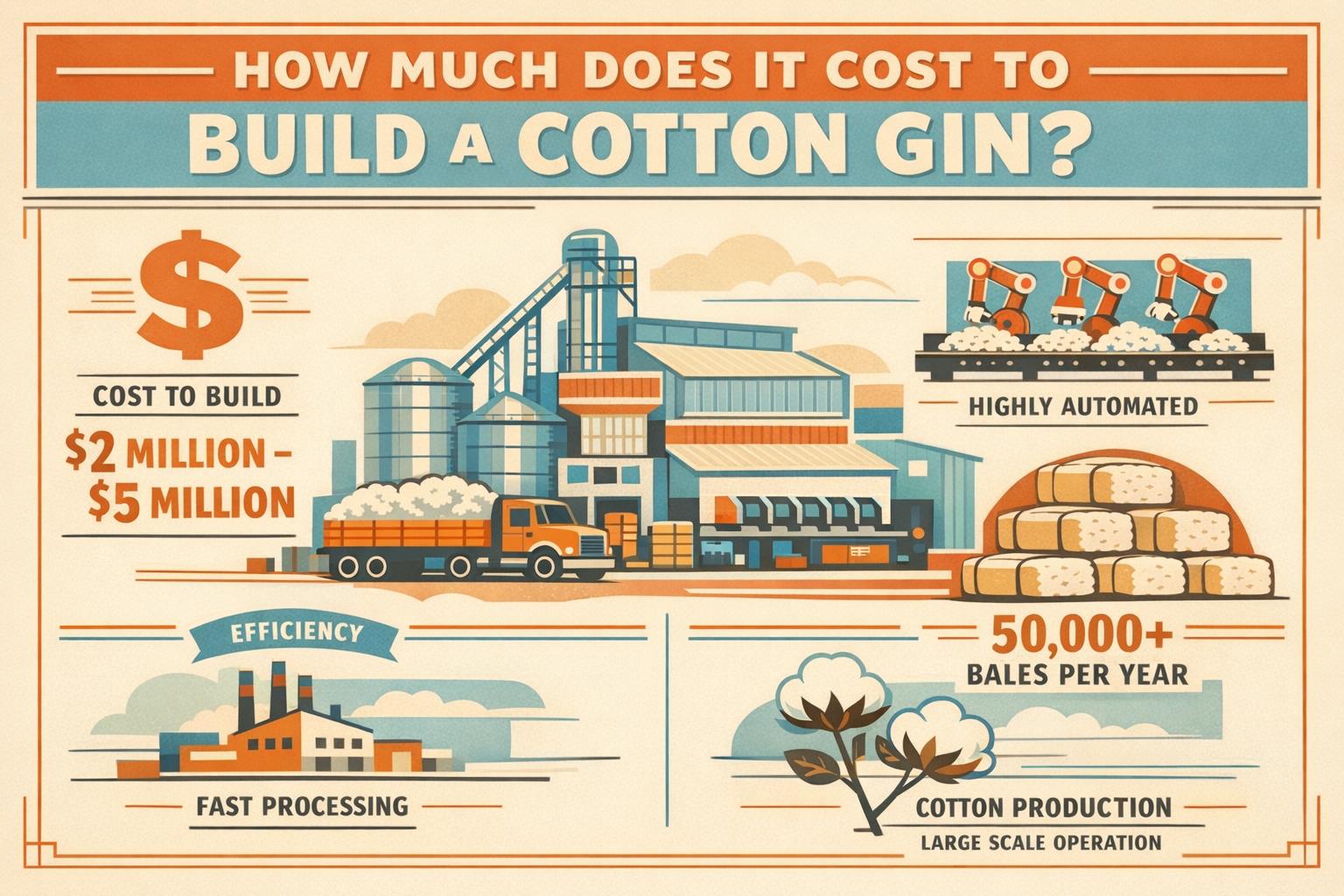

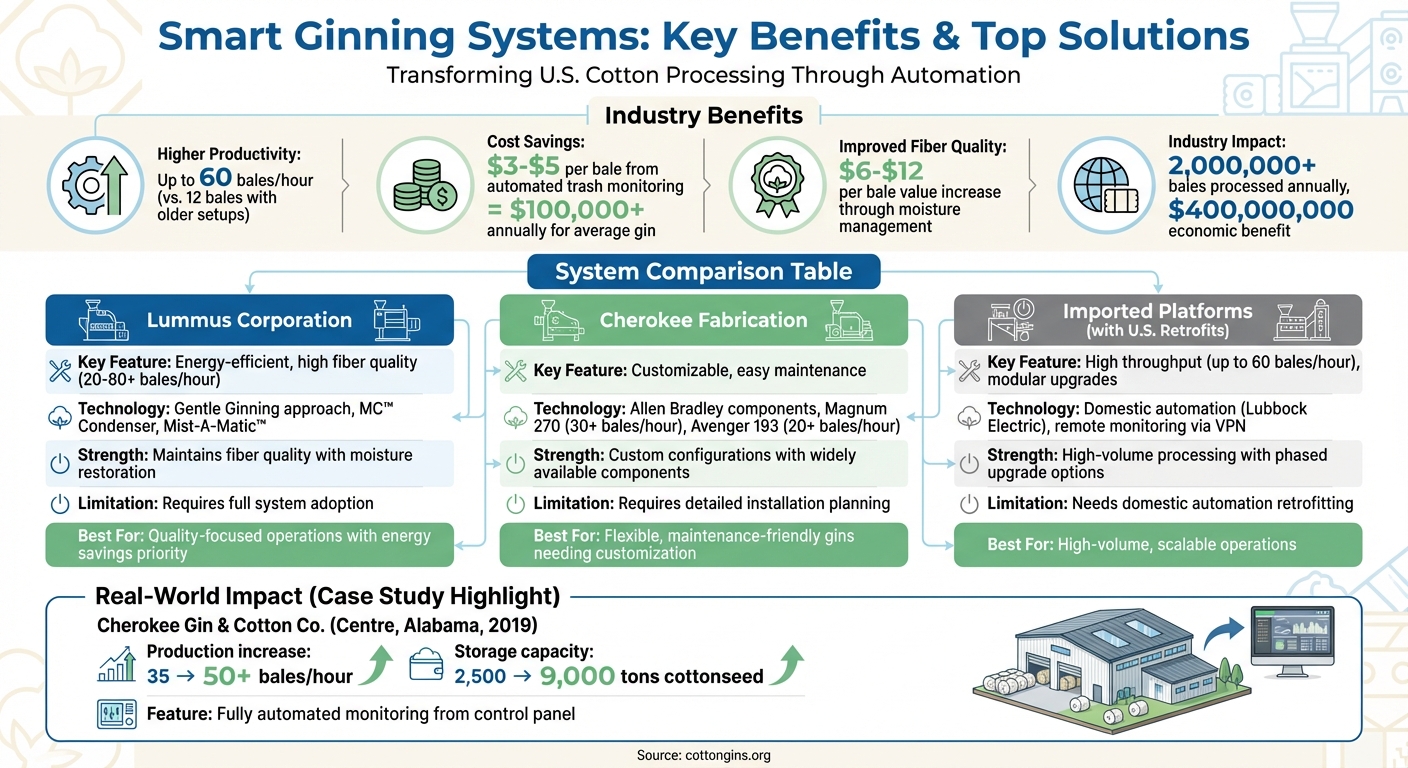

The U.S. cotton industry is transitioning to smart ginning systems to address labor shortages and improve efficiency. These systems use automation, machine vision, and remote monitoring to manage cotton processing with minimal human intervention. Key benefits include:

- Higher Productivity: Modern systems process up to 60 bales per hour, compared to 12 bales with older setups.

- Cost Savings: Automated trash monitoring can save $3–$5 per bale, adding over $100,000 annually for an average gin.

- Improved Fiber Quality: Moisture management and intelligent cleaning enhance cotton value by $6–$12 per bale.

- Reduced Labor Needs: Automation replaces manual tasks, enabling remote operation and improving safety.

Top systems include Lummus Corporation, Cherokee Fabrication, and imported platforms with U.S. automation retrofits. Each offers unique advantages in efficiency, scalability, and integration. For details on locations using these technologies, visit cottongins.org.

Smart Ginning Systems Comparison: Features, Benefits, and Cost Savings

Smart Cotton Processing - Instant Test, Real-Time Adjust, Maximum Output!

Quick Comparison

| System Type | Key Feature | Limitation | Best For |

|---|---|---|---|

| Lummus Corporation | Energy-efficient, high fiber quality | Requires full system adoption | Quality-focused operations |

| Cherokee Fabrication | Customizable, easy maintenance | Requires detailed planning | Flexible, maintenance-friendly gins |

| Imported Platforms | High throughput, modular upgrades | Needs retrofitting for automation | High-volume, scalable operations |

What Are Smart Ginning Systems?

