Transporting raw cotton is harder than it looks. The process faces major hurdles like weather risks, poor infrastructure, and rising costs. Without proper handling, cotton quality can degrade, leading to losses. Here's what you need to know:

- Weather Risks: Rain, humidity, and extreme heat damage fibers.

- Infrastructure Issues: Poor rural roads and long distances slow delivery.

- Handling Problems: Improper loading and storage lead to contamination and damage.

- Solutions: Use climate-controlled storage, specialized equipment, and better route planning.

Efficient transport is critical to maintaining cotton quality and ensuring smooth supply chain operations.

Attacking Transportation Challenges in the Retail Supply Chain

Main Challenges in Raw Cotton Transport

Effects of Weather Conditions

Weather plays a huge role in maintaining cotton quality during transport. Extreme temperatures, heavy rainfall, and high humidity can cause serious damage. For instance, the devastating floods in Pakistan during 2010-2011 caused €35 billion in losses to cotton crops [2].

Here’s how different weather conditions can impact cotton:

| Weather Factor | Impact on Cotton | Risk Level |

|---|---|---|

| Rain & Humidity | Fiber degradation, mold growth | High |

| Extreme Heat | Fiber weakening, brittleness | Medium |

| Temperature Fluctuations | Quality inconsistency | High |

Road and Infrastructure Issues

In areas like Texas, the shift from rail to road transport has put extra strain on road networks, leading to delays and inefficiencies [1].

Some of the biggest road and infrastructure challenges include:

- Poor rural road conditions and limited access to proper loading facilities.

- Lack of sufficient storage options and long distances between farms and processing facilities.

These issues complicate the handling of cotton modules, making it harder to ensure quality during transport.

Challenges with Cotton Module Handling

Handling cotton modules is another major hurdle. It requires extra care to avoid damage and maintain quality [1].

Here are some common problems and potential solutions:

| Handling Aspect | Challenge | Solution |

|---|---|---|

| Loading & Transit | Module compression, shifting during transport | Specialized lifting equipment, fastening systems |

| Quality Preservation | Fiber contamination, moisture variation | Covered vehicles, protected storage |

To tackle these challenges, cotton transport needs a mix of weather protection, better infrastructure, and tailored handling methods to ensure the cotton stays in good condition from the field to the processing facility.

Solutions for Raw Cotton Transport Challenges

Use of Specialized Transport Equipment

Transporting raw cotton safely requires vehicles and tools designed specifically for the job. These vehicles come with features like moisture barriers and ventilation systems to protect the fibers from damage.

| Equipment Type | Features and Purpose |

|---|---|

| Sealed Containers | Protect against moisture and maintain climate control to prevent water damage. |

| Covered Trailers | Equipped with tarps and reinforced walls to shield cotton from weather and debris. |

| Flatbeds with Custom Covers | Offer flexible loading and secure protection with tailored covers and fastening systems. |

While this equipment safeguards the cotton, ensuring timely delivery also depends on smart route planning.

Improving Transport Routes

Good route planning is essential for efficient cotton delivery. Modern logistics rely on advanced tools to streamline delivery paths and avoid weather-related delays.

Using real-time tracking, transport companies can:

- Keep an eye on weather and traffic conditions.

- Adjust routes on the fly to avoid disruptions.

- Coordinate deliveries to ensure on-time arrivals.

For example, the Texas mini-landbridge service integrates rail and truck transport, speeding up transit and making deliveries more reliable [1]. This kind of hybrid approach has proven effective in cutting down transit times and improving consistency.

But equipment and routes aren’t the only factors - having skilled logistics teams is equally important.

