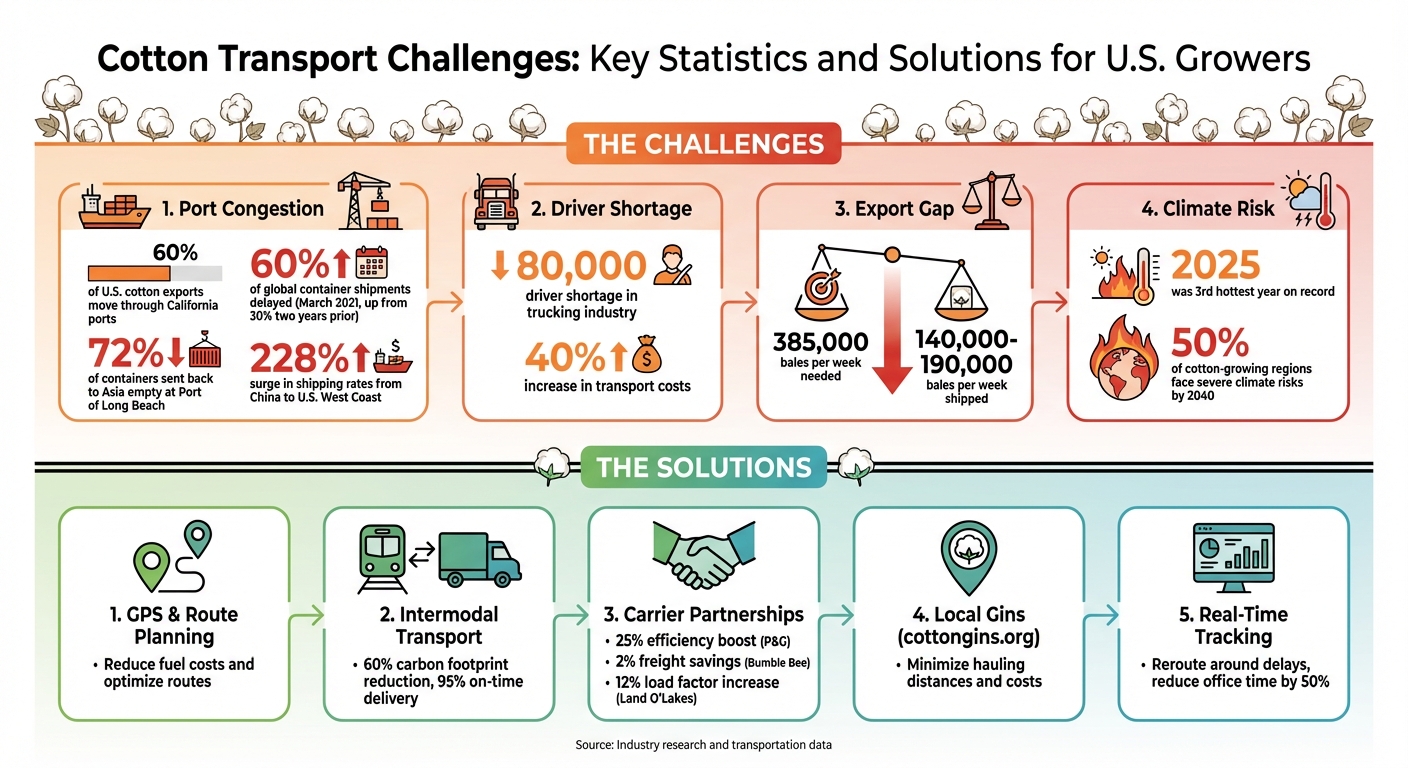

Getting cotton to market is harder than it looks. U.S. cotton growers face major hurdles like port congestion, a truck driver shortage, aging infrastructure, and extreme weather. These issues cause delays, increase costs, and hurt profits. But there are ways to improve efficiency and reduce headaches.

