Cotton Gin Automation 2026: Smart Hydraulics and Robotics for Tighter Supplies

sbb-itb-0e617ca

TL;DR

Global cotton production drops to 119.4M bales in 2025/26 with US yields falling to 856 lb/acre, tightening supply chains, and pushing farm prices to 61¢/lb. West Texas gins counter with automation: SmartFlow hydraulics deliver 50 bales/hour (25% faster), robotic cleaners cut non-lint content 20%, and AI predictive maintenance eliminates 30% of downtime. These upgrades turn supply constraints into 2-3¢/bale premiums through cleaner fiber and higher throughput.

Why Automate Now? The 2025/26 Supply Crunch Hits Gins Hardest

USDA's January 2026 WASDE report delivered sobering news: world cotton production slashed 350,000 bales to 119.43 million, with US output down 2% to 13.9 million bales on Delta yield declines and larger Southwest harvested area. National average yield dropped 8% to 856 pounds/acre, pushing ending stocks to 74.48 million bales—a stocks-to-use ratio under 63% that signals tighter margins ahead.

For West Texas High Plains gins serving 5-6 million acres of PHY 433 W3FE and DP 2618 B3TXF (see Top Cotton Varieties for West Texas 2026), this means variable volumes and basis pressure. Irrigated yields hold 800-1,200 lb/acre, but La Niña risks and 61¢/lb prices demand efficiency. Legacy equipment—20-year-old hydraulics cavitating at 40 bales/hour—can't handle surge capacity without fiber damage or overtime labor.

Manual processes exacerbate non-lint issues (trash, bark) that plague spinning mills, as detailed in Non-Lint Content in Cotton. Automation tailors cleaning to variety specs: lighter for PHY 357's density, aggressive for stripper-harvested dryland (link Dryland Cotton Playbook).

The math is simple: at $25-35/bale ginning fees and 40-60k bale seasons, 20% throughput gains add $50-100k revenue without new stands. Cleaner HVI profiles (staple 1.22", micronaire 4.2-4.8) fetch 1-2¢ premiums to Vietnam and China—critical when basis tracks 1,000-1,500 points under NY futures.

Hydraulic Revolutions: SmartFlow Ends Cavitation Forever

Lubbock Electric's SmartFlow system redefines gin hydraulics with a flooded-suction design: pumps sit below minimum oil level, using gravity to pressurize intake lines and eliminate cavitation—the air-pocket failures that sideline 2-stage pumps mid-season. Three-stage vane pumps double oil volume and flow versus legacy 2-stagers, pushing reliable throughput from 40 to 50 bales/hour.

Texas gins report concrete gains: one High Plains operation jumped from 40-42 bales/hour to 50+ during peak 2025 harvest, adding 8-10 bales/hour without fiber damage or energy spikes. Variable-speed motors auto-adjust for module density—critical for PHY 433 W3FE's cleaner but heavier packs versus DP 2618's stripper harvest.

Technical Breakdown:

| Feature | Legacy 2-Stage | SmartFlow 3-Stage | Gain |

|---|---|---|---|

| Oil Flow | 20-30 GPM | 50-60 GPM | +100% |

| Peak Speed | 40 bales/hr | 50 bales/hr | +25% |

| Energy Use | 15% spikes | Steady 85% load | -15% |

| Downtime | 5-10%/season | <1% | -90% |

Installation runs $25-35k but pays in 18-24 months at $25/bale fees. IoT integration enables remote diagnostics—adjust dryer loads from your phone during La Niña storms. Pairs perfectly with Best Equipment for Cotton Gins lint cleaners for end-to-end automation.

Robotics and Precision Cleaning: Variety-Specific Ginning

Robotic feeders revolutionize seed-cotton intake, using computer vision to auto-adjust for moisture and trash content—vital post-rain when Fiber Quality vs. Yield decisions get tricky. Electrostatic and high-frequency vibration cleaners remove 20-30% more non-lint than manual systems, preserving staple while hitting micronaire targets.

AI-driven precision ginning tailors parameters per variety:

- PHY 433 W3FE: Lighter pressure, 1.22" staple protection

- DP 2618 B3TXF: Higher speed for dryland density

- PHY 357 W3FE: Aggressive trash zap for export premiums

Double-roller automatic gins dominate at 70kg lint/hour with 2.8% lower power than saw gins—South Asia's preference now hitting US co-ops. Labor drops 40% amid shortages, while HVI rejects fall 25% for 1-3¢/bale uplift.

Real-World Example: A Plainview gin retrofitted robotics in 2025, cutting non-lint from 3.2% to 2.1% on West Texas modules. Spinning mills paid 2.5¢ premium; throughput rose 18% without new hires.

