Cotton gins face intense pressure during the harvest season. With a narrow 12–16-week window, gins must process massive volumes of cotton quickly. The U.S. has only 509 active gins today, down from over 2,254 in 1980, forcing each facility to handle significantly higher workloads. Delays in ginning can lead to crop damage, storage issues, and strained grower relationships.

Key challenges include:

- Trailer shortages: Harvesting pauses when trailers fill up, risking crop exposure to weather.

- Energy costs: These account for 25% of variable expenses, spiking as gins run 24/7.

- Backlogs: Processing bottlenecks disrupt operations, driving up costs and creating delays.

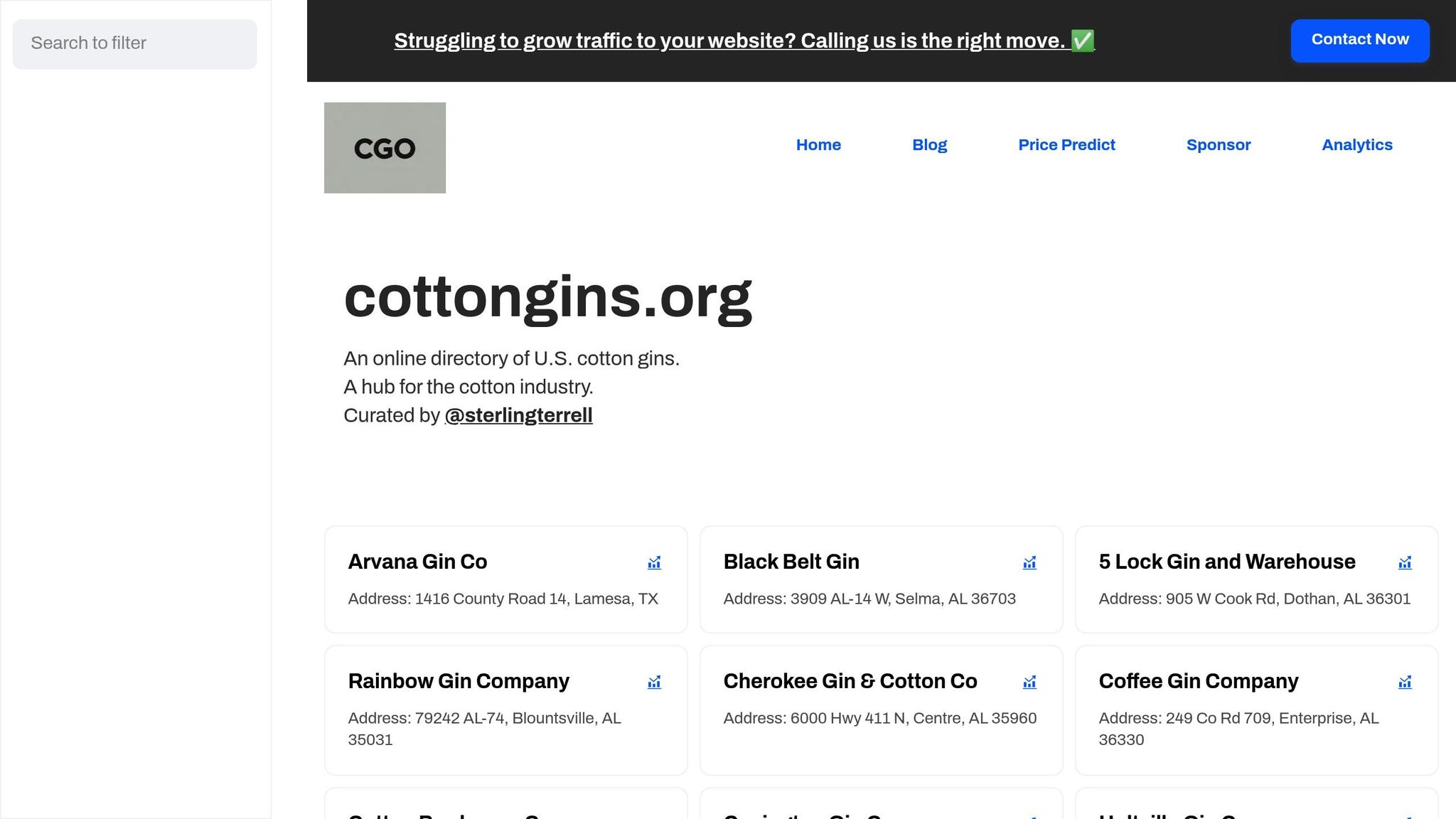

Solutions focus on preparation, efficiency, and collaboration. Upgrading equipment, optimizing energy use, and implementing grower incentive programs help manage peak demand. Regional coordination, like shared trailer pools and scheduling systems, further reduces bottlenecks. Tools like cottongins.org assist growers in locating gins and balancing workloads.

