Executive Summary (TL;DR)

- Short-staple cotton presents unique spinning challenges including fiber breakage, neps, and weak yarn strength.

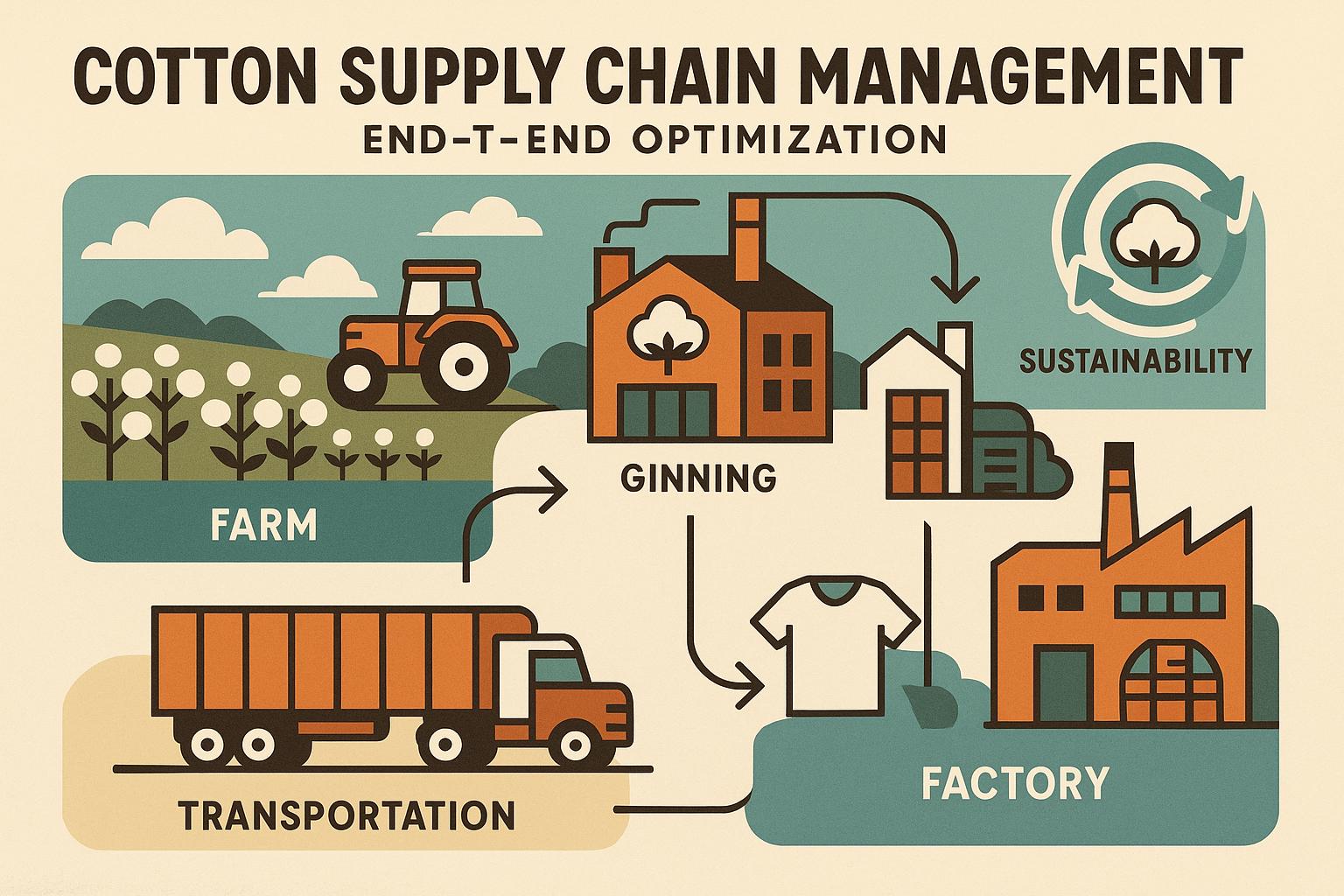

- Proven strategies like careful bale selection, refined ginning, and process optimization are essential for quality yarn production.

