Heat stress is a major concern for workers in cotton gins. These facilities combine high temperatures, physically demanding tasks, and poor ventilation, creating dangerous conditions. Without proper precautions, workers face serious health risks like heat stroke, heat exhaustion, and even fatalities. Here’s a quick look at the key points:

- Heat stress dangers: Core body temperature can rise to 106°F in minutes, leading to severe illnesses.

- High-risk factors in cotton gins: Extreme heat from machinery, heavy workloads, and inadequate ventilation.

- Health impacts: Symptoms range from heat rash to life-threatening conditions like heat stroke and kidney damage.

- Productivity and safety issues: Heat stress reduces efficiency and increases accidents due to impaired focus.

- Prevention strategies: Improved ventilation, cooling systems, hydration programs, and acclimatization protocols.

Key takeaway: Cotton gin managers must implement safety measures like heat monitoring, cooling facilities, and adjusted work schedules to protect workers and maintain productivity.

Heat Stress Statistics and Prevention Measures in Cotton Gins

Heat Stress Risk Factors in Cotton Gins

Temperature and Environmental Conditions

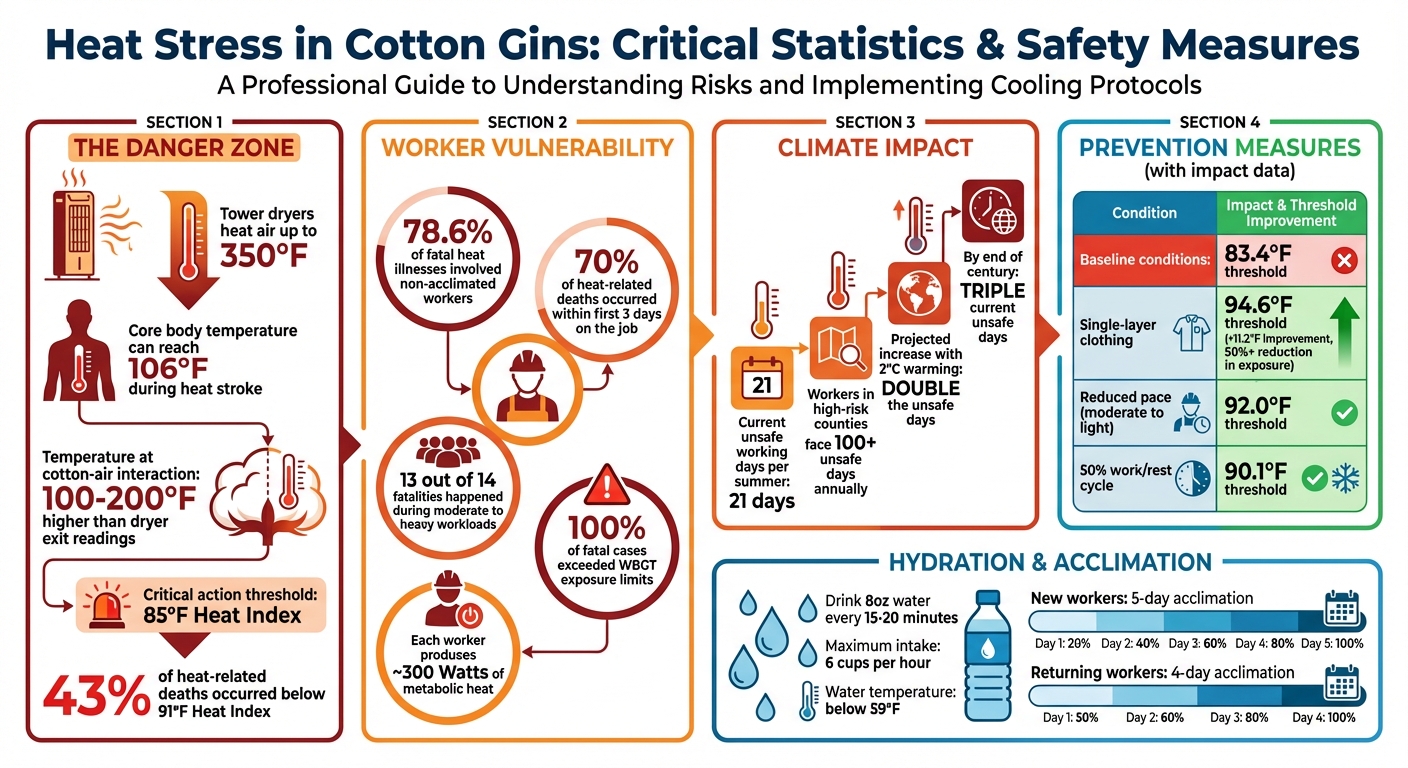

Cotton gin operations come with unique environmental challenges that significantly heighten heat stress risks. These facilities generate intense heat from multiple sources. For instance, tower dryers heat air up to 350°F to reduce cotton moisture levels below 7%. Even with insulation, some of this heat escapes into the workspace. The temperature where cotton and air interact can soar 100–200°F higher than the readings recorded at the dryer exit.