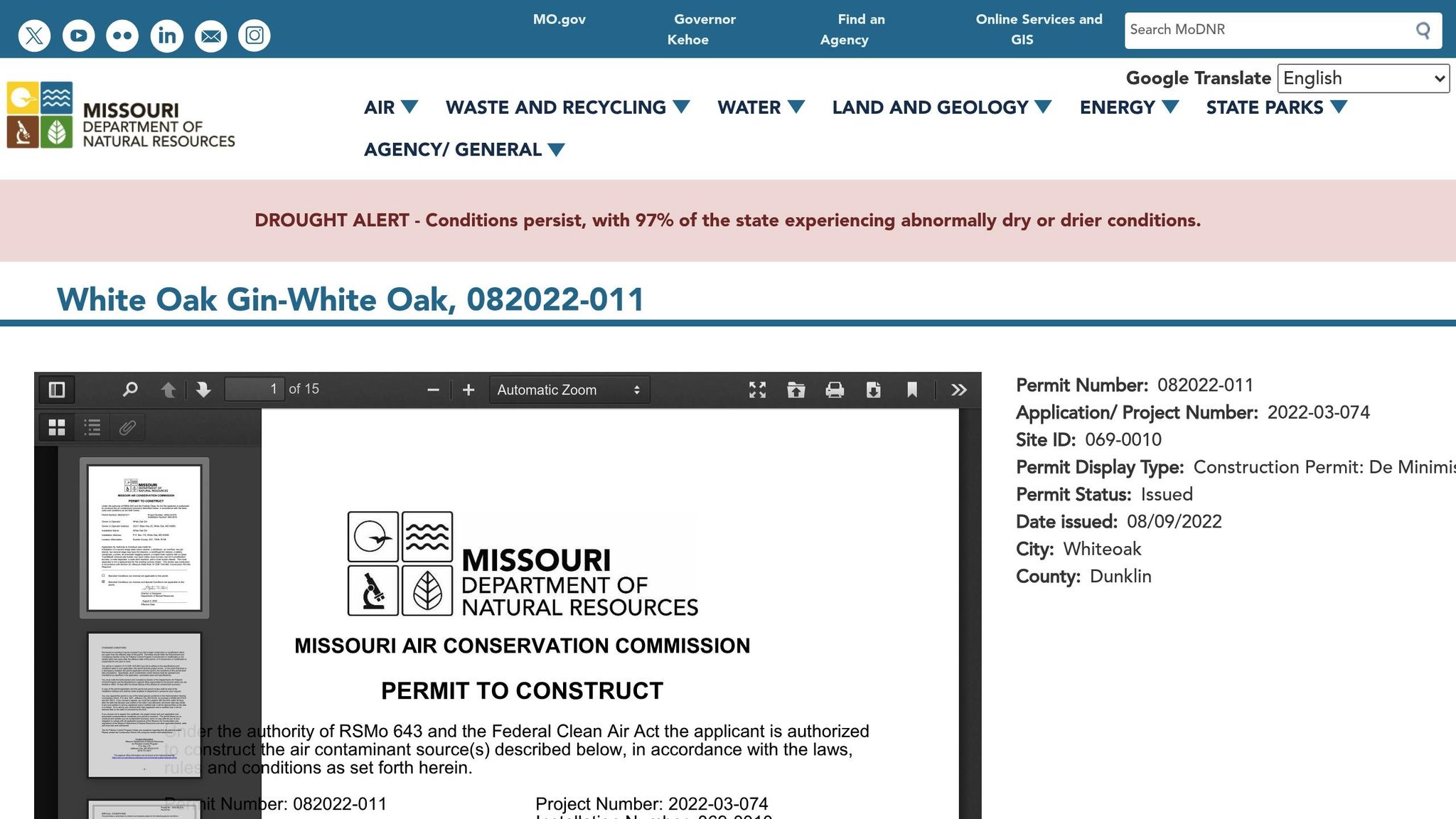

Exploring New Cotton Gin Technology at White Oak Gin in Missouri

How Seasonal Demand Patterns Affect Cotton Gins

The seasonal nature of cotton production creates a mismatch between harvest timing and processing capacity. This imbalance drives many of the operational challenges faced by the ginning industry today. Below, we’ll dive into the key issues shaped by this seasonal demand.

The Short Harvest Window

Cotton harvests are heavily influenced by weather patterns and crop maturity, leading to a short, intense period of activity. Modern mechanical harvesters can pick cotton much faster than gins can process it, creating a bottleneck that ripples through the entire supply chain. As a result, harvested cotton often piles up faster than it can be processed.

The introduction of mechanization and the module system has only heightened this challenge. While these technologies have improved storage and throughput, they’ve also compressed the harvest timeline, making it harder for gins to keep up. When gins fall behind, trailers loaded with cotton form long queues at processing facilities, forcing growers to pause harvesting operations. This delay risks exposing cotton to adverse weather, which can harm crop quality and disrupt market timing. The financial stakes are high, as even minor delays during harvest season can have significant consequences.

Trailer capacity is a critical factor in managing these seasonal bottlenecks. The logistics of trailer availability vary widely. In some regions, gins provide trailers, while in others, growers rely on their own equipment. When all available trailers are tied up waiting at gins, harvesting grinds to a halt until capacity frees up. Addressing these bottlenecks is essential, and later sections will explore potential operational and technological solutions.

Regional Differences in Demand

