Rain can wreak havoc on cotton ginning. It delays harvests, increases costs, and lowers cotton quality. Here’s what you need to know:

- Moisture Problems: Cotton gins work best with 5-7% moisture. Rain-soaked cotton complicates processing, damages equipment, and weakens fiber quality.

- Quality Issues: Rain exposure leads to discoloration, mold, and weaker fibers, reducing market value.

- Higher Costs: Delays cause increased labor, energy use, and storage needs.

Solutions include: using weather forecasting tools, advanced storage systems, and automated moisture control technologies. Collaboration among farmers and gin operators, along with resources like cottongins.org, can also help maintain efficiency during wet conditions.

Read on to learn how to manage these challenges effectively.

Problems from Rain Delays

Moisture and Humidity Issues

Too much moisture makes separating seeds from fibers more difficult, forcing ginning machines to work harder and use more energy. The ideal moisture range is 5%-7%; anything above that can cause inefficiencies and even damage equipment [1][4].

Cotton Quality Problems

Rain exposure can lead to mold, discoloration, and weaker fibers, all of which lower the market value of cotton and increase the chances of rejection by textile mills [2][3].

Some key quality issues include:

- Fiber discoloration

- Mold spots

- Weakened fiber strength

- Uneven fiber length distribution

Delays and Higher Costs

In areas like the Mid-South, prolonged rainy periods have caused yield losses due to problems like boll rot and hardlock [2][3].

| Cost Factor | Impact |

|---|---|

| Energy Usage | More power needed for extended processing |

| Labor Costs | Longer work hours to clear backlogs |

| Storage Requirements | Extra space for storing delayed modules |

| Quality Control | Additional resources for monitoring moisture |

"The impact of weather on cotton gin efficiency in regions like Lubbock underscores the importance of proactive planning and adaptation strategies." [1]

Rain delays drive up costs through increased energy use, longer work hours, and added storage demands, all while putting extra pressure on quality control efforts. These issues highlight the importance of planning ahead to reduce the effects of rain and keep operations running smoothly.

Solutions for Rain Delays

Planning and Weather Monitoring

Cotton gin operators are increasingly relying on modern weather forecasting tools to reduce rain-related disruptions. In the Lubbock region, a study showed that strategic weather monitoring cut harvesting delays by 30% and reduced cotton quality loss by 25% [1]. These results were achieved by adjusting harvesting schedules based on detailed forecasts and focusing on areas less prone to rainfall.

Real-time humidity tracking also allows facilities to make quick adjustments during processing. While these tools help manage rain-related challenges, proper storage and processing solutions are just as important.

Improved Cotton Storage

Modern storage facilities are designed to protect cotton from moisture damage during wet periods. Features like climate control, advanced ventilation, waterproof roofing, and polyethylene covers play a key role in keeping cotton safe. Polyethylene covers, in particular, offer added protection for outdoor storage, especially during extended rainy periods.

Effective storage methods are just one part of the equation. New technologies are also helping to make cotton ginning operations more efficient during challenging weather.

Leveraging New Technology

Technological advancements are reshaping how moisture is managed during cotton ginning. For example, a cotton gin in the Mid-South region introduced automated moisture control and lint restoration systems, cutting processing time by 20% and improving fiber quality by 15% [1].

In drier climates, moisture restoration hoppers help maintain the ideal moisture levels in seed cotton, boosting ginning efficiency [4]. These systems ensure that cotton isn't over-dried or exposed to excessive moisture.

For operators thinking about upgrading their technology, it's important to consider:

