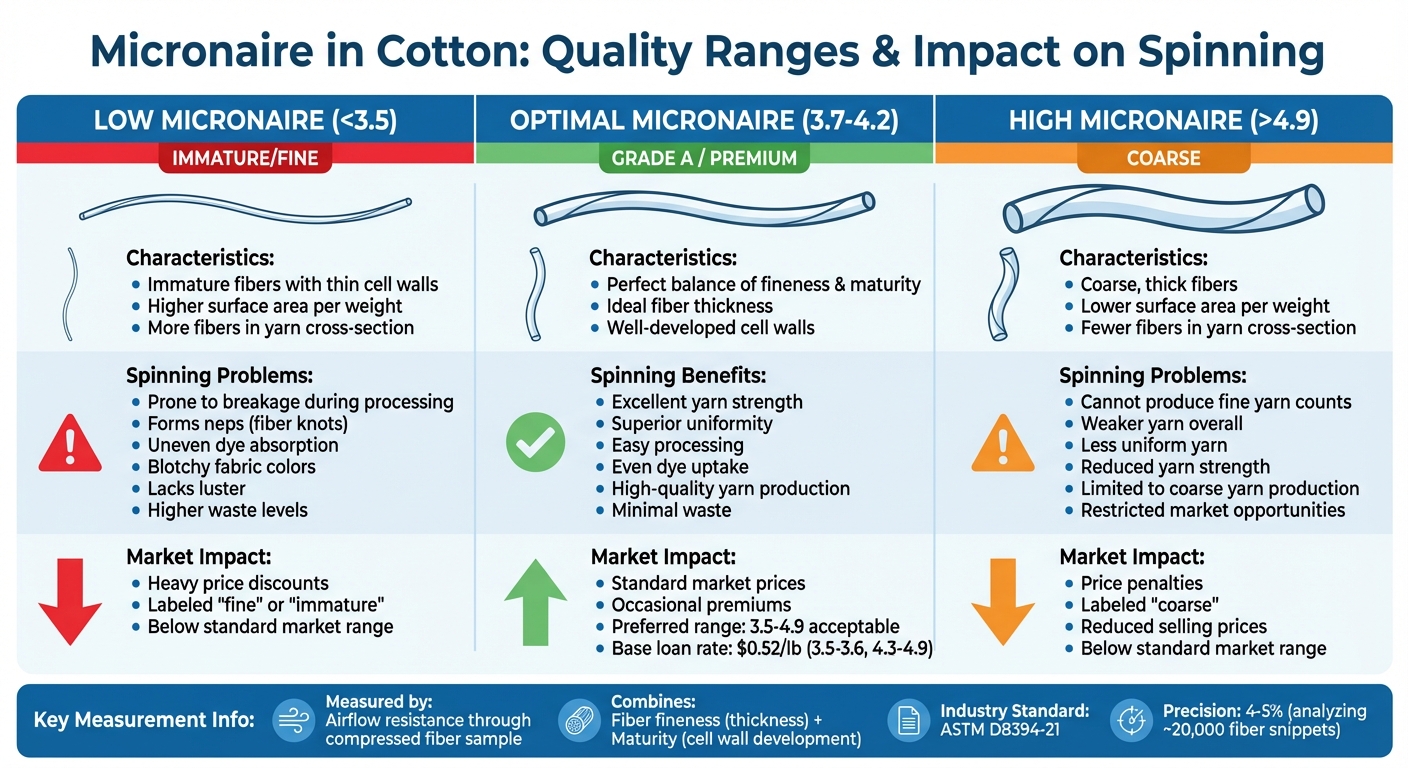

Micronaire is a key measurement in cotton quality, reflecting both fiber fineness (thickness) and maturity (cell wall development). These factors directly impact yarn strength, uniformity, and dye uptake during spinning. Cotton with micronaire values between 3.7 and 4.2 is optimal for producing high-quality yarn, while values outside this range can lead to processing issues, uneven fabrics, and price penalties.

Key Points:

- What It Measures: Micronaire combines fiber fineness and maturity, assessed through airflow resistance in a controlled test.

- Ideal Range: 3.7–4.2 (Grade A) ensures balance between strength, uniformity, and processing ease.

- Low Micronaire (<3.5): Indicates immature fibers, prone to breakage, neps, and uneven dyeing.

