Cotton warehousing is more than just storage - it's about protecting quality, meeting regulations, and ensuring profitability. The U.S. exports 75% of its cotton crop, making proper handling critical. Key challenges include fire risks, moisture issues, and regulatory compliance. Here's what you need to know:

- Security: Use fencing, surveillance, RFID tracking, and USDA-compliant security plans to protect inventory.

- Storage Conditions: Maintain 55%-65% humidity for bales and below 60°F for cottonseed to prevent damage.

- Efficiency: Climate-controlled facilities, IoT sensors, and digital inventory systems reduce errors and improve operations.

- Profitability: Lower energy costs with efficient fans, LED lighting, and zonal aeration. Partner with regional networks and use digital tools like cottongins.org to optimize logistics.

Eliminating Downtime & Increasing Market Control with Cottonseed Storage | North West Gin

How to Secure Your Cotton Warehouse

Protecting a cotton warehouse involves implementing a combination of physical safeguards, digital defenses, and adherence to regulatory standards. Given the risks of theft and tampering, these steps form the groundwork for the tracking and compliance strategies outlined later.

Surveillance Systems and Access Control

Start by securing the perimeter with fencing, controlled gates, and restricted access driveways. Keep the exterior well-lit and the surrounding area open to enhance visibility for law enforcement. Require all visitors to sign in, be escorted, and display clear "No Trespassing" signs to deter unauthorized entry. An alarm monitoring system adds an active layer of protection against breaches.

On the digital front, strengthen defenses with firewalls, updated antivirus software, frequent password changes, and secure hardware. Regularly back up records to off-site locations to safeguard sensitive data.

These physical and digital measures form the first line of defense, while electronic tracking takes security to the next level.

Bale Tagging and Electronic Tracking

RFID technology offers a game-changing way to track cotton bales in real time. A trial in Baoding, Hebei showed that using RFID with multiple readers reduced positioning errors to under 6.7%, improving both inspection efficiency and storage security. According to the research team:

"This study improved the management personnel's effective positioning and inspection of the cotton bale, prevented the loss of cotton bale, reduced the deterioration probability of cotton bale, and effectively improved the storage management level."

The Permanent Bale Identification (PBI) system ensures each bale is uniquely identifiable through a standardized 12-digit number - a combination of a 5-digit gin code and a 7-digit bale number. These tags link to the USDA National Database, which stores critical data like fiber length, strength, and micronaire. This system makes misrepresentation of inventory nearly impossible.

For durability in warehouse conditions, PBI tags should be printed with Permanent Ultra Violet Black Ink on tag stock weighing 175 to 200 lbs. and measuring 0.013 to 0.015 inches thick.

USDA Compliance Requirements

To meet USDA requirements, cotton warehouses must maintain a written security plan that addresses both physical and digital safeguards, including measures to prevent tampering during shipping and receiving. The National Cotton Council underscores this necessity:

"Presidential Directives and USDA expectations make it clear that cotton warehousemen must have functioning security plans."

Protecting key operations starts with identifying vulnerabilities. Under the United States Warehouse Act (USWA), licensed facilities must allow USDA agents to perform unannounced inspections of their premises, records, and accounts during business hours. Additionally, warehouses must file a bond, irrevocable letter of credit, or U.S.-guaranteed obligations and keep thorough financial and inventory records for audits.

Staff training is crucial - ensure employees are familiar with security protocols, conduct regular emergency drills, and maintain connections with local police and fire departments. During peak receiving periods, daily inventory inspections by trained personnel or watch services are highly recommended. These practices not only safeguard your inventory but also ensure compliance with USDA regulations, setting the stage for improved operational efficiency and profitability.

Modern Storage Technologies for Better Efficiency

Upgrading storage systems not only speeds up cotton processing but also helps maintain its quality. These advancements build on established security measures to make operations smoother and ensure the cotton stays in top condition.

