The journey of cotton from a seed in the ground to the fabric you wear is a fascinating, intricate process that involves multiple stages, countless individuals, and a global network. This supply chain is not only vast but also faces numerous challenges, from environmental concerns to labor practices. Let's delve into the world of cotton, understanding each step from cultivation to the final product on the fashion rack.

1. Cultivation: Planting and Growing Cotton

Cotton begins its journey in the fields of countries like the United States, China, India, and Brazil, which are among the top producers globally. Cotton is a warm-season crop that thrives with plenty of sunlight and moderate rainfall. Here's how it starts:

- Planting: Farmers select high-quality seeds, sometimes genetically modified for resistance to pests or for better yield. Planting occurs with the help of mechanical planters that can cover vast areas quickly, dropping seeds into tilled soil.

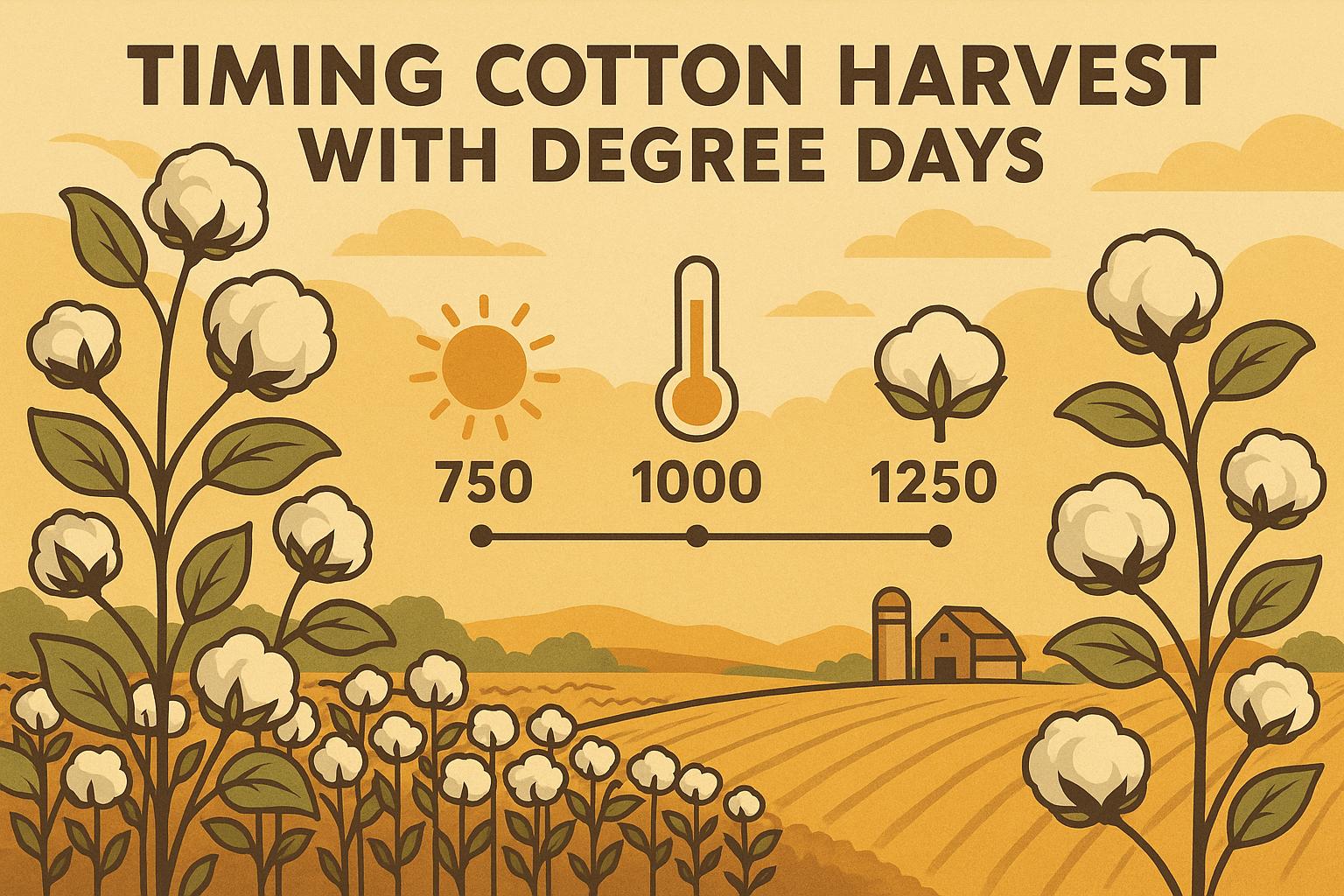

- Growth: Cotton plants require about 160 days from planting to harvest. During this time, they're tended for weed control, pest management, and soil nutrition. Water management is crucial since cotton is one of the thirstiest crops, consuming vast amounts of water.

