvest doesn’t just stop there - it follows the fiber through processing, helping gin operators cut costs and tap into premium markets.

Improving Ginning Efficiency

For gin operators, energy expenses are a major concern. Electricity alone accounts for 17% of the $24.81 it costs to process a single bale, with the gin stand being the second-largest energy consumer after material handling. Data analytics helps break down "active energy" used for defibering from "baseline energy" consumed when equipment is idling. Advanced software tools provide insights into metrics like ginning times, total energy usage, and average power. These insights allow operators to identify inefficiencies, such as equipment that’s not properly warmed up, and make necessary adjustments.

In April 2025, Cotton Incorporated teamed up with the SAS Institute to showcase how linking data from the field, harvester, and gin can improve processing rates based on the unique characteristics of incoming cotton. Dr. Ed Barnes, Senior Director of Agricultural & Environmental Research at Cotton Incorporated, explained:

"Advanced data analytics can provide gins with a more accurate estimate of the best processing rate based on the characteristics of the incoming cotton."

Modern tools like RFID tags track cotton modules from sub-field to gin, while harvesters equipped with cellular modems transmit real-time data on yield and quality directly to the gin. This real-time exchange ensures better logistics and coordination even before the cotton arrives.

These innovations pave the way for greater transparency and efficiency across the supply chain.

Traceability and Market Opportunities

Beyond ginning, data is now driving accountability across the entire supply chain. What was once a voluntary sustainability goal has evolved into a market necessity. Regulations like the Uyghur Forced Labor Prevention Act (UFLPA) and the EU's Corporate Sustainability Due Diligence Directive (CSDDD) require verifiable origin data. Big data makes it possible to move from "mass balance" accounting to true physical traceability, ensuring cotton can be tracked from the gin all the way to the retailer.

In November 2025, the Better Cotton Initiative (BCI) celebrated a major achievement: traceable "Physical BCI Cotton" volumes surged from 90 metric tonnes in November 2024 to over 23,000 metric tonnes a year later. This effort involved more than 2,000 suppliers and manufacturers across 15 countries, allowing 17 major retail brands to receive products with verified cotton origins. Jacky Broomhead, Director of Traceability at BCI, highlighted the importance of this progress:

"The complexity of textile supply chains, combined with increased legislation, makes traceability non-negotiable."

Data-powered tracking systems also open the door to preferred supplier programs, which often come with higher pricing opportunities. Initiatives like the U.S. Cotton Trust Protocol enable brands and retailers to verify sustainability metrics, meeting the growing demand for transparency. Dr. Ed Barnes emphasized the broader impact:

"Data-backed improvements unlock access to preferred supplier programs, premium prices, and help mitigate risks, ultimately boosting profitability and fostering a more thriving future for U.S. cotton."

Challenges and Future of Big Data in Cotton Farming

Barriers to Adoption

Even with its clear advantages, many cotton farmers are hesitant to embrace data analytics. As of 2023, only 27% of U.S. farms or ranches reported using precision agriculture techniques to manage crops or livestock. The high price tags on sensors, automated equipment, and data platforms are significant hurdles for many.

Data ownership is another sticking point. Farmers often question who truly owns the information collected from their fields and worry about how third parties might use it. The Government Accountability Office highlighted this concern:

"Farmers often do not trust the ways farm data are being collected and managed; thus, terms and conditions regarding data use should be simple, transparent, and accountable."

Technical challenges further complicate matters. Many systems - whether equipment or software - lack compatibility, making it hard for farmers to integrate tools seamlessly. Efforts to standardize data protocols could help unify these fragmented platforms. On top of that, rural broadband limitations hinder real-time data sharing in many cotton-growing areas. And even when the tools are available, many farmers lack the training needed to analyze data and make informed decisions. Overcoming these hurdles is essential to unlocking the full potential of big data in agriculture.

What's Next for Big Data in Cotton

Despite these obstacles, new technologies are beginning to close the gap. Tools powered by artificial intelligence (AI), such as machine vision for weed management and genomic analytics for developing resilient cotton, are poised to reduce costs and improve productivity.

AI-driven weed control is making strides, with machine vision systems leveraging open-source image libraries to identify and target weeds with remarkable precision. This approach minimizes herbicide use, cutting both costs and environmental impact.

Meanwhile, genomic data analytics is revolutionizing how cotton varieties are bred. By using techniques like marker-assisted selection and gene editing, breeders can now develop plants tailored to specific climate challenges and pests more quickly than ever before. These advancements promise to enhance yields and improve resource efficiency, building on the foundation of existing data-driven methods.