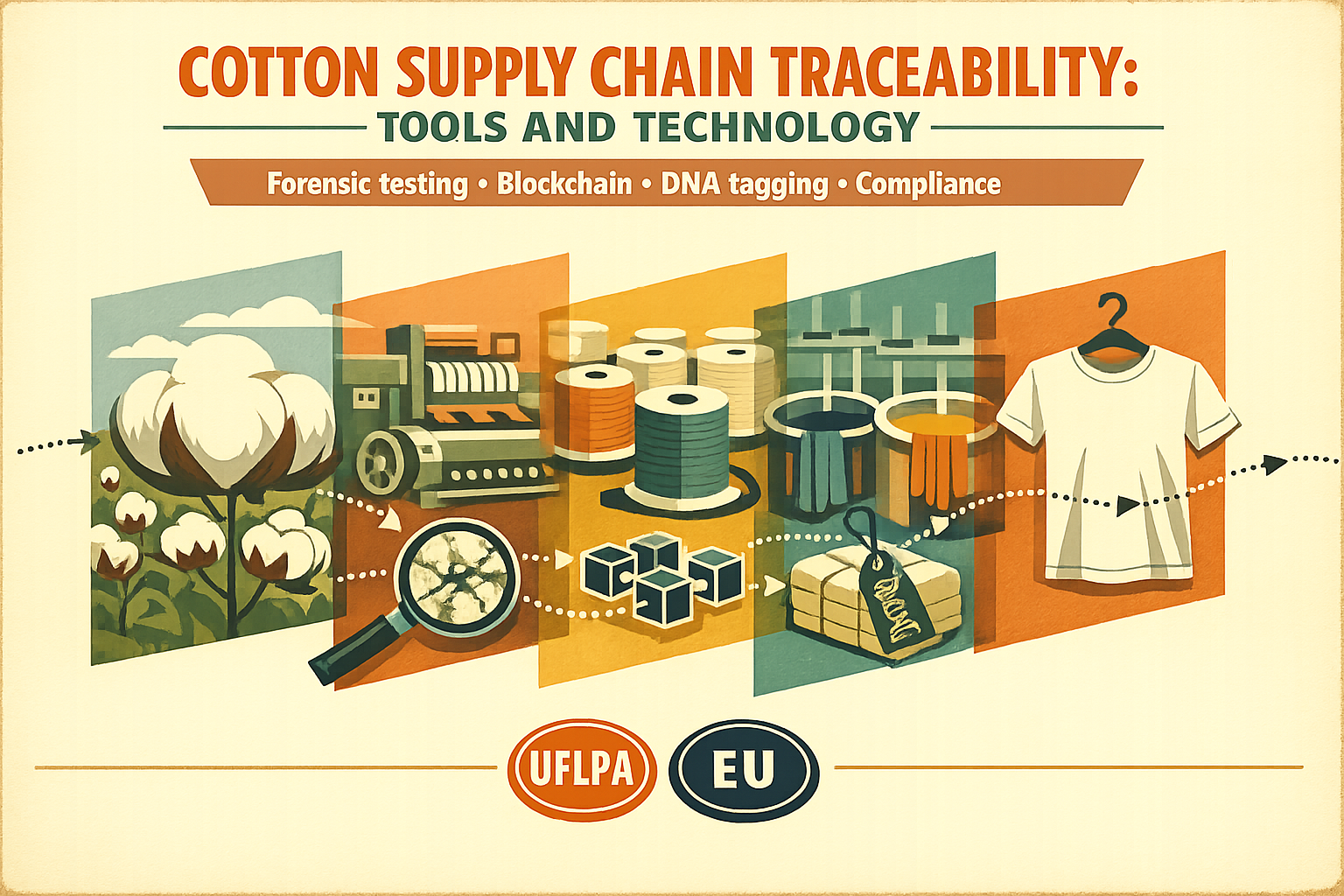

Sustainability and Industry 4.0: The Full Integration

IoT networks tie gins to farms—pivot irrigation data (link Center-Pivot Irrigation for Cotton) predicts dryer needs, saving 10-15% energy. Closed-loop water systems and waste-to-fiber recycling align with the Ultimate Guide to Sustainable Cotton Gins, meeting EU traceability mandates.

Market momentum: Cotton ginning machines hit $195M by 2032 (2.8% CAGR); US automatic segment grows 7.15% on labor dynamics. Co-ops scale first—your 40-60k bale models integrate seamlessly, boosting Cotton Gin Profitability in tight stocks.

Energy Savings Table:

| Upgrade | kWh/Bale Saved | Annual (50k bales) | CO2 Reduction |

|---|---|---|---|

| SmartFlow | 0.8 kWh | $4,000 @10¢/kWh | 6 tons |

| Robotics | 1.2 kWh | $6,000 | 9 tons |

| IoT Dryers | 2.0 kWh | $10,000 | 15 tons |

ROI Checklist: Deploy Automation in 2026

- Baseline Audit (Week 1): Time 100 bales. Cavitation? Log HVI rejects >2.5% non-lint.

-

Prioritize Upgrades:

- Year 1: Hydraulics ($30k, +20% speed)

- Year 2: Robotics ($50k, +15% quality)

- Year 3: AI/IoT ($20k, -30% downtime)

- Finance Smart: USDA REAP grants cover 25-50%; lease spreads over 36 months.

- Track KPIs: Bales/hour, non-lint %, energy kWh/bale. Target 2-year payback at 61¢ prices.

- West Texas Specs: Pivot-ready for 800-1,200 lb/acre irrigated; La Niña volume buffer.

Pro Forma (50k bale gin):

| Scenario | Bales/Season | Revenue @$28/bale | Automation Lift |

|---|---|---|---|

| Status Quo | 50k | $1.4M | Baseline |

| Hydraulics | 62k (+24%) | $1.74M | +$340k |

| Full Stack | 70k (+40%) | $1.96M | +$560k |

Automation transforms 2026's supply squeeze into a competitive edge. Cleaner bales, faster turns, lower costs—exactly what mills demand at 63% stocks-to-use.

Find upgrade-ready partners in the cottongins.org directory—submit your gin today for High Plains visibility and leads.