- High Micronaire (>4.9): Reflects coarse fibers, limiting fine yarn production and reducing yarn strength.

- Influencing Factors: Genetics, irrigation, potassium management, and harvest timing affect micronaire levels.

- Market Impact: Cotton outside the optimal range faces price discounts due to reduced spinning and fabric quality.

Understanding micronaire helps growers, ginners, and textile mills optimize cotton for better spinning performance and market value.

Micronaire Range Effects on Cotton Spinning Quality and Market Value

Testing cotton fiber quality

What Is Micronaire and How Is It Measured?

Micronaire plays a key role in determining how cotton performs during spinning. It measures the specific surface area of cotton fibers per unit weight. While often thought of as a measure of fineness, micronaire actually combines two factors: fineness (the thickness or linear density of the fiber) and maturity (how developed the fiber's cell wall is).

This combination makes micronaire a valuable predictor of how cotton will behave during spinning. However, it also means that a single reading can’t distinguish between fine, mature fibers and coarse, immature ones - both of which can yield similar values. To make informed production decisions, it’s crucial to understand what the micronaire number actually represents. This dual nature highlights the importance of precise measurement techniques, which we’ll explore next.

The Airflow Principle in Micronaire Measurement

The measurement process is straightforward. A specific mass of cotton fibers is compressed into a chamber, and air is passed through the sample under controlled conditions. The instrument then measures the resistance these fibers create to the airflow.

Fibers with a higher specific surface area generate more resistance to airflow, leading to a lower micronaire reading. This occurs because finer or immature fibers, with their thinner cell walls, have a larger surface area relative to their weight. This airflow-based method provides a quick and reliable way to assess fiber properties, eliminating the need for time-consuming microscopic analysis.

This approach helps connect the dots between fineness, maturity, and how cotton performs during spinning.

Micronaire: Fineness vs. Maturity

Fineness refers to the fiber’s thickness or linear density. Finer fibers are essential for producing fine yarn counts and contribute to better yarn strength and evenness.

Maturity, on the other hand, measures how well-developed the fiber’s cell wall is. Mature fibers have thicker cell walls, making them stronger and less likely to break during processing.

Since micronaire reflects both fineness and maturity together, Lord’s equation is often used to interpret these readings. This formula helps mills understand the relationship between the two factors, enabling them to predict how the cotton will perform during spinning and dyeing processes.

How Micronaire Affects Yarn Quality and Spinning Performance

Micronaire plays a key role in determining both yarn quality and spinning efficiency. In the textile industry, readings between 3.7 and 4.2 are considered ideal (Grade A), as they strike a balance between strength, uniformity, and processing ease. Cotton outside this range often faces market discounts and can create challenges during spinning.

"Fiber fineness affects yarn count, evenness and strength."

- ASTM D8394-21

Cotton with a high micronaire (above 4.9) has its pros and cons. On the plus side, these fibers are better at withstanding mechanical stress and tend to produce fewer neps. However, they pose difficulties in spinning fine yarns because fewer fibers fit into the yarn's cross-section, which weakens overall yarn strength.

On the other hand, low micronaire cotton (below 3.5) can enhance yarn strength and uniformity by allowing more fibers in the cross-section. But there's a catch - very low readings often indicate immature fibers, which are prone to breaking and forming neps during processing. This is because fiber maturity is closely linked to length and strength, meaning immature fibers can disrupt the entire spinning process.

Micronaire variations can lead to inconsistent yarn quality. When cotton falls outside the premium range, issues like uneven yarn thickness, weaker yarn, and higher processing waste become more common. To optimize results, it's crucial to match the cotton's micronaire to the desired yarn count. For instance, higher micronaire cotton works well for coarser yarns, improving processing efficiency. Meanwhile, lower micronaire cotton is better suited for fine yarns, ensuring there are enough fibers in the cross-section to maintain strength.

Problems with Low and High Micronaire Cotton

Cotton that falls outside the 3.5 to 4.9 micronaire range often faces pricing penalties and creates challenges during spinning. Both extremes - low and high micronaire - can negatively affect yarn quality. Let’s break down the specific issues tied to each.

Impact of Low Micronaire on Spinning

Cotton with a micronaire value below 3.5 is particularly troublesome for textile mills due to its tendency to form neps - tiny fiber knots that disrupt the spinning process. According to ASTM International:

"Immature fibers break more easily during processing and have a tendency to form into neps (small entanglements) during processing in the spinning mill."