Dr. Ed Barnes, Senior Director of Agricultural & Environmental Research at Cotton Incorporated, underscored the importance of standardization in this space:

"The International Standards Organization (ISO) is undertaking an ambitious effort to globally standardize agricultural data... which will foster greater interoperability and make it easier for growers to gain benefits from their data."

On the horizon, reinforcement learning is enabling irrigation systems that can adjust water usage in real time. At the same time, edge computing is making it possible for lightweight AI models to run directly on farm equipment or mobile devices, providing actionable insights without relying on constant cloud connectivity. These advancements could make big data tools more accessible and practical for cotton farmers everywhere.

Conclusion

Big data analytics has become a game-changer for profitable and competitive cotton farming. Precision agriculture technologies, for instance, have been shown to boost the average return on investment by 22.3% and increase net profit by 18.5%. Over the last 40 years, U.S. cotton growers have made significant strides in sustainability - improving irrigation water use efficiency by 58%, cutting soil loss by 45%, and lowering greenhouse gas emissions by 25%. These achievements are rooted in data-driven decision-making.

But the value of data extends beyond the farm. It opens doors to preferred supplier programs and premium pricing as brands and retailers increasingly demand transparency and traceability in their supply chains. Whether it’s precision irrigation or supply chain tracking, every innovation highlights how data transforms cotton farming at every stage. Dr. Ed Barnes, Senior Director of Agricultural & Environmental Research at Cotton Incorporated, captures this sentiment:

"Data-backed improvements unlock access to preferred supplier programs, premium prices, and help mitigate risks, ultimately boosting profitability and fostering a thriving future for U.S. cotton."

For farmers, integrating big data tools is a gradual process that starts in the field. Many cotton pickers already come equipped with yield monitors and cellular modems that provide instant field variability maps. From there, farmers can build on these tools by adding systems like precision irrigation, variable-rate fertilizer applications, or pest monitoring technologies - tailored to their needs and budgets. Small, manageable steps like these can lead to significant long-term benefits.

These advancements not only help farmers tackle current challenges but also prepare them for the future. The cotton industry faces growing pressures from unpredictable weather, resource constraints, and evolving regulations. By adopting data analytics now, farmers can reduce costs, improve yields, and better navigate these uncertainties. It’s not just about staying competitive - it’s about securing your bottom line.

No matter the size of the farm, the real question is: how soon can you start using these tools to safeguard your future?

FAQs

How does big data analytics help cotton farmers manage water more efficiently?

Big data analytics is transforming how cotton farmers manage water, offering smarter and more precise irrigation strategies. With IoT sensors embedded in irrigation systems, farmers can track real-time data like soil moisture levels, plant water stress, and surrounding environmental conditions. This information helps create irrigation schedules that are tailored to the needs of the crops, reducing water waste without sacrificing yields.

On top of that, tools like thermal imaging and drones (UAVs) provide a bird's-eye view of water requirements across extensive fields. These technologies make it easier to pinpoint areas that need more or less water, enabling farmers to adjust field zones and allocate resources more effectively. By embracing these data-driven approaches, cotton farmers can save water, cut expenses, and boost the efficiency of their operations.

What challenges do cotton farmers face when adopting big data technologies?

Farmers often encounter steep upfront costs when trying to implement big data technologies. For smaller farms, this can be particularly challenging. Tools like precision agriculture systems and IoT sensors demand a hefty initial investment, which can be hard to justify without seeing clear and immediate benefits.

On top of that, the technical know-how needed to operate these tools effectively can be another roadblock. Many farmers may require extra training to navigate and manage these advanced systems, which can feel daunting - especially for those less experienced with digital tools. Larger farms, with more resources and infrastructure, tend to be better equipped to adopt these technologies, often leaving smaller farms struggling to keep up.

Big data holds the promise of transforming cotton farming by boosting yields, improving efficiency, and supporting sustainable practices. However, the economic and technical challenges it presents continue to be significant hurdles for many farmers.

How does big data improve traceability in the cotton supply chain?

Big data is transforming the cotton supply chain by using technologies like RFID tags, which assign a unique identifier to each cotton module. This innovation enables farmers and other stakeholders to precisely track cotton from the moment it’s harvested all the way to the ginning process.

With the ability to monitor in real-time, these tools ensure accurate ownership records, simplify logistics, and enhance transparency across the supply chain. The result? A more efficient process that upholds quality standards and strengthens trust within the cotton industry.