Here’s a quick look at the key problems and solutions:

- Port Congestion: California ports handle 60% of cotton exports but often face delays due to container shortages and vessel backups.

- Driver Shortages: The trucking industry is short by 80,000 drivers, raising transport costs by nearly 40%.

- Aging Infrastructure: Limited chassis and rail capacity slow down movement from farms to export hubs.

- Weather Disruptions: Extreme weather impacts crop timing and shipment schedules.

Solutions:

- GPS Tools: Use route planning software for faster, fuel-efficient trips.

- Intermodal Transport: Combine trucking and rail to bypass congested ports and cut costs.

- Carrier Partnerships: Build relationships with reliable transport providers for flexibility during peak seasons.

- Local Gins: Use tools like cottongins.org to find closer gins and save on trucking distances.

- Real-Time Tracking: Monitor shipments to reroute around delays.

Smart planning and modern tools can help growers reduce delays, lower costs, and keep cotton moving efficiently.

Cotton Transport Challenges: Key Statistics and Solutions for U.S. Growers

Soluções na logística do algodão

Main Cotton Transport Problems

Cotton growers in the U.S. are grappling with logistical hurdles that drive up costs and delay shipments. Issues like driver shortages, clogged ports, limited infrastructure, and unpredictable weather create a chain reaction of challenges throughout the supply network. Let’s break down these problems and their effects.

Port Congestion and Vessel Delays

U.S. ports, particularly in California, are critical gateways for cotton exports - but they’re also major bottlenecks. About 60% of U.S. cotton exports move through California ports, leaving the industry highly vulnerable to congestion. In March 2021, nearly 60% of global container shipments were delayed, a sharp rise from just 30% two years earlier. Ports like Los Angeles and Long Beach often see ships anchored for days or even weeks, waiting for available docking space.

Adding to the chaos is a shortage of shipping containers. Many carriers prioritize sending empty containers back to Asia, where they can quickly be reused, rather than waiting to fill them with U.S. agricultural exports like cotton. At the Port of Long Beach, 72% of containers were sent back to Asia empty, leaving cotton exporters scrambling for equipment. This scarcity drives up costs - during peak disruptions, shipping rates from China to the U.S. West Coast surged by 228% compared to the previous year.

"Shipping empty containers back to China has become so profitable that companies are hurrying to load empty containers rather than waiting for them to be refilled." - Supply Chain Game Changer

Next, we’ll look at how driver shortages further complicate the cotton transport system.

Truck Driver Shortages and Higher Costs

The trucking industry is short by 80,000 drivers, creating a massive gap in transport capacity. This shortage directly impacts the movement of cotton from farms to export hubs, causing delays and driving up costs. In fact, transport costs have risen by nearly 40% as a result.

Federal agencies now flag this driver shortage as a critical weak point in the nation’s supply chain. The Bureau of Transportation Statistics even tracks "Transportation Labor and Capacity Tightness" as a key measure of freight health. Without enough trucks on the road, cotton sits idle - and that downtime adds up in costs for growers and exporters alike.

But driver shortages aren’t the only infrastructure problem.

Infrastructure and Border Delays

Another key issue is the lack of chassis, the specialized trailers used to move shipping containers. This shortage has been described as a "weak link" in the supply chain, particularly in major hubs like Memphis. Without enough chassis, containers can’t be transported from warehouses to ports, causing a ripple effect of delays.

"We've identified the way we provision chassis as a weak link in the chain." - Buddy Allen, President and CEO, American Cotton Shippers Association

Rail capacity and border crossing delays also add friction to the system. For example, the merger of Canadian Pacific and Kansas City Southern has prompted new weekly data tracking for rail carloads and intermodal movements across North America. While tracking data helps monitor the problem, it doesn’t solve the physical capacity constraints that slow down shipments.

And even when infrastructure runs smoothly, weather disruptions can throw everything off schedule.

