Cotton gin workers face noise levels as high as 106 dBA, risking hearing loss and safety. Compliance with OSHA and NIOSH standards is crucial to protect workers and avoid penalties. Here’s what you need to know:

- Noise Risks: Machines like gin stands and lint cleaners expose workers to harmful noise, with averages around 96 dBA.

- Regulations: OSHA limits exposure to 90 dBA over 8 hours; NIOSH recommends 85 dBA. Hearing conservation programs are mandatory at 85 dBA or higher.

- Solutions: Use quieter equipment, install noise barriers, enforce protective gear, and conduct regular noise surveys.

- Key Tools: Sound level meters, dosimeters, and regular audiometric testing track and manage noise exposure.

- Action Steps: Start with engineering controls, add administrative adjustments, and use PPE as a last resort.

Managing noise isn’t just about compliance - it’s about creating a safe, efficient workplace. Let’s dive into how you can tackle noise pollution in your cotton gin.

Regulatory Framework and Standards

Given the noise exposure risks in cotton gins, strict regulations are in place to safeguard workers and ensure compliance. Cotton gin operators must adhere to both federal and state noise standards to protect employees and avoid penalties. Understanding these rules is essential for implementing effective noise control strategies.

OSHA Standards for Noise Exposure

The Occupational Safety and Health Administration (OSHA) sets clear guidelines for workplace noise. When noise levels exceed the limits outlined in OSHA's Table G-16 - measured on the A scale with a slow response - employers must take action. This includes applying administrative or engineering controls and, if necessary, providing personal protective equipment (PPE).

Here’s how the permissible exposure limits break down:

- 8 hours at 90 dBA

- 6 hours at 92 dBA

- 4 hours at 95 dBA

- 3 hours at 97 dBA

- 2 hours at 100 dBA

- 1½ hours at 102 dBA

- 1 hour at 105 dBA

- ½ hour at 110 dBA

- ¼ hour or less at 115 dBA

Additionally, impulsive or impact noise cannot exceed a peak sound pressure level of 140 dB.

OSHA also requires a hearing conservation program when noise exposure hits or exceeds an 8-hour time-weighted average of 85 dB. This program includes regular noise monitoring, notifying employees of exposure levels, audiometric testing to monitor hearing, providing hearing protection at no cost, and training workers on noise hazards and proper use of protection methods.

EPA and State-Level Regulations

Beyond OSHA, the Environmental Protection Agency (EPA) and state governments play a role in noise regulation. The EPA’s Noise Control Act of 1972 set the foundation for a national noise policy aimed at protecting public health and welfare. While the EPA coordinates federal efforts, state and local governments bear the primary responsibility for noise control. Many local ordinances are stricter, particularly in areas near cotton gins.

The EPA also provides advisory noise levels to safeguard public health. For example:

- A 24-hour exposure level of 70 dB is recommended to prevent long-term hearing loss.

- Outdoor noise levels of 55 dB and indoor levels of 45 dB are suggested to minimize disruptions and annoyance.

Recent or Pending Regulatory Updates

The regulatory environment for cotton gin noise compliance is changing. OSHA has been increasingly relying on the General Duty Clause to address hazards not explicitly covered by its existing standards. This approach has already led to enforcement actions at some Texas cotton gins for noise levels exceeding 90 dBA. While cotton gins fall under OSHA’s 1928 Agricultural Standard, they are not directly covered by the noise standard, creating a gap that OSHA is now addressing through these citations.

This shift has prompted industry leaders to act. For instance, Lee Tiller, President of the National Cotton Ginners Association, emphasized the importance of being proactive:

Given recent and upcoming budget cuts, the ginning industry can't afford to sit on the sidelines.

With economic pressures mounting, planning ahead for compliance is more critical than ever.

Measuring and Monitoring Noise Levels

Keeping a close eye on noise levels is a must for cotton gin operators. Accurate measurements not only ensure compliance with safety regulations but also help identify problem areas and protect workers from harmful noise exposure. According to the CDC, around 22 million workers are exposed to potentially damaging noise levels at work each year. Below, we’ll explore methods for measuring noise, pinpoint common sources, and outline best practices for conducting noise surveys.

Noise Measurement Methods

Choosing the right tools to measure noise is key to staying within regulatory standards. Cotton gin facilities commonly rely on three types of instruments, each designed for specific tasks:

- Sound level meters (SLM): These devices provide instant noise readings. They range in price from $500 to $1,000 and come in two types: Type 1 meters, which offer high accuracy for engineering and research, and Type 2 meters, which are suitable for industrial applications [15, 16].