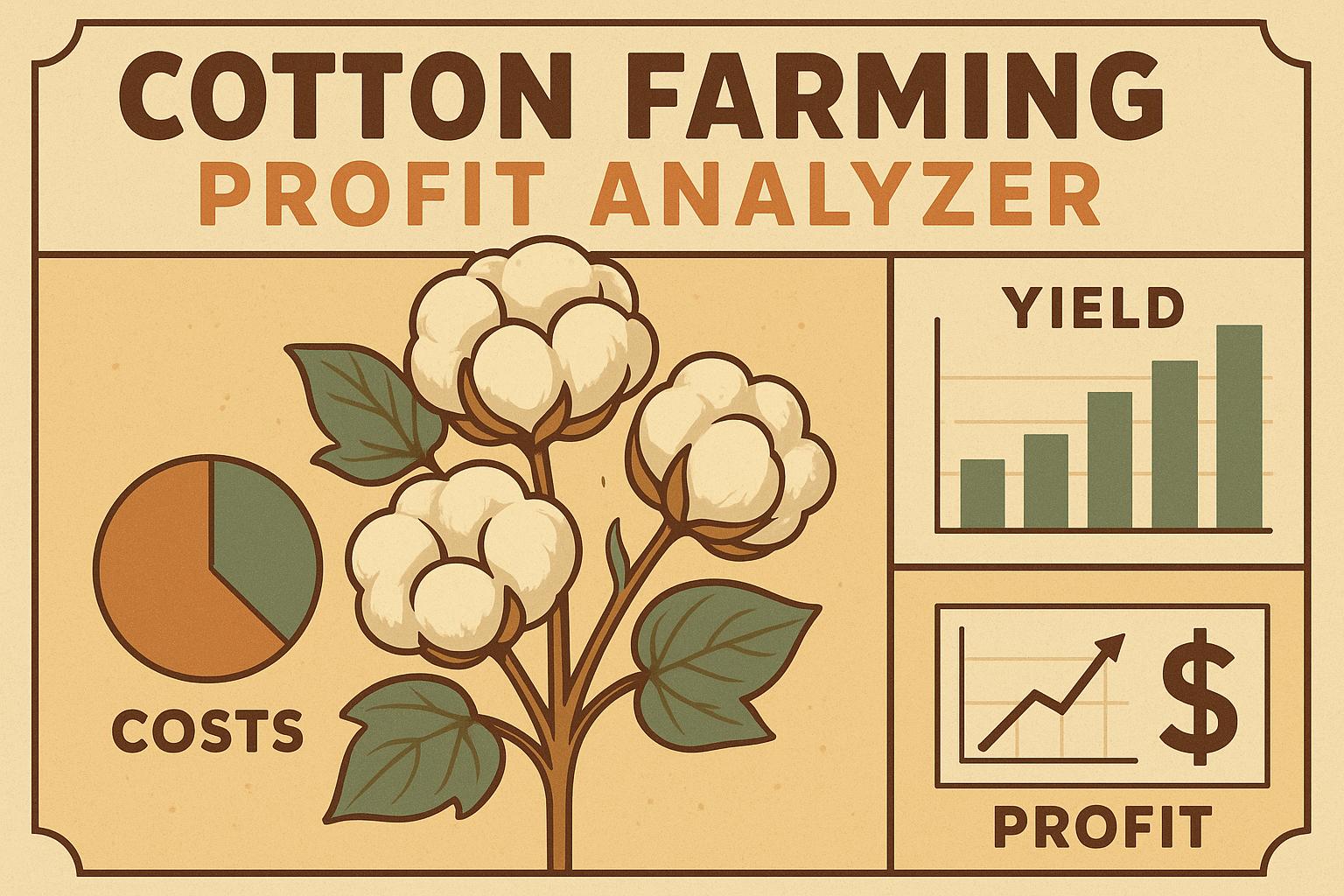

- Awareness and monitoring throughout lint processing reduce defects and improve profitability for growers and spinners.

Related Post: For more insight into fiber quality management, visit our guide on "Enhancing Cotton Fiber Quality Through Agronomic Practices."

Introduction

Handling short-staple cotton during spinning remains a challenge that seasoned cotton farmers and spinning professionals face worldwide. While the agricultural production of short-staple cotton varieties like Upland and Acala forms a significant part of the cotton supply, their fiber characteristics often complicate subsequent mill processes and yarn quality. This article explores the technical difficulties during spinning, uncovers root causes, and highlights actionable solutions to help farmers and processors improve outcomes.

