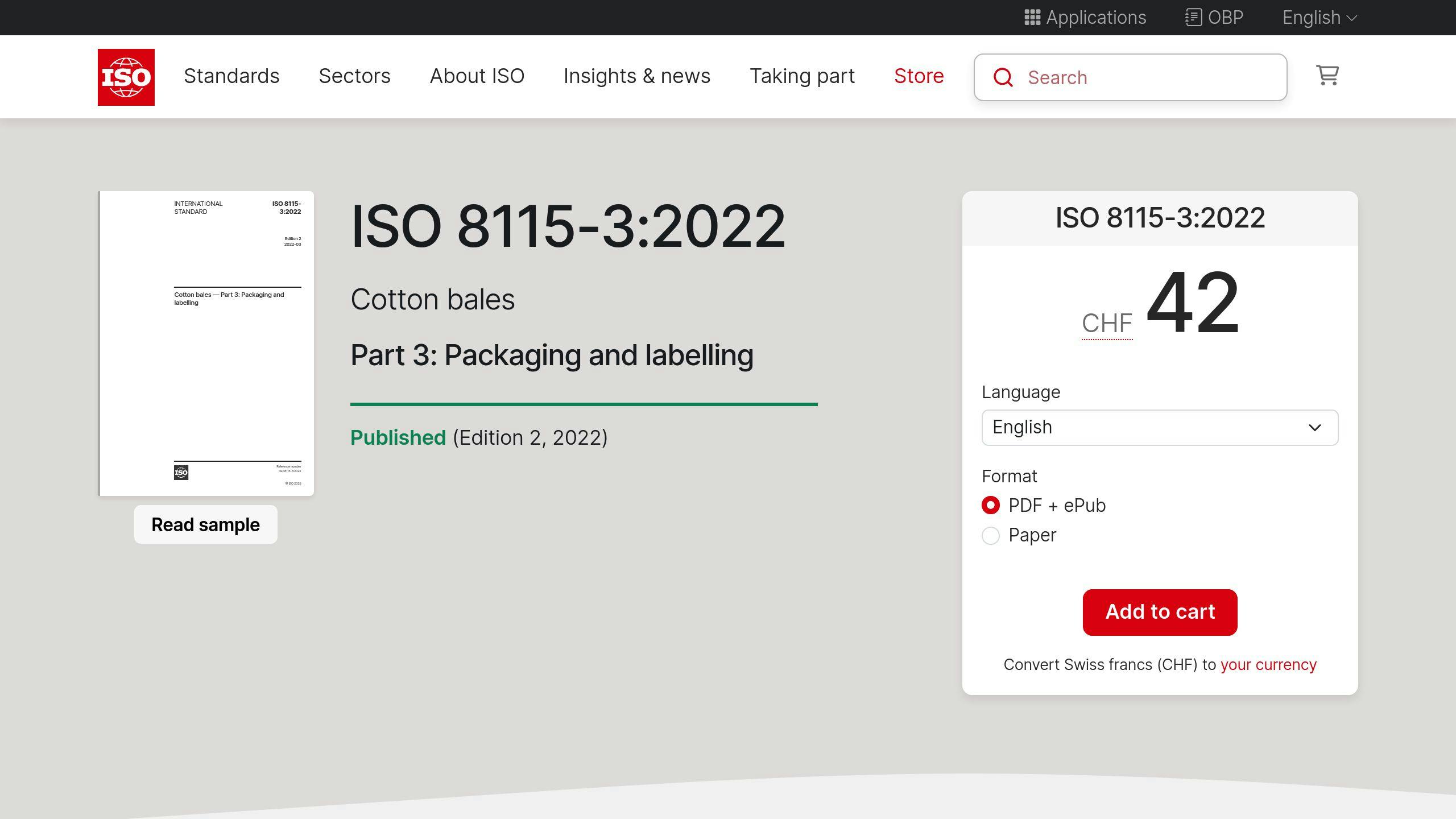

ISO 8115-3 sets global rules for labeling and packaging cotton bales to ensure traceability, quality, and efficiency in trade. It focuses on the Permanent Bale Identification (PBI) system, durable packaging materials, and clear labeling. Here's what you need to know:

- PBI System: Each bale gets a unique barcode for tracking.

