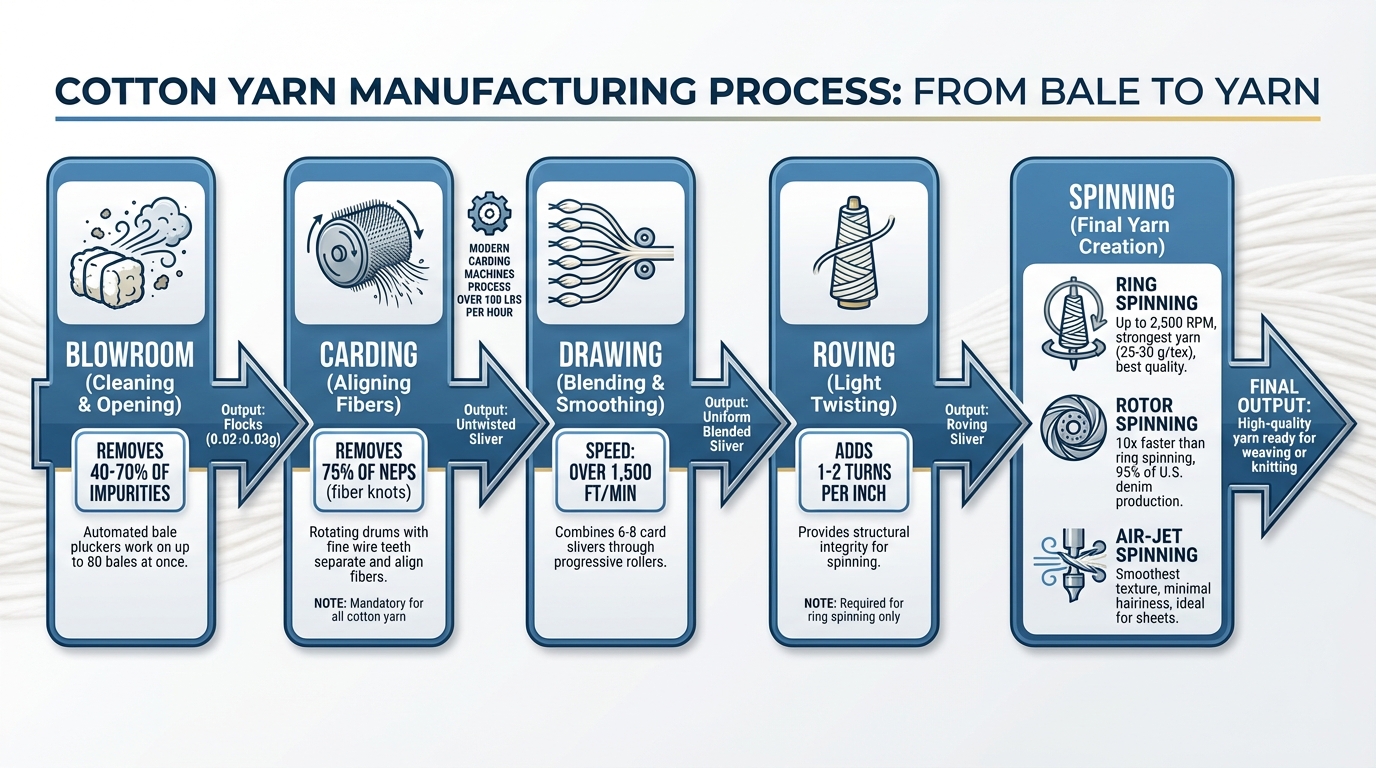

Transforming raw cotton into yarn involves several mechanical steps: cleaning, carding, drawing, roving, and spinning. These processes remove impurities, align fibers, and create a durable strand ready for weaving or knitting. Modern machinery has replaced manual labor, significantly increasing speed and precision. For example:

- Blowroom: Breaks down compressed bales and removes up to 70% of impurities.

- Carding: Separates and aligns fibers, forming untwisted slivers.

- Drawing: Combines and smooths slivers for uniformity.

- Roving: Adds light twists to prepare fibers for spinning.