Climate-Controlled Storage Facilities

Fluctuating temperature and humidity can harm cotton fibers, encouraging mold and mildew growth. Climate-controlled storage facilities address this by maintaining consistent conditions throughout the year. Humidity levels are kept between 55% and 65%, which is ideal for preventing moisture-related damage.

These facilities also enhance operational flexibility. According to the National Cotton Council, storing cotton in modules allows gins to process seed cotton more efficiently, extend the ginning season, and operate for longer hours without costly downtime. Since modules became standard in 1972, almost all seed cotton is now stored this way before ginning. Additionally, sealed buildings protect against dust, pests, and pollutants, while continuous airflow prevents moisture buildup that could harm fibers and associated documentation.

Vertical Stacking and Airflow Management

Good ventilation is key to avoiding mildew, fire risks, and fiber deterioration. Strategic airflow management ensures humidity levels remain stable. For instance, Cotton Storage Warehouse Inc., with its 337,000 square feet of enclosed space across eight warehouses, demonstrates how large-scale operations maintain dry, ventilated environments.

Vertical stacking is another way to maximize storage space, but it works best when paired with effective airflow systems. Calcot's storage network, which safely houses over 600,000 bales, combines efficient warehouse movement strategies with responsive teams that quickly adapt to market demands. Digital tools, like mobile bale scanning and automated picking lists, further streamline operations by reducing handling time and eliminating the need for manual searches. Together, these physical and digital upgrades ensure smooth and efficient warehouse management.

Real-Time Monitoring with IoT Sensors

IoT sensors have replaced manual inspections with 24/7 automated monitoring, providing instant alerts when temperature or humidity levels go beyond set thresholds. A notable example is YIN XIANG Cotton Industry Co., Ltd., which implemented an RFID-based intelligent inspection system in December 2020. This system, equipped with wireless temperature and humidity sensors and 10 card readers, achieved a monitoring error of less than 6.7% for positioning and displayed real-time coordinates for each tagged bale.

Weipeng Zhang and his research team highlighted the value of this technology:

"It was of great practical significance to realize the networking, automation, and intelligence of cotton bale storage management."

High-precision SHT20 sensors ensure accurate readings, with temperature and humidity errors kept below 8% and 7%, respectively. Active RFID tags operating at 433 MHz enable real-time bale tracking, while low-power sensors powered by CR2032 batteries can function continuously for about a year. Reflecting this trend, the global IoT warehouse management market is expected to grow from $12.13 billion in 2023 to $28.79 billion by 2030, with implementations reducing manual errors by over 50%.

