Executive summary (TL;DR)

- Map fields with GPS for variable-rate seeding at 30,000-40,000 plants/acre—cuts seed costs 10-15% while boosting cotton yields in variable soils.

- Use soil sensors and VRT for nitrogen apps at 80-120 lbs/acre sidedress; real-time data slashes over-fertilization by 20%, enhancing boll set without runoff.

- Integrate drones for pest scouting at V6-V12 stages—spot thrips early to reduce sprays 25%, protecting fiber quality in high-pressure zones.

Related Post: For complementary tech insights, check out our post on Digital Tools for Cotton Growers: Enhancing Farm Efficiency.

Chasing bales across the Belt, you start seeing patterns in what separates a good year from a forgettable one. It's not just rain or prices—it's how you wring every drop of efficiency from your acres without guessing. That's where precision agriculture in cotton farming comes in, turning data into decisions that hit your bottom line hard. We're not talking pie-in-the-sky tech; this is stuff that's paying off now for operations like yours, trimming inputs while pushing yields north of 1,200 lbs/acre on variable ground.

I've watched neighbors tweak their setups with GPS and sensors, turning patchy fields into consistent producers. This isn't about gadgets—it's problem-solving for real pains like uneven stands or over-fertilizing sandy knolls. We'll unpack the nuts and bolts, backed by extension trials and field results from spots like Texas A&M and NCSU. No fluff; just how to layer it into your system for gains that stick. Let's roll through it, like we're laying out your next pivot pass.

The Core of Precision Ag: Mapping Your Acres for Smarter Starts

Precision agriculture in cotton farming kicks off with knowing your dirt inside out. Soil sampling on a grid—every 2.5 acres or tighter—builds variability maps that show pH swings, OM levels, and nutrient hotspots. I've seen ops ignore this and chase averages, only to burn cash on blanket apps that starve highs and drown lows.

Use EC (electrical conductivity) scans to zone fields: High EC clays hold water better, so dial seeding down to 35,000/acre there versus 45,000 on sands. Arkansas trials peg variable-rate seeding (VRS) at 10-15% seed savings with no yield dip— that's $20-30/acre back in your pocket. GPS planters make it seamless; calibrate for depth at 0.5-0.75 inches, ensuring even emergence without skips.

Why bother? Uniform stands close canopy faster, shading out pigweed and cutting herbicide passes. In nematode-prone spots, zone fumigants only where thresholds hit 100/100cc— Clemson data shows 20% chem reduction, easing resistance worries.

Variable-Rate Technology: Fertilizer and Irrigation That Fit

Blanket fertility is yesterday's game. Precision ag lets you VRT (variable-rate tech) nutrients based on yield maps from prior years. Sidedress N at 80-120 lbs/acre, ramping up on high-potential zones identified by NDVI (normalized difference vegetation index) from satellite imagery.

Texas AgriLife studies link VRT N to 15-25% efficiency gains—less leaching, better boll retention. Pair with tissue sampling at first square: Target 3.5-4.5% N, adjusting on the fly. For P and K, grid-sample every 3-4 years; apply 40-60 lbs P2O5 where Mehlich-3 dips below 30 ppm.

Irrigation? Sensors like capacitance probes at 6-24 inches track volumetric water content—keep it 50-70% field capacity to avoid stress without waste. Pivot VRI (variable-rate irrigation) zones deliver 0.5-1 inch/week tailored to soil type; Oklahoma State trials show 20-30% water savings, holding yields in droughty years.

Table of VRT benchmarks from extension data:

| Input | Zone Strategy | Savings Potential | Yield Impact |

|---|---|---|---|

| Seeding | 30-45k/acre by EC | 10-15% seeds | Even stands +5-10% |

| Nitrogen | 80-120 lbs sidedress via NDVI | 15-25% fert | Boll set +10-15% |

| Irrigation | 0.5-1 in/week by sensors | 20-30% water | Drought tolerance +15% |