Smart ginning systems bring automation to what was once a labor-intensive process, eliminating the need for constant manual oversight. Traditional ginning methods required significant human intervention, but modern systems can now handle up to 15 tons (33,000 pounds) per hour. This dramatic increase in efficiency has paved the way for advanced control technologies.

The key difference lies in centralized control paired with intelligent automation. Instead of outdated push-button panels, today’s systems feature touch-screen consoles and integrate tools like color video cameras and machine vision to monitor and adjust operations in real time. As USDA ARS researcher Don Comis described:

The system uses color video cameras for a hands‐off monitoring of the 'on-the-fly' flow of cotton and attendant debris through the many machines that make up a modern cotton gin.

These advanced systems also come equipped with motor load sensors to protect machinery, Internet-enabled controllers for remote operation, and moisture management features that help maintain fiber quality while cutting energy use.

The financial benefits are clear: better moisture control can save about $6 per bale, while improved cleaning can add $3–$6 to a bale's value. For operations processing more than 2,000,000 bales annually, these savings add up quickly.

Beyond cost savings, smart ginning systems reduce labor needs by automating tasks like module feeding, increase capacity by 10–25%, and improve safety by using remote temperature monitoring to catch potential hazards early. As Lubbock Electric Co. put it:

We put the power of automation and remote monitoring in your gin, reducing your labor costs and increasing employee safety.