- Label Requirements: Must include bale number, gin name, origin, and harvest year.

- Packaging Rules: Use fabric-based wrapping and specific strapping methods.

- Prohibited Materials: Avoid polypropylene and extra stickers to reduce contamination.

- Compliance Steps: Ensure proper labeling, approved materials, and regular inspections.

Components of ISO 8115-3 Standards

Permanent Bale Identification System

The Permanent Bale Identification (PBI) system relies on standardized barcodes to streamline tracking and inventory management processes [2]. Each PBI number must stay unique for several years, with the numbering sequence continuing rather than restarting every five years [3].

Labeling and Packaging Requirements

ISO 8115-3 outlines clear rules for label content and packaging. Labels must include:

| Required Information | Optional Details |

|---|---|

| Unique bale number | Quality information |

| Gin number/name | Gross mass and tare |

| Country of origin | |

| Year of harvest |

For protective wrapping, woven or knitted fabric is mandatory [1]. Plastic wrapping is discouraged due to issues during processing. Strapping requirements include six hoops for 1,060mm bales and nine hoops for 1,590mm bales, with hoops aligned parallel and locks placed on one side for automatic opening [1]. Buyers may request a 300-350mm gap in the bale center for sampling purposes [1].

These packaging rules are closely aligned with the recommendations from the Joint Cotton Industry Bale Packaging Committee (JCIBPC), which further refines industry practices.

JCIBPC Guidelines

The JCIBPC has suggested moving away from materials like woven polypropylene and wire ties to improve the global competitiveness of U.S. cotton [3]. Some of their key recommendations include:

- Avoiding extra stickers beyond standard business needs to reduce contamination risks [5].

- Using only approved packaging materials that meet safety and quality standards.

- Following specific label placement instructions to ensure visibility and durability [1].

The committee also stresses the importance of quality control, such as routine inspections of wrapping materials, strapping, and label security [1][4]. These practices not only help businesses stay compliant but also simplify the overall implementation of ISO 8115-3 standards.

Steps to Comply with ISO 8115-3

Implementing Compliance

Meeting ISO 8115-3 standards involves focusing on accurate labeling and proper packaging practices. The first step is setting up a reliable Permanent Bale Identification (PBI) system to ensure seamless tracking from gin to mill [2].

Here are three critical areas to address for compliance:

- Labeling: Attach labels securely in easy-to-access spots. Make sure they can withstand handling and transportation [1].

- Packaging Materials: Use fabric-based protective wrapping with rustproof steel or synthetic hoops. Avoid polypropylene to align with industry standards [3].

- Quality Checks: Perform regular inspections to ensure label security, proper strapping, material compliance, and accurate documentation.

Key quality control tasks include:

- Inspecting how labels are attached

- Confirming packaging materials meet requirements

- Reviewing documentation for accuracy

- Checking the integrity of strapping

Resources for Compliance Support

After covering the basics, companies can tap into industry resources to simplify compliance. Organizations like the National Cotton Council (NCC) and Joint Cotton Industry Bale Packaging Committee (JCIBPC) offer valuable tools, including guidance and reporting systems [3].

| Resource Type | Provider | Support Offered |

|---|---|---|

| Technical Documentation | National Cotton Council | Specifications and detailed guidelines |

| Training Materials | JCIBPC | Staff training and best practices |

To keep compliance on track:

- Stay informed about regulatory updates

- Take part in industry training programs

- Maintain regular communication with certification bodies

"Accurate reporting of tare weights and packaging codes on warehouse receipts prevents misreporting issues", according to the National Cotton Council's guidelines [3].

Best Practices for Cotton Bale Labeling and Packaging

Quality Control Strategies

Effective quality control in cotton bale labeling requires consistent monitoring and inspections. Here are key steps to ensure high standards:

- Check labels daily for proper placement and readability.