Understanding Short-Staple Cotton

Short staple cotton fibers typically range from ½ inch to around 1¼ inch in length. Compared to long-staple varieties like Pima or Egyptian cotton, these fibers require more delicate handling and specialized spinning techniques to avoid breakage and defects. The staple length results largely from genetics, regional growing conditions, and harvesting practices, with secondary influences from ginning and processing.

Challenges in Spinning Short-Staple Cotton

1. Fiber Breakage and Weak Yarn Strength

Short fibers inherently provide fewer overlaps in yarn, leading to reduced cohesion and strength. During the draft and twist stages of spinning, these fibers are more prone to breakage—causing frequent yarn breaks and interruptions.

2. Increased Neps and Imperfections

Short-staple cotton tends to produce more neps—small tangled fiber knots—that degrade yarn appearance and impose challenges in downstream processing. This disrupts smooth spinning and results in higher waste.

3. Difficulties in Drafting and Spinning Control

Spinners must adjust drafting zones and twisting speeds carefully to maintain continuous yarn. Poor adjustments lead to inconsistent yarn tension, affecting final product uniformity.

Root Causes of Spinning Problems

- Genetic fiber length variations often cluster around the top and bottom cotton bolls, influencing bale quality.

- Mechanical damage during harvesting, ginning, and cleaning raises the short-fiber content unintentionally by breaking longer fibers.

- Suboptimal machine settings in the blowroom and carding processes can increase short fiber percentages and damaged fiber handling.

- Insufficient quality control and bale testing challenge consistent blending and sizing.

Solutions and Best Practices

Bale Selection and Quality Testing

- Comprehensive bale testing for Short Fiber Content (SFC) is critical before purchase or processing. Rejecting bales exceeding acceptable limits ensures more uniform spinning batches.

- Choosing cotton from earlier pickings and managing harvest to minimize mechanical damage improves fiber length distribution.

Process Optimization in Blowroom and Carding

- Adjusting cleaning intensity to balance trash removal with fiber damage control reduces short fiber production.

- Regular testing and calibration of carding machines optimize nep removal without sacrificing fiber integrity.

Spinning Adaptations

- Fine-tuning drafting suction, roller settings, and twist insertion controls minimizes breakage during spinning.

- Use of comber noils for short fiber removal further refines yarn quality, enhancing strength while maintaining good fiber retention.

Training and Automation

- Skilled operators combined with inline monitoring systems allow real-time adjustments to maintain consistent yarn characteristics.

- Automating waste collection and reprocessing reduces fiber loss and improves sustainability.

Farmer-Centric Insights for Improving Spinning Outcomes

- Invest in early bale testing and rejection frameworks focused on SFC to avoid processing low-quality fiber.

- Collaborate with ginners to adopt gentler mechanical handling, preserving fiber length.

- Understand that investment in modern process controls and skilled labor at mills can directly correlate with better prices at the farm gate through quality premiums.

Actionable Takeaways

- Regularly measure bale short fiber content and set supplier limits based on SFC thresholds.

- Invest in training for bale blending that prioritizes long fiber retention.

- Work closely with processing partners to optimize cleaning and carding to minimize fiber damage.

- Promote investment in spinning technology adjustments specific to short staple cotton characteristics.

Frequently Asked Questions

Q: What short fiber content is acceptable for spinning?

A: Typically, less than 8-10% short fiber content is desirable to keep yarn strength and uniformity high.

Q: How can farmers directly influence spinning quality?

A: By producing and harvesting cotton with minimal mechanical damage and by selecting seed varieties known for longer staple lengths within their growing conditions.

Q: Are there new technologies to help with short-staple spinning?

A: Advances in compact spinning and inline optical sensors offer improved control over fiber alignment and defect detection.

Conclusion

While short-staple cotton spinning presents undeniable challenges, targeted interventions at the farm, gin, and mill levels dramatically improve yarn outcomes and profitability. Seasoned cotton farmers who understand and address fiber length distribution, mechanical damage, and processing quality control pave the way for premium pricing and long-term success. Being proactive in quality measurement and process optimization is the key to turning short staple into a profitable opportunity.