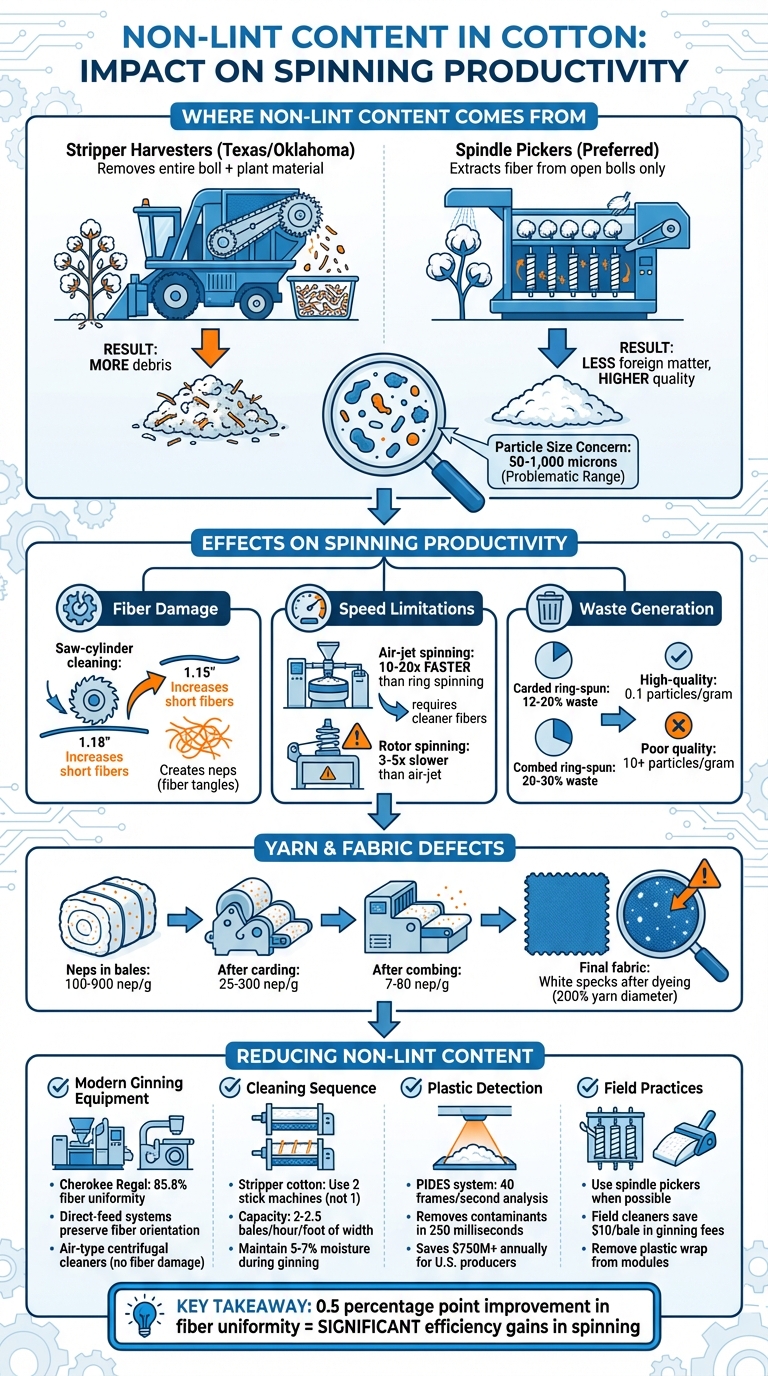

Non-lint content in cotton - like dust, leaf fragments, and seed-coat pieces - creates major challenges for spinning mills. These impurities increase machine wear, slow production, and reduce yarn quality. Advanced spinning methods, such as air-jet spinning, demand cleaner and more uniform fibers, making non-lint content a critical issue for efficiency and product value.

Key points:

- Non-lint content sources: Harvesting methods (stripper vs. spindle pickers) and field conditions.

- Impact on productivity: More cleaning damages fibers, shortens length, and increases costs.

- Machinery issues: Trash particles cause wear and higher maintenance.

- Yarn and fabric defects: Residual impurities weaken yarn strength, create neps, and cause visible flaws in textiles.

- Solutions: Improved ginning processes, better harvesting practices, and advanced cleaning equipment like PIDES for plastic detection.

Cleaner cotton improves spinning productivity, reduces waste, and enhances fabric quality, but achieving this balance requires careful handling from harvest to ginning.

How Non-Lint Content Impacts Cotton Processing from Harvest to Fabric

Yarn Manufacturing: Rotor Spinning

What is Non-Lint Content in Cotton?