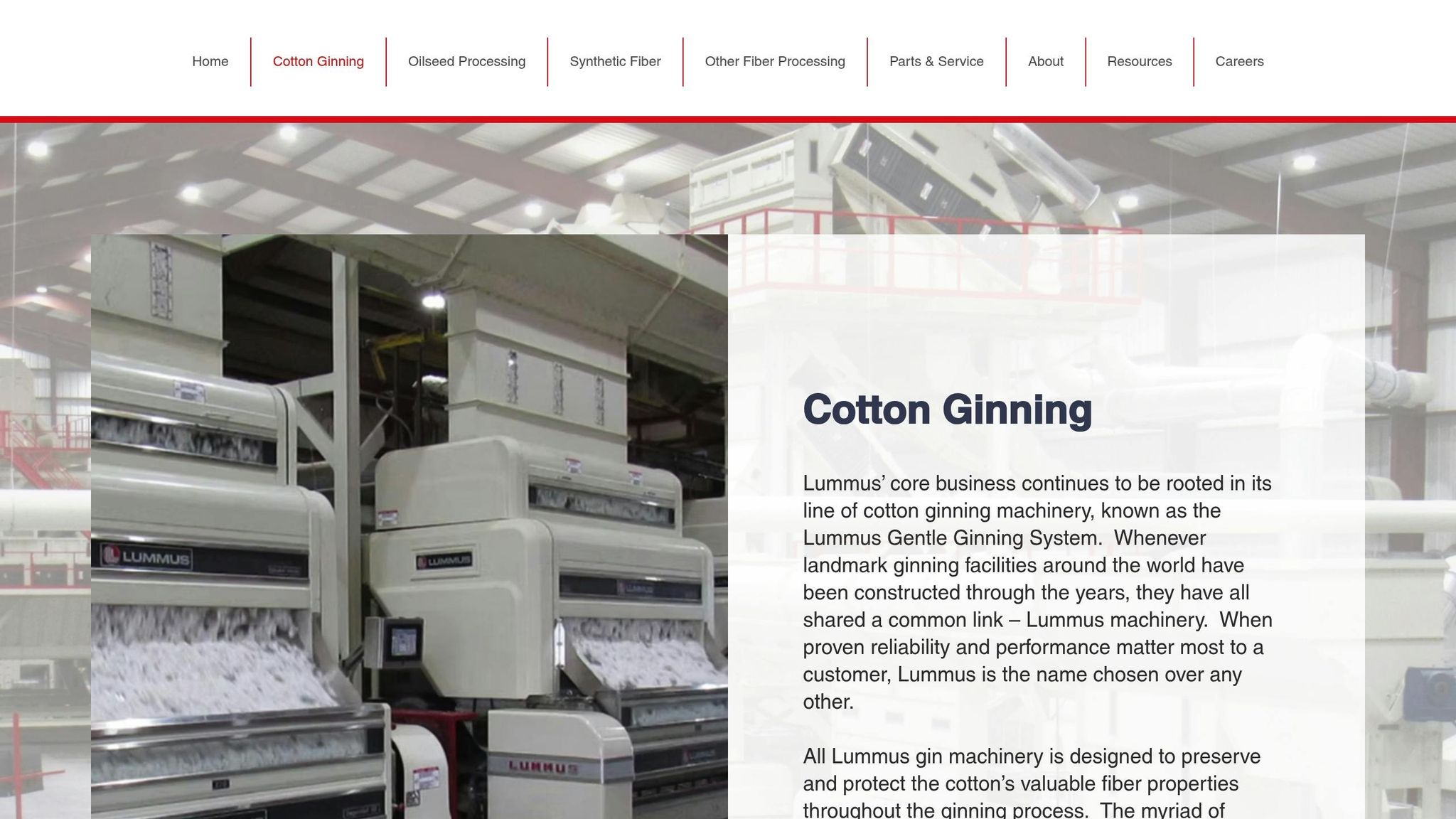

1. Lummus Corporation Smart Ginning and Control Solutions

Automation and Smart Controls

Lummus Corporation has streamlined every step of the ginning process with automation, starting right from intake. Their unloading systems are designed to handle a variety of inputs, including sacks, trailers, trucks, and modules, ensuring minimal delays during intake. Once the cotton is inside, Distribution and Overflow Systems take over, automatically moving seed cotton and redirecting any excess material to maintain a consistent feed.

In the U.S., gins frequently use third-party controllers like Lubbock Electric's MasterFlow™ III, which provide advanced features such as load sensing, overload protection, and remote monitoring. This seamless integration of automation ensures efficient fiber handling and maximized throughput.

Fiber Quality and Throughput

To maintain high fiber quality, Lummus employs centrifugal and mechanical lint cleaners. These cleaners are designed to remove trash effectively while minimizing stress on the fibers. According to the company:

All Lummus gin machinery is designed to preserve and protect the cotton's valuable fiber properties throughout the ginning process.

When it comes to baling, Lummus presses can handle capacities ranging from 20 to over 80 bales per hour. These presses produce bales at standard densities of 28 lbs/ft³ for Universal Density (UD) and 32 lbs/ft³ for High Density (Hi-D), available in both down-packing and up-packing configurations. Alongside quality and speed, Lummus incorporates energy-efficient control technologies to make the process more sustainable.

Energy Efficiency and Environmental Controls

Energy efficiency is a key focus for Lummus, particularly through their moisture management systems. Their MC™ Condenser and Mist-A-Matic™ Moisture Unit add moisture to the cotton, which reduces the compression required during baling and, in turn, lowers energy consumption. For high-volume operations, this approach can lead to noticeable energy savings.

The cleaning stages are tailored to the harvesting method. For hand-harvested cotton, a single stage of drying and precleaning is typically sufficient. However, mechanically harvested cotton often undergoes two to three cleaning stages to remove debris like sticks and burrs. This customized approach not only preserves fiber quality but also optimizes energy use throughout the process.

sbb-itb-0e617ca

2. Cherokee Fabrication Custom Smart Ginning Systems

Automation and Smart Controls

Cherokee Fabrication takes automation to the next level with its proprietary hybrid systems. Key features like the Powered Roll Box Door streamline the opening and closing process, while the Automatic Seed Roll Retainer keeps seed rolls secure during interruptions. These innovations reduce manual labor, improve safety, and make maintenance more efficient. Mike Greene from Decatur Gin Company highlighted these advancements:

The powered roll box door is a great idea, and the new seed roll retainer means we don't drop seed rolls when the breast comes out. These features cut downtime and reduce costs.

The control systems integrate Allen Bradley components, ensuring dependable performance and easier access to local support. Operators can select from fully automatic, fully manual, or hybrid operation modes to match their needs. The system also monitors key metrics like moisture levels, drying operations, static pressure, and safety systems in real time. This robust control framework supports better fiber processing and higher throughput.

Fiber Quality and Throughput

Cherokee’s precise control systems directly enhance output and fiber quality. Their Magnum 270 saw gin stand delivers throughput exceeding 30 bales per hour per stand, while the Avenger 193-saw model achieves over 20 bales per hour within an 8-foot footprint. Field tests show a 0.5% improvement in turnout, even when processing modules from the same field on the same day.

The Cirrus Moisture Restoration System plays a key role in maintaining fiber integrity during lint cleaning and conditioning. Additionally, Cherokee’s Regal lint cleaners efficiently remove trash and present fibers in a combed format that preserves quality. For large-scale operations, such as the South Georgia Gin project, Cherokee’s systems have demonstrated the ability to handle over 90 bales per hour.

