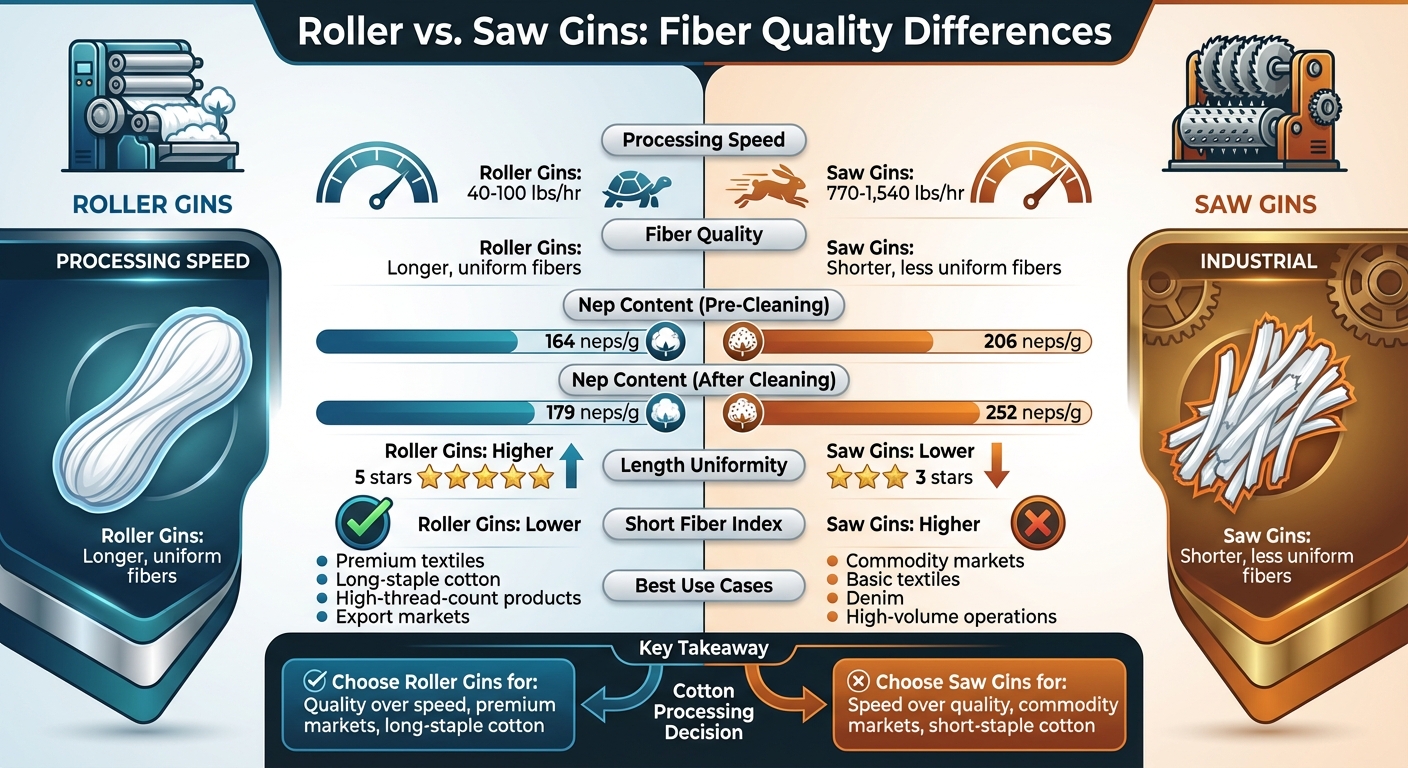

Choosing between roller and saw gins comes down to fiber quality versus processing speed. Roller gins are gentler on cotton, producing longer, more uniform fibers with fewer defects, making them ideal for premium markets. Saw gins, however, are faster and better at removing trash, suiting high-volume operations and commodity-grade cotton.

Key Takeaways:

- Roller Gins: Preserve fiber length and uniformity, resulting in higher-quality cotton with fewer neps (164 neps/g before cleaning vs. 206 for saw gins). Best for long-staple cotton and premium textiles but slower and costlier.

- Saw Gins: Prioritize speed, handling more cotton per hour but at the cost of shorter, less uniform fibers. Ideal for short-staple cotton and basic textiles.