- ASTM International

These neps weaken the yarn, leading to breakage and higher waste levels during modern spinning operations.

Low micronaire cotton also struggles with dye absorption, causing uneven and blotchy fabric colors. Additionally, the resulting yarn and fabric often lack the smooth, lustrous appearance that buyers prefer.

Challenges with High Micronaire Cotton

On the other hand, cotton with a micronaire value above 4.9 brings its own set of complications. High micronaire indicates coarser fibers, which, while more durable under mechanical stress, limit the production of fine-count yarn due to their lower fiber density. This results in yarn that is less even and weaker overall.

High micronaire cotton also restricts mills to producing coarser yarn counts. This limitation narrows market opportunities and often leads to reduced selling prices. The yarn produced under these conditions tends to be less uniform, ultimately impacting the quality of the final textile product.

Factors That Affect Micronaire in Cotton Production

Getting micronaire just right is crucial for producing high-quality cotton and ensuring smooth spinning performance. While genetics play a role, the real game-changers are environmental factors and crop management practices. Micronaire is more closely tied to how mature the fibers are than to traits like strength or length. By understanding what impacts these values, you can make smarter decisions throughout the growing season. Let’s dive into some key agronomic practices that directly shape these fiber characteristics.

Agronomic Practices That Affect Micronaire

Potassium management is one of the most important aspects to consider. When cotton plants don’t get enough potassium, they pull the nutrient from their leaves to support boll production. This causes the leaves to age and drop prematurely, cutting down on photosynthesis. With fewer carbohydrates available, fiber maturity suffers, leading to lower micronaire values. Bayer Crop Science highlights this issue:

"Potassium-deficient plants can have low micronaire, because they shift available K from leaves to boll production, resulting in leaf senescence and reduced photosynthesis."

Irrigation levels also play a big role. Overwatering can reduce micronaire values. The trick is to maintain proper plant-water balance by ensuring no more than 50% of the plant-available soil water is depleted before irrigating again. Additionally, excessive fertilization and high plant populations stretch carbohydrate resources thin, leaving less available for each boll and resulting in low micronaire.

Harvest aid timing makes a difference too. Applying defoliants too early halts fiber development prematurely, leading to immature fibers and lower micronaire. On the flip side, losing a significant number of late-season bolls - due to something like monsoon weather - can concentrate carbohydrates in the remaining bolls, pushing micronaire values above 5.0. Jeffrey C. Silvertooth, an Extension Agronomist at the University of Arizona, explains:

"Without gaining a significant boll load late in the season, plant carbohydrates are loaded into existing bolls, creating fibers with higher micronaire."

Environmental and Seasonal Influences

Management practices aside, environmental and seasonal factors also have a big say in fiber development. Weather conditions during the growing season directly influence fiber wall thickness and maturity. For instance, soil quality and water availability, whether from rainfall or irrigation, are key to healthy fiber development. Moderate weather that improves boll retention can actually lower micronaire by spreading available carbohydrates across more bolls.

Plant diseases can also disrupt fiber maturity, throwing off the usual balance between micronaire, length, and strength. Additionally, extreme temperatures and moisture stress during key growth stages can negatively impact fiber development. Interestingly, the same cotton variety can produce different micronaire values depending on the environmental conditions of the region where it’s grown.

sbb-itb-0e617ca

How to Achieve Optimal Micronaire Levels for Spinning

Hitting the sweet spot for micronaire levels - typically between 3.7 and 4.2 - is key to producing high-quality cotton for spinning. Achieving this consistently requires careful variety selection and thoughtful crop management.

Choosing Cotton Varieties for Desired Micronaire

The foundation of achieving the right micronaire starts with genetics. Fiber fineness is primarily determined by the variety you choose. While characteristics like fiber length and strength are largely locked in by genetics, micronaire is influenced by fiber maturity - a factor that growers can manage through environmental and agronomic practices.

To stay within the ideal micronaire range, select varieties with the genetic potential to achieve 3.7 to 4.2 micronaire. This is where working closely with your seed supplier becomes crucial. Keep in mind that even the same variety can produce different micronaire values depending on environmental conditions, so management practices play a significant role in fine-tuning results.