Integration and Scalability

Cherokee designs its systems to replace outdated equipment while significantly boosting capacity. MaLeisa Finch from Kiech-Shauver-Miller Gin Company shared her experience:

Just one of our Magnum gin stands will gin more cotton than four stands in our old gin. Less equipment means less maintenance – Cherokee is ahead of the game in that area.

Their modular product line covers every stage of the ginning process, from unloading to baling, giving operations the flexibility to upgrade individual components or entire facilities. Cherokee also plans for future growth, as seen in their Dooly County project, by recommending floor plans that allow for future expansion. By using standardized Allen Bradley hardware, Cherokee simplifies maintenance and troubleshooting while ensuring compatibility with existing infrastructure.

3. Imported Automation-Ready Ginning Platforms Used in the U.S.

Automation and Smart Controls

When equipped with modern control technologies, imported ginning platforms can deliver efficiency and safety on par with U.S.-designed systems. Retrofitting these platforms with domestic automation solutions, like Lubbock Electric's controls, allows for features such as remote monitoring via VPN and intelligent load sensing. These systems include networked controls that let gin managers oversee equipment, fine-tune programs, and troubleshoot issues from anywhere. Safety is a priority, with fire detection sensors designed to identify choking or overheating in the gin stand, triggering automated responses to prevent accidents. Advanced master consoles with touch-screen interfaces provide a detailed view of operations, helping pinpoint and resolve issues quickly across the facility. As Brandon and Clark put it:

The key is gin controls.

These advanced controls not only enhance safety but also pave the way for better fiber quality and increased throughput in subsequent processing stages.

Fiber Quality and Throughput

Automation-ready platforms incorporate computerized process control systems to ensure cotton quality is maintained throughout the ginning process. According to the USDA Agricultural Research Service:

Application of the Computerized Process Control Systems (CPCS) will improve fiber quality substantially and increase farmer profits $10 to $20 per bale with a potential impact of $400,000,000 annually.

Currently, these systems handle over 2,000,000 bales of cotton each year in the U.S. Specialized platforms like the Compass MicroGIN are particularly suited for research and development, offering unmatched flexibility for short runs. They also boast the lowest tested Visual Mechanical Damage (VMD) on the market and utilize delinting bags that last 50 times longer than standard materials.

Energy Efficiency and Environmental Controls

Smart monitoring tools, such as Seed Trac, allow operators to optimize aeration fan schedules based on real-time temperature readings, cutting down on energy waste and preventing unnecessary weight loss from over-aeration. Moisture restoration systems add controlled humidity to lint cotton, reducing the energy needed during bale compression. These upgrades also improve efficiency, cutting box turn times from 10–12 seconds to just 4 seconds, which increases throughput by at least 2 bales per hour while simultaneously lowering power consumption. Integrated dust collection systems ensure compliance with U.S. health standards, while automated drying systems with multiple BTU configurations maintain precise temperature control without manual adjustments.

Integration and Scalability

The benefits of these imported platforms can be expanded further through modular retrofits. Operators can integrate domestic master consoles and hydraulic units like SmartFlow™ to enhance output, safeguard motor life, and maximize the value of their existing equipment. As Lubbock Electric explains:

Our mission is to prevent and quickly resolve downtime in your gin.

Cybersecurity measures are built into these systems to protect ginning operations from potential threats. Additionally, platforms designed to meet global electrical standards are compatible with U.S. facilities and adaptable for diverse field applications. Features such as two-touch motor starting and remote operation ensure workers remain at a safe distance from heavy machinery. The modular design allows facilities to upgrade specific components rather than replacing entire systems, making automation an achievable goal for operations of all sizes and budgets.

Advantages and Disadvantages

Selecting the right smart ginning system requires weighing a range of trade-offs that impact performance and how well the system integrates with existing operations. These pros and cons relate to the specific features discussed earlier in this article.

Lummus Corporation stands out with its Gentle Ginning approach, which helps maintain fiber quality and offers a bale handling capacity between 20 and over 80 bales per hour. However, its fully integrated design means you’ll need to commit to the entire system, limiting the ability to mix and match equipment from other manufacturers. On the other hand, Cherokee Fabrication and imported platforms bring their own sets of strengths and challenges.

Cherokee Fabrication uses industry-standard Allen Bradley components, which are readily available to U.S.-based technicians. This makes it easier to source parts and allows for custom configurations tailored to specific needs. However, this level of customization often requires detailed planning, making it less straightforward than plug-and-play setups.

