Cotton gins must follow EPA rules to control air pollution, especially particulate matter (PM10 and PM2.5), to protect air quality and avoid fines. Here's what you need to know:

- Emission Limits: Facilities emitting over 100 tons of PM annually face stricter regulations. Operators must calculate emissions using EPA-approved methods like AP-42 guidelines.

- Permits: Title V permits require detailed emissions data and can take 6-12 months to secure.

- Control Equipment: High-efficiency cyclones and regular maintenance are key to reducing emissions.

- Compliance Tips: Keep records of maintenance, train staff, and stay proactive with inspections to avoid fines of up to $50,000 per day.

Understanding Next Generation Compliance and Enforcement

Steps to Follow EPA Rules

Meeting EPA regulations requires knowing emission limits, obtaining the right permits, and using appropriate control equipment.

Understanding Emission Limits and Calculations

Cotton gin operators need to calculate emissions using EPA's AP-42 guidelines for estimating air pollutants [1]. Potential-to-emit (PTE) refers to the maximum emissions a facility could release under standard operations.

Here are key thresholds to keep in mind:

| Emission Type | Major Source Threshold |

|---|---|

| PM-10 | 100 tons per year |

| PM-2.5 | 35% of PM-10 |

| NOx/SOx | Minor amounts |

If your PM-10 emissions approach 70 tons annually, it's time to take a closer look and ensure you're staying within limits.

How to Get Required Permits

To secure a Title V permit, you'll need to prepare an application that includes emissions data, facility details, and information about your control equipment. Submit the application to the relevant authorities, who typically take 6-12 months to review it. Be ready to respond to any follow-up questions during this process [2].

The National Cotton Council emphasizes the importance of staying in regular contact with regulators to keep the process running smoothly.