- Spinning: Converts fibers into yarn using methods like ring spinning, rotor spinning, or air-jet spinning.

Each step ensures the production of high-quality yarn suited for various textile applications. Advances like automated blending and high-speed spinning have streamlined production while maintaining consistency and strength.

Cotton to Yarn: 5-Step Manufacturing Process from Raw Fiber to Finished Thread

Cleaning and Opening Raw Cotton

Raw Cotton Structure and Components

Raw cotton bales are far from pure when they arrive at the mill. Along with the usable fibers, they contain natural debris like leaves and seeds, as well as modern contaminants such as plastics and bale ties. These impurities can weaken yarn, cause visible defects, and wear down machinery faster. The ideal fibers for producing high-quality yarn are between 1 inch and 1.75 inches long, but they are tightly compressed within the bale and mixed with unwanted materials that need to be removed.

To tackle this, mills use advanced cameras that identify plastics based on their shininess, color, and transparency. This step is critical to avoid contamination during later processes like dyeing and finishing. Once these contaminants are pinpointed, the blowroom process begins, breaking down the raw bales into cleaner, more uniform material.

Blowroom Operations

The blowroom is where raw cotton bales are opened and prepared for the next stage of processing. Automated bale pluckers play a key role here, pulling thin layers of fiber from as many as 80 bales at once . This blending process helps smooth out natural differences in fiber properties, ensuring consistency. As the dense bales are broken down, they form "flocks" that weigh just 0.02–0.03 grams. By the time the material reaches the carding stage, tuft weight can be reduced to as little as 0.1 mg.

"The more intensively the cotton fibers have been individualized, the more contamination particles appear on the surface of the fiber bulk and may be removed."

Cleaning machines in the blowroom remove between 40% and 70% of impurities. Coarse cleaners handle larger debris, while fine cleaners target smaller particles just before the material moves to carding. Despite the efficiency of this process, about 40–60% of the waste generated in the blowroom consists of good fibers that are unintentionally discarded. After this preparation, modern carding machines can process over 100 pounds of cotton per hour.

sbb-itb-0e617ca

Carding: Aligning Cotton Fibers

The Carding Process

After the blowroom breaks down raw cotton into smaller flocks, the next step - carding - separates and aligns individual fibers. This process uses rotating drums equipped with fine wire teeth. As the cotton moves through the machine, these surfaces, operating at different speeds or in opposing directions, create a combing effect. This action untangles fibers and aligns them parallel to each other, preparing them for further processing.

The carding machine operates across three main zones:

- Taker-in (or licker-in): This section opens compressed cotton batts into smaller flocks and removes larger debris.

- Carding zone: Here, the main cylinder rotates against stationary or slower-moving "flats", disentangling around 75% of neps (tiny fiber knots).

- Doffer: This final stage gathers the fibers into a thin web, which is then compressed into an untwisted "sliver."

"Well carded is half-spun."

- Prof. Lipsa Mohapatra, Assistant Professor, National Institute of Fashion Technology

While carding is critical, it does have a drawback: it often creates "hooks" at the ends of fibers. These hooks need to be straightened in later stages, such as drawing or combing, to avoid losing fiber length. Despite this, carding remains a cornerstone of cotton yarn production.

Carding vs. Combing

Carding is a non-negotiable step in cotton yarn production, but combing is an optional refinement reserved for higher-quality yarns. Carding focuses on basic cleaning, untangling, and aligning of fibers, whereas combing goes a step further. It removes the shortest fibers and any remaining fine impurities, creating yarn with nearly perfect fiber alignment.

This distinction means combed yarn is stronger, smoother, and more uniform, making it ideal for luxury products like high-end dress shirts and premium bedding. On the other hand, carded yarn, while less refined, is perfectly suited for everyday items like denim and casual apparel.

| Feature | Carding | Combing |

|---|---|---|

| Necessity | Mandatory for all cotton yarn | Optional; used for premium grades |

| Primary Function | Untangles, cleans, and aligns fibers | Removes shortest fibers and fine impurities |

| Fiber Alignment | Parallel alignment into a sliver | Near-perfect alignment for uniformity |

| Typical End-Use | Everyday apparel, denim, basic knits | Luxury bedding, high-end dress shirts |

The decision to use carded or combed yarn ultimately depends on the quality and purpose of the final textile. Proper fiber alignment during this stage lays the foundation for efficient downstream processes like drawing and roving.