Quick Comparison:

| Feature | Roller Gins | Saw Gins |

|---|---|---|

| Processing Speed | 40–100 lbs/hr | 770–1,540 lbs/hr |

| Fiber Quality | Longer, uniform | Shorter, less uniform |

| Nep Content (Pre-Cleaning) | 164 neps/g | 206 neps/g |

| Best Use | Premium textiles | Commodity markets |

Your choice depends on whether you value quality or speed. Roller gins excel for high-end products, while saw gins dominate high-volume, cost-sensitive operations.

Roller vs Saw Gins: Fiber Quality and Performance Comparison

Roller Gins: How They Work and Affect Fiber Quality

Roller Gin Operating Mechanism

Roller gins operate by using a rotating roller to gently pull cotton fibers through a narrow gap, leaving the larger seeds behind. This separation process happens at a controlled, steady pace. Modern high-speed roller gins (HSRG) have taken this technology a step further by incorporating multiple rollers and advanced engineering, enabling them to process cotton at rates closer to saw gins while still maintaining a gentle touch on the fibers. Unlike saw gins, which use aggressive saw teeth to separate fibers, roller gins handle each fiber individually, reducing stress and preserving fiber quality.

Fiber Quality Results from Roller Gins

The roller ginning process offers clear advantages in fiber quality. Studies show that upland cotton processed with roller gins produces fibers that are one staple length longer compared to saw-ginned cotton. Additionally, roller ginned cotton demonstrates better length uniformity. Research also highlights fewer neps - one study found 164 counts per gram before lint cleaning for roller-ginned cotton, compared to 206 for saw-ginned cotton - and a lower short fiber index. When it comes to yarn production, roller-ginned cotton excels: carded yarns are stronger, and combed yarns have a smoother appearance with fewer imperfections. High-speed roller ginning, when paired with optimized lint cleaning, can produce fibers that result in stronger and more stretchable yarns. However, there is a trade-off - roller-ginned cotton may contain more visible foreign matter, as the gentler cleaning process prioritizes fiber length over trash removal, leaving mills with additional cleaning work.

When to Use Roller Gins

The superior fiber quality achieved through roller ginning makes it ideal for specific cotton types and applications. Roller gins are particularly effective for long-staple upland and Pima cotton, where preserving fiber length significantly boosts market value. These gins are the go-to choice for producers aiming to supply premium, high-thread-count, and export-oriented textile products that demand long, even fibers with minimal hairiness. Products like fine-count yarns, combed yarns, and luxury knitwear benefit greatly from the enhanced fiber characteristics provided by roller ginning. While roller ginning operates more slowly and may involve higher per-unit costs, the improved fiber quality often justifies the expense. For more information on locating nearby facilities or optimizing lint-cleaning setups, visit cottongins.org.

Saw Gins: How They Work and Affect Fiber Quality

Saw Gin Operating Mechanism

While roller gins focus on gentle fiber handling, saw gins are all about speed, which creates notable differences in fiber quality. Saw gins use sharp-toothed saw blades to pull cotton fibers through narrow gaps between metal ribs, leaving the seeds behind. These rotating saw cylinders work quickly, separating fibers in bundles rather than individually. The saw teeth grab multiple fibers at once, pulling them away from the seeds with an emphasis on speed and efficiency rather than preserving the delicate structure of the fibers. This makes saw gins a staple for processing short-staple upland cotton in the U.S., where high processing speed often outweighs the need for premium fiber quality. These operational priorities lead to distinct outcomes in fiber characteristics.

Fiber Quality Results from Saw Gins

The aggressive nature of saw ginning comes at a cost to fiber quality. Studies reveal that saw-ginned cotton contains 206 neps per gram before lint cleaning, which increases to 252 neps per gram after cleaning - a significant jump compared to the 164-179 neps per gram typically found in roller-ginned cotton. The saw teeth often break fibers during processing, leading to shorter staple lengths, higher short fiber content, and reduced uniformity compared to roller-ginned cotton. When this cotton is spun into yarn, the results often include more imperfections and increased hairiness, making it less ideal for high-quality textiles.

That said, saw gins have a clear advantage when it comes to removing trash and foreign material. Their aggressive cleaning action produces cleaner lint that requires less processing later on. However, pairing saw gins with additional lint cleaners can further increase nep content during cleaning.

When to Use Saw Gins

The choice to use a saw gin often boils down to the type of cotton being processed and the scale of operations. Saw gins are best suited for high-volume processing of short-staple upland cotton, where speed and throughput are critical for profitability. They are an economical option for producers aiming at commodity-grade cotton used in basic textiles and denim, where fiber length and uniformity are less important.