- Harvesting: Once the cotton bolls are mature, they are harvested either by hand or with mechanical pickers. This stage marks the beginning of the transformation from raw material to usable fiber.

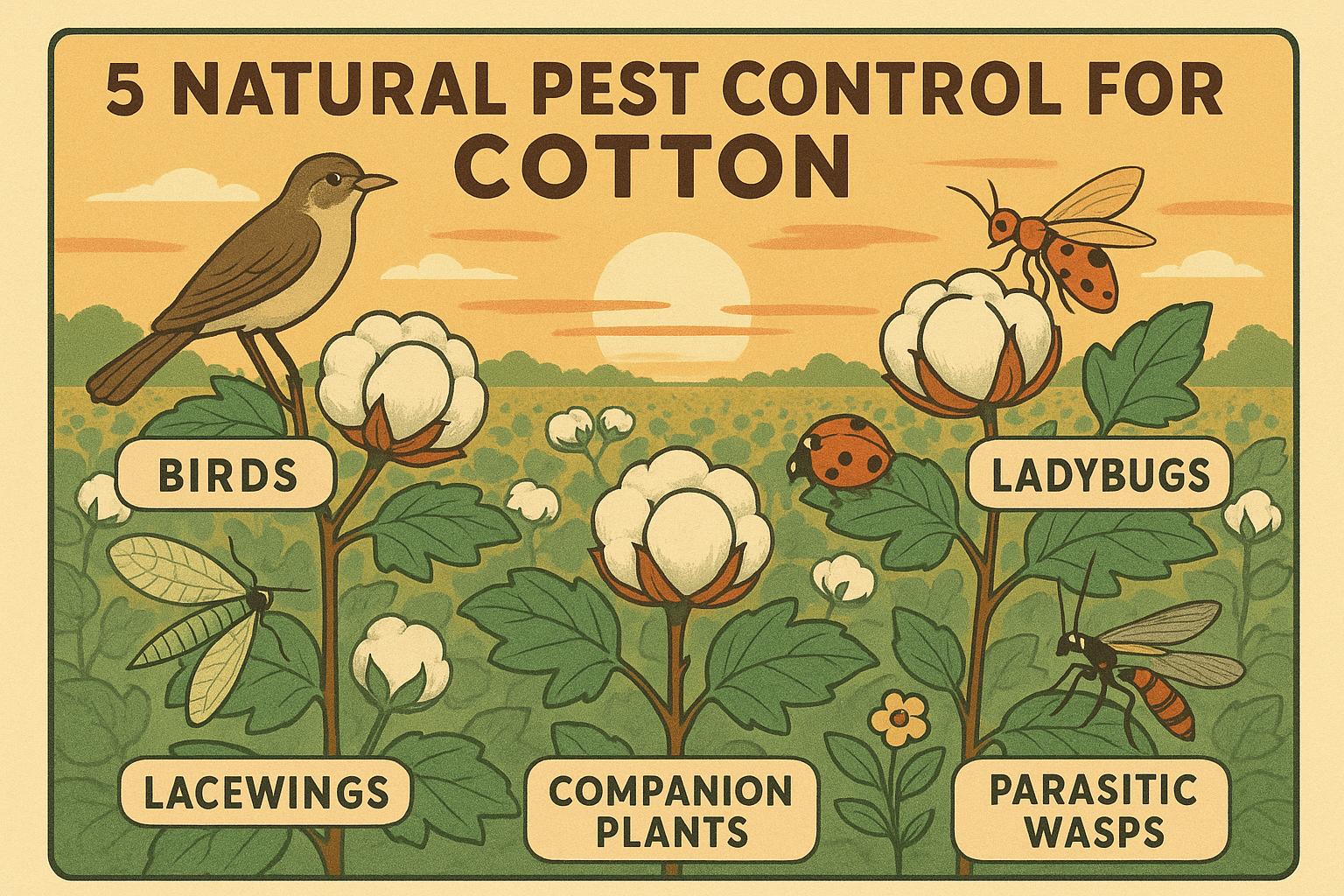

Understanding the cultivation phase highlights sustainability challenges, including water usage and pesticide dependence. Initiatives like organic cotton farming aim to mitigate these impacts by using natural methods for pest control and more efficient irrigation techniques.