- Compatibility with current equipment

- Training needs for staff

- Availability of technical support

- Performance in various weather conditions

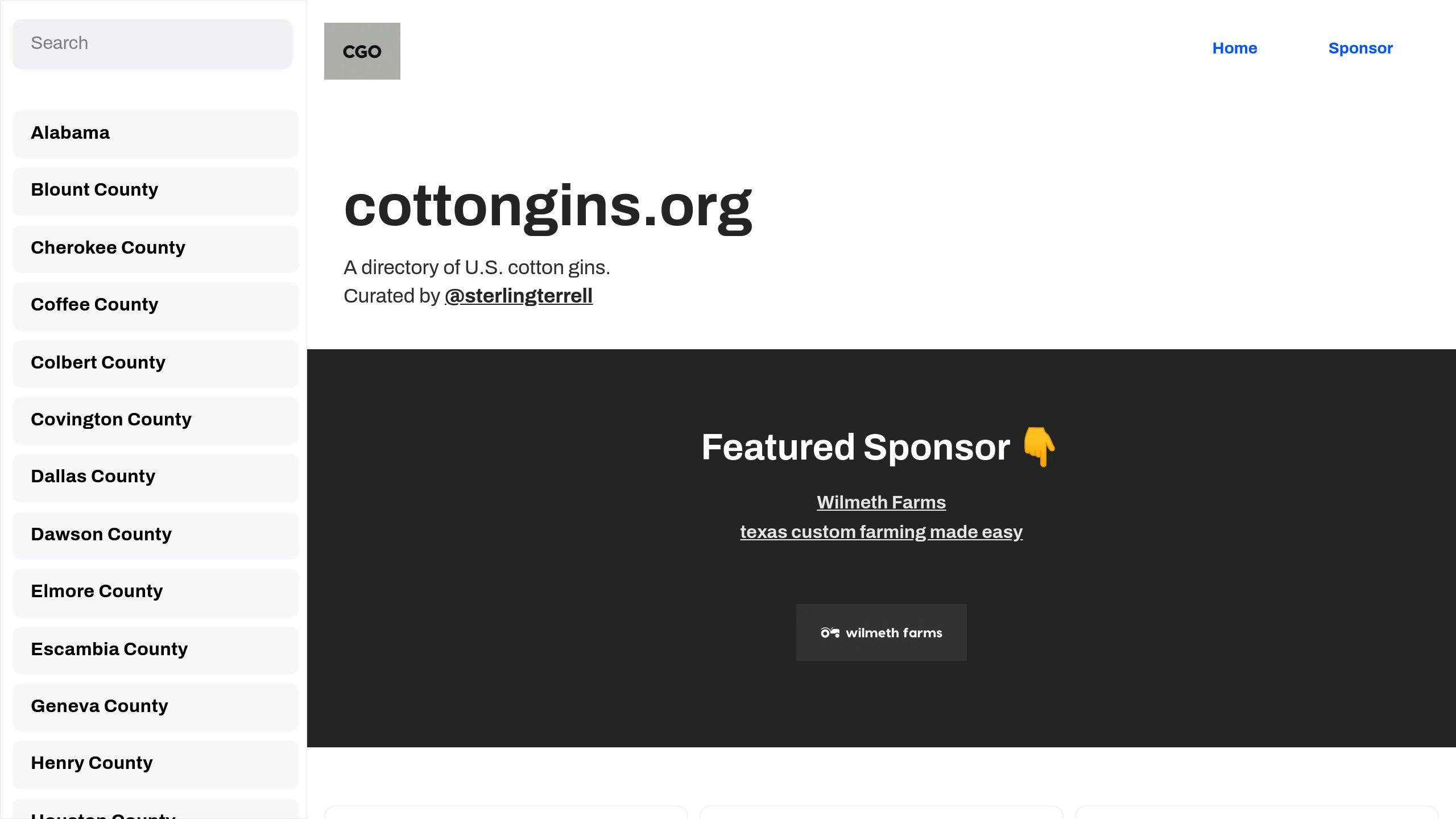

Resources like cottongins.org can connect operators to nearby facilities and provide guidance on adopting advanced technologies that improve efficiency during difficult weather conditions.

Cotton harvest: trash and moisture

sbb-itb-0e617ca

Using Industry Resources

Industry resources and partnerships are key to navigating weather-related disruptions, complementing the technological and operational strategies already discussed.

cottongins.org: A Resource for Cotton Professionals

Cottongins.org serves as a directory of U.S. cotton gins, helping operators locate alternative facilities during rain delays and connect with others in the industry to find solutions. This platform supports quick decision-making during weather challenges, ensuring operations can continue even when primary facilities are impacted.

Collaboration in Action

While platforms like cottongins.org provide helpful tools, effective management of rain delays depends heavily on collaboration among farmers, gin operators, and industry groups. Working together allows for resource sharing, better scheduling, and quicker responses during wet conditions.

| Partnership Benefits | How They Help Manage Rain Delays |

|---|---|

| Access to Shared Resources | Use of additional drying equipment and storage. |

| Coordinated Schedules | Improved processing times aligned with weather. |

| Shared Expertise | Better moisture management techniques. |

| Emergency Backup | Quick access to alternative processing options. |

In the Mid-South, gin operators have created networks to share equipment and storage during weather emergencies. This approach ensures that processing can continue even when individual facilities are forced to shut down [1].

Conclusion: Managing Rain Delays in Cotton Ginning

Managing moisture effectively is key to reducing rain delays and protecting cotton quality. This challenge requires precise strategies and practical solutions across the cotton ginning industry.

In dry areas, moisture restoration hoppers help maintain ideal moisture levels (5-7%), ensuring fiber quality and cutting equipment wear by up to 40% [4]. These tools highlight how targeted approaches can boost efficiency.

Using weather forecasting tools and flexible scheduling, operators can better prepare for and handle rain-related disruptions. Paired with shared industry resources, these strategies create a stronger system for dealing with weather challenges.

Platforms like cottongins.org allow operators to find alternative ginning facilities and share resources during disruptions. This collaborative approach has been especially useful in areas like the Mid-South, where teamwork has kept operations running smoothly despite tough weather [1].

Data analytics further supports decision-making during adverse weather, complementing advanced drying systems and moisture monitoring. Together, these technologies, industry collaboration, and careful planning provide the foundation for managing rain delays effectively.

FAQs

Does rain affect cotton?

Rain has a noticeable impact on cotton quality and ginning efficiency. Too much moisture can harm fiber quality - causing discoloration and weakening its strength - while also slowing down processing and putting extra strain on equipment. Here's a quick breakdown:

| Impact Area | Effect of Rain |

|---|---|

| Fiber Quality | Lower color grade and weaker fiber strength |

| Processing Time | 30-40% longer ginning duration |

| Equipment Wear | Up to 40% more hydraulic pressure required |

| Moisture Content | Disrupts the ideal range (which is 5-7%) |

The situation worsens during prolonged rainfall. To keep things running smoothly, lint moisture levels shouldn't exceed 7.5%. This highlights how important it is to manage moisture effectively.

To handle these challenges, solutions like better storage options, advanced drying systems, and collaboration within the industry are key. Platforms such as cottongins.org can support facilities in maintaining efficiency even under tough weather conditions.