Non-lint content, often referred to as foreign matter or trash, includes all non-fiber materials found in ginned cotton. These materials can range from dust, small leaf fragments, and pepper trash to larger debris like sticks, seed-coat pieces, and hull material. Even the tiniest particles, such as microscopic dust, can negatively impact spinning efficiency and the overall quality of textiles.

The textile industry is particularly concerned about particles between 50 and 1,000 microns in size. These small contaminants are problematic because they can bypass certain cleaning equipment but are still large enough to disrupt spinning machinery and compromise yarn quality.

To measure and analyze non-lint content, tools like the Advanced Fiber Information System (AFIS) are used to evaluate particle size distribution in ginned cotton. Another widely used device, the Shirley Analyzer, operates under the ASTM D2812 standard to determine the total weight-based percentage of non-lint content in raw cotton and other processing stages, such as sliver and picker lap. These measurements are essential for mills to estimate usable fiber yields and anticipate potential processing challenges.

Where Non-Lint Content Comes From

The amount of foreign matter in cotton largely depends on the harvesting method. Stripper harvesters, commonly used in places like Texas and Oklahoma, remove the entire cotton boll - including unopened bolls and attached plant material - using rollers or mechanical brushes. This method tends to pull in more debris compared to other harvesting techniques.

On the other hand, spindle pickers are more precise. They use rotating barbed spindles to extract fiber from open bolls, leaving much of the plant material behind. Research from the Southern High Plains shows that picker-harvested cotton typically contains less foreign matter, yields more lint, and delivers better overall fiber quality than stripper-harvested cotton. This difference directly affects market prices, with picker-harvested cotton often fetching higher values.