For growers in areas where roller gins are scarce or where the premium for higher-quality fiber doesn’t justify slower processing speeds, saw ginning offers a practical solution. With well-established technology and a strong support network across cotton-growing regions, saw gins remain a reliable choice. To locate facilities near you, visit cottongins.org.

Direct Comparison of Fiber Quality Metrics

Fiber Quality Metrics Explained

To understand how roller and saw gins impact cotton, it’s essential to break down the main fiber quality metrics. Take staple length, for example - this refers to the average length of individual fibers, typically measured in 32nds of an inch in the U.S. Longer fibers are generally preferred because they produce stronger, smoother yarns. Another key metric, length uniformity, measures how consistent fiber lengths are within a sample. Higher uniformity means better spinning performance and fewer weak spots in the finished yarn.

Then there’s nep count, which tracks the number of small, tangled fiber knots per gram of cotton. The short fiber index is another critical measure, indicating the percentage of fibers below a specific length threshold, which can affect both the strength and appearance of the yarn. Micronaire values, which reflect fiber fineness and maturity, are also vital. Most mills favor values between 3.5 and 4.9. Lastly, fiber strength (or tenacity) measures how much force a fiber can endure before breaking. While fiber strength doesn’t vary much between ginning methods, the other metrics show notable differences. Below, we’ll compare how roller and saw gins perform across these metrics.

Roller vs. Saw Gins: Performance Data

When it comes to upland cotton, roller and saw gins deliver noticeably different results. For example, a USDA-aligned study revealed that roller gins produced 164 neps per gram before lint cleaning, compared to 206 neps per gram from saw gins - about 25% more. After lint cleaning, the gap widened: roller-ginned cotton reached 179 neps per gram, while saw-ginned cotton climbed to 252 neps per gram due to the more aggressive cleaning processes used with saw gins.

Roller ginning also outshines saw ginning in several other areas. It yields longer, more uniform fibers and a lower short fiber index. While fiber strength at the individual fiber level shows minimal differences between the two methods, the benefits of roller ginning become more apparent at the yarn stage. Studies confirm that carded yarns made from roller-ginned cotton are stronger than those produced from saw-ginned cotton.

Here’s a quick summary of the key performance metrics:

| Metric | Roller Ginning | Saw Ginning |

|---|---|---|

| Nep Content (before cleaning) | 164 neps/g | 206 neps/g |

| Nep Content (after cleaning) | 179 neps/g | 252 neps/g |

| Micronaire | 4.38 | 4.23 |

| Length Uniformity | Higher | Lower |

| Short Fiber Index | Lower | Higher |

| Fiber Strength (tenacity) | Similar | Similar |

However, roller-ginned cotton does come with a trade-off. Because it often undergoes gentler or fewer cleaning processes, it can contain more visible foreign matter. That said, it typically has fewer seed-coat fragments and less mechanical damage overall. While this might shift some cleaning responsibilities to the mill, many buyers see this as a worthwhile exchange for the superior fiber length and lower nep counts that roller ginning provides. These differences can play a significant role in choosing the right ginning method for your operation.

sbb-itb-0e617ca

Choosing the Right Gin for Your Operation

Factors That Determine Gin Selection

When deciding on the best gin for your cotton, several factors come into play, especially when considering fiber quality and your target market.

First, think about the cotton variety you're growing. For Pima, extra-long staple (ELS), or long-staple upland cotton - typically destined for premium yarn markets - roller ginning is the go-to choice. It’s designed to protect fiber length and reduce issues like short fibers and neps. On the other hand, if you're working with conventional short- to medium-staple upland cotton, saw gins remain the industry standard.

Your target market also matters. Mills producing high-end fabrics, such as ring-spun or combed yarns, often pay more for the longer, more uniform fibers that roller gins produce. For instance, studies on Pima S-1 cotton revealed that roller-ginned fibers resulted in stronger carded yarns and better-looking combed yarns compared to saw-ginned fibers. However, if your buyers prioritize visual cleanliness over fiber length - common in open-end yarn production - saw ginning may be the better fit due to its faster processing and aggressive cleaning capabilities.

Volume and cost are equally important. While roller ginning typically increases the cost per pound, the enhanced fiber quality can justify higher lint prices. High-speed roller gins (HSRG) have made strides in narrowing the speed gap with saw gins, while still delivering better fiber length and fewer neps. This makes HSRG a strong option when both quality and volume are priorities. To make an informed decision, consider running side-by-side tests: gin a representative cotton lot at both a roller gin and a saw gin, then compare High Volume Instrument (HVI) data - such as fiber length, uniformity, short fiber index, neps, trash content, and micronaire - along with any price differences your buyers are willing to offer.