Seasonal demand doesn’t affect all cotton-growing regions in the same way. For example, the Texas High Plains illustrates how regional concentration can amplify seasonal pressures. Over the years, this area’s share of Texas cotton production has skyrocketed - from 20% in 1942 to over 60% by 1981. This concentration means that during harvest, the demand for ginning services becomes highly localized and intense.

The trend toward consolidation has also created regional disparities. While larger, more efficient gins now dominate, fewer processing facilities in some areas mean limited options during peak demand. To manage these challenges, regions have adopted various strategies. Some gins offer rebates of $1.00–$2.50 per bale to growers who bring their own trailers, helping to ease transportation bottlenecks and improve delivery efficiency.

Infrastructure investments also vary by region, with some areas adopting newer, higher-capacity trailers capable of carrying up to 10 bales. Labor availability and costs further shape how regions handle peak-season scaling. For instance, regions with more accessible and affordable labor can adapt more easily to seasonal surges.

These regional differences highlight the importance of tailored operational strategies to address the unique challenges faced by each area.

Operational Problems During Peak Seasons

Capacity Limits and Backlogs

During peak harvest times, the amount of cotton being picked often surpasses the capacity of gins to process it, leading to trailer backlogs at gin sites. Once all available trailer space is filled, harvesting has to pause. This not only risks exposing the crop to bad weather but also disrupts the entire processing workflow. Delays in processing can leave cotton vulnerable to moisture and pests, which lowers its quality. On top of that, these interruptions drive up labor and storage costs, and in some cases, gins may need to offer rebates or incentives to growers for timely deliveries. The problem is further complicated by regional differences in equipment, which can make backlogs even worse. Adding to this, high energy costs during peak times only make the situation more challenging.