Heat stress in these facilities stems from a mix of factors: air temperature, humidity, solar radiation, and wind speed. On top of that, physical labor contributes significantly, with each worker producing around 300 Watts of metabolic heat as they perform their tasks.

Geography and seasonality make the situation even more challenging. Cotton-growing regions like the Mississippi Delta, Central California, and the Southeast experience the highest heat exposure during harvest months, typically from May through September. Workers in areas such as Imperial County, California, and Hillsborough County, Florida, already face over 100 days annually with unsafe heat levels. If global temperatures rise by 2°C, the number of unsafe working days in these regions is expected to double. These combined operational and environmental conditions paint a clear picture of the heat stress risks workers face.

Worker Risk Factors

In addition to environmental hazards, specific worker-related factors amplify the danger. A study of 25 heat-related illnesses revealed that 13 out of 14 fatalities occurred during moderate to heavy workloads.

Simple adjustments can make a significant difference. For example, switching to single-layer breathable clothing can reduce unsafe heat exposure by over 50%. The table below outlines how various measures impact heat stress thresholds:

| Adaptation Measure | Heat Stress Threshold (°F) |

|---|---|

| Baseline (90% effort, double-layer clothing, shade rest) | 83.4°F |

| Single-layer Clothing | 94.6°F |

| Reducing Pace (Moderate to Light) | 92.0°F |

| Reduced Effort (50% work/rest cycle) | 90.1°F |

Workers are especially vulnerable during their first one to two weeks on the job. Alarmingly, 78.6% of fatal heat-related illnesses involved employees who had not yet acclimated to the conditions. Other factors, such as age, chronic health issues like obesity and diabetes, and medications that interfere with the body's ability to regulate temperature, further increase individual risks. Taken together, these environmental and personal factors underline the urgent need for robust heat stress prevention strategies in cotton gin facilities.

Health Effects of Heat Stress on Gin Workers

Heat-Related Illnesses and Symptoms

Heat stress can lead to a range of health issues, from mild irritations to severe, life-threatening conditions. Early signs include heat rash, muscle cramps, and fainting spells. If exposure continues, workers may develop heat exhaustion, which brings symptoms like headaches, nausea, dizziness, extreme fatigue, heavy sweating, and reduced urination. In the most severe cases, heat stroke occurs, marked by a dangerous rise in core body temperature (up to 106°F), confusion, slurred speech, seizures, and even unconsciousness.

Another serious condition is rhabdomyolysis, where muscle tissue breaks down rapidly, releasing proteins into the bloodstream that can damage the kidneys. Symptoms of this condition include muscle pain, difficulty exercising, and dark, tea-colored urine.

"Heat stroke is the most serious heat-related illness. It occurs when the body can no longer control its temperature: the body's temperature rises rapidly, the sweating mechanism fails, and the body is unable to cool down." - NIOSH

In cotton gins, the combination of high ambient temperatures and heat generated by heavy machinery significantly increases these risks. Research has shown that fatalities are often linked to heat stress levels exceeding recommended safety thresholds. This has led experts to establish 85°F as the critical temperature point for initiating protective measures.

These immediate health risks highlight the pressing need for better understanding and mitigation of heat stress in industrial environments.

Research from Cotton Processing and Similar Industries

Studies from cotton processing and related industries show that poor ventilation, combined with heat from machinery, significantly worsens the dangers of heat stress. Research in agricultural and industrial settings has linked chronic heat exposure to serious health problems, including acute kidney injuries and persistent dehydration. This has been particularly documented among workers in states like California, Florida, and Washington.

Extended exposure to high temperatures in poorly ventilated facilities can overwhelm the body’s natural cooling systems. This leads to cardiovascular strain, organ damage, and even a heightened risk of physical injuries. Additionally, heat stress can impair cognitive abilities, making it harder for workers to focus and make decisions - issues that are exacerbated when wearing heavy protective gear that traps heat and moisture. There is also evidence linking occupational heat exposure to negative mental health effects.

For cotton gin workers, these risks are amplified by the heat generated indoors by processing equipment. Even when outdoor temperatures are moderate, the machinery can create dangerously hot conditions inside. This makes it crucial to address workplace safety measures to protect workers from the compounding effects of heat stress.

How Heat Stress Affects Productivity and Safety

Productivity Losses from Heat Stress

Heat stress takes a toll on both worker output and efficiency. Studies highlight that occupational heat exposure is a well-documented cause of declining productivity in agricultural and processing industries. The problem is particularly severe in environments like cotton gins, where workers have limited control over their surroundings and often feel compelled to maintain their pace, even when conditions become hazardous.