These considerations help lay the groundwork for understanding the balance between speed and quality.

Speed vs. Fiber Quality Trade-offs

One of the most critical decisions is balancing processing speed with fiber quality. Saw gins are faster but tend to damage fibers, while roller gins preserve fiber integrity at the expense of slower throughput. Research on upland cotton from the Southern High Plains found that high-speed roller ginning improved fiber length and uniformity to the extent of being "about one staple length longer" than saw-ginned cotton from the same batch. However, this improvement comes with slower processing speeds compared to traditional saw gins.

If your priority is maximizing throughput and your market doesn’t reward higher fiber quality, saw ginning’s speed advantage might make more sense economically. But if your cotton can fetch premiums for length and uniformity - particularly with newer upland varieties capable of producing higher-quality fibers - roller ginning’s slower pace can pay off through better market prices. In fact, more growers in regions like the Southern High Plains are adopting high-speed roller gins, recognizing that the investment in quality-preserving equipment can lead to better returns in length-sensitive markets.

For help finding gins in your area and understanding the available ginning technologies, tools like cottongins.org offer a detailed directory of U.S. cotton gins by county and state. This resource can help you align your production needs with local ginning options.

Cotton Picking and Cotton Ginning process: Saw Ginning and Roller Ginning

Conclusion

Deciding between roller and saw gins ultimately comes down to prioritizing either fiber quality or processing speed. Roller gins excel at preserving fiber integrity, producing cotton with longer fibers, fewer neps, better length uniformity, and a lower short fiber index. These qualities make roller ginning particularly appealing for premium markets where superior fiber performance fetches higher prices.

On the other hand, saw gins are the backbone of conventional upland cotton production. They deliver faster processing and efficient cleaning, making them ideal for commodity markets. Saw gins are especially useful when visual cleanliness is more critical than fiber length, such as in open-end yarn manufacturing. However, recent advancements are changing the game.

New high-speed roller ginning technologies have significantly reduced the speed gap between roller and saw gins, all while maintaining the fiber quality advantages that justify higher market prices. For growers in regions like the Southern High Plains, working with newer upland cotton varieties, this technology offers a practical compromise - preserving fiber quality while boosting processing efficiency.

Studies show that roller-ginned cotton consistently produces combed yarns with better appearance and carded yarns with much higher strength compared to saw-ginned cotton. When your target market values these enhanced qualities enough to pay a premium, the slower processing speeds of roller gins become a worthwhile trade-off. Choosing the right ginning technology can directly impact your market value, making it essential to align your ginning method with your production goals. For help finding gins equipped with the latest technology tailored to your cotton variety and market needs, visit cottongins.org for a detailed directory of U.S. cotton gins by county and state.

FAQs

How do roller gins and saw gins differ in terms of fiber quality?

Roller gins and saw gins have distinct impacts on cotton fiber quality. Roller gins handle the fibers more gently, maintaining their length and structure. This gentler process results in cotton of higher quality with minimal damage. On the other hand, saw gins work faster and are more efficient but often lead to more fiber breakage and contamination during processing.

The choice between these two ginning methods largely depends on the type of cotton and the intended use. Roller gins are the go-to option for processing finer, longer-staple cottons, while saw gins are favored for shorter-staple cottons, where speed and efficiency take precedence.

What are the advantages of using roller ginning instead of saw ginning?

Roller ginning stands out when fiber quality takes center stage. It's particularly well-suited for long-staple cotton varieties, as it carefully processes the cotton to minimize damage and retain its natural properties.

Farmers and producers often turn to roller gins for premium cotton, where preserving strength, length, and overall quality is non-negotiable. While it may not match the speed of saw ginning, the exceptional fiber quality it ensures makes it the go-to option for high-value cotton.

What are the differences between high-speed roller ginning and traditional saw ginning in efficiency and fiber quality?

High-speed roller ginning offers a more efficient way to process cotton while preserving fiber quality. This method is gentler on the cotton, helping to retain the fibers' length and strength - qualities that are especially important for producing high-end cotton products.

On the other hand, saw ginning is designed for speed and handling larger quantities. However, its faster process can be rougher on the fibers, which might lead to some damage. Both techniques have their strengths, and the choice between them often depends on the type of cotton being processed and its intended use.