Higher Energy Costs

Energy consumption skyrockets during peak operations, with energy expenses making up roughly 25% of the variable costs associated with ginning. Material handling alone accounts for more than half of the electricity used. Even brief periods of downtime can result in significant financial losses . Inefficiencies in handling materials not only slow things down but also exacerbate bottlenecks. Tackling these issues is essential to improve gin efficiency during the busiest times of the season.

Here’s a quick breakdown of the main challenges during peak operations and their effects:

| Challenge | Impact on Operations | Financial Consequences |

|---|---|---|

| Trailer Capacity Limits | Harvest delays and higher crop damage risk | Strained grower relationships and potential rebates |

| Energy Cost Spikes | Energy costs at about 25% of variable costs | Increased per-bale costs and reduced profit margins |

| Material Handling | Downtime and lower throughput | Lost processing capacity and higher labor expenses |

Together, the pressures of limited capacity and rising energy costs force gin operators to juggle speed, efficiency, and cost management - all while ensuring the cotton meets the quality standards that growers expect.

Methods for Managing Seasonal Gin Operations

Managing the challenges of seasonal demand in cotton ginning requires thoughtful strategies that balance efficiency and cost control. To keep operations running smoothly throughout the harvest season, it's crucial to optimize every step of the ginning process.

Increasing Ginning Rates

During peak harvest times, boosting ginning rates is key to keeping per-bale costs low and meeting demand effectively. With U.S. cotton demand expected to hit 14.2 million bales for the 2025/26 season - a 5% increase from the previous year - gins need to operate at full capacity to handle the workload efficiently.

One way to achieve this is by optimizing labor shifts to ensure continuous operation. Cross-training employees to handle various equipment and processes can prevent production slowdowns if specific operators are unavailable during critical periods.

Another essential tactic is using real-time monitoring systems to quickly spot and address issues before they disrupt production. Additionally, scheduling preventive maintenance ahead of the harvest season can help avoid unexpected equipment breakdowns, ensuring every operational hour is used effectively.

By focusing on these measures, gins can not only increase production rates but also minimize interruptions during the busiest times.

Reducing Downtime During Peak Demand

Minimizing downtime is just as important as increasing ginning rates when it comes to maintaining smooth operations during peak periods.

Cross-training is a powerful tool here as well. Operators who are well-versed in their equipment can quickly troubleshoot and resolve problems, preventing minor issues from escalating. Training multiple team members to handle critical machinery ensures operations don’t hinge on a single individual.

Real-time monitoring also plays a vital role, providing early warnings about potential performance issues. Responding promptly to these alerts can stop small problems from causing major delays.

Another practical step is maintaining a strategic spare parts inventory. Having commonly needed parts on hand means repairs can be made immediately, avoiding delays caused by waiting for deliveries. This is particularly crucial during peak spring periods when U.S. cotton exports are at their highest.

Using Net Weight Trading Practices

Beyond operational efficiency, adopting better trade practices can further streamline the ginning process. One such approach is net weight trading, which focuses on the actual fiber content of cotton, excluding packaging and debris.

This method reduces transportation costs by increasing the amount of fiber per load, cutting down on the number of trips required. In a market where the average U.S. upland farm price is projected at 62 cents per pound for 2025/26, these savings can make a significant difference.

Net weight trading also improves processing efficiency. By eliminating non-cotton materials, less energy and labor are needed for handling, which can significantly lower electricity usage - especially since material handling accounts for over half of the energy consumed during ginning.

To implement this system successfully, gins need accurate and standardized weighing equipment to ensure transparency and trust in transactions. While the initial investment in equipment and training may seem steep, the long-term savings in operational costs make it worthwhile.

Educating growers about the advantages of net weight trading is also essential. Many producers may be hesitant to move away from traditional methods, but clear communication about the potential for higher prices and cleaner cotton can ease this transition.