Weather-Related Disruptions

Extreme weather has become a major disruptor for cotton transport. Scientists have confirmed that 2025 was the third-hottest year on record, following closely behind 2024 and 2023. These temperature extremes affect crop timing, leading to unpredictable surges in shipping demand when infrastructure can’t keep up.

Looking ahead, the situation could worsen. By 2040, half of the world’s cotton-growing regions are expected to face severe climate risks. Hurricanes, floods, and extreme heat events already cause delays that ripple through the supply chain, sometimes halting shipments entirely.

"We are continuing to inundate our supply chain with more cargo than it is physically able to handle." - Buddy Allen, President and CEO, American Cotton Shippers Association

The numbers highlight the challenge: to meet export targets of 15.5 million bales, the U.S. needs to ship 385,000 bales per week. Currently, actual shipment rates hover between 140,000 and 190,000 bales per week, leaving a significant gap that translates into lost revenue and missed opportunities for cotton growers.

Proven Methods to Solve Cotton Transport Problems

Cotton growers face a range of logistical hurdles, from congested ports to a shortage of drivers and outdated infrastructure. Fortunately, there are practical solutions that can help address these challenges. By combining smart tools and partnerships, growers can simplify cotton transport and improve efficiency.

Using GPS Tracking and Route Planning Tools

Route planning and GPS tracking tools have become essential for optimizing transportation. Software like TruckLogics and TruckingOffice integrates with electronic logging devices (ELDs) to provide real-time driver updates, identify the fastest routes, and even reduce fuel consumption. These tools also offer automated dispatching, sending instructions directly to drivers' mobile devices with just one click.

For growers working closely with gins, the Cotton Module Transportation Calculator, developed by engineers at Texas A&M, provides a data-driven way to balance hauling costs and gin capacity. This Excel-based tool uses four key inputs - gin capacity, average bales per module, estimated bales over various distances, and fuel costs - to determine "percent utilization" and calculate the most economical travel distance. It’s particularly effective for gins operating at or above 70% capacity and is supported by Cotton Incorporated and the Texas Department of Agriculture.

Additional features, like "Trucker Stats", help monitor per-mile costs and adjust to fluctuating fuel prices. Many of these tools even offer free trials, making them accessible for growers looking to test their benefits.

Partnering with Dependable Transport Providers

Strong relationships with reliable carriers can make a big difference, especially during peak harvest seasons. These partnerships provide flexibility, such as access to drop trailers and Quick Pay services, which improve cash flow and ensure consistent transport capacity.

Real-world examples highlight the value of these partnerships. Procter & Gamble boosted service efficiency by 25% at one distribution center, while Bumble Bee Foods saved 2% on freight costs by implementing multistop routes. Land O'Lakes used supply-chain analytics to increase shipment load factors by 12%. These results show how strategic carrier relationships can enhance capacity, reduce delays, and strengthen financial stability.

Growers can attract dependable carriers by making their operations more driver-friendly. This includes reducing turnaround times, offering 24-hour facility access, and using drop trailers for flexible scheduling. Platforms like Navisphere Carrier connect growers with vetted carriers and provide access to over 302,000 available loads, including a variety of dry vans and flatbeds. Sharing predictable volume estimates and early shipment notifications also helps carriers allocate resources more effectively.

"Their carrier management program has allowed us to become a Key Carrier ... [The] relationship with everyone within our company, owners, dispatchers, and drivers is vital to us." – Jay, Owner, Dinkel Carrier Group LLC

Using Intermodal Transport Options

Intermodal transport, which combines rail and trucking, offers a compelling solution to bypass congested ports and address driver shortages. Rail transport is not only cost-efficient but also reduces a shipment's carbon footprint by an average of 60%. Modern intermodal services now achieve up to 95% on-time delivery, rivaling the speed of traditional trucking.