Role of Dedicated Logistics Teams

Specialized logistics teams ensure smooth cotton transport by managing schedules, responding to demand, and maintaining quality standards. Their efforts help minimize delays and reduce damage during transit.

| Team Function | Impact |

|---|---|

| Schedule Management | Cuts down on wait times at facilities. |

| Demand Response | Makes better use of resources and adjusts to changing requirements. |

| Quality Control | Lowers the risk of damage to cotton during transport. |

Some large milling firms have implemented centralized warehousing systems managed by these teams, resulting in smoother operations across the supply chain [1]. Additionally, digital platforms now connect farmers, transporters, and buyers, enabling quicker decisions and faster responses to any issues. This tech-driven approach enhances team coordination and overall efficiency.

sbb-itb-0e617ca

Future Outlook for Raw Cotton Transport

Responding to Climate Change

Rising temperatures and unpredictable weather are creating challenges for transporting raw cotton. By 2040, many cotton-growing regions are expected to face temperatures above 40°C, making it harder to maintain fiber quality during shipping [2]. Transport companies are stepping up with strategies to ensure cotton stays in good condition while reaching its destination on time.

| Climate Challenge | Proposed Strategy |

|---|---|

| Extreme Weather Events | Early warning systems and backup routes |

| Environmental Risks | Climate-controlled storage and shipping |

| Infrastructure Vulnerability | Diversified routes and contingency plans |

To tackle these issues, companies are investing in weather-resistant storage and flexible shipping routes. While these measures address immediate concerns, technology plays a key role in making operations even more efficient and reliable.

Using Technology for Better Efficiency

Technology is helping the cotton transport industry handle climate-related disruptions while boosting overall efficiency. Modern logistics platforms bring together data from various sources to streamline operations and safeguard cotton quality.

Some standout innovations include:

- Intelligent Transport Systems: These systems combine route optimization with real-time monitoring, ensuring deliveries are both safe and efficient, all while keeping cotton in optimal conditions.

- Forecasting Tools: Using data-driven insights, these tools predict potential disruptions and suggest ways to avoid them.

By analyzing past weather patterns and shipping data, these technologies help logistics teams:

- Spot and fix potential bottlenecks

- Fine-tune loading schedules

- Cut operational costs

- Lower risks tied to extreme weather

With these tools in place, the cotton transport industry is building a system that can adapt to environmental changes while keeping the product in top shape.

Conclusion and Resources

Challenges and Their Solutions

Transporting raw cotton comes with its own set of difficulties, but targeted solutions can help overcome these problems. By integrating technology and logistics expertise, the process becomes smoother and more efficient.

| Challenge | Solution | Impact |

|---|---|---|

| Weather Exposure | Climate-controlled storage and monitoring | Maintains fiber quality by controlling temperature and humidity. |

| Infrastructure Issues | Route optimization systems for rural roads | Cuts down on delays and minimizes damage caused by poor infrastructure. |

| Module Handling | Specialized transport equipment with securing systems | Reduces material loss and prevents damage during loading and unloading. |

Using advanced transport systems not only improves delivery times but also ensures the cotton remains in good condition. While these methods address many logistical hurdles, tapping into industry-specific tools and platforms can take efficiency to the next level.