These coordinated efforts are particularly important given that U.S. cotton exports average 13.6 million bales per year, accounting for 85% of annual production. Efficient gin operations not only support domestic production but also help U.S. cotton remain competitive in global markets, especially as competition from countries like Brazil intensifies and global stocks rise.

sbb-itb-0e617ca

Technology and Infrastructure Investments for Seasonal Efficiency

When it comes to managing peak demand, smart investments in technology and infrastructure can make all the difference. For cotton gins, adopting advanced tools and systems has proven to be a game-changer, especially during the busiest times of the year. The consolidation of the industry has led to fewer but more advanced gins, capable of handling higher capacities with greater efficiency. These advancements pave the way for targeted upgrades that improve both equipment performance and energy efficiency.

Equipment Upgrades

Modern gins equipped with high-capacity saw gins can process significantly more seed cotton per hour compared to older systems, helping to alleviate bottlenecks during peak seasons.

The introduction of module builders has revolutionized the way cotton is handled. By allowing seed cotton to be stored safely, this technology separates harvesting from ginning. As a result, gins can extend their operational season and make better use of their capacity.

Automated machinery adds another layer of efficiency. These systems enable continuous operation, reducing the need for seasonal labor while increasing throughput. Larger gin stands and automation also help lower fixed costs per bale, making operations more cost-effective.

Paired with these equipment upgrades, energy-saving solutions are critical for reducing operational costs during high-demand periods.

Energy-Saving Solutions

Energy expenses can quickly pile up when gins operate at full capacity, cutting into profit margins. Implementing energy-efficient solutions can help offset these costs.

- Energy-efficient motors and variable frequency drives (VFDs) are key upgrades that can reduce energy consumption by as much as 25% during peak operations. Given that over half of a gin's electricity usage comes from material handling systems powered by large centrifugal fans, these improvements have a notable impact.

- Optimized air systems ensure that airflow for conveying and drying is properly calibrated, reducing electricity costs without compromising cotton quality.

- Dryer control systems help manage fuel usage. Advanced controls prevent unnecessary fuel consumption while maintaining ideal moisture levels. Insulating drying systems further minimizes heat loss and ensures consistent temperatures.

| Technology Upgrade | Primary Benefit | Energy Impact |

|---|---|---|

| Energy-efficient motors | Lower electricity usage | Up to 25% savings |

| Variable frequency drives | Optimized fan performance | Significant reduction in peak demand |

| Dryer control systems | Reduced fuel consumption | Lower heating costs |

| Optimized air systems | Efficient material handling | Decreased fan energy use |

To avoid disruptions, plan these upgrades during slower periods by analyzing past throughput and downtime data. Training staff on new systems ahead of the next peak season ensures that operations run smoothly when demand spikes.

Resources like cottongins.org can be invaluable for benchmarking technology investments. This directory offers insights into successful upgrades implemented by other operators in similar markets, helping identify the best options for specific conditions.

After implementing upgrades, it’s important to track key performance indicators like energy usage per bale, processing speed, and downtime. This data not only validates the investment but also highlights additional opportunities for improvement.

Regional Coordination and Long-Term Planning

While individual gins can manage small-scale challenges, addressing seasonal demand spikes effectively requires a broader, regional approach. By working together, stakeholders can share resources, reduce bottlenecks, and ensure smoother operations during peak periods.

The data backs this up. Export demand typically surges in March (12.5%), April (11.1%), and May (10.9%), creating a tight timeframe to move cotton through the supply chain efficiently. With U.S. cotton ending stocks for 2025/26 projected at 4.6 million bales - the highest since 2022/23 - the strain on individual gins could become overwhelming without coordinated efforts.

To tackle these challenges, regions focus on smarter trailer management and incentivizing growers to spread out demand.