- Integrating sound level meters (ISLM): Unlike basic SLMs, these record average noise levels over time. While they’re great for assessing general exposure, they don’t measure personal exposure since they’re handheld devices.

- Noise dosimeters: These are worn by workers throughout their shifts, making them ideal for tracking personal exposure in dynamic environments. They automatically calculate average noise exposure and typically cost between $750 and $1,500 [15, 16].

Here’s a quick breakdown of the tools and their uses:

| Measurement Type | Best Instrument | What It Measures | Benefits |

|---|---|---|---|

| Personal noise exposure | Dosimeter | Dose or equivalent sound level | Tracks individual exposure throughout shifts |

| Equipment noise levels | Sound Level Meter | dBA at specific locations | Identifies noisy machinery |

| Facility noise mapping | Sound Level Meter | dBA across work areas | Creates a complete noise profile |

| Impact/impulse noise | Impulse Sound Level Meter | Peak pressure dBA | Captures sudden noise spikes |

Calibration is critical to ensure accuracy. Always calibrate sound level meters and dosimeters before and after use [15, 16].

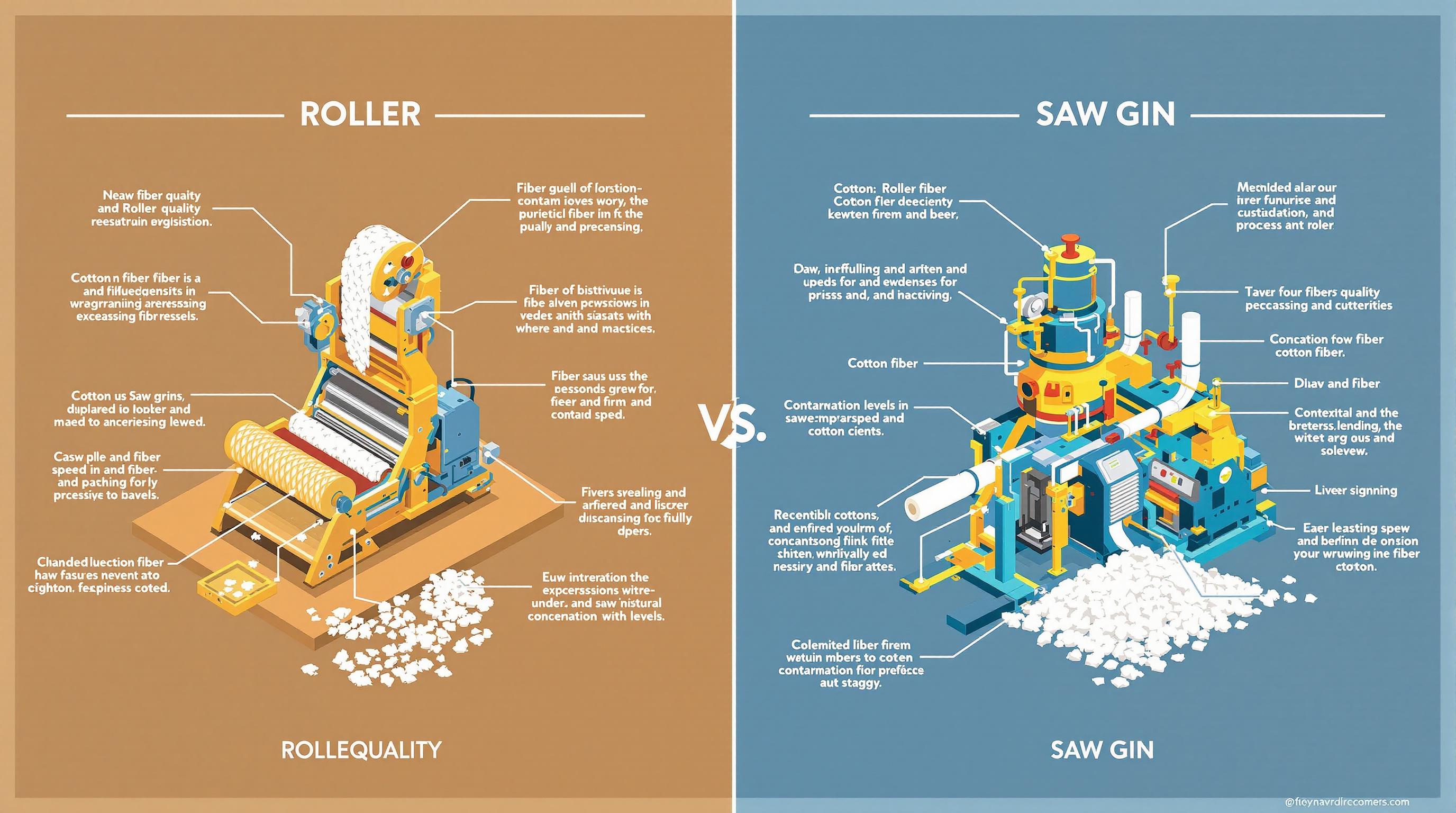

Common Noise Sources in Cotton Gins

Cotton gins are filled with noise-generating equipment that demands attention. Here are some of the main culprits:

- Gin stands: These machines work continuously during processing seasons, producing high decibel levels. Studies show noise levels ranging from 87.0 to 97.7 dBA when idle and 85.9 to 97.7 dBA during operation.

- Lint cleaners: These are another major source of noise. However, using solid-wound brush cylinders can reduce noise levels from 94 dBA to 78 dBA.

- Gin houses: These areas are often the loudest in the facility, with average noise levels reaching 96 dBA. Workers in these zones need proper protective equipment and administrative controls to minimize risks.

Routine maintenance is a game-changer when it comes to noise control. Machines that are well-maintained run more quietly than those with worn or misaligned parts. Preventive maintenance not only reduces noise but also supports overall compliance and safety.

Conducting Regular Noise Surveys

Once you’ve measured noise levels and identified problem areas, regular surveys help validate and refine your noise control strategies. These surveys are essential for maintaining a safe environment and ensuring compliance.

- Walk-through surveys: These are a great starting point. Use a sound level meter to measure noise in each area for about 30 seconds, then plot the results on a facility diagram. This helps identify high-noise zones. Using frequency weighting A and slow time settings ensures consistency with regulations [19, 21].

- Sound mapping: By plotting noise readings on a facility diagram, you can visually highlight problem areas. Include details like location, time, equipment status, and any unusual conditions that might affect the readings.

- Periodic remonitoring: If there are changes in machinery or processes, it’s time for another survey. Many operators conduct these assessments annually or biannually to keep their hearing conservation programs effective.

- Personal exposure monitoring: When noise levels fluctuate or workers move around frequently, dosimeters can track individual exposure over an entire shift. These assessments are usually done near the end of the workday to capture a complete picture of exposure.

Four elements are crucial for an effective noise survey: understanding noise levels in each area, determining how much sound reaches workers’ ears, analyzing the frequency characteristics, and pinpointing the sources of hazardous noise. This thorough approach ensures that compliance programs are based on actual conditions, not assumptions.

Simple signs can indicate when a formal noise assessment is overdue. If workers have to shout to communicate within three feet, experience ringing in their ears after work, or crank up the volume on their radios or TVs, it’s time to take action [6, 15].

Noise Control and Reduction Strategies

After conducting a thorough noise survey and measurement, the next step is to apply targeted strategies to minimize risks. The best approach follows a hierarchy of controls - starting with engineering solutions to tackle noise at its source, followed by administrative adjustments, and finally, using personal protective equipment (PPE) as a last resort.

Engineering Controls

Engineering controls are a reliable, long-term way to reduce noise because they work automatically, without depending on workers' actions. These methods focus on reducing noise at its origin or along its path of transmission. Even small reductions can make a big difference in protecting workers' hearing.

Start with regular maintenance of machinery - equipment in good condition generally operates more quietly than machines with worn or misaligned parts. For example, enclosing equipment can effectively contain low-frequency noise, which is common in environments like cotton gins. Similarly, using acoustic barriers can help reduce high-frequency noise. To prevent vibrations from amplifying sound, consider vibration isolation techniques like dampeners, flexible couplings, or isolation mounts.

The physical environment also plays a role. Hard surfaces, such as concrete walls or metal roofs, tend to reflect sound, so installing sound-absorbing materials like acoustic panels or foam can significantly reduce reflected noise. Additionally, addressing issues in pneumatic systems - like removing obstructions - can lower noise caused by turbulence.

When purchasing new equipment, prioritize models designed with lower noise emissions. This approach is often more cost-effective than retrofitting older, noisier machines later. As industry professionals have pointed out:

Engineering solutions and expenditures that can actually reduce noise emissions are sometimes "sold to management" by highlighting their other advantages, such as gains in productivity or quality.

For more complex noise challenges, consult with noise control specialists to develop solutions tailored to your facility's layout and equipment.

Administrative Controls

Administrative controls aim to reduce workers' overall noise exposure by altering schedules or operations. As the CDC notes:

If you cannot eliminate or reduce noise to a safe level, simple changes in scheduling and operations can significantly decrease the total amount of noise exposure for each worker.