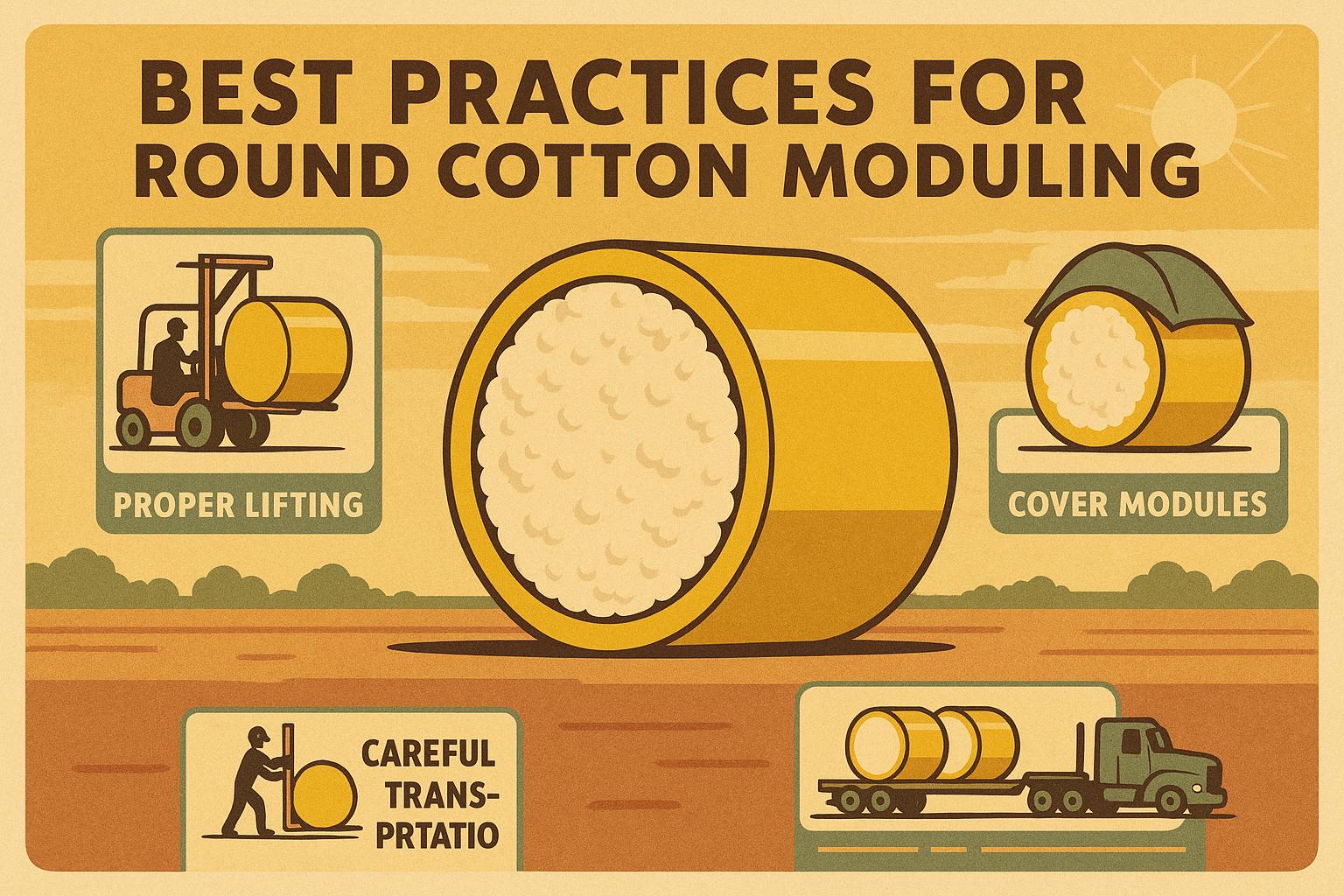

Environmental factors also play a significant role in determining trash levels before processing begins. Conditions like soil moisture, wind exposure, weather during harvest, and even the cotton variety all influence the amount of non-lint content. Additionally, cotton modules - some weighing up to 25,000 pounds - may sit in fields for extended periods before ginning, potentially accumulating more dust and debris during storage.

Understanding and accurately measuring these impurities is crucial for maintaining quality standards and optimizing cleaning processes.

Industry Standards for Non-Lint Levels

The ASTM D2812 standard test method is the industry benchmark for assessing non-lint content in cotton. This method provides objective data for quality control, helping mills fine-tune their machinery to achieve efficient cleaning. It plays a key role in routine quality testing.

Cleaning requirements during ginning vary depending on the harvesting method. For picker-harvested cotton, using one stick machine (seed cotton extractor cleaner) is usually sufficient. Stripper-harvested cotton, however, requires two stick machines due to its higher levels of foreign matter. These recommendations align with the reality that stripper cotton arrives at gins with significantly more debris.

Beyond quality testing, non-lint content data serves multiple purposes for mills. It helps estimate the usable fiber yield from each bale, predict the visual quality of finished textiles, and guide bale blending strategies for consistent processing. While the overall percentage of non-lint content is important, the particle size distribution measured by AFIS is even more critical for determining spinning performance. Particles in the 50 to 1,000 micron range are particularly troublesome for mill operations.

How Non-Lint Content Affects Spinning Productivity

Excessive trash in cotton forces mills to rely on additional opening and cleaning equipment, which increases fiber-machine interactions. This not only damages the fibers but also slows down production.

When cotton is loaded with foreign matter, mills face a tough balancing act. Aggressive cleaning methods can remove impurities, but they often harm the fibers in the process. For instance, saw-cylinder lint cleaners are effective at reducing trash, but they also shorten fiber length from 1.18 inches to 1.15 inches and increase the amount of short fibers. This makes it harder to use high-speed processes like air-jet spinning. Air-jet spinning operates 10 to 20 times faster than traditional ring spinning, but it demands long, uniform fibers with minimal impurities. The strain caused by excessive cleaning also accelerates wear and tear on spinning machinery.

Machinery Wear and Maintenance Costs

Foreign matter in cotton doesn't just affect fiber quality - it also takes a toll on the machinery. Hard particles like seed-coat fragments cause abrasive damage to key components such as rollers and cylinders. This leads to higher maintenance needs and increased costs for replacement parts.

The cleaning process itself can create additional challenges. For example, at the saw-type lint cleaner feed bar, fibers are pinched and pulled by fast-moving saw teeth to remove trash. While this method removes impurities, it also breaks fibers and generates neps, which complicate further processing. This creates a frustrating cycle: the more aggressive the cleaning to remove trash, the more damage is done to the fibers, requiring mills to carefully adjust their equipment to find the right balance between cleaning and preservation. On top of this, excessive impurities slow down the entire processing system.

Reduced Processing Efficiency

High levels of impurities and short fibers (those under 0.5 inches) significantly lower processing speeds and increase waste. These issues lead to higher ends-down rates, which measure how often yarn breaks during spinning. Every yarn break halts production, requiring operators to restart the process. Frequent stops not only reduce productivity but also drive up labor costs.

