Cotton gins are high-risk environments where flammable chemicals like propane and ammonia mix with combustible cotton fibers. Without proper storage, even a small spark can cause catastrophic fires. Here's what you need to know:

- Use Approved Containers: Store flammable liquids in FM-approved or UL-listed safety cans with flame arresters.

- Follow OSHA Guidelines: Limit flammable liquid storage to 25 gallons outside safety cabinets. Cabinets can hold up to 60 gallons for Categories 1–3 liquids.

- Separate Chemicals: Keep flammables away from cotton dust, oxidizers, and acids to prevent dangerous reactions.

- Ensure Ventilation: Maintain airflow to prevent vapor buildup and reduce fire hazards.

- Train Employees: Provide regular training on handling, storage, and emergency response.

These steps reduce fire risks, improve compliance with OSHA and NFPA regulations, and protect workers. Let’s dive deeper into the details.

OSHA Guidelines for Handling Flammable and Combustible Liquids | Safety Training Course

Regulatory Standards and Compliance

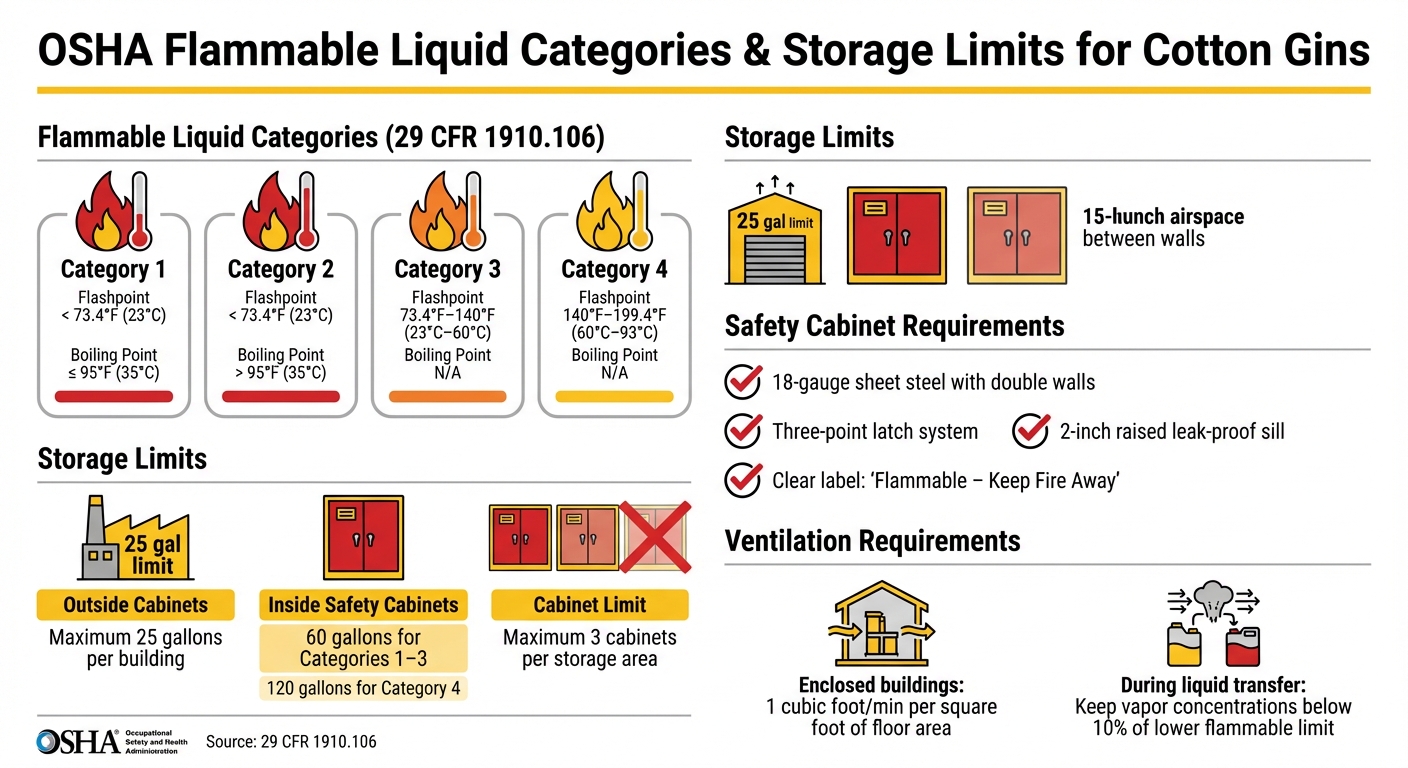

OSHA Flammable Liquid Categories and Storage Limits for Cotton Gins

Cotton gin operators are required to follow federal regulations when storing flammable chemicals. Agencies like the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) establish the foundational rules, while the National Fire Protection Association (NFPA) provides additional technical guidelines. Adhering to these standards not only reduces the risk of violations but also ensures worker safety. Below is an overview of the OSHA, EPA, and NFPA requirements.

OSHA and EPA Requirements

OSHA's 29 CFR 1910.106 is the key regulation for storing and handling flammable liquids. This standard classifies liquids based on their flashpoints and boiling points:

- Category 1: Flashpoint below 73.4°F (23°C) and boiling point at or below 95°F (35°C).

- Category 2: Flashpoint below 73.4°F (23°C) but boiling point above 95°F (35°C).

- Category 3: Flashpoint between 73.4°F (23°C) and 140°F (60°C).

- Category 4: Flashpoint between 140°F (60°C) and 199.4°F (93°C).

| Liquid Category | Flashpoint | Boiling Point |

|---|---|---|

| Category 1 | < 73.4°F (23°C) | ≤ 95°F (35°C) |

| Category 2 | < 73.4°F (23°C) | > 95°F (35°C) |

| Category 3 | ≥ 73.4°F (23°C) and ≤ 140°F (60°C) | N/A |

| Category 4 | > 140°F (60°C) and ≤ 199.4°F (93°C) | N/A |

Source: 29 CFR 1910.106(a)