Trailer Capacity Management

One of the biggest hurdles during peak harvest times is trailer shortages, which can delay harvesting and leave gins sitting idle. To combat this, many regions now use shared trailer pools. Instead of each gin managing its own limited fleet, gins work together to create a regional network that can allocate trailers to where they’re needed most. Real-time tracking technology ensures trailers are routed efficiently to meet demand.

Some areas have gone further, adopting scheduling systems that use live data to allocate trailers dynamically. For instance, if one gin experiences a surge in activity, trailers can be redirected from less active areas. This flexible approach minimizes downtime and ensures trailers are used as effectively as possible.

The technology driving these improvements includes GPS tracking on trailers and mobile apps that allow drivers to update their status in real time. This gives dispatchers the tools to make quick, informed decisions about where to send the next available trailer.

Grower Incentive Programs

For regional coordination to work, growers need to be on board - and that often means offering financial incentives. Successful programs reward growers for adjusting their harvesting and delivery schedules to help balance demand.

In the Mississippi Delta, for example, some gins offer per-bale rebates to growers who deliver outside peak harvest periods. These rebates, which typically range from $2 to $5 per bale, have reduced peak congestion by 10–15% while creating a steadier workload for participating gins. For larger operations, these savings can add up significantly, making it worthwhile to spread out deliveries.

Other regions have introduced bonus programs tied to digital scheduling tools. Growers who use these platforms to align their deliveries with gin capacity can earn extra payments or receive priority processing during busy times. These initiatives have reduced wait times and improved throughput for everyone involved.

The key to these programs is simplicity and transparency. Growers need clear terms - what they’ll earn and when they’ll be paid. Complex paperwork or unclear guidelines can discourage participation, even if the financial rewards are appealing.

Platforms like cottongins.org help support these efforts by connecting growers with nearby gins and providing insights into regional capacity. The site also allows growers to explore scheduling programs and find alternative processing options if their primary gin is overwhelmed. Features like adding new gin entries or exploring sponsorship opportunities further strengthen regional collaboration.

Tracking and Adjusting for Long-Term Success

To ensure ongoing success, regions must monitor critical metrics like average wait times, trailer utilization rates, and seasonal capacity distribution. By analyzing this data, stakeholders can identify recurring issues and refine their strategies. These insights also help justify infrastructure investments and demonstrate the benefits of continued collaboration.

Using cottongins.org to Find Regional Gin Capacity

During peak harvest season, finding the right cotton gin can mean the difference between smooth operations and costly delays. With fewer active gins in operation today, knowing their locations has become essential for effective planning and capacity management.

cottongins.org is a powerful directory designed to help growers and operators locate ginning facilities across all cotton-producing states. The platform organizes gins by state, making it easy to search for facilities in specific areas. Each listing includes the gin's name and full physical address, providing the critical details needed to contact facilities directly. This information is a valuable resource for growers mapping out their regional plans.

As the industry consolidates, the importance of tools like cottongins.org grows. Technological advancements and consolidation have led to fewer gins, but with much larger capacities. This often requires growers to transport cotton over longer distances, making it crucial to identify all viable gins within a reasonable hauling range.

Growers can use the directory strategically, especially in areas with multiple facilities, such as Lamesa, Texas. For example, growers can quickly locate gins like Arvana Gin Co, Punkin Center Gin, United Gin Co, and King Mesa Gin in the same city. Similarly, in Florence, Alabama, facilities like Oakland Gin Co and Scruggs & Vaden Gin Co are listed. Having access to multiple options allows growers to plan ahead and pivot quickly if their primary choice reaches capacity limits.

The platform also supports long-term planning by allowing users to submit new gin entries. This feature ensures the directory stays up-to-date as the industry evolves, reflecting new facilities or capacity expansions. By enabling the community to contribute, cottongins.org helps maintain accurate and current data, giving growers the tools they need for effective regional planning.

For gin operators, cottongins.org offers sponsorship opportunities to increase visibility during the busy harvest season. The Featured Sponsor plan ($400 per month) provides top placement on the site and includes two free sponsored posts annually. The Official Sponsor plan ($200 per month) offers main page footer placement and one free sponsored post with an annual commitment. These options help gins communicate their capacity and services when growers need them most.