Drawing and Roving

Drawing Frames for Blending

After the carding stage, drawing takes over to refine and unify the fibers even further. Carding produces individual slivers, and the drawing process blends and smooths them by combining six to eight card slivers at once. These slivers are pulled through rollers that progressively increase in speed, with the front rollers moving faster than the back ones. This creates a draft that straightens any remaining hooks from carding and aligns the fibers in a parallel formation.

As the fibers pass through, the thin web is condensed into a uniform sliver using a trumpet mechanism. Modern drawing frames, equipped with PLC systems and laser sensors, operate at speeds over 1,500 feet per minute, allowing for quick corrections to any irregularities. According to Bidco International:

"Proper control of the drawing process contributes to a significant reduction in mass variations and enhances fiber distribution."

The main distinction between drawing and carding lies in their goals. While carding focuses on separating and initially aligning the fibers, drawing blends multiple slivers into one without adding any twist. This ensures uniformity and prepares the material for the next step: roving. The consistent sliver produced in this stage is critical for achieving the necessary adjustments in twist and strength during the roving process.

Producing Roving

Once the sliver is uniformly drawn, the roving process prepares it for spinning, particularly for ring spinning. In this step, the roving frame thins a single drawn sliver to optimize its linear weight for the desired yarn count. A slight twist - about 1 to 2 turns per inch - is added to give the roving enough structural integrity.

This light twist allows the roving to be wound onto bobbins, making it ready for feeding into the ring-spinning frame without breaking. While modern spinning systems like rotor (open-end) and air-jet spinning skip the roving stage entirely and produce yarn directly from the sliver, mills using ring spinning still depend on roving to achieve the strength and uniformity needed for producing high-quality yarns.

Spinning Cotton into Yarn

Ring Spinning

Ring spinning is where the roving takes its final form as yarn, undergoing drafting, twisting, and winding processes. The roving passes through a three-roll drafting system, which reduces its thickness to the desired yarn count. After leaving the drafting zone, a high-speed spindle - spinning at up to 2,500 revolutions per second - adds twist to the fibers. A small metal traveler moves rapidly around a stationary ring, simultaneously twisting and winding the yarn onto a bobbin.

This process ensures excellent yarn quality by allowing precise control over the twist. As CottonWorks explains:

"The frictional forces created by the twist are the means by which all yarns are held together."

Most yarns are given a "Z" twist, where the angle follows the center stroke of the letter Z. However, "S" twists are used for specific technical needs. The twist level is measured in Turns Per Inch (TPI), with the relationship between yarn count and TPI calculated using the Twist Multiple (TM) formula: TM = TPI / √Ne. Ring spinning produces the strongest yarn - typically 25–30 grams per tex - while also delivering a soft hand feel. This combination makes it the gold standard for quality yarn production. Once spun, the yarn is transferred from smaller bobbins to larger cones for further processing.

Though ring spinning is prized for quality, alternative methods focus on higher efficiency by skipping intermediate roving steps.

Air-Jet and Open-End Spinning

Modern spinning technologies, like air-jet and open-end spinning, prioritize speed and streamlined production.

Rotor spinning eliminates the roving step by feeding sliver directly into a combing roll, which separates and aligns the fibers. These fibers are then drawn into a rotating rotor cup, where they attach to the "open end" of the forming yarn, creating a continuous strand. This method operates up to 10 times faster than ring spinning and includes automated processes like piecing and doffing. While rotor spinning is best for coarse yarns below Ne 20/1, it dominates denim production in the U.S., accounting for over 95% of the market. Its efficiency and durability make it ideal for everyday textiles.