One effective strategy is increasing the distance between workers and noise sources. For instance, doubling the distance from a noise source can lower noise levels by up to 6 dB. Relocating workstations away from loud equipment and rotating workers between noisy and quieter tasks are practical solutions. Providing quiet break areas allows workers to give their ears a rest, while scheduling the noisiest tasks during shifts with fewer employees present can further reduce exposure.

Other tips include keeping doors and windows closed to block external noise and avoiding propping open doors to noisy machinery areas. Discourage the use of high-volume personal music devices in noisy environments, and consider alternative communication tools like radio headsets that work with hearing protection, so workers don’t have to remove their gear.

Dennis J. Murphy, a retired Professor of Agricultural Safety and Health, highlights the value of such measures:

Practices such as workstation rotation, where workers are limited to how long they are at a noisy workstation, can be an effective means of reducing noise hazard exposure.

Consistency is key. Workers with known hearing loss should not be assigned to high-noise areas, and administrative strategies must not inadvertently increase exposure for others. When engineering and administrative controls fall short, PPE becomes the next layer of protection.

Personal Protective Equipment (PPE)

PPE is the last line of defense against noise exposure and should only be used when other methods are not enough. While effective, PPE does not remove the noise hazard itself and relies on proper usage to work. OSHA regulations require hearing protection when noise levels exceed a time-weighted average of 90 dBA, or when workers are exposed to 85 decibels or more over an eight-hour period.

Selecting the right hearing protection is crucial. Offer workers a variety of options - such as earplugs, earmuffs, or canal caps - and involve them in the decision-making process to ensure comfort and proper fit. Earplugs are often preferred for long shifts or hot conditions, while earmuffs are easier to fit and ideal for intermittent use. In extremely loud environments, using both earplugs and earmuffs (dual protection) may be necessary to bring noise levels to acceptable ranges.

Training is just as important as the equipment itself. Workers need to understand when and how to use their hearing protection, and regular fit testing ensures the devices are effective. Establish clear rules requiring hearing protection in noisy areas, reinforce compliance with signage, and perform periodic inspections.

Keep in mind, personal audio headphones are not a substitute for approved hearing protection. Since PPE is often used inconsistently or incorrectly, it’s vital to focus on engineering and administrative controls as the primary methods for managing noise risks.

sbb-itb-0e617ca

Compliance Best Practices and Resources

Creating an effective noise compliance program is more than just ticking off regulatory boxes. For cotton gin operators, it’s about ensuring worker safety while fostering a safer and more efficient workplace.

Developing a Compliance Program

The backbone of a successful hearing conservation program lies in understanding and meeting legal requirements. Start by conducting noise sampling to pinpoint employees at risk. Regular monitoring is crucial, as noise levels can shift over time due to aging equipment or operational changes. Share these monitoring results with workers and let them observe the process firsthand - it’s a great way to build trust and awareness.

Keep detailed records of all noise monitoring and sampling activities. These records not only help you stay compliant during OSHA inspections but also allow you to track how well your noise control measures are working.

Invest in quieter equipment and maintain it regularly to avoid unnecessary noise increases. Consider installing barriers to shield workers from noise sources, enclosing or isolating noisy machinery, or scheduling high-noise tasks during shifts with fewer workers. Providing quiet zones for breaks and limiting exposure time near loud equipment are also effective strategies.

As OSHA succinctly puts it:

Hearing conservation programs strive to prevent initial occupational hearing loss, preserve and protect remaining hearing, and equip workers with the knowledge and hearing protection devices necessary to safeguard themselves.

To ensure these strategies are effective, focus on training and regular hearing assessments.

Employee Training and Audiometric Testing

Ongoing training and hearing health monitoring are essential pillars of any compliance program. The National Institute for Occupational Safety and Health (NIOSH) estimates that around 22 million U.S. workers are exposed to hazardous noise levels each year. Audiometric testing plays a critical role in tracking hearing health, evaluating the effectiveness of protective measures, and meeting regulatory requirements.

OSHA requires baseline audiograms within six months of an employee’s first exposure to noise levels above 85 dB, followed by annual testing. These tests should be conducted by qualified technicians using calibrated equipment. Keep an eye out for standard threshold shifts (STS), defined as a 10 dB or greater change in hearing sensitivity at specific frequencies (2,000, 3,000, and 4,000 Hz) compared to baseline. If an STS occurs, follow up with retesting, medical evaluations, and improved hearing protection.

Training is equally important. Workers should understand how noise impacts hearing, how to properly use hearing protectors, and why regular audiometric testing matters. Refresher sessions are especially helpful when new employees join or when equipment and processes change.