Storage limits are tightly regulated. If flammable liquids are stored outside approved cabinets, only 25 gallons may be kept within a building. For larger quantities, operators must use cabinets made from 1-inch thick plywood or approved metal, clearly marked with "Flammable - Keep Away from Open Flames." These cabinets can hold up to 60 gallons for Categories 1–3 and 120 gallons for Category 4. However, no more than three such cabinets are allowed in a single area.

OSHA 29 CFR 1910.119 outlines Process Safety Management (PSM) requirements for facilities handling large quantities of hazardous chemicals. If a cotton gin stores 10,000 pounds or more of flammable liquids under 73.4°F (23°C), it must implement comprehensive safety measures, including hazard analyses, mechanical integrity checks, and employee training every three years. However, this rule excludes hydrocarbon fuels like propane used solely for workplace consumption unless part of a larger process.

The EPA's Spill Prevention, Control, and Countermeasure (SPCC) rule applies to facilities storing oil or fuel above specific thresholds. Cotton gins with significant amounts of propane, ammonia, or ammonium nitrate may also need to comply with the Department of Homeland Security's Chemical Facility Anti-Terrorism Standards (CFATS).

Proper ventilation is another critical requirement. Enclosed buildings must maintain airflow of at least 1 cubic foot per minute per square foot of floor area. During liquid transfer, ventilation must ensure vapor concentrations stay below 10% of the lower flammable limit .

NFPA Guidelines

While OSHA and EPA lay the groundwork, NFPA guidelines add specialized safety measures. NFPA 30, the Flammable and Combustible Liquids Code, specifies emergency venting and safety devices for portable tanks. Tanks under 660 gallons must follow Chapters III and IV, while larger tanks adhere to Chapters II and III. These measures aim to prevent tank ruptures during a fire.

Since 2000, NFPA has classified cotton fibers as "combustible", which introduces specific fire code requirements. For instance, flammable liquid storage rooms must meet fire-resistive ratings outlined in NFPA 251. Rooms within 100 feet of a workstation must have at least a one-hour fire resistance rating, an automatic fire suppression system, or an early-warning fire detection device.

Windows and doors in chemical storage areas must follow NFPA 80 standards for fire protection. Self-closing fire doors should meet Class E or F opening standards, and liquid-tight sills at least 4 inches high are required to contain spills.