In November 2023, J.B. Hunt Transport Services and BNSF Railway introduced Quantum, a joint intermodal service based at the Intermodal Innovation Center in Fort Worth, Texas. This initiative aims to shift millions of highway loads to rail, offering 95% on-time delivery and 24/7 oversight. Quantum is part of a broader effort, including BNSF’s Barstow International Gateway project and J.B. Hunt’s expansion to 150,000 containers.

"Quantum allows customers with service-sensitive freight to benefit from the cost savings of intermodal, while reducing their carbon footprint and maintaining the level of service and consistency needed in their supply chains." – Darren Field, President of Intermodal, J.B. Hunt

To maximize the benefits of intermodal transport, growers should align their harvest schedules with available drayage, container, and rail capacity well before peak seasons. Digital platforms like J.B. Hunt 360 can help identify opportunities to switch from trucking to rail, offering flexibility for high-value or time-sensitive shipments. Monitoring port congestion and labor conditions can also help growers decide when to make the switch.

Using Technology for Real-Time Supply Chain Tracking

Real-time visibility is transforming supply chain management. Integrated Transportation Management Systems (TMS) provide automatic updates on driver locations and settlements, eliminating manual errors and cutting down on data entry. This real-time tracking allows growers to reroute shipments quickly to avoid unexpected delays, such as bad weather or port congestion.

API integrations further simplify operations by enabling one-click booking and automated document management, saving growers valuable time. Financial tools like C.H. Robinson’s Quick Pay service also provide cash flow flexibility, allowing businesses to take on larger projects without financial strain. As Wayne Timmons, President of Timmons Transit Inc., put it:

"C.H. Robinson's Quick Pay is great because it enables us to take on bigger projects that typically require more assets and personnel without cutting into our cash flow."

Advanced weather forecasting tools and automated alerts ensure growers can proactively address potential disruptions, keeping their supply chains responsive and efficient.