Best Practices for Crop and Harvest Management

Managing for "earliness" is a critical step in maintaining stable micronaire levels. This involves synchronizing planting dates, fertility programs, plant growth regulators, and pest control to encourage uniform fruit development. Jeffrey C. Silvertooth, an Extension Agronomist at the University of Arizona, highlights the importance of this:

"Management factors that lead to crop earliness and uniform fruit retention patterns are very important in terms of fiber micronaire."

Fruit retention patterns are another key factor. Early-season bolls tend to develop higher micronaire, while later bolls often have lower values. A uniform fruiting pattern helps balance these differences, ensuring an acceptable overall micronaire range. Regularly monitoring fruit retention can also prevent excess carbohydrates from accumulating in remaining bolls, which could push micronaire levels too high.

Irrigation management is equally important. Avoid depleting more than 50% of soil water to prevent water stress, which can hinder fiber development. On the flip side, over-irrigation can lead to lower micronaire values. If you’re dealing with severe boll loss and anticipate high micronaire levels, applying harvest aids earlier than usual can help halt further fiber development.

Timely defoliation and harvest are essential to preserving fiber maturity. Applying defoliants too early can result in immature fibers and lower micronaire levels. And don’t forget the financial implications - market prices are directly tied to micronaire. For example, the 2025 loan rate for base-quality upland cotton is $0.52 per pound for cotton with micronaire levels of 3.5–3.6 and 4.3–4.9. By following these best practices, you can achieve the fiber quality needed for optimal spinning performance while maximizing your returns.

Micronaire's Role in Ginning and Pre-Spinning Preparation

When cotton reaches the gin, micronaire becomes a key factor in how fibers handle the mechanical stresses of processing. While ginning itself can't improve the inherent quality of cotton, it plays a vital role in preserving the fiber's existing attributes. As Steven Brown, Extension Specialist at Auburn University, explains:

"Farming and ginning practices can preserve but not create superior fiber quality."

By understanding the relationship between micronaire and fiber behavior, ginners can fine-tune their processes to protect the integrity of the fibers before they move on to spinning.

Ginning Practices to Protect Fiber Integrity

The ginning process starts with measuring the cotton's moisture content. This step is crucial because the moisture level determines the amount of heat needed to prepare the fiber for seed separation. Maintaining moisture levels between 6%–8% is ideal, as it prevents fiber breakage. When moisture drops below 5%, even a 1% decrease can shorten fiber length by 1/100 of an inch.

Micronaire values also play a big role in how well fibers withstand the mechanical action of sawblades and cleaners. Fibers with low micronaire (3.4 and below) are immature and more prone to compression and damage. These delicate fibers are especially vulnerable during cleaning, where aggressive techniques meant to remove debris can reduce their staple length.

Natural variations in fiber maturity within each bale add another layer of complexity. For example, after Hurricane Sally in September 2020, prolonged rain and high humidity degraded seed quality, leading to fiber downgrades that cost Alabama growers around $4 million.

Micronaire Data in Production Decisions

Preserving fiber quality during ginning directly impacts how micronaire data is used in production. Every U.S. cotton bale comes with a permanent ID and High Volume Instrument (HVI) data, which includes the micronaire measurement. This information helps textile mills decide which bales are best suited for specific yarn production runs. Since micronaire affects dye absorption and fiber luster, mills rely on this data to group bales and create uniform blends, avoiding issues like color streaks or uneven fabric appearance.

For ginners and farmers, micronaire data provides valuable insights for future planning. These measurements inform seed selection and evaluate whether farming practices achieved the desired results. With automated instruments capable of analyzing up to 20,000 fiber snippets with 4%–5% precision, producers gain fast and accurate feedback for both immediate adjustments and long-term strategies.

| Fiber Property | Impact of Ginning | Impact of Variety | Impact of Environment |

|---|---|---|---|

| Micronaire | No | Yes | Yes |

| Leaf and Trash | Yes | Yes | Yes |

| Staple (Length) | Yes | Yes | Yes |

| Strength | No | Yes | Yes |

| Extraneous Matter | Yes | Yes | Yes |

Source: Adapted from Table 1, ACES Extension Article

Market Implications of Micronaire in Cotton Trade

Micronaire plays a pivotal role in determining the value of a cotton bale. As a trusted indicator of both fiber fineness and maturity, it stands alongside staple length and color grade as one of the key factors used by the USDA and global trade organizations to assess the commercial worth of cotton bales.