Imported automation-ready platforms are designed for high-volume processing and offer modular upgrade options. While this modularity provides flexibility, these systems usually require domestic retrofitting to integrate automation solutions. This makes them ideal for operations that need scalability but are prepared for some initial adjustments.

| System Type | Primary Strength | Key Limitation | Best For |

|---|---|---|---|

| Lummus Corporation | Maintains fiber quality with energy-efficient moisture restoration | Requires adoption of the full system | Operations focused on fiber quality and energy savings |

| Cherokee Fabrication | Custom configurations with widely available components | Requires detailed installation planning | Gins needing customizable, maintenance-friendly solutions |

| Imported Platforms | High-throughput processing (up to 60 bales/hr) with modular upgrades | Needs domestic automation retrofits | High-volume operations seeking phased modernization |

Each system also approaches efficiency in unique ways. Lummus Corporation reduces energy costs with moisture restoration units like the Mist-A-Matic™, which makes lint easier to compress. Cherokee Fabrication focuses on maintenance-friendly designs that enhance overall plant efficiency. Meanwhile, imported platforms achieve efficiency by spreading fixed costs over their high throughput capacity.

Scalability depends heavily on the gin’s current setup. Operations that use equipment from multiple brands benefit from systems with flexible integration. Fully integrated systems, however, are better suited for those planning long-term expansion. The best choice ultimately depends on whether the priority is seamless compatibility now or complete integration for the future.

Conclusion

Choosing the right ginning system involves assessing your equipment, workforce skills, and plans for upgrades. If your operation uses mixed-brand machinery, Lubbock Electric offers automation solutions compatible with any brand, ensuring seamless integration. For those prioritizing fiber quality and long-term growth, Lummus Corporation provides a fully integrated approach tailored to these goals. Additionally, remote monitoring technology allows managers to oversee multiple sites from a central location, reducing the need for constant on-site supervision. These advancements are reshaping modern ginning operations with measurable results.

Automation is transforming the industry. Currently, over 80 Computerized Process Control Systems process more than 2,000,000 bales annually, contributing to an estimated $400,000,000 in economic benefits across the industry.

A compelling example of automation's impact comes from Cherokee Gin & Cotton Co. in Centre, Alabama. In February 2019, their newly automated facility boosted production from 35 bales per hour to over 50 and increased cottonseed storage capacity from 2,500 to 9,000 tons.

"Our fully automated system is the first one built from the ground up using this technology. We can monitor the entire gin - what's happening every step of the way - from a control panel."

– Rich Lindsey, Gin Manager, Cherokee Gin & Cotton Co.

The documentation of such installations on cottongins.org serves as an invaluable resource for tracking the adoption of smart ginning technologies across various regions. This centralized platform not only quantifies the economic benefits but also facilitates the grassroots transfer of technology. By staying updated with these advancements, gin managers can make informed decisions, while cottongins.org cements its role as the go-to directory for the industry's technological evolution.

FAQs

How do smart ginning systems enhance cotton fiber quality?

Smart ginning systems take cotton fiber quality to the next level by leveraging AI-driven vision technology and sensor-based monitoring. These advanced tools work in real-time to identify and eliminate impurities, ensuring fibers are cleaner and more consistent.

These systems also carefully regulate moisture levels and adjust cleaning processes to maintain the natural strength and structure of the fibers. By automating critical tasks, such as gin stand operations, they minimize mechanical damage, producing lint that meets the high demands of the industry.

How do smart ginning systems help reduce costs?

Smart ginning systems streamline operations and cut costs in multiple ways. By automating tasks, they significantly reduce labor expenses. Their efficient design also lowers energy consumption and minimizes water usage while limiting waste. On top of that, these systems boost equipment reliability, which means less maintenance downtime and fewer repair costs. Plus, they enhance the quality of cotton bales, making them more valuable in the market and improving overall profitability.

How does the scalability of U.S. smart ginning systems compare to imported ones?

U.S.-based smart ginning systems stand out for their ability to handle large-scale operations with ease. With high-throughput capacity, modern gin stands can process up to 15 tons of cotton per hour. These systems feature modular automation, IoT-enabled monitoring, and flexible handling capabilities, making them versatile enough to cater to both small-scale and large-scale operations.

When it comes to imported ginning platforms, there isn't much information available about their scalability, making a direct comparison difficult. That said, U.S. systems are specifically designed to meet the needs of domestic operations, which could give them an edge in terms of efficiency and adaptability for local use.