Key Resources for Operators

Fortunately, operators have access to a wealth of resources to stay on top of regulations and implement effective noise control measures. OSHA provides detailed guidance on hearing conservation programs, including standards for workplaces where noise levels exceed 85 dB.

One standout innovation comes from the Agricultural Research Service (ARS), which has developed noise-reducing technology tailored for cotton gin operations. For example, the ARS Cotton Ginning Research Unit replaced standard doffing brush cylinders with solid-wound brush cylinders. In a 2003 field trial in Marked Tree, AR, led by W. Stanley Anthony, this change processed over 40,000 bales without issues and reduced noise levels from 94 dB to 78 dB.

W. Stanley Anthony, Research Leader of the ARS Cotton Ginning Research Unit, highlighted the impact of this advancement:

Adoption of this technology in cotton gins would significantly reduce noise levels.

This solution achieved an 80% reduction in one major noise source. The ARS is also partnering with brush manufacturers to make solid-wound brush replacements more affordable, further increasing their accessibility to operators.

For additional support, operators can turn to resources like cottongins.org, which provides a directory of U.S. cotton gins by county and state. This platform helps connect operators with peers and service providers experienced in cotton gin operations.

Industry associations and state agricultural extension services are also valuable. They often offer training materials, compliance checklists, and updates on regulatory changes. Networking through these channels can lead to the exchange of best practices and insights, strengthening compliance efforts across the board.

Conclusion and Key Takeaways

Managing noise compliance in cotton gin operations goes beyond simply adhering to regulations - it's about fostering a workplace that's safe, efficient, and supportive of your team. After all, your employees are your most valuable asset. The Agricultural Research Service has shown that engineering adjustments can make a big difference, cutting noise levels from 94 decibels to 78 decibels - a reduction of 80% in one major noise source. This underscores the real-world benefits of taking proactive steps to control noise.

An effective noise management strategy requires multiple layers. Start by implementing engineering controls to tackle noise at its source. Then, complement these efforts with administrative controls and personal protective equipment. Conducting regular noise surveys helps pinpoint problem areas and measure the success of your interventions. As equipment ages, ongoing monitoring becomes even more critical.

Employee involvement is also key. Training programs and audiometric testing are essential components of a strong hearing conservation plan. They ensure workers understand the risks and have the tools to protect themselves.

Regulations add another layer of urgency. The evolving regulatory landscape, highlighted by the 2015 citations of two Texas gins under OSHA's General Duty Clause for noise levels exceeding 90 decibels, makes it clear that robust noise management is non-negotiable. Ron Craft, president of the National Cotton Ginners Association, advises seeking expert guidance before engaging with OSHA:

Ginners should never sign any kind of agreement or settlement with OSHA until they have contacted their ginner association or NCGA or someone knowledgeable about OSHA regulations related to agriculture.

FAQs

What are the best engineering controls to reduce noise in cotton gins?

Reducing Noise Levels in Cotton Gins

Lowering noise levels in cotton gins can be achieved by introducing engineering controls like:

- Adding noise-dampening guards and soundproof enclosures around machinery.

- Incorporating sound-absorbing materials and barriers to cut down on noise transmission.

- Keeping equipment in top condition through regular maintenance to ensure smoother operation and reduced noise output.

These steps not only help align with regulatory requirements but also contribute to a safer and more pleasant workplace for operators.

What steps can cotton gin operators take to comply with federal and state noise regulations?

To meet federal noise regulations, cotton gin operators must adhere to OSHA's standards for occupational noise exposure outlined in 29 CFR 1910.95. These rules establish limits on acceptable noise levels in the workplace. Additionally, the Noise Control Act of 1972 offers guidance to reduce environmental noise pollution. One effective approach, as shown in USDA research, involves implementing noise-reduction technologies capable of lowering decibel levels from 94 to 78.

On the state level, regulations can differ, so operators should familiarize themselves with local requirements. For instance, in Texas, cotton gins must keep noise levels below 90 dBA and address nuisance noise under the state's air quality and nuisance rules. By staying updated on both federal and state mandates and integrating noise-reduction strategies, operators can ensure compliance while promoting a safer and quieter work environment.

What should I do if an employee's hearing test shows a significant change?

If an employee's hearing test shows a standard threshold shift - indicating a noticeable change in their hearing - you’re required to inform them in writing within 21 days. To determine if the change is permanent, a follow-up test should be scheduled within 30 days.

If the shift is confirmed as permanent, it’s important to reassess the employee’s work environment. Check that their hearing protection is adequate and consider whether further steps are necessary to lower noise exposure levels.