NFPA 704 labels, commonly known as "fire diamonds", provide quick hazard information for stored chemicals. These labels complement OSHA's Hazard Communication Standard (HCS) labeling. Additionally, any tank vehicles transporting or dispensing flammable liquids within a facility must comply with NFPA 385 standards.

Fire safety equipment is essential. Place six B, C-rated fire extinguishers within 75 feet of pumps, dispensers, or lubrication rooms. "No Smoking" and "No Open Flame" signs must be clearly posted wherever flammable liquids are handled or stored. Emergency shutoff switches should be visible and easily accessible near dispensing systems .

Storage Best Practices

Storing flammable chemicals safely starts with choosing the right containers and cabinets. For quantities up to 5 gallons, FM-approved or UL-listed safety cans are a must. These cans come equipped with spring-loaded spout caps and built-in flame arresters, offering an added layer of safety. For amounts under 1 gallon, the original shipping container is acceptable.

Approved metal storage cabinets should be made from at least 18-gauge sheet steel, with double walls separated by a 1.5-inch airspace. They should also feature riveted or welded joints, a three-point latch, and a leak-proof sill raised at least 2 inches above the bottom. Wooden cabinets are another option, provided they are constructed from 1-inch thick exterior-grade plywood with rabbeted joints fastened by wood screws and coated with fire-retardant paint. All cabinets must have clear labeling stating: "Flammable – Keep Fire Away".

Here’s why this matters: just 1 gallon of vaporized gasoline can explode with the same force as 20 sticks of dynamite. Proper containment isn't just a recommendation - it’s a necessity.

Approved Containers and Cabinets

Stick to capacity limits for safety cabinets: 60 gallons for Categories 1–3 and 120 gallons for Category 4 flammable liquids per cabinet. No more than three cabinets should be placed in a single storage area. If your storage needs exceed this, transfer the excess to a dedicated inside storage room. Outside of approved cabinets, you should store no more than 25 gallons of flammable liquids in a room.

Avoid storing cardboard or paper in safety cabinets, as these materials increase fire risks. Improper storage is responsible for 25% of chemical accidents in industrial environments. Once your containers are secured, the next step is organizing designated storage areas to further reduce hazards.

Designated Storage Areas

Beyond regulatory compliance, proper storage areas can significantly lower risks, especially in cotton gin or similar environments.

For inside storage rooms, ensure openings are equipped with noncombustible, liquid-tight raised sills (or ramps) at least 4 inches high, or floors that are 4 inches lower to contain spills. Ventilation systems must provide at least six full air changes per hour, with exhaust intakes positioned within 12 inches of the floor. Additionally, all electrical wiring and equipment in these rooms must meet Class I, Division 1, Hazardous Locations standards.

When it comes to outdoor storage, keep container piles (maximum 60 gallons each) at least 20 feet away from buildings, and ensure no area exceeds 1,100 gallons of total storage. Maintain a 12-foot-wide access path within 200 feet of storage piles for fire control equipment. Outdoor storage areas should be graded to direct spills away from buildings or surrounded by a curb or earth dike at least 12 inches high. Always have a portable fire extinguisher rated 20-B or higher within 10 feet of indoor storage room doors, or between 25 and 75 feet of outdoor storage areas.

Segregation and Inventory Control

Proper chemical segregation is just as critical as storage.

Group chemicals by compatibility rather than alphabetically. Flammables, oxidizers, acids, and bases should be stored separately. Use secondary containers, like polypropylene tubs, to create barriers within the same cabinet. Water-reactive materials must never be stored in the same room as flammable liquids.

"Substances which, when mixed, react violently, or evolve toxic vapors or gases... shall be evaluated for compatibility before storing." – California Code of Regulations

Keep inventory levels low - no more than a 6-month supply - to reduce risks. For chemicals that degrade over time, such as peroxide formers, maintain detailed records with the date received, date opened, and date tested. Always consult Sections 7 (Handling and Storage) and 10 (Stability and Reactivity) of the Safety Data Sheets to identify specific storage requirements and potential incompatibilities. Place hazardous materials on lower shelves to prevent spills or falls, and limit the amount of flammable liquids near active operations to what’s needed for a single day or shift.

sbb-itb-0e617ca

Safety Measures and Risk Mitigation

When it comes to preventing fires in cotton gins, proper storage is just one piece of the puzzle. Effective safety measures are equally essential, especially since the environment combines flammable chemicals with combustible cotton lint. This creates a high-risk setting where even a small mistake can lead to a major disaster. In fact, nearly 300 industrial fires and explosions are reported in the U.S. each year due to static discharge.