- Monitor moisture levels to prevent damage.

- Verify PBI documentation for accuracy.

- Ensure storage areas are clean and well-maintained.

A clean, dry, and ventilated storage environment is essential to protect both labels and packaging materials.

Approved Materials and Techniques

To comply with ISO 8115-3, certain materials must be used for wrapping and strapping cotton bales [1]. Here's a quick guide:

| Material Type | Approved Options | Prohibited Materials |

|---|---|---|

| Wrapping | Woven fabric, Knitted fabric | |

| Strapping | Rustproof steel, Synthetic (non-PP) | Polypropylene |

| Labels | Weather-resistant materials | Paper-based materials |

Labels should withstand handling without losing clarity. Using durable, weather-resistant materials ensures they remain legible throughout the supply chain. Beyond material selection, working with dependable gins is crucial for meeting compliance standards.

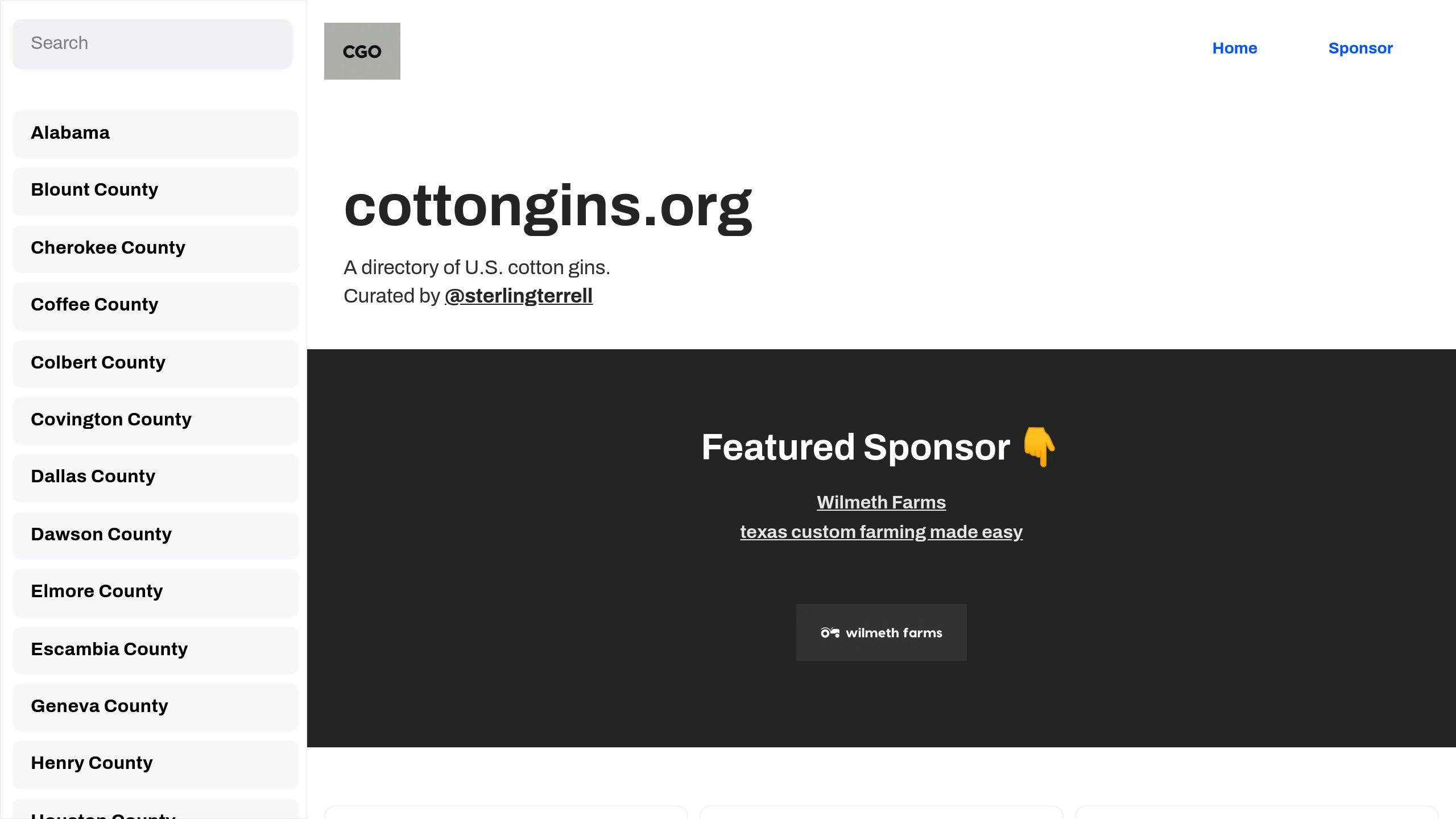

Leveraging Directories like cottongins.org

Finding gins that adhere to ISO 8115-3 is key. Websites like cottongins.org can help you locate U.S. cotton gins that follow proper labeling and packaging practices. This directory allows stakeholders to:

- Locate certified gins in specific areas.

- Connect with facilities using approved materials and methods.

- Access updated compliance details.

By partnering with certified gins, businesses can maintain consistent quality and meet regulatory requirements across the supply chain.

"Accurate reporting of tare weights and packaging codes on warehouse receipts prevents misreporting issues", states the National Cotton Council's guidelines [3].

Regularly communicating with your chosen gin facility and confirming their compliance with the latest ISO 8115-3 standards is essential for ensuring reliable bale labeling and packaging throughout the process.

sbb-itb-0e617ca

Related video from YouTube

Conclusion

ISO 8115-3 has brought consistency to the global cotton trade by establishing clear guidelines for labeling and packaging. These standards have reshaped how cotton bales are handled throughout the supply chain.

Key Points

The PBI system plays a crucial role in improving traceability and streamlining operations, while the use of approved materials ensures quality and compliance. This structured approach has reduced handling mistakes and enhanced supply chain management.