Currently, U.S. crop workers endure around 21 unsafe working days each summer growing season. If no action is taken, climate predictions indicate that this number could double by the middle of the century and triple by its end. For cotton gin workers, the pressure to sustain productivity under such conditions can lead to unsustainable work speeds, increasing the likelihood of accidents.

Implementing safety measures often comes at the cost of productivity. For instance, adopting a 50% work/rest cycle can effectively eliminate heat-related risks but significantly cuts output and raises labor expenses. Another approach, reducing work intensity to a "light" pace during peak heat hours, lowers risk but directly impacts hourly productivity. Managers in cotton gins face a tough dilemma: safeguarding workers while ensuring operations remain efficient during the critical harvest period.

This drop in productivity is closely tied to a rise in safety risks, as heat stress not only affects physical performance but also compromises operational safety.

Safety Risks and Increased Errors

Beyond the productivity challenges, heat stress poses serious safety concerns. Workers under heat stress often experience impaired cognitive functions, such as reduced ability to think clearly, perceive hazards, and plan effectively. These mental impairments make it harder to identify and avoid dangerous situations. On top of that, physical symptoms like clumsiness, slurred speech, and fainting significantly raise the chances of accidents, especially around heavy machinery.

"Thinking clearly, perception, planning, and other mental processes become impaired, and the worker may be unable to recognize dangerous situations." - OSHA Technical Manual

The dangers are clear when looking at heat-related illness data. A study of 25 outdoor heat-related illnesses found that every fatality occurred under excessive heat stress. Alarmingly, 43% of heat-related deaths happened when the Heat Index was below 91°F, showing that risks persist even in what might seem like moderate conditions.

New and returning workers are especially vulnerable. Nearly 70% of heat-related deaths occurred within the first three days on the job, underscoring the heightened risk for those who haven’t yet acclimatized to the heat. In cotton gins, where machinery can generate temperatures as high as 350°F for fiber drying, these risks are even greater. Supervisors must act quickly to address the impaired cognition and coordination that heat stress can cause.

sbb-itb-0e617ca

Preventing and Managing Heat Stress in Cotton Gins

Equipment and Facility Improvements

Creating a safer work environment is the most effective way to combat heat stress in cotton gins. Installing air conditioning in break rooms and equipment cabs can significantly lower the surrounding temperature, while better ventilation helps disperse heat throughout the facility. Local exhaust systems near heat-generating areas, like dryers or processing equipment, can pull hot air out before it spreads.

"The best engineering controls to prevent heat-related illness is to make the work environment cooler and to reduce manual workload with mechanization." - Occupational Safety and Health Administration

Additional measures, such as reflective shields and insulating surfaces, can redirect radiant heat away from workers. Misting systems and fans enhance cooling through evaporation, while mechanization - like using conveyors or forklifts - reduces the physical effort required, cutting down on heat produced by exertion. To monitor conditions, WBGT (Wet Bulb Globe Temperature) meters measure factors like air temperature, humidity, sunlight, and airflow. If WBGT meters aren't available, use the Heat Index as a guide and initiate protective measures when it hits 85°F. These engineering upgrades create a solid foundation for further adjustments to work schedules and safety protocols.

Work Schedules and Hydration Programs

Environmental changes alone aren't enough - proper scheduling and hydration are key to keeping workers safe. New employees should be gradually introduced to heat exposure, starting at 20% of a full workload on the first day and increasing by 20% each day until they reach full capacity by day five. Returning workers should follow a shorter acclimatization schedule, beginning with 50% exposure on day one and reaching 100% by day four.

To minimize risks, schedule demanding tasks during cooler parts of the day, like early morning or late afternoon, and enforce mandatory rest breaks in shaded or air-conditioned spaces. Workers should drink about 8 ounces of water every 15–20 minutes when performing moderate activity in the heat, but total fluid intake should not exceed six cups per hour. Keep drinking water below 59°F and ensure it’s readily available near work areas. A buddy system can also help, as workers can watch for signs of heat stress in each other, such as confusion, irritability, or muscle cramps.

Heat Monitoring and Emergency Response

Even with environmental and schedule adjustments, real-time monitoring and quick action are critical. Assign specific staff to track daily weather and on-site heat conditions using tools like WBGT meters or the NIOSH/OSHA Heat App, which calculates the Heat Index and provides real-time safety recommendations based on workload. Supervisors and workers should be trained to identify symptoms of heat-related illness and know how to respond. Studies show that all fatal heat stress cases exceeded WBGT exposure limits, highlighting the importance of vigilance.