Preferred Micronaire Range for Market Viability

The cotton market favors a micronaire range of 3.5 to 4.9. Cotton within this range typically commands standard market prices, with occasional small premiums depending on contract specifics. This range strikes the ideal balance: fibers are mature enough to endure processing while still fine enough to yield high-quality yarn.

Cotton outside this range, however, faces price penalties. Micronaire values below 3.5 are labeled as "fine" or "immature", while those above 4.9 are considered "coarse". Low-micronaire cotton (below 3.5) is heavily discounted due to its tendency to form neps and its poor dye absorption. Likewise, high-micronaire cotton (above 4.9) is penalized because its coarse fibers are less compatible with high-speed spinning for fine yarns and result in weaker finished products. These quality benchmarks significantly influence decisions not just in trading but also during the spinning process.

Micronaire as a Key Quality Metric in Spinning

For textile manufacturers, micronaire serves as a dependable measure of a bale's fineness and maturity. As ICA Bremen highlights:

"For spinners, fineness is crucial in predicting the spinnability of cotton and the fineness, evenness and strength of the yarn that might be produced from it."

Variations in micronaire levels compel manufacturers to adjust their laydowns - the mix of cotton bales used during production. Inconsistent readings can lead to uneven dyeing and structural flaws in the final fabric. This makes micronaire, alongside staple length, a critical factor in fiber selection for the spinning industry.

Conclusion

Micronaire plays a key role in predicting how cotton will perform during spinning, as it measures both fiber fineness and maturity - two factors that directly impact yarn strength and uniformity. According to ASTM D8394-21, immature fibers are more prone to breaking and forming neps, which can lower the overall quality of yarn and fabric. Additionally, fabrics made from immature fibers often lack luster and may not absorb dye evenly, leading to noticeable differences in appearance after dyeing. These insights highlight why accurate measurement of micronaire is so important.

Advanced automated tools now assess about 20,000 fiber snippets with a precision range of 4%–5%. This level of accuracy supports better decision-making in areas like variety selection, harvest timing, and ginning practices.

FAQs

What happens if cotton has low or high micronaire values during spinning?

Micronaire values play a crucial role in the spinning process and directly impact the quality of the final yarn.

Low micronaire cotton usually consists of finer, less mature fibers. While this might sound appealing, it often leads to challenges such as uneven dye absorption, weaker yarn strength, and the formation of neps - those tiny, pesky fiber knots. These issues can cause fabric defects like white specks and disrupt the spinning process, reducing overall efficiency.

On the flip side, high micronaire cotton features coarser, more mature fibers. These fibers are stronger and more durable but come with their own limitations. They’re not ideal for creating fine yarns and are better suited for products like denim or batting, where a thicker, less refined material works well. Unfortunately, this restricts their use in finer, more delicate textile applications.

To achieve smooth spinning and top-notch yarn quality, it’s critical to maintain a micronaire range between 3.5 and 4.9. This balance ensures the fibers are neither too fine nor too coarse, making them suitable for a variety of textile needs.

How do environmental factors and farming practices affect cotton micronaire levels?

Environmental factors and farming techniques heavily influence micronaire levels in cotton, which measure fiber maturity and fineness. Key elements like water availability and temperature during the growing season play a pivotal role. For example, high temperatures combined with water stress can thicken fiber walls, pushing micronaire values higher. On the other hand, cooler or overly wet conditions can hinder fiber development, resulting in lower micronaire levels.

Farming decisions, including when to irrigate, schedule harvests, or apply defoliants, also affect micronaire. By carefully managing resources and timing interventions, farmers can encourage proper fiber maturity, producing cotton that aligns with spinning industry standards.

Why is micronaire important for cotton's quality and market value?

Micronaire is a crucial measure of cotton fiber quality, as it combines two important traits: fineness and maturity. These factors play a significant role in determining how efficiently the cotton can be spun into yarn and the overall quality of the finished product.

In the U.S., cotton with micronaire values that are too high or too low often results in price penalties. This is because such fibers can cause problems like uneven dyeing or reduced efficiency during spinning. By keeping micronaire levels within the ideal range, producers can secure better prices and meet the expectations of textile manufacturers.