Recent trends in the industry highlight a growing emphasis on contamination prevention and quality assurance. Efforts to maintain high standards reflect the ongoing evolution of cotton bale management practices [3].

The success of ISO 8115-3 relies on using approved materials and consistently applying the standards. For instance, the U.S. cotton industry actively bans materials that may contaminate or obscure PBI tags [5], underscoring the need for strict adherence to these guidelines.

By following ISO 8115-3 and best practices, stakeholders can achieve:

- Greater efficiency through standardized operations

- Better traceability across the global supply chain

- Minimized contamination risks and quality concerns

- Simplified trade processes on an international level

As the industry continues to prioritize sustainability and operational improvements, adhering to ISO 8115-3 allows businesses to meet regulatory requirements while staying competitive in a changing global market. Effective implementation of these standards ensures measurable benefits in trade and quality management.

FAQs

These FAQs address common questions businesses have when working to meet ISO 8115-3 standards, offering practical advice to help ensure compliance.

What is Bale ID?

The Permanent Bale Identification (PBI) system assigns each cotton bale a distinct number and barcode, ensuring it can be traced and minimizing contamination risks. The PBI system includes:

- Classing office identifier

- Gin code

- Individual bale number

The National Cotton Council advises that nothing should be attached to bales if it could obscure PBI tags or negatively affect cotton quality [5].

How does ISO 8115-3 define label requirements?

Labels must display a unique bale number and gin identification. Additional optional details may include [1][4]:

- Mass specifications

- Cotton variety

- Country of origin

- Harvest year

- Quality indicators

- Shipper information

What happens if a business doesn't comply?

Non-compliance with ISO 8115-3 can lead to several issues, including:

- Problems with traceability

- Failures in quality control

- Increased transport risks

- Potential fines from regulators

- Strained or damaged business relationships

To stay compliant, participants in the cotton industry can use tools like cottongins.org to confirm gin details and ensure labels meet the latest standards.

These FAQs highlight the importance of following ISO 8115-3 standards to maintain quality and remain competitive in the global cotton market.