sbb-itb-0e617ca

Cotton Inventory Management Best Practices

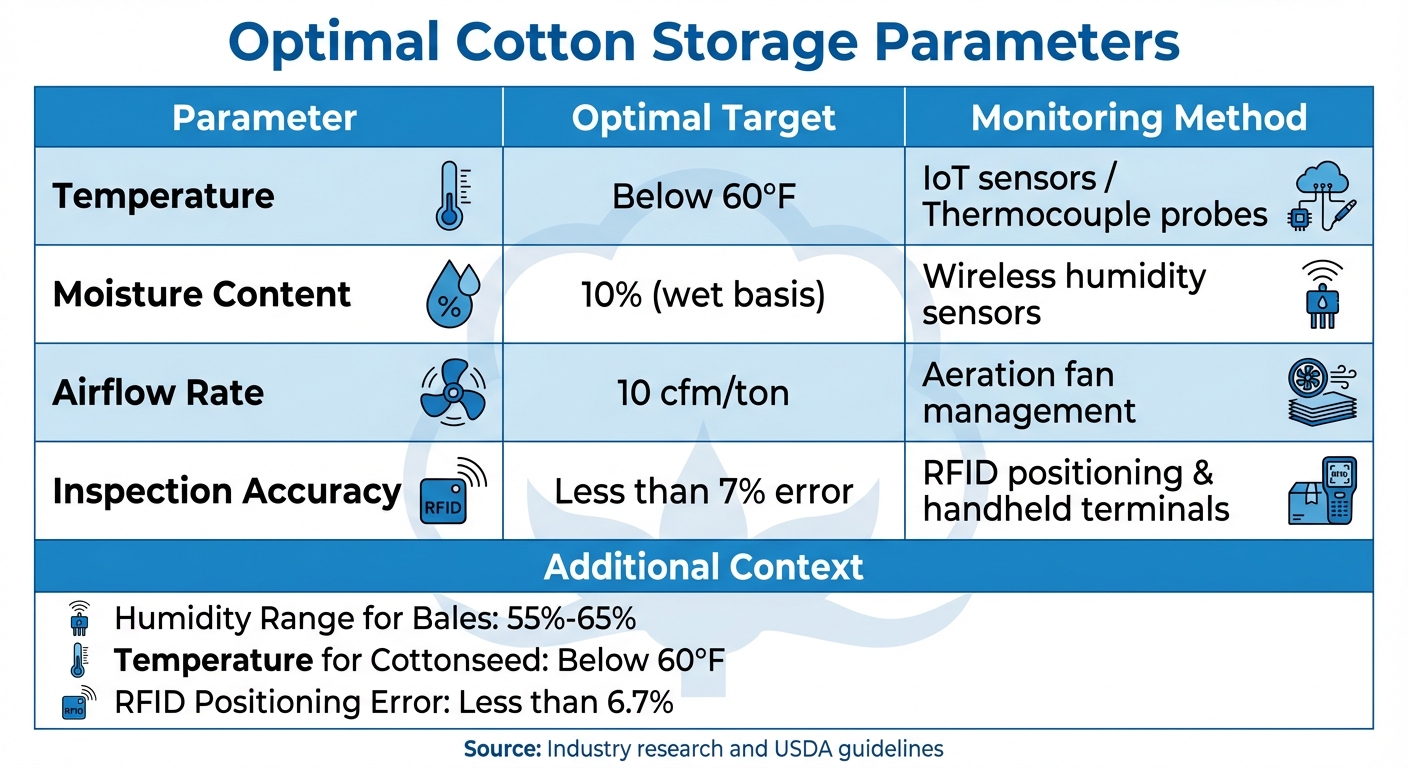

Cotton Warehousing Optimal Storage Conditions and Monitoring Parameters

Effective inventory management is key to maintaining the quality of your cotton while ensuring smooth operations and profitability. By combining established techniques with modern technology, you can streamline the movement of every bale in your warehouse.

First-In, First-Out (FIFO) Methods

Using FIFO principles ensures older cotton is shipped out first, reducing the risk of degradation from prolonged storage. This system starts with attaching digital receipts and RFID or barcode tags to each bale upon arrival, documenting its entry date and storage location. A Warehouse Management System (WMS) then automates tasks like calculating storage fees and generating picking lists that prioritize older stock for outgoing shipments.

RFID systems have proven to be highly accurate, with positioning errors of less than 6.7%. Mobile scanning devices further enhance efficiency, instantly updating inventory records during peak shipping periods. Coupling this with environmental monitoring ensures the condition of older bales is consistently tracked. Given that cotton is classified as a combustible material under International Code Council and National Fire Protection Association guidelines, following strict storage protocols is non-negotiable.

These practices create a solid foundation for incorporating advanced digital tools to optimize inventory tracking.

Digital Inventory Tracking Software

Modern warehouse management software minimizes manual errors by automating data integration between gin systems and warehouse records. For example, the eCotton Warehouse System, which costs around $3,000 annually, generates digital receipts automatically and syncs data directly with gin systems. This real-time functionality gives managers a clear view of inventory levels and locations at any given moment.

Permanent Bale Identification (PBI) tags, which include a 12-digit number and barcode, link each bale to its quality data in the USDA National Database. This traceability is vital, especially since about 75% of U.S. cotton is exported to over 35 countries, making precise tracking essential for global trade. The software also simplifies order fulfillment by generating automated picking lists and offering features like wave planning, which organizes orders by shipping date or zone to boost packing efficiency.