| Pesticides | Scout-triggered VRA | 20-30% chems | Quality preservation |

Scouting Upgraded: Drones and AI for Pest and Stress Detection

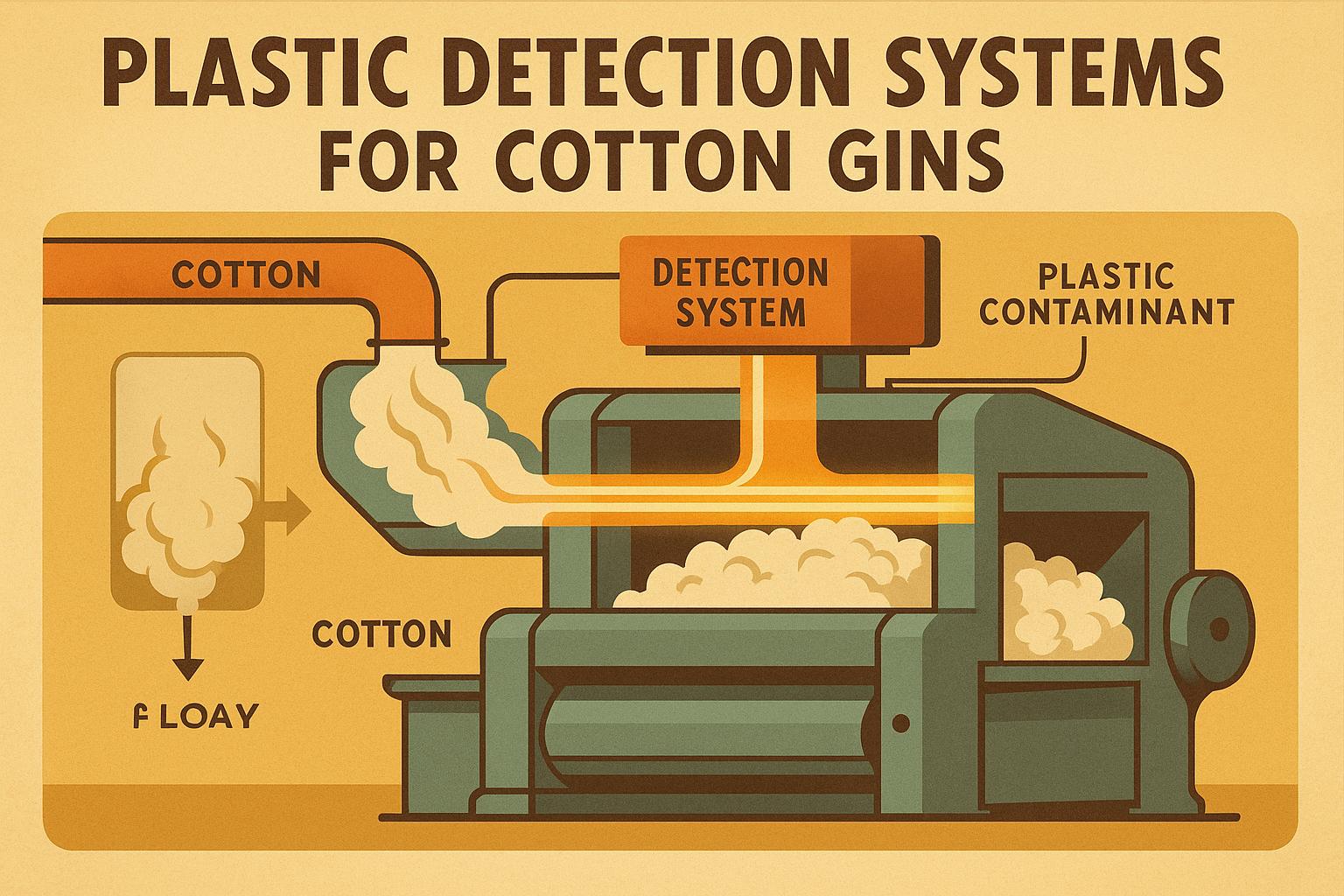

Forget walking every row—drones with multispectral cameras spot stress at V6-V12, flagging thrips or aphids before thresholds hit 2-3/plant. Precision agriculture in cotton farming shines here: AI algorithms analyze imagery for chlorosis or wilting, tying back to fertility maps.

Mississippi State data shows drone scouting cuts response time 50%, enabling targeted sprays—25% less volume with boom section control. For bollworm, the threshold at 5% square damage; VRA (variable-rate application) hits hot spots only, dodging resistance.

Disease? Thermal cams detect verticillium wilt via canopy temp spikes—early flags let you rogue or fumigate zones, per UC trials, saving 10-20% yield. Integrate with apps for real-time alerts; one Delta farm I know halved scouting labor, freeing time for markets.

Data Integration: Yield Monitors and Analytics Platforms

Harvest data closes the loop. Yield monitors on pickers log GPS-tagged lbs/acre, overlaying with input maps to spot ROI drags—like low-yield zones from compaction. Analytics platforms crunch it, prescribing tweaks for next season.

NCSU benchmarks show data-driven farms averaging 100-200 lbs/acre gains over three years. Export to farm management software for budgeting: If a zone yields under 800 lbs, rotate to sorghum—breaks cycles, rebuilds soil.

Challenges? Data overload—start small, one field with basic GPS. Connectivity in remote spots? Offline modes sync later. Cost: Entry-level kits run $5k-10k, ROI in 1-2 seasons via savings.

Economics: Crunching the Numbers on Precision Payback

Upfront bite—$10-20/acre for tech—but payouts stack. Variable seeding alone saves $15-25/acre; add fert/irrigation efficiencies for $50-100 net. Georgia trials peg 10-20% yield bumps on variable fields, translating to $100-200/acre at $0.70/lb.

Scale matters: 500+ acres justify full suites; smaller ops start with free apps and shared drones. Premiums for traceable cotton add 2-5 cents/lb—buyers love data-backed sustainability.

One High Plains grower layered VRI and VRT, cutting water 25% amid droughts—kept operation viable when neighbors folded.

Overcoming Hurdles: Adoption Tips for Seasoned Ops

Tech intimidation? Extension workshops demystify—start with soil mapping, build from there. Integration glitches? Compatible systems from John Deere or Case ease it.

Labor shift: Retrain hands on data interpretation; it empowers decisions, cuts guesswork.

Future-proof: As AI evolves, platforms predict yields pre-plant—Why AI-Driven Yield Prediction Matters, but grounded in your data.

Fine-Tuning: Customizing for Your Dirt

Precision agriculture in cotton farming isn't plug-and-play—adapt to your setup. Sandy loams? Prioritize irrigation zoning. Clay heavies? Focus compaction relief via controlled traffic.

Track metrics yearly: Yield variance under 10% signals success. Logs beat memory; review post-harvest for pivots.

I've seen it turn marginal ground into moneymakers. What's holding you back? Share below—we're all dialing it in.

Actionable Takeaways

- Grid-sample soils every 2.5 acres; zone VRS for 10-15% seed efficiency.

- Deploy sensors for VRT N/Irrigation; aim for 20% input cuts with steady yields.

- Drone-scout weekly V6+; target sprays to slash chems 25%.

- Analyze harvest data annually; rotate low-ROI zones for cycle breaks.