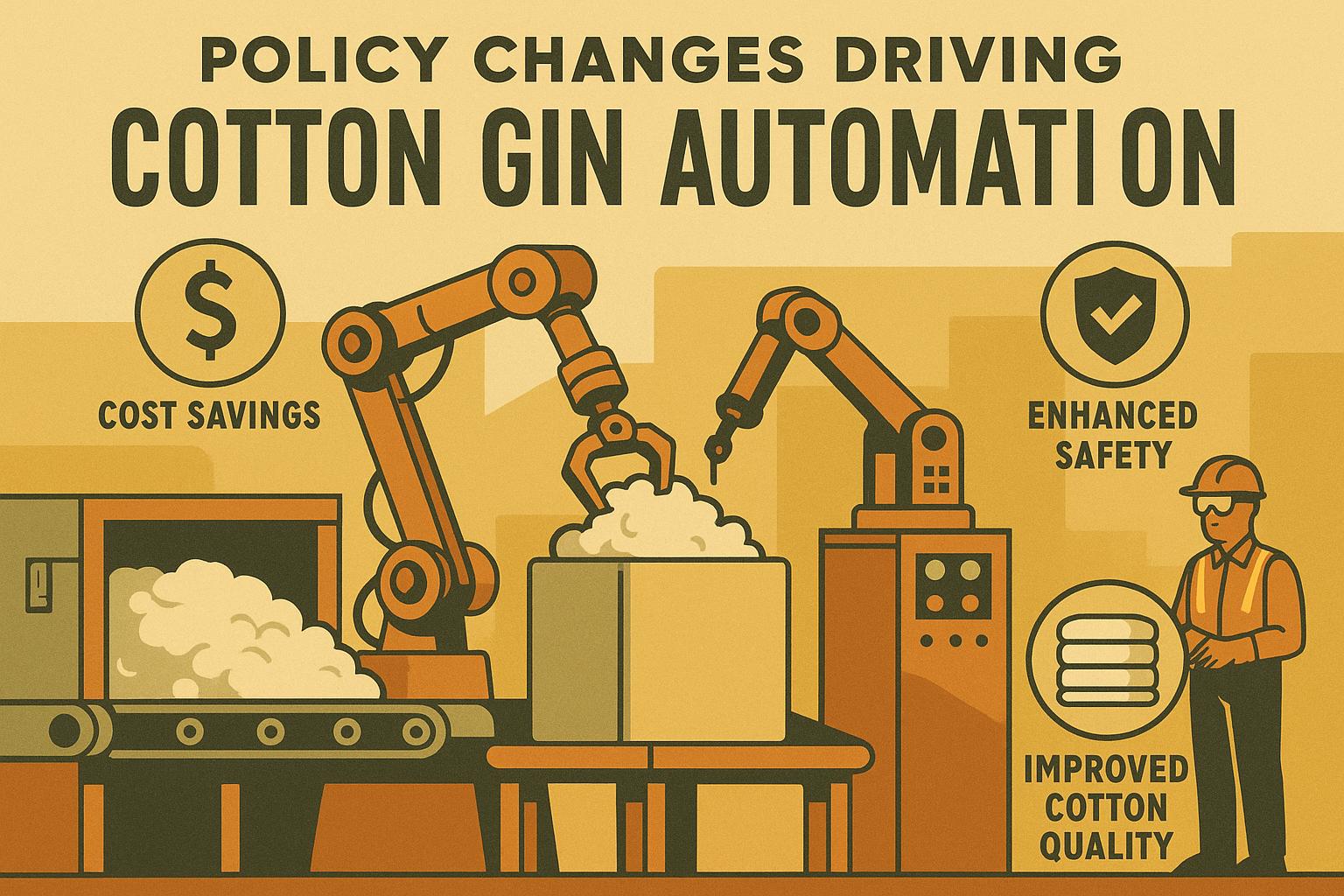

Using Equipment to Control Emissions

Cyclones are commonly used in cotton gins to manage emissions effectively [1][3]. Install high-efficiency cyclones at exhaust points and maintain them regularly to ensure they work as intended.

To get the best results:

- Choose equipment that fits your facility’s specific needs and complies with local and state regulations.

- Stick to a routine maintenance schedule.

- Track performance regularly to catch and fix issues early.

Using the right equipment is only part of the equation. Regular upkeep and training your team on proper operations are just as important for staying compliant.

Tips for Staying Compliant

Staying on top of EPA regulations involves a structured approach to maintenance, staff education, and organized record-keeping. According to the National Cotton Ginners Association, managing compliance proactively can help you avoid expensive fines and interruptions to operations [3].

Regular Maintenance and Inspections

A solid maintenance plan is key for keeping emission control systems in check. The Louisiana Department of Environmental Quality suggests:

- Daily checks for leaks, unusual noises, and visible emissions.

- Weekly upkeep like cleaning filters and assessing cyclone performance.

- Annual professional inspections to thoroughly evaluate all systems [2].

Keep detailed records of maintenance activities, including dates, issues found, and fixes made. These records not only show your commitment to meeting environmental standards but also help during regulatory inspections.

Training Staff and Keeping Records

The National Cotton Council highlights the importance of training employees in areas such as [1]:

- Understanding EPA regulations and how they apply in practice.

- Operating emission control equipment correctly.

- Emergency response protocols.

- Proper record-keeping procedures.

It’s also crucial to maintain well-organized records, such as compliance test results, maintenance logs, and training documentation. Use a centralized system to store these records, making it easier to handle EPA inquiries and inspections efficiently.

sbb-itb-0e617ca

How to Avoid Penalties

How EPA Enforces Rules

The EPA ensures compliance through inspections and penalties. Under the Clean Air Act, violations can lead to fines of up to $50,000 per day for each infraction [1]. Here's how they typically enforce their rules:

Regular Monitoring: The EPA conducts both scheduled and surprise inspections, often collaborating with state environmental agencies. These inspections focus on emission levels, equipment performance, and accurate record-keeping [3].

Documentation Review: Inspectors carefully examine key records, including:

- Emission reports and calculations

- Maintenance logs

- Staff training records

- Permits and renewal documents

A particular focus is placed on particulate matter emissions, with cotton gin emissions contributing roughly 35% PM10 and 2.5% PM2.5 [3].

Understanding these enforcement methods is just the beginning. Taking action to address potential issues is critical to staying compliant.