Modern spinning technologies, like air-jet spinning, are particularly impacted by poor fiber quality. Air-jet spinning operates 3 to 5 times faster than rotor spinning, but this speed advantage depends on high-quality fibers. Even a slight improvement in fiber length uniformity - just 0.5 percentage points - can lead to noticeable gains in efficiency. However, when non-lint content disrupts that uniformity, mills are forced to slow down their machines or deal with higher defect rates and more frequent yarn breaks, undermining their ability to maximize productivity.

sbb-itb-0e617ca

Effects on Yarn and Fabric Quality

Non-lint content poses serious challenges to both the spinning process and the overall quality of textiles. These impurities lead to defects that remain visible in the final product, negatively impacting the appearance and performance of yarn and fabric. Even after undergoing multiple cleaning stages, leftover foreign matter can still compromise the finished textile.

Yarn Strength and Uniformity

Foreign matter weakens the yarn structure by creating weak spots. Seed coat fragments and other residual trash that escape early cleaning stages become embedded in the yarn, forming neps - small knots of tangled fibers. These neps disrupt fiber alignment, weaken the yarn, and cause inconsistencies in diameter, making the yarn less uniform and durable.

The waste generated during spinning highlights the severity of this issue. Carded ring-spun processes produce 12%–20% waste, while combed ring-spun processes generate 20%–30% waste, much of it due to residual trash and seed-coat fragments. This waste not only represents lost material but also reflects the damage fibers endure during aggressive cleaning. High-quality spinners manage to keep trash content as low as 0.1 particles per gram in 50s count yarn, whereas poorly managed processes may result in over 10 particles per gram.

These defects at the yarn level inevitably translate into flaws in the final fabric.

Fabric Appearance and Performance

Non-lint content doesn't just weaken yarn - it also affects the fabric’s aesthetic and functional qualities. After dyeing, residual neps appear as "white specks" because immature fibers fail to absorb dye evenly. This uneven absorption creates visible imperfections, as immature fibers don’t take up dye at the same rate as mature ones. Additionally, these defects, technically defined as short faults exceeding 200% of the yarn diameter, result in thick spots that disrupt the fabric's uniform appearance.

"Neppy cotton fabric can contain two types of neps: those composed of immature fibers and those composed of thick-walled, thin-walled mature fibers that were tangled and occasionally damaged during processing." - Asim Kumar Roy Choudhury, Principles of Textile Finishing

The extent of neps in cotton bales typically ranges from 100 to 900 nep/g. Carding reduces this to 25–300 nep/g, while combing further lowers it to 7–80 nep/g. Despite these thorough cleaning processes, residual neps often remain, creating permanent defects that diminish both the fabric's appearance and durability.

These persistent quality issues highlight the importance of effectively removing non-lint content at every stage of cotton processing to ensure high-quality yarn and fabric.

How to Reduce Non-Lint Content in Cotton

Reducing non-lint content in cotton relies heavily on thorough cleaning during ginning and careful handling in the field. The industry has shifted towards more rigorous seed-cotton cleaning before ginning, paired with gentler lint cleaning methods. This approach removes trash earlier in the process while protecting fiber quality, minimizing damage that could lead to weak spots or neps.

Modern Ginning Equipment and Cleaning Systems

Advances in ginning technology have made it possible to strike a better balance between trash removal and preserving fiber quality. Modern gins now feature alternative lint cleaner designs that reduce foreign matter without compromising fiber length uniformity. Traditional saw-type cleaners, which pinch the fiber batt between a feed plate and roller, often damage fibers. Newer systems avoid this by using different mechanisms.

Take the Lummus Sentinel II, for instance. Its batt-less design feeds individual tufts directly to the saw using a high-speed brush, eliminating the need for a condenser batt. Similarly, the Cherokee Regal employs a direct-feed system that maintains the fiber's orientation by feeding the batt onto the saw without altering its direction. Field tests conducted in New Mexico, Mississippi, and Georgia revealed that the Cherokee Regal delivered an impressive 85.8% fiber uniformity, comparable to the 85.3%–85.6% range achieved by high-end roller ginning systems.

"A small numerical improvement in uniformity (0.5 percentage points) results in significant gains in efficiency during spinning."

– Carlos B. Armijo, USDA-ARS

The sequence of seed-cotton cleaning also plays a vital role. Using two stick machines instead of one significantly improves fiber reflectance and reduces foreign matter, especially in stripper-harvested cotton. Slower cleaning rates allow these machines to remove more material without rushing through the process. For lint cleaning, air-type centrifugal cleaners are often used in the first stage because they lack moving parts, ensuring no fiber damage.

