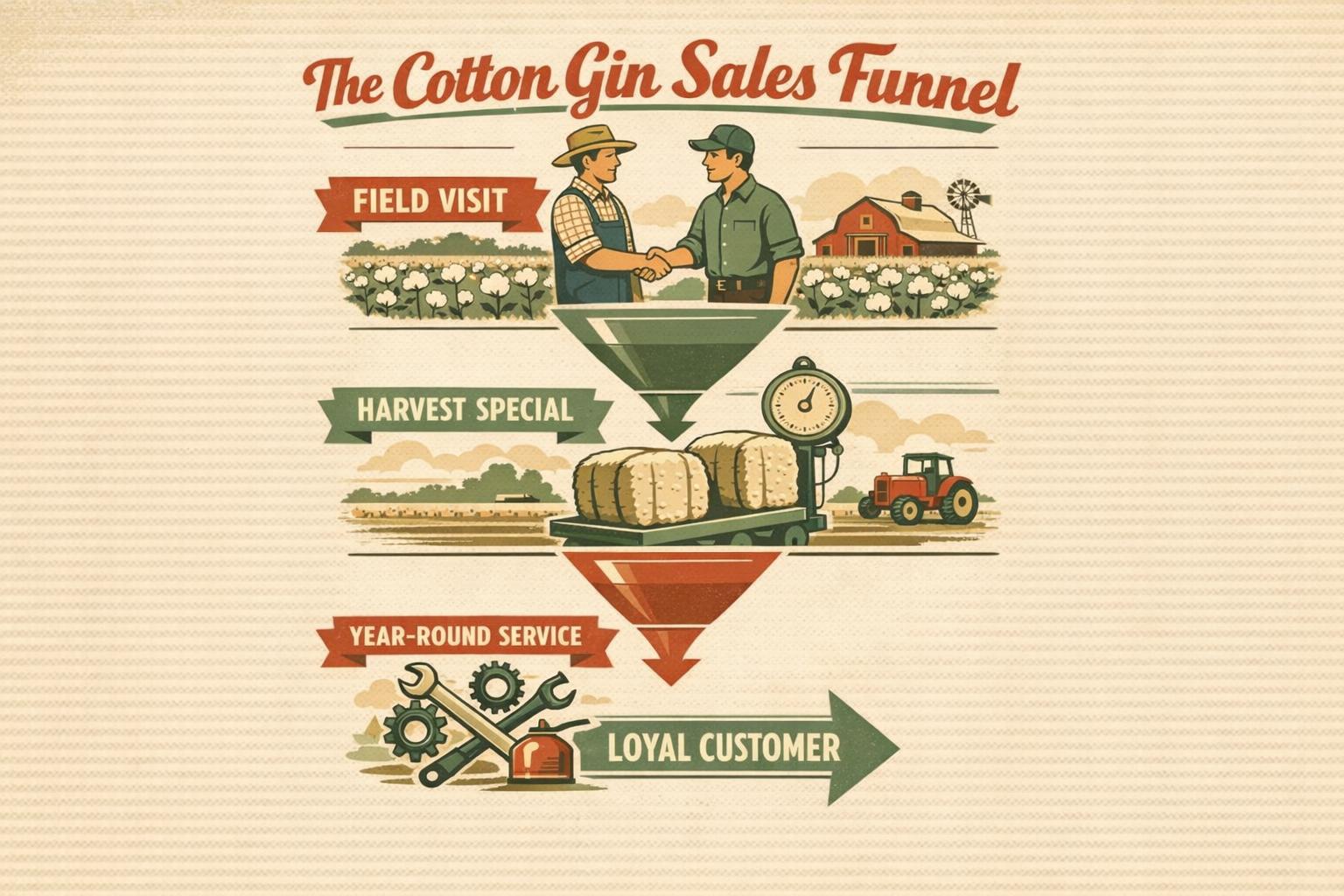

Want to cut energy costs at your cotton gin? Here’s what you need to know:

Energy costs per bale vary widely across the U.S. due to factors like utility rates, gin size, and equipment type. Modern equipment and strategic upgrades can significantly reduce these costs. Here’s a quick breakdown:

- U.S. Averages: Energy costs depend on local utility rates, seasonal demand, and equipment efficiency.

-

Regional Differences:

- Southeast: High summer electricity rates hurt smaller gins.

- Mid-South: Moderate rates favor larger gins with modern setups.

- West: High natural gas costs require careful energy management.

- Equipment Impact: Modern systems with automation and energy-efficient motors save energy and reduce waste, despite higher upfront costs.