Steps to Stay Ahead of Problems

Proactively addressing compliance helps prevent fines and keeps operations running smoothly.

Key Compliance Steps:

- Use a calendar to track audits, inspections, training sessions, and permit deadlines.

- Document any issues, determine their root causes, and resolve them quickly.

- Leverage tools and resources from industry groups to stay compliant.

- Consult with EPA compliance experts for more complex challenges.

Helpful Resources for Cotton Gin Operators

Support from Industry Groups

The National Cotton Council (NCC) and the National Cotton Ginners Association (NCGA) team up with the EPA to make compliance easier for operators. They offer workshops on topics like emission estimates and record-keeping, while also collaborating with federal and state agencies to create practical permitting guidelines [1].

"EPA will continue to be very active on regulatory issues, particularly with the development and implementation of new standards for ambient air quality" [1].

EPA Tools and Guides

The EPA offers several tools designed to help operators stay on track with regulations:

- AP-42 documentation for detailed emission factors

- Online calculators to figure out permit requirements

- State-specific guidance, including permits tailored for minor source cotton gins

Some states, like Arkansas, even provide specialized programs such as the General Air Permit program, which outlines clear steps for cotton gin operations [4].

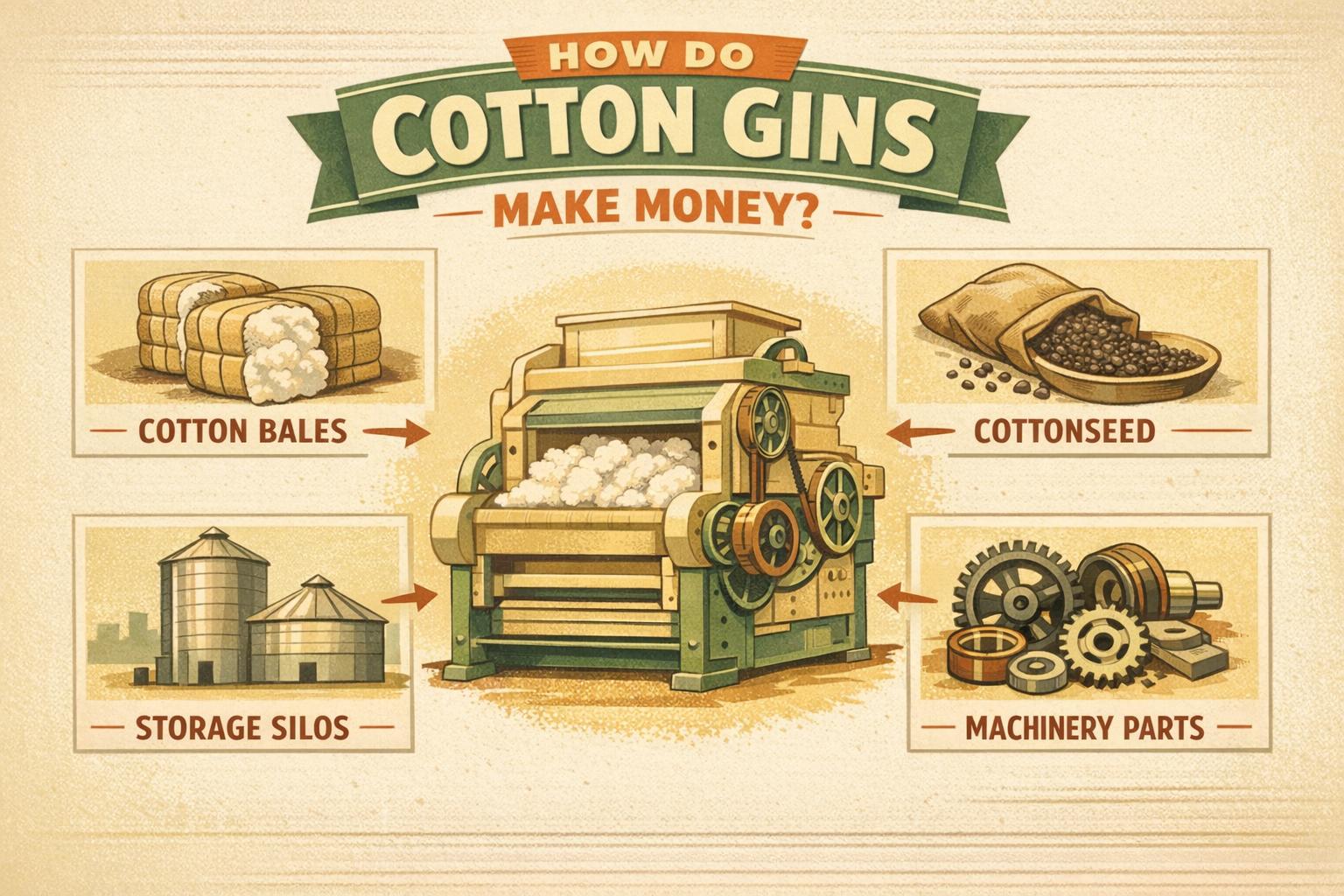

Leveraging cottongins.org

Cottongins.org serves as a helpful addition to EPA and industry resources. It allows operators to exchange compliance strategies and discover best practices specific to their region. The platform’s directory connects operators facing similar challenges, making it easier to learn from others’ successes.

| Resource Type | Benefits |

|---|---|

| Industry Associations | Training, expert advice, updates |

| EPA Tools | Documentation, permit calculators |

| Cottongins.org | Networking, regional compliance tips |

Conclusion

Key Takeaways

Meeting EPA compliance standards for cotton gins involves a thoughtful approach that integrates technical solutions, thorough documentation, and effective use of resources. Operators must calculate allowable emission rates using EPA-approved methods tailored to their bale processing capacity.

Here are the three main focus areas for successful compliance:

1. Equipment and Controls

Modern cotton gins need to use advanced emission control systems like high-efficiency cyclones to manage particulate matter effectively and stay within EPA’s limits.