2. Ginning: Separating Fiber from Seed

Post-harvest, the cotton bolls go to the gin:

- Ginning Process: Here, the cotton fibers are separated from the seeds in a process invented in the late 18th century but still fundamental today. The lint (fiber) is cleaned, and the seeds are removed, leaving behind cotton that's ready for further processing.

- Baling: The cleaned cotton fibers are compressed into bales for transportation. Each bale can weigh around 500 pounds and is wrapped for protection during transit.

Ginning is where the first significant transformation occurs, setting the stage for the cotton's journey through the supply chain. Innovations in this stage focus on reducing waste and improving energy efficiency.

3. Textile Production: From Fiber to Fabric

The transformation of raw cotton into textile involves several steps:

- Spinning: Cotton fibers are spun into yarn. This process involves carding to clean and align the fibers, followed by spinning machines that twist the fibers into thread.

- Weaving or Knitting: The yarn is then either woven into fabric on looms or knitted into fabric. Weaving produces a more structured fabric used for items like shirts and trousers, while knitting offers stretch and flexibility, suitable for underwear or sweaters.

- Dyeing and Finishing: Fabric or yarn might be dyed before or after weaving/knitting. Finishing includes treatments to enhance properties like colorfastness, wrinkle resistance, or water repellency.

This phase is where the environmental footprint of cotton can be significant, with concerns over water pollution from dyeing and the use of harmful chemicals. However, there's a push towards more sustainable practices, including the use of natural dyes and water recycling systems.

4. Garment Manufacturing: Fashioning the Fabric

Once the fabric is ready, it moves to apparel manufacturing:

- Cutting: Fabric is cut into patterns according to clothing designs. Precision is key to minimize waste.

- Sewing: Components are sewn together by machines or skilled workers. This labor-intensive phase is often criticized for poor working conditions in some parts of the world.

- Assembly and Finishing: Garments are assembled, buttons and zippers added, and final touches like embroidery or prints applied. Quality checks ensure the product meets standards.

This stage underscores issues of labor rights, with initiatives like the Fair Labor Association pushing for better conditions. Transparency in sourcing cotton becomes vital to ensure ethical practices are followed.

5. Distribution: From Manufacturer to Retail

After manufacturing:

- Logistics: The garments are packed, labeled, and shipped. This involves complex logistics, moving products across continents.

- Retail: Goods reach stores or online platforms where they are displayed for consumers. Here, branding and marketing play significant roles in influencing consumer choices.

The distribution phase highlights the global nature of the cotton supply chain, with challenges in traceability and ensuring that sustainability and ethical standards are not lost in transit. Blockchain technology is being explored to enhance transparency.

6. Consumer Use and End of Life

- Consumer Phase: Consumers purchase clothing, influencing future production through their choices. Trends towards sustainability are pushing more brands to offer eco-friendly options.

-

End of Life: Eventually, garments wear out or go out of style. Here, the concept of circular economy comes into play:

- Recycling: Cotton textiles can be recycled, though currently, only a small fraction is due to technical challenges.

- Upcycling: Turning old clothes into new products.

- Donation: Extending the life cycle of the garment by giving it to others.

This phase is crucial for reducing the environmental impact, emphasizing the need for better recycling and upcycling technologies.

Challenges and Future Directions

- Sustainability: The cotton supply chain has a significant environmental footprint, with water use, pesticide application, and carbon emissions being major issues. Sustainable practices like organic farming, water-saving irrigation, and natural pest control are on the rise.

- Traceability and Transparency: Consumers and regulators demand to know more about where products come from. Blockchain and other tech solutions are helping trace cotton back to its source, ensuring ethical practices are adhered to.

- Labor Rights: Issues like child labor, forced labor, and unsafe working conditions plague parts of the supply chain. Enhanced oversight and certification programs aim to improve worker conditions.

- Innovation: New business models, such as direct trade with farmers or vertical integration, could transform how cotton is sourced and sold, potentially benefiting both the environment and the farmers.

- Regulation and Consumer Pressure: With increased awareness, there's pressure for more sustainable and transparent practices. This might lead to stricter regulations on how cotton is grown and processed.

Conclusion

The cotton supply chain is a microcosm of global trade, highlighting both human ingenuity and the challenges of sustainability. As we move forward, the industry must continue to innovate, embracing technologies and practices that reduce environmental impact while ensuring fair labor practices. The journey from farm to fashion is not just about creating clothes but about weaving a better future for both people and the planet.

By understanding this supply chain, consumers can make more informed choices, pushing for a fashion industry that values the earth as much as it does style and functionality. Let's hope that with each thread we pull from the cotton bale, we're also pulling towards a more sustainable world.