Next Steps for Operators:

- Conduct an energy audit to identify inefficiencies.

- Benchmark your costs against regional and size-specific averages.

- Prioritize upgrades that deliver the best ROI.

CIRCOT BAJAJ Cotton Seed Dryer

1. U.S. Average Energy Costs

Energy costs for cotton gins can differ greatly across the U.S., influenced by factors like local utility rates, how operations are managed, seasonal demand, equipment performance, regional climate, and infrastructure. The heavy use of natural gas and electricity, combined with unique processing needs, contributes to these variations.

Steps like routine maintenance, scheduling operations during off-peak hours, and closely tracking energy use can help lower costs. However, actual expenses are shaped by specific operational setups and local utility rates. These variables play a key role in evaluating the potential savings from energy efficiency improvements.

2. Cost Differences by Region and Gin Size

Energy costs for cotton gins vary widely across the U.S., influenced by utility rates, seasonal trends, and the size of the operation. Here's a breakdown of how these factors play out in different regions and for gins of various sizes.

In the Southeast, electricity rates spike during the summer months. Smaller gins feel the pinch, as they can't spread fixed energy costs across a large output, leading to higher costs per bale. Mid-sized gins, however, manage to balance these expenses better by operating at a scale that spreads costs more efficiently.

The Mid-South offers a more favorable landscape with moderate utility rates. Larger gins here benefit from modern equipment and negotiated utility contracts, which help reduce energy costs per bale.

In the Western states, the picture is more complex. Natural gas prices are generally high, but some areas offset this with lower electricity rates. Medium-sized gins must carefully manage their energy mix to keep costs in check.

Larger gins across all regions have a significant advantage. They employ advanced, energy-efficient technologies and automation systems, which cut down on energy waste. These facilities also tend to secure better utility rates, further lowering their operational costs. This sets the stage for a deeper look at cost-benefit considerations in the next section.

sbb-itb-0e617ca

3. Modern vs. Basic Gin Equipment

Modern gin equipment, equipped with advanced automation and efficient motors, offers clear advantages when it comes to cutting energy costs. These systems are designed to operate more efficiently than basic setups.

For example, modern equipment uses variable frequency drives to adjust motor performance based on the workload. It also includes smart monitoring systems that track energy use in real time, making it easier to spot and fix inefficiencies. On the other hand, basic equipment runs at full power no matter the load, leading to unnecessary energy waste.

Temperature control is another area where modern systems shine. They use precise drying methods and adjustable heat settings tailored to the moisture level of the cotton. While the upfront cost of modern equipment is higher, the long-term savings on energy and maintenance make it a worthwhile investment. These features demonstrate the strong cost-saving potential of upgrading to modern systems.

Cost-Benefit Analysis

While exact numerical benchmarks for energy efficiency between older and newer equipment are not yet available, modern cotton gin systems come with several clear benefits:

- Energy Efficiency: Updated technologies typically use less energy per bale, helping to reduce electricity and fuel costs.

- Lower Operating Costs: New designs often require less maintenance and experience fewer operational disruptions.

- Faster Production: Advanced processing capabilities can increase throughput without compromising product quality.

- Return on Investment (ROI): Payback periods depend on factors like annual processing volume, local utility rates, and maintenance routines.

To make the most of these benefits, it’s essential for gin operators to conduct an energy audit. This will provide a clearer picture of potential savings and ROI, enabling better decisions about equipment upgrades and operational changes based on regional and size-specific benchmarks.

Summary and Next Steps

Operators now have clear strategies to improve efficiency by focusing on energy costs per bale. Our analysis highlights that modern equipment and regular maintenance can make a big difference in reducing energy use and expenses.

Here’s what gin operators can do next:

- Conduct an Energy Audit: Identify areas where energy use can be improved.

- Benchmark Energy Costs: Compare your operation’s energy expenses with regional averages and similar-sized gins to uncover savings opportunities.

- Upgrade Equipment Strategically: Use audit results and ROI estimates to prioritize upgrades that deliver the most impact.

By following these steps and tracking results, operators can maintain and improve energy efficiency over time.

For additional support, connect with peers on cottongins.org. The platform offers tools to:

- Find nearby gins for collaboration on energy-saving projects.

- Add your gin’s details to the directory and expand your network.

- Stay informed on industry updates by subscribing to the blog.

Maintaining efficiency requires ongoing effort. Start by documenting your energy use and setting clear reduction goals based on your benchmarks. Regularly reviewing these metrics will help you stay on track and ensure continued progress.

As new tools and methods become available, staying connected with industry peers will be key to keeping operating costs competitive.