Bonding and Grounding

Static electricity is often overlooked as a fire hazard but can be a serious ignition source in chemical storage areas. During liquid transfers, ensure metal-to-metal bonding and grounding to equalize electrical potential and safely dissipate any static charge. Sand down connection points to remove paint, rust, or dirt that might interfere with conductivity.

"Category 1 or 2 flammable liquids, or Category 3 flammable liquids with a flashpoint below 100°F (37.8°C), shall not be dispensed into containers unless the nozzle and container are electrically interconnected." – OSHA 1910.106(e)(2)(ii)

Use braided or stranded "airplane" cables with clamps designed to penetrate surface coatings. To comply with NFPA 77 standards, ensure circuit resistance is 1 megohm or less.

Plastic containers present a unique challenge since they don’t conduct electricity. To manage static buildup, use funnels with long brass flame arresters to minimize splashing and place plastic drums on grounded metal plates to dissipate static. If you’re dispensing Class 1 flammable liquids inside a storage cabinet, make sure the cabinet is grounded through its external grounding lugs.

Once static risks are under control, focus shifts to ventilation and temperature management.

Ventilation and Temperature Control

Flammable vapors are heavier than air and tend to settle in low areas, forming dangerous pockets of explosive potential. A well-designed ventilation system can prevent vapor buildup while also removing combustible cotton dust. Install systems that capture low-level vapors and include suction nozzles to automatically remove lint.

Statistics show that one in three fires in cotton processing facilities occurs in opener and picker rooms. To limit fire spread, ensure ductwork is designed to isolate fires to a single machine rather than allowing them to travel through the entire system.

"Lint concentrations need to be minimized by practicing sensible housekeeping... Sources of ignition need to be minimized by properly designing and maintaining electrical and mechanical equipment." – AXA XL Property Risk Consulting

All electrical equipment in areas with flammable chemicals or lint should be explosion-proof. Suspended ceilings, often used for temperature and humidity control, can trap lint and dust above tiles. Regular inspections are essential to prevent these hidden fire hazards.

While ventilation reduces vapor risks, being prepared for spills is also critical.

Spill Prevention and Response

Even the best storage practices can’t eliminate the possibility of spills. A quick and effective response can mean the difference between a minor issue and a major incident. Keep spill kits within 25 feet of fueling and transfer stations, and ensure they contain absorbents specifically suited to the chemicals being stored - oil-only, universal, or chemical-resistant. Each kit should handle at least 15 gallons of fuel or the minimum discharge volume specified in your SPCC Plan.

In cotton gins, where fine lint is highly flammable, always use non-sparking tools for cleanup to avoid creating sparks. Over a 25-year period, the U.S. Chemical Safety and Hazard Investigation Board documented nearly 280 dust-related fires and explosions in industrial facilities, underscoring the dangers of combining chemical spills with combustible dust. Use absorbent socks or booms to contain spills and prevent them from spreading to drainage systems. Storm drain plugs can also block flammable liquids from entering stormwater infrastructure.

Spill kits should include nitrile gloves and safety goggles for worker protection. A laminated instruction sheet near each kit should outline cleanup steps, kit contents, and emergency contact numbers. Dispose of used absorbents in 5-gallon buckets with lids or heavy-duty bags, and consult local regulations to determine if the waste is classified as hazardous. If a spill involves flammable vapors or leads to a fire, shut off aeration fans immediately to prevent smoke spread or additional oxygen from feeding the flames.

Employee Training and Emergency Preparedness

Training employees effectively is a cornerstone of maintaining safety in environments where flammable chemicals are present. Beyond having safety equipment in place, employee preparedness plays a critical role in minimizing risks. Under the Hazard Communication Standard (HCS), employees must be trained to read and understand Safety Data Sheets (SDS) in line with GHS standards and interpret NFPA 704 labeling. Facilities are required to provide hazard training at least once a year, although more frequent safety meetings and drills are strongly recommended to reinforce awareness and readiness. This training approach complements earlier chemical storage protocols, creating a more robust safety framework.