Air-jet spinning, on the other hand, uses high-speed air currents to wrap fibers around a central core. This creates a yarn with exceptional uniformity and minimal hairiness. Though air-jet yarn is less strong than ring-spun yarn, its smooth texture and rapid production make it a favorite for products like sheets, pillowcases, and synthetic blends.

Each of these methods serves distinct purposes, balancing quality, speed, and application-specific needs in the textile industry.

Finishing and Quality Control

Winding Yarn

Once spinning is complete, yarn needs to be transferred to larger packages to make it suitable for weaving or knitting. For ring-spun yarn, this involves an additional winding step, as the initial bobbins are too small for efficient use. Winding machines repackage the yarn onto cones, cheeses, or skeins, creating formats that can easily feed high-speed textile equipment.

Modern winding machines do more than just repackage; they also enhance the yarn's quality. As the yarn moves through the machine, sensors detect and eliminate defects like slubs, neps, or entanglements. Automated tensioning systems ensure consistent package density, reducing the risk of weak spots that could lead to breakage during subsequent production. Once wound and cleared of imperfections, the yarn moves on to quality inspections and, if required, dyeing.

Quality Checks and Dyeing

Before the yarn leaves the mill, it undergoes thorough testing to ensure it meets industry standards. Advanced optical inspection systems equipped with cameras and sensors identify any lingering contaminants, such as seed coat fragments, trash, or stray colored fibers that might have slipped through earlier cleaning stages. Yarn is also assessed using Uster statistics, which measure attributes like evenness, hairiness, strength, and elongation. These benchmarks help maintain consistent quality across production batches.

Dyeing, while optional, is a critical step for certain applications. One common method is package dyeing, where yarn is wound onto perforated cylinders, and dye is forced through under pressure. This technique is particularly effective for producing patterned fabrics, such as gingham checks, plaids, or denim, which combine dyed warp yarns with undyed filling yarns. According to the National Cotton Council of America:

"Computers are used increasingly in dyeing processes to formulate and match colors with greater speed and accuracy."

Some mills also use mercerization, a chemical treatment that enhances the yarn's appearance and durability. This process causes cotton fibers to swell, increasing their luster and improving dye uptake. The result is a more vibrant and long-lasting yarn, ideal for premium textile applications.

Cotton Yarn Manufacturing Process | How it's Made

Conclusion

Transforming raw cotton into finished yarn is a fascinating journey that relies on a series of precise mechanical processes. Starting with raw, unrefined fibers, the material undergoes cleaning in the blowroom, carding to disentangle and align, drawing to refine, and roving to prepare for spinning. Each step plays a crucial role in removing impurities, organizing fibers, and laying the groundwork for creating strong, uniform yarn. These processes not only speed up production but also ensure consistent quality throughout.

Modern advancements have revolutionized how cotton is processed. Machinery has significantly increased production efficiency while improving fiber alignment and overall quality. With computer-controlled systems overseeing everything - from automated feeding in the blowroom to optical inspections during winding - mills can now maintain high standards at every stage. The result? A highly efficient process that converts raw cotton into industrial-grade yarn, ready for weaving, knitting, or finishing applications .

FAQs

What does a cotton gin do before spinning starts?

A cotton gin is a machine that cleans raw cotton by separating seeds and debris from the fibers. This step prepares the cotton for the next stages of yarn production, like carding and spinning.

When should mills choose combed vs. carded cotton yarn?

Mills aiming for higher-quality yarns should opt for combed cotton yarn. This type of yarn produces finer, stronger threads with a smoother and silkier finish, making it perfect for premium products. On the other hand, carded cotton yarn is better suited for creating standard, coarser threads, which are commonly used in everyday textiles.

Which spinning method is best for my fabric: ring, rotor, or air-jet?

The spinning method you choose should align with your fabric's requirements for quality, production scale, and budget. Ring spinning delivers fine, soft yarns with great consistency, making it perfect for high-end fabrics. However, it’s a slower and more expensive option. Rotor spinning, on the other hand, is faster and more economical, producing coarser yarns often used for items like denim or towels. Finally, air-jet spinning offers a middle ground, combining decent quality and speed to create soft, bulky yarns suitable for specific types of apparel fabrics.