sbb-itb-0e617ca

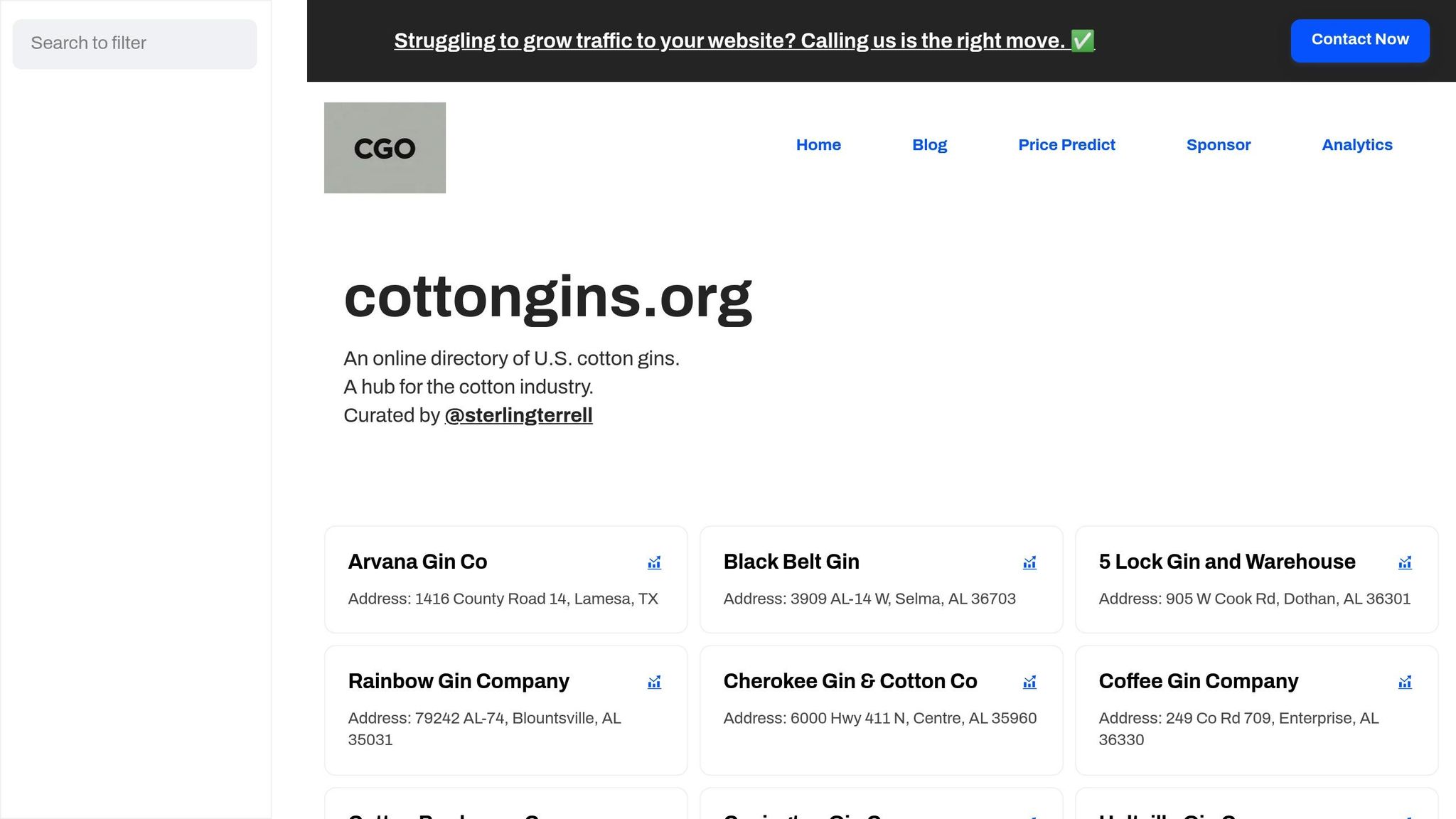

Using cottongins.org for Better Ginning Logistics

Cutting down on transportation costs starts with making smart, local choices. With trucking expenses up nearly 40% and a shortage of about 80,000 drivers in the industry, every mile between your field and the gin adds up. That’s where cottongins.org comes in, offering a detailed directory of cotton gins across the U.S. This tool helps growers quickly find nearby facilities, saving both time and money by minimizing hauling distances.

The platform’s search tool allows users to locate gins by county and state - an essential feature when the U.S. cotton industry needs to move around 385,000 bales each week to meet export demands. Shorter trips mean less travel time, lower fuel costs, and less strain on already limited transport resources. The directory, built on a community-driven model, ensures growers have access to the most current and relevant information.

What makes cottongins.org stand out is its crowdsourced updates. Growers can actively contribute by adding new gin entries, keeping the directory accurate as facilities evolve. This collaborative approach ensures the database remains a reliable resource for everyone in the cotton industry, while also giving individuals a chance to help others improve their logistics.

Beyond just a directory, cottongins.org also offers sponsorship opportunities. These partnerships can help growers expand their professional networks and strengthen supplier relationships - key strategies for tackling equipment shortages and capacity challenges. By combining precise location tools with opportunities to build stronger local connections, the platform addresses the logistical roadblocks that growers face every day.

Conclusion

The cotton industry faces a host of transportation hurdles, including port congestion, truck driver shortages, infrastructure bottlenecks, and unpredictable weather patterns. As the Texas A&M Transportation Institute points out, "The mode of transportation has a direct impact on the cost, efficiency, and reliability of moving export products to overseas markets". These challenges demand smart, well-planned strategies to maintain efficiency and profitability.

Several solutions are already proving their worth. Tools like GPS tracking, intermodal transport, real-time supply chain monitoring, and strategic partnerships have shown measurable benefits. Laura Cameron Hernandez, a trucking company owner, shared her experience: "This app has reduced our office time by half, as we were using excel, quick books, etc for each different function. My husband has all of