2. Documentation and Monitoring

Keeping detailed records - such as emission data and maintenance logs - is crucial, especially with the stricter particulate matter standards introduced by the EPA since 1993. These documents are vital for passing inspections.

3. Resource Utilization

Leveraging tools and guidance from industry associations and the EPA helps operators stay updated on regulatory changes. Accurate record-keeping and using these resources ensure compliance and preparedness.

"Staying informed about evolving EPA standards is critical for long-term compliance."

Achieving sustained compliance requires consistent effort. By adopting emission control technologies, maintaining comprehensive written programs, and performing regular audits, cotton gin operators can ensure they meet environmental standards while optimizing operations.

| Compliance Area | Key Actions | Benefits to Operations |

|---|---|---|

| Technical Controls | Install monitoring systems, filtration equipment | Reduces particulate emissions and meets EPA limits |

| Administrative Tasks | Maintain records, update permits | Ensures compliance is well-documented |

| Training and Education | Train staff on procedures, standards | Prevents violations and keeps operations running smoothly |

FAQs

Understanding the impact of cotton ginning on air quality is crucial for ensuring compliance with regulations and protecting public health.

What are the air quality concerns associated with cotton ginning?

Cotton ginning releases fine particles like PM10 and PM2.5 into the air. These particles can lower air quality and pose health risks, which is why the EPA enforces strict regulations in this area. Operators need to focus on controlling these emissions effectively.

The process emits dust, plant debris, and cotton lint fibers. PM10 makes up about 35% of these emissions, while PM2.5 accounts for 2.5%. The smaller the particles, the more harmful they can be, as they can reach deep into the lungs. Tools like cyclones and water suppression systems play a key role in managing these emissions [1][3].

| Processing Stage | Type of Particulate | Control Method |

|---|---|---|

| Processing Stages | Dust, debris, and lint | Cyclones |

| Lint Cleaning | Ultra-fine particles | Water suppression systems |

The National Cotton Council provides guidance to help operators reduce emissions without sacrificing efficiency. Cyclones and water suppression systems are among the most effective methods for managing PM emissions during different stages of cotton processing [1][4].