Training Programs

Employees should be trained in safe handling practices as outlined in the Worker Protection Standard (WPS), which includes the correct use and upkeep of personal protective equipment (PPE). Facilities with an SPCC Plan must ensure employees are familiar with conducting facility inspections, testing, and maintaining records to prevent and respond to oil or chemical spills.

For forklift operators, OSHA-certified training is mandatory for powered industrial trucks. Additionally, employees should learn to identify and manage "suspect fire bales", which refer to situations where visible flames, fire odors, or detection alerts signal potential risks.

Facilities storing chemicals like propane, ammonia, or ammonium nitrate may need to comply with DHS Chemical Facility Anti-Terrorism Standards (CFATS), requiring specialized training. If hazardous materials are transported, employees must also complete DOT transportation security plans training.

Training is most effective when paired with regular inspections to ensure emergency equipment is in top condition.

Inspection and Maintenance

Routine inspections are essential to ensure emergency equipment operates properly when needed. Monthly checks should include:

- Fire extinguishers: Confirm pressure gauges, seals, and accessibility.

- Eyewash and shower stations: Ensure water flow and clear access.

- Chemical containers: Look for signs of rust, leaks, or swelling.

- Storage cabinets: Check door latches, ventilation, and proper GHS labeling.

- Spill kits: Verify they are fully stocked and easily accessible.

All findings should be recorded in a safety log. During walkthroughs, inspect that there’s at least an 18-inch clearance below fire sprinklers and ensure aisles are free of obstructions. For facilities in earthquake-prone areas, verify that shelving fasteners and seismic anchors are secure.

| Equipment/Area | Inspection Task | Frequency |

|---|---|---|

| Fire Extinguishers | Check pressure gauges, seals, and accessibility | Monthly |

| Eyewash/Showers | Verify water flow and clear access | Monthly |

| Chemical Containers | Check for rust, leaks, or swelling | Monthly |

| Storage Cabinets | Inspect door latches, ventilation, and labeling | Monthly |

| Spill Kits | Ensure fully stocked and accessible | Monthly |

Fire Suppression and Evacuation Plans

Every facility should have an Emergency Action Plan (EAP) that clearly outlines fire response and evacuation procedures. This plan should integrate fire suppression systems with chemical storage areas and include color-coded floor plans that map out evacuation routes. A designated safe assembly point outside the facility is essential, along with procedures to account for all personnel after an evacuation.

"Preplanning is encouraged to facilitate coordination and cooperation between facility personnel and those who may be called upon for assistance during an emergency." – Occupational Safety and Health Administration

An employee alarm system must be installed that is easily distinguishable from other signals, such as air horns or public announcements. Coordination with local fire departments should also be part of the emergency action plan. For tasks like welding or cutting, implement a "hot work" permit system to ensure fire extinguishers and fire watches are in place before operations begin. While annual training is the minimum standard, holding more frequent safety meetings and emergency drills is strongly advised to keep employees prepared.

Conclusion and Key Takeaways

Summary of Best Practices

Safely storing flammable chemicals in cotton gins requires a layered approach that blends adherence to regulations, proper infrastructure, and thorough employee training. Start with ensuring good ventilation in storage areas to prevent dangerous vapor buildup. Storage spaces should also meet at least one of these safety standards: a one-hour fire resistance rating, an automatic fire suppression system, or an early warning fire detection device.

Using approved safety cabinets is another critical step. These cabinets are designed to keep internal temperatures below 325°F during a 10-minute fire test, significantly reducing the risk of ignition.

To comply with OSHA’s Hazard Communication Standard (HCS) and align with the Globally Harmonized System (GHS), replace outdated Material Safety Data Sheets (MSDS) with updated Safety Data Sheets (SDS) and ensure all chemical containers are properly labeled. Additionally, secondary containment systems should be capable of holding either 10% of the total volume of all stored chemicals or 100% of the largest container’s volume - whichever is greater - to minimize the risk of environmental contamination.

These steps lay the groundwork for immediate improvements in safety.