To maintain data accuracy, regular reconciliation reports compare software records with Electronic Warehouse Receipt (EWR) systems. Advanced systems can even integrate IoT sensors to monitor temperature and humidity, reducing risks like mildew and fiber deterioration.

Regular Bale Inspections and Quality Checks

Even with digital tools, routine inspections are crucial for maintaining cotton quality. Handheld RFID-based systems have improved inspection accuracy, as highlighted by Weipeng Zhang:

"It is very important to carry out real-time inspection and temperature and humidity monitoring of cotton stacks in the process of cotton storage."

Inspectors can use handheld devices to photograph cotton stacks and upload these images to a central database, tracking physical conditions over time. Fire safety is another priority - inspect for signs like flames, unusual odors, or alerts from detection devices to identify potential "suspect fire bales". Monitoring exhaust air temperature and odors from aeration fans can also provide early warnings of internal issues.

Set automated alerts for temperature spikes above 60°F or moisture levels exceeding 10% to prevent spoilage. Avoid running aeration fans during high humidity, rain, or fog, as cotton can absorb moisture from the air. To optimize inspection routes, algorithms like the Greedy algorithm can ensure thorough coverage with minimal time waste.

| Parameter | Optimal Target | Monitoring Method |

|---|---|---|

| Temperature | Below 60°F | IoT sensors / Thermocouple probes |

| Moisture Content | 10% (wet basis) | Wireless humidity sensors |

| Airflow Rate | 10 cfm/ton | Aeration fan management |

| Inspection Accuracy | Less than 7% error | RFID positioning & handheld terminals |

How to Increase Warehousing Profitability

Boosting profitability in warehousing starts with securing efficient operations and cutting costs without compromising storage quality. By focusing on energy management, regional partnerships, and digital tools, warehouses can transform into profit centers. Let’s explore how these strategies work.

Reducing Energy Costs

Energy expenses rank among the largest controllable costs in cotton warehousing. To cut these costs, consider implementing single-duct fan systems, which help lower power consumption. Selecting fans that match specific static pressure and the depth of stored mass is key to avoiding wasted energy. Aeration management also plays a critical role: once the initial ginning heat is removed, operate fans only on cool, dry days. Avoid running them during high humidity, rain, or fog to prevent moisture absorption.

For optimal efficiency, maintain airflow between 1,500–2,000 ft/min. At a depth of 20 feet, airflow of 10 cfm/ton requires about 1.7 horsepower per 100 tons. Using zonal aeration with slide valves can direct airflow to specific ducts or "hot spots", further improving efficiency. In cooler, drier regions, reducing airflow to 5 cfm/ton can lower energy use without affecting storage quality. Additionally, switching to LED lighting and fine-tuning HVAC systems can significantly reduce monthly energy bills.

Cutting energy costs is just the beginning - streamlined partnerships can also make a big difference.

Working with Regional Warehousing Networks

Collaborating with regional warehousing networks can help reduce operational expenses by sharing resources and improving logistics. Third-party logistics (3PL) partnerships eliminate the need for costly in-house infrastructure. Leased storage space typically costs between $4 and $7 per square foot annually, while cross-docking services allow goods to move directly from suppliers to customers, minimizing long-term storage costs.

Labor, often the largest expense in distribution centers, can be optimized through shared labor pools. Administrative and management costs generally range from $30 to $40 per hour, while equipment expenses, such as forklift leases, usually fall between $750 and $1,000 per month. Another cost-saving opportunity lies in module storage for seed cotton, which separates harvesting from ginning. This allows gins to operate more hours and extend the season without costly downtime. For peak harvest periods, emergency cottonseed storage in modules is available at about $10 per ton, offering flexibility when it’s needed most.

Digital tools can further enhance these strategies, making operations even more efficient.