Emergency plans should include clear steps for immediate action. For instance, if a worker shows symptoms of heat stroke - such as confusion, slurred speech, or unconsciousness - call 911 and begin aggressive cooling measures right away. Continuous monitoring with apps or WBGT meters ensures that heat stress symptoms are caught early. Additionally, it’s important to note that some medications can make individuals more sensitive to heat, and protective clothing can add the equivalent of 5.4°F to 19.8°F to the WBGT reading. Staying proactive can make all the difference in keeping workers safe.

Conclusion

What Cotton Gin Managers Should Do

Heat stress is a serious concern in cotton gins, with studies showing that 50% to 70% of outdoor heat-related fatalities occur during the first few days of working in hot conditions. This highlights the critical need to follow acclimatization protocols closely.

To monitor conditions effectively, use WBGT (Wet Bulb Globe Temperature) meters, which factor in temperature, humidity, radiant heat, and air movement. If WBGT meters aren’t available, consider a Heat Index of 85°F as the threshold for action. Research has shown that 43% of heat-related fatalities occurred when the Heat Index was below 91°F.

Beyond monitoring, focus on practical safety measures like upgrading ventilation, installing air conditioning, and providing cooling options. Schedule demanding tasks during cooler parts of the day and implement a buddy system to quickly spot early signs of heat stress. It's worth noting that WBGT-based exposure limits were exceeded in 100% of fatal cases, proving that monitoring alone isn’t enough - rapid emergency response protocols are equally vital.

While these steps provide a strong foundation for managing heat risks, continued research is necessary to refine and enhance these strategies.

Where More Research is Needed

Despite advancements, there are still gaps in understanding heat stress in industrial settings. Occupational exposure limits need further validation in real-world conditions, and Heat Index–based guidelines must better account for the physical demands and clothing specific to cotton processing.

Naflath Thenveettil from Mississippi State University points out:

"Little is known about the influence of different combinations of day/nighttime temperature on cotton flowering and boll maturation under ambient and elevated CO2 conditions."

There’s also a need to study how modern medications interact with heat exposure, especially since 48% of workers experiencing heat-related illnesses have at least one predisposing condition, such as hypertension or obesity. Research using micro-gins could offer insights into how heat-stressed cotton impacts machinery performance and fiber quality. Additionally, exploring ways to upgrade ginning machinery for better resilience against extreme temperature shifts could help maintain efficiency under challenging conditions.

FAQs

What are the warning signs of heat stress for cotton gin workers?

The first signs of heat stress in cotton gin workers often show up as heavy sweating, increased thirst, headache, nausea, dizziness, fatigue, and irritability. These are the body's way of signaling that internal temperatures are climbing, and they shouldn't be taken lightly.

Working in cotton gins, particularly in hot and humid areas like the Southeast, can quickly lead to heat stress. Spotting these symptoms early is crucial to avoiding more severe conditions like heat exhaustion or heat stroke. Employers play a key role here - they should provide workers with easy access to water, shaded areas, and regular breaks. Encouraging open conversations about how workers are feeling can go a long way in protecting their health and keeping operations running smoothly.

What are the best ways to improve ventilation in cotton gins to prevent heat stress?

Improving ventilation is a practical way to tackle heat stress in cotton gins. Start by pinpointing areas where airflow is limited, then install high-capacity exhaust fans or roof-mounted blowers to push out hot air and replace it with cooler air. Place fans strategically near heat-producing equipment like dryers and lint cleaners, and use variable-speed controls to fine-tune airflow as temperatures climb. Opening doors, windows, and louvers can help create natural cross-breezes, while portable floor or wall-mounted fans can further enhance air circulation.

For a more thorough approach, think about incorporating ventilation upgrades into a Heat Illness Prevention Program (HIPP). Equip the facility with temperature sensors to track indoor conditions and automate fan speeds when temperatures near 82°F. Keep fans in good working order through regular maintenance, and make sure workers have access to shaded or air-conditioned break areas to cool off. These measures not only help manage heat stress but also contribute to a more comfortable and efficient work environment during the busiest ginning periods.

Why is it important for new workers in cotton gins to adjust to the heat?

Acclimatization is crucial for new workers in cotton gins because their bodies need time to adjust to the intense heat and humidity typical of these environments. Without this adjustment period, they face a greater risk of heat-related illnesses, as their bodies struggle to cool down efficiently through sweating and managing cardiovascular strain.

A gradual exposure period of 7–14 days, starting with lighter tasks and shorter shifts, allows workers to build up their heat tolerance. This process improves how effectively their bodies sweat, reduces fatigue, and lowers the likelihood of heat-related injuries. Employers play a key role in this adjustment by ensuring access to plenty of water, providing electrolyte replacements, and closely monitoring workers' health during this critical period.

Beyond protecting workers' health, proper acclimatization enhances productivity by reducing downtime and avoiding medical emergencies. For more resources and guidance on cotton gin operations, visit cottongins.org.