Plastic contamination is another major issue, costing U.S. producers over $750 million annually. To tackle this, specialized detection systems like the Plastic Inspection Detection and Removal System (PIDES) have been introduced. During commercial field trials in Texas and Georgia between 2018 and 2019, PIDES used low-cost color cameras and an ARM processor to analyze images at 40 frames per second. When plastic was detected on the feeder apron (where cotton moves at about 9.8 ft/s), pneumatic air-knives removed the contaminant within 250 milliseconds. The system was particularly effective at detecting green and blue plastics, though yellow and pink wraps proved more challenging due to their similarity in color to natural cotton.

Field practices are equally critical in reducing non-lint content before cotton even reaches the gin.

Harvesting and Handling Methods

Field methods, such as harvesting with spindle pickers, help minimize the initial amount of trash, reducing the need for extensive cleaning later on. For operations using stripper harvesters, incorporating field cleaners is essential. These cleaners not only decrease the initial trash load but can also save producers around $10 per bale in ginning fees.

Proper handling during module transportation is another key factor. Removing trapped plastic wrap from cotton modules prevents large contaminants from entering the ginning process. This step not only enhances cotton quality but also boosts its market value.

Maintaining seed cotton moisture levels between 5% and 7% during ginning helps preserve fiber strength and reduces breakage. Machine-harvested cotton, which typically contains more moisture and foreign matter than hand-harvested cotton, requires at least two precleaning stages for effective trash removal. For optimal results, precleaning machines should operate at a capacity of 2 to 2.5 bales per hour per foot of machine width.

Conclusion

Reducing non-lint content is essential for maintaining efficiency and quality in textile spinning. Cotton with high levels of impurities - such as trash, seeds, and other debris - forces mills to slow production and accept lower-quality output. Issues like poor fiber uniformity and too many short fibers can make it nearly impossible to take full advantage of modern high-speed spinning technologies like air-jet systems.

The challenge lies in balancing aggressive cleaning with preserving fiber quality. Modern ginning equipment, such as direct-feed lint cleaners like the Cherokee Regal, has shown it can achieve fiber uniformity levels of 85.8% - similar to premium roller ginning - while effectively removing impurities.

Field practices also play a major role in fiber quality. Spindle-picked cotton generally contains less trash compared to stripper-harvested varieties, which reduces the need for extensive cleaning. For stripper-harvested cotton, using two stick machines instead of one and incorporating field cleaners during harvest can save producers about $10 per bale in ginning fees while improving fiber quality. Textile mills prefer longer, uniform fibers with minimal neps because these qualities allow them to produce finer count yarns on ring-spinning systems with 100% cotton. Without a focus on reducing non-lint content from harvest through ginning, producers risk losing market value and falling short of the demands of high-efficiency textile operations.

To remain competitive, investing in advanced ginning technology and adopting best practices for cotton handling is critical. These steps ensure the production of high-quality cotton that meets the needs of modern textile mills while minimizing contamination.

FAQs

How does non-lint content in cotton impact the performance of air-jet spinning machines?

Non-lint content - like trash, seeds, and other impurities - can seriously interfere with the operation of air-jet spinning machines. These unwanted materials introduce foreign particles into the fiber stream, leading to frequent stoppages, slower spinning speeds, and more downtime for cleaning and maintenance.

On top of that, non-lint content can hurt yarn quality by creating uneven textures, weak points, or defects in the finished product. To keep machines running efficiently and ensure high-quality yarn, it’s crucial to reduce non-lint content during cotton processing. This can be achieved by improving ginning technologies and following best practices for cleaning and handling cotton.

How can I reduce non-lint content in cotton during harvesting and ginning?

Reducing unwanted material in cotton, such as seed coat fragments and trash, calls for a mix of fine-tuned harvesting practices and advanced ginning techniques. On the harvesting side, using larger spindle diameters and adjusting spindle speeds can help cut down on impurities, leading to better fiber quality. Regular maintenance of harvesting equipment also plays a key role in keeping contamination levels low.

When it comes to ginning, incorporating multiple seed cotton cleaners and using advanced lint cleaning systems can efficiently remove foreign materials without compromising fiber integrity. Technologies like machine-vision systems are especially useful for detecting and eliminating contaminants like plastics, which is becoming increasingly important for ensuring cotton purity. Together, these methods can improve spinning efficiency and elevate the overall quality of the cotton.

Why does the size of non-lint particles in cotton matter for spinning performance?

The size of non-lint particles, like trash and impurities, has a major impact on spinning performance. Smaller particles, especially those between 50 and 1,000 microns, can create serious problems during the spinning process. These tiny particles can interfere with machinery, lower efficiency, and affect the quality of the finished product.

To tackle this issue, advanced lint cleaning equipment focuses on removing these smaller particles. This not only improves spinning performance but also helps manufacturers boost productivity, safeguard their equipment, and deliver better-quality textiles.