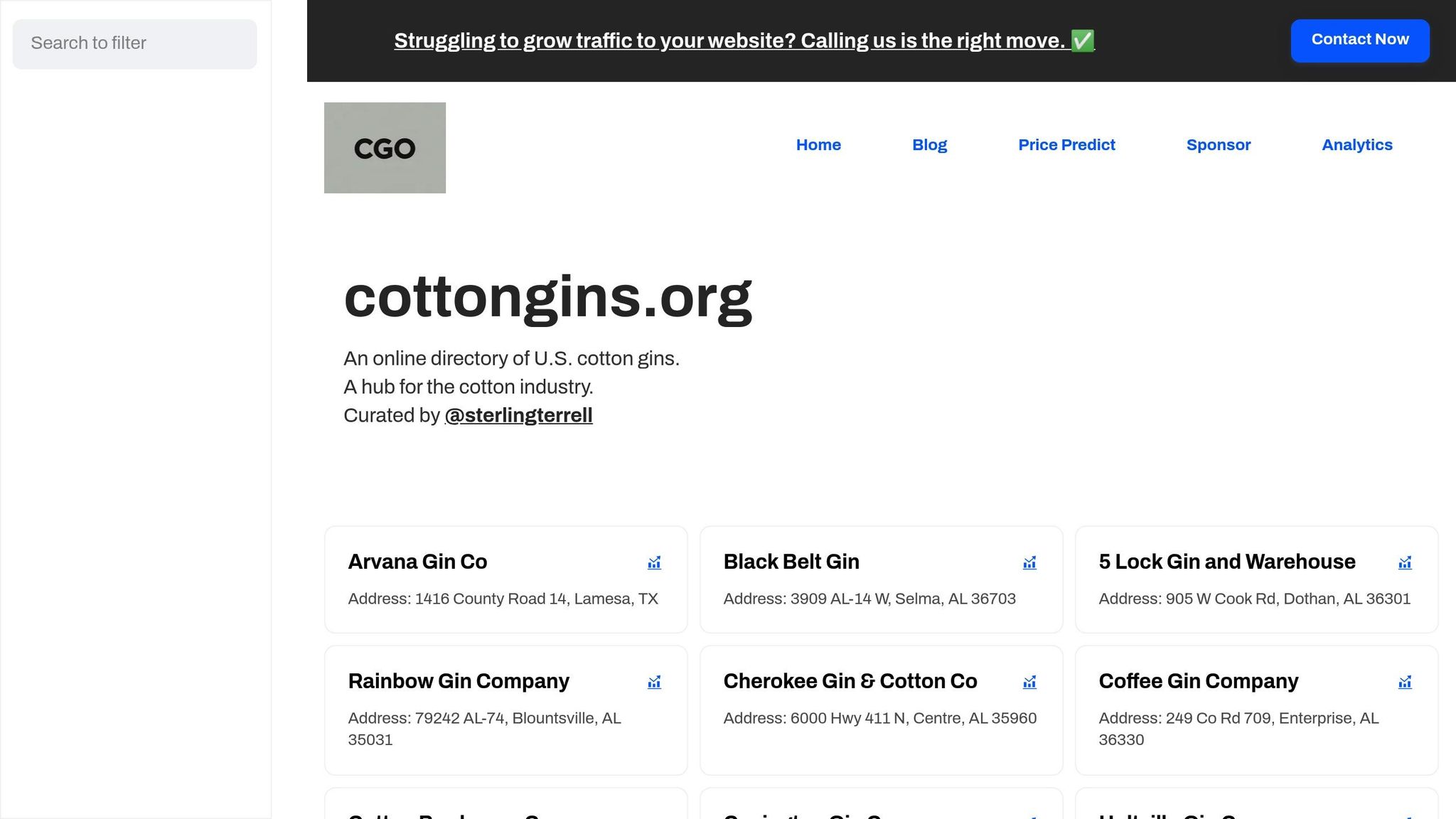

Using cottongins.org for Business Growth

Digital platforms like cottongins.org provide valuable tools to integrate cost-saving measures into daily operations. For example, the "Find a Gin Near You" feature allows users to enter a zip code and locate nearby cooperative and regional facilities. This reduces transportation-related energy costs and improves logistics efficiency.