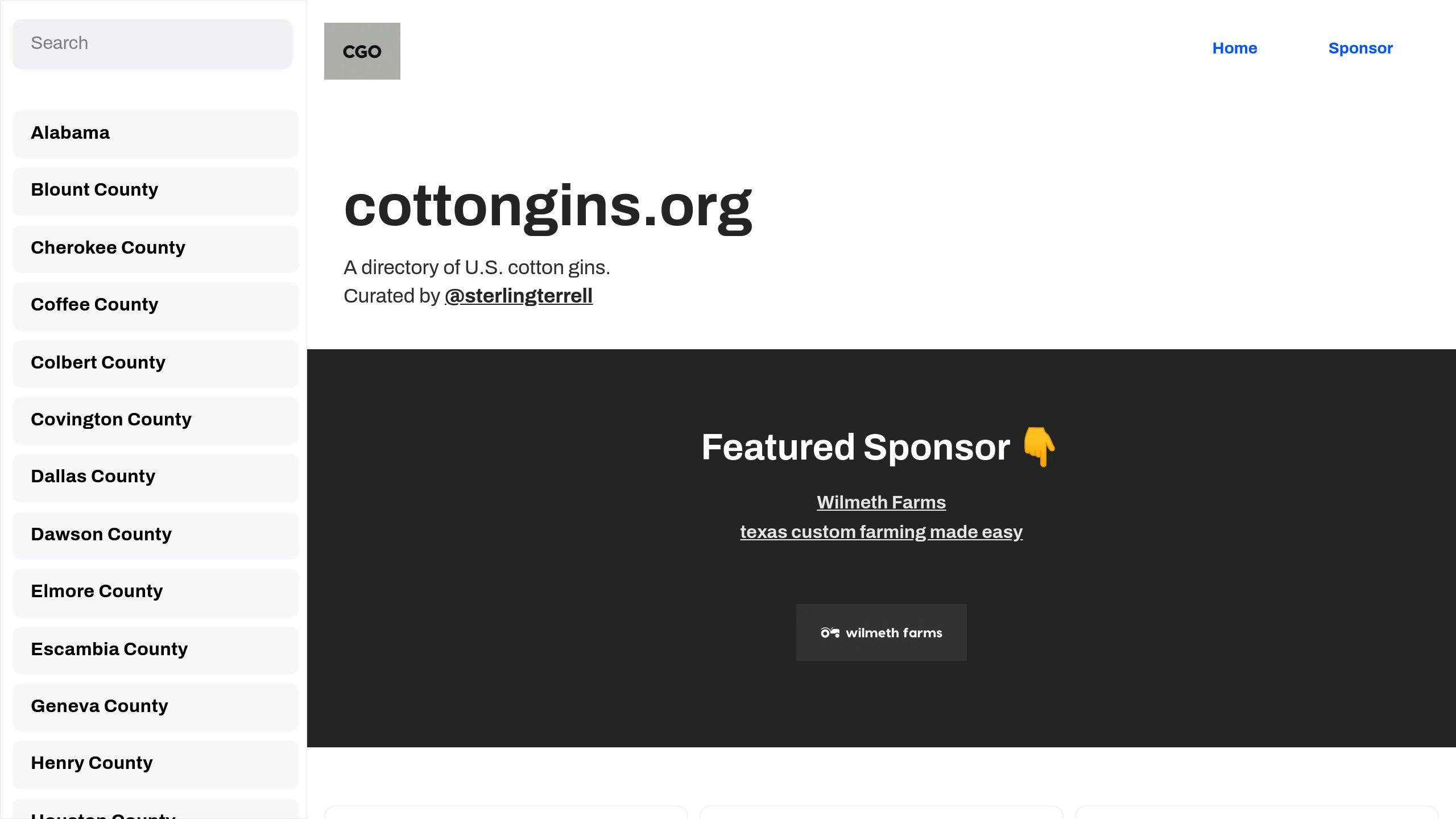

Industry Resources: cottongins.org

If you're looking to streamline cotton transport operations, resources like cottongins.org can be incredibly helpful. This platform offers a directory of U.S. cotton gins, making it easier to plan routes and connect with facilities. Here's how it can assist:

- Find nearby cotton gins quickly.

- Access detailed facility information for better route planning.

- Keep logistics data accurate and up-to-date.

Combining modern logistics tools with reliable industry resources ensures the cotton transport sector is prepared to tackle future challenges while staying efficient. Staying informed and connected is key to adapting to changes and maintaining smooth operations.

FAQs

What is the best way to transport cotton?

Transporting cotton efficiently requires a mix of proper equipment and established practices. Using covered vehicles, secure fastening methods, climate-controlled storage, and well-planned logistics are crucial to maintaining cotton's quality during transit.

Here’s a quick breakdown:

| Transport Element | Best Practice | Key Benefit |

|---|---|---|

| Equipment Type | Covered vans or flatbed trailers | Shields cotton from weather |

| Securing Method | Steel straps or wire ties | Keeps bales tightly compressed |

| Environmental Control | Climate-monitored storage | Protects against quality loss |

| Route Planning | Optimized routing | Minimizes transit time and damage |

Covered vehicles protect cotton from rain, wind, and other weather conditions, while secure fastening methods, like steel straps, ensure the bales stay compressed. Climate-controlled storage is key to avoiding fiber damage caused by extreme temperatures or humidity. Proper route planning not only shortens transit time but also reduces the risk of damage during transport.

Logistics teams that specialize in cotton transport play a critical role. They understand the unique requirements and are prepared to handle challenges quickly to ensure smooth delivery [1].