Next Steps for Cotton Gin Operators

It’s time for operators to take these best practices and put them into action. Begin by reviewing your DHS CFATS inventory against Appendix A to determine whether additional reporting is required for chemicals like propane or ammonium nitrate. Inspect all storage areas to confirm they meet the one-hour fire resistance standard or are equipped with operational automatic fire suppression systems.

Make sure all documentation is up to date with the current SDS format. Clearly label storage cabinets with reflective warning signs, such as "Flammable - Keep Fire Away", to assist first responders in case of an emergency.

Update your Spill Prevention, Control, and Countermeasure (SPCC) Plan to include regular inspections, testing schedules, and detailed employee training records. Develop a fire prevention policy that addresses "suspect fire bales" to improve safety between gin and warehouse operations. Regularly inspect fire extinguishers, eyewash stations, chemical containers, and spill kits, and log all findings in a safety record.

Finally, work with your local fire department to review your Emergency Action Plan. Make sure your team is familiar with evacuation routes, assembly points, and fire suppression procedures. By following these actionable steps, operators can enhance workplace safety while staying compliant with federal and state regulations.

FAQs

What are the differences between OSHA and NFPA guidelines for storing flammable chemicals in cotton gins?

OSHA guidelines are legally enforceable under federal law and are designed to ensure workplace safety. When it comes to cotton gins, OSHA regulations strictly control the storage of flammable liquids. Specifically, facilities can store no more than 25 gallons of flammable liquids outside an approved cabinet, up to 60 gallons per cabinet, and a maximum of three cabinets per fire area - unless additional fire safety measures are implemented. Compliance is verified through inspections, and violations can lead to fines or other penalties.

NFPA guidelines, in contrast, are fire safety codes that only become enforceable when adopted by state or local building codes. These standards classify flammable liquids based on their flash points and offer recommendations for safe storage, container materials, and fire suppression systems. Unlike OSHA, NFPA doesn't impose strict quantity limits but instead focuses on broader safety measures. For cotton gins, NFPA standards also address building construction and sprinkler system requirements to reduce fire risks.

By combining OSHA's enforceable safety regulations with NFPA's fire prevention best practices, cotton gin operators can create a facility that is both compliant and safe.

What steps should cotton gin operators take to train employees on safely handling flammable chemicals?

To help employees safely manage flammable chemicals, cotton gin operators should implement a robust training program that blends classroom learning, hands-on practice, and periodic refreshers. Start by teaching workers about the properties of the chemicals they’ll handle, the correct use of personal protective equipment (PPE) - like gloves, safety glasses, and dust masks - and how to properly operate fire extinguishers. It's also crucial to cover emergency response steps, such as spill containment and evacuation procedures.

Hands-on training is vital. Workers should practice tasks like correctly labeling chemicals, using Material Safety Data Sheets, and locking out equipment safely before maintenance. Conducting regular fire drills can help employees identify hazards, such as hot surfaces or strange odors, and respond effectively. Keep detailed training logs to track attendance, the topics covered, and how well employees demonstrate their skills.

To reinforce these safety measures, schedule quarterly refresher courses and conduct spot-checks to ensure everyone complies with safety standards. Combining education, practical experience, and consistent follow-ups can significantly reduce risks and create a safer work environment for handling flammable chemicals.

How can static electricity be prevented from igniting flammable chemicals in cotton gin facilities?

To help prevent static electricity from igniting flammable chemicals in cotton gin facilities, take these essential precautions:

- Maintain proper moisture levels: Keep seed cotton moisture between 6–7% and ensure warehouse humidity stays above 40%. This reduces the chance of static electricity building up.

- Ground and bond equipment: Properly ground and bond all containers, pipes, and equipment. After maintenance, always test grounding connections to ensure they remain effective.

- Use antistatic measures: For non-conductive containers, apply antistatic coatings or use conductive liners to minimize static charge accumulation.

- Eliminate ignition sources: Ban smoking, open flames, and tools that can create sparks in storage areas. Make sure fire extinguishers are easily accessible and inspected regularly.

- Focus on cleanliness: Clean daily to remove lint and debris that can contribute to static hazards. Regularly inspect equipment to catch potential issues early.

Combining moisture control, proper grounding, and consistent safety practices helps reduce the risk of static-related ignition in cotton gin facilities.