The platform also connects cotton producers with warehousing services across counties and states, streamlining supply chain coordination. For warehouse operators, cottongins.org offers sponsorship opportunities to boost visibility. Sponsored Posts cost $200 each, while Official Sponsor listings are $200 per month (with one free post for annual commitments). Featured Sponsor options, priced at $400 per month, include two free posts annually. These tools not only enhance operational efficiency but also open up new marketing channels for businesses.

Conclusion

Cotton warehousing thrives when security, efficiency, and profitability work hand in hand. By following the strategies in this guide, warehousing operations can shift from being mere cost centers to becoming key competitive assets.

Prioritizing security is essential - install fencing, enforce controlled access, and implement surveillance systems. Don’t stop there; secure both the physical and digital aspects of your operation. As the National Cotton Council emphasizes:

Security plans should address physical plants as well as computer databases and other records.

This dual approach safeguards not just the inventory but also the digital records that validate its worth.

Modern technology plays a vital role in maintaining cotton quality and ensuring traceability. Tools like climate-controlled storage, IoT sensors, and Permanent Bale Identification tags help prevent quality loss and provide transparency throughout the supply chain - from the gin to the mill. These advancements are especially crucial when you consider that the U.S. exports about 75% of its cotton crop to more than 35 countries worldwide. Reliable traceability isn’t just a bonus; it’s a necessity for staying competitive in global markets.

By integrating these practices, you can create a streamlined warehouse operation that delivers better performance. Platforms like cottongins.org can help you connect with regional warehousing networks, broadening your reach and enhancing efficiency while driving profitability.

Combining traditional best practices with cutting-edge innovations ensures improved storage conditions, faster operations, and higher returns. This balanced approach sets the stage for long-term success in cotton warehousing.

FAQs

How does RFID technology improve security in cotton warehouses?

RFID technology plays a key role in boosting cotton warehouse security by offering real-time tracking for every cotton bale. This level of precision makes it easier to spot unauthorized movements, providing tighter inventory control. With a positioning accuracy of less than 7%, RFID systems deliver dependable monitoring to help reduce potential losses.

On top of that, RFID tags can keep an eye on environmental factors like temperature and humidity. This continuous monitoring helps safeguard cotton from damage and ensures it stays in ideal storage conditions. By combining tracking with environmental oversight, RFID systems enhance warehouse security while lowering risks.

Why is climate-controlled storage important for cotton?

Climate-controlled storage plays a key role in keeping cotton bales safe from damage caused by changes in temperature and humidity. By maintaining steady conditions, it prevents issues like moisture buildup, mold, and fiber breakdown, ensuring the cotton lint stays in top condition.

This storage method not only reduces losses and waste but also helps maintain the value of the cotton, which can lead to better profits. For cotton businesses, it’s a smart solution to protect inventory and keep operations running smoothly.

How can digital tools help increase profitability in cotton warehousing?

Digital tools are transforming cotton warehousing, making operations smoother and more cost-effective. Technologies like RFID systems and wireless sensors allow for precise tracking of bale locations and real-time monitoring of storage conditions, such as temperature and humidity. This helps reduce losses caused by environmental factors while cutting down on manual labor and enhancing inventory accuracy.

When paired with a warehouse management system, these tools bring automation to crucial tasks, including generating receipts, applying tariff codes, and tracking payments. Features like mobile bale scanning and real-time picking lists streamline workflows, saving time and lowering handling costs. Traceability tools, which follow bales from the field to the gin, eliminate repetitive data entry, aid in logistics planning, and improve cash flow forecasts. By boosting efficiency and minimizing shrinkage, digital solutions make cotton warehousing a more profitable and efficient operation.