The directory complements other industry resources by providing precise location data that supports quick decision-making. While government reports offer insights into regional processing volumes, cottongins.org delivers the specific addresses and contact details needed to secure ginning services without delay.

With immediate access to this comprehensive gin directory, growers can make faster, more informed decisions during peak periods. The platform not only simplifies capacity management but also fosters collaboration among regional facilities, helping to balance demand effectively across available resources.

Conclusion: Getting Ready for Seasonal Cotton Demand

Meeting the challenges of seasonal cotton demand requires careful planning, smart technology upgrades, and strong collaboration across regions. Over the years, the industry has seen a significant shift, with the number of cotton gins dropping from more than 2,254 in 1980 to just 509 active gins by 2022. This consolidation has pushed gins to process larger volumes within tighter harvest windows, making efficiency more critical than ever.

Preparation during the off-season is key to navigating these demands successfully. Gins that dedicate downtime to equipment maintenance, staff training, and organizing inventory are better equipped to handle the pressures of peak season. With energy costs accounting for about 25% of total variable costs in ginning operations, upgrading to energy-efficient equipment not only reduces expenses but also enhances long-term sustainability.

The adoption of the module system has allowed growers to access larger, more efficient gins, highlighting the importance of regional coordination. Gins working together to balance workloads can better manage the seasonal surge in demand.

Grower incentive programs have also emerged as a practical solution for easing operational bottlenecks. These programs encourage off-peak deliveries and optimize trailer usage, benefiting both growers and gins by reducing congestion and improving processing flow.

Investments in technology continue to shape the industry's progress, particularly in boosting energy efficiency and throughput. Gins that prioritize advanced control systems and strategic equipment upgrades can maximize ginning rates while minimizing downtime, ensuring they are ready to handle seasonal peaks effectively.

As the trend toward consolidation continues, the remaining gins face mounting pressure to operate at peak efficiency and foster regional partnerships. Those that focus on year-round preparation, invest in cutting-edge technology, and maintain strong relationships with growers and neighboring facilities will be best positioned to manage future seasonal demands.

Successfully navigating seasonal cotton demand comes down to preparation, efficiency, and the ability to adapt. With a solid foundation in place, operators can tackle the challenges of harvest season head-on.

FAQs

How do trailer shortages during peak cotton harvests affect gin operations, and what steps are being taken to address this challenge?

Trailer shortages during peak harvest times can seriously impact cotton processing. They can slow down intake, cause bottlenecks, and ultimately disrupt the flow of gin operations. The result? Longer wait times and a noticeable drop in productivity.

To tackle this challenge, many gins are taking proactive steps. These include improving logistics, increasing the number of trailers available, and collaborating with transportation providers to ensure deliveries stay on schedule. With better planning and stronger coordination, gins can handle the seasonal rush more efficiently and keep operations running smoothly.

How does regional coordination help manage seasonal cotton demand, and what are the benefits for growers?

Regional coordination is essential for keeping cotton gin operations running smoothly during peak demand periods. By synchronizing schedules and managing resources across different regions, it helps prevent bottlenecks and ensures a more seamless and efficient ginning process.

For growers, this teamwork translates into faster access to ginning services, reducing delays and helping them stay on track with their harvest schedules. This approach not only safeguards the quality of their cotton but also gives them the ability to plan their harvest activities more effectively during the hectic season.

What technological upgrades can help cotton gins operate more efficiently and cut energy costs during busy seasons?

To increase efficiency and cut down on energy expenses during peak seasons, cotton gins can take advantage of several technological advancements. Automation systems simplify processes and reduce the need for manual labor, making operations faster and more reliable. Using energy-efficient motors can significantly decrease power usage, helping to lower overall costs. Moreover, real-time monitoring tools give operators the ability to oversee performance and spot problems early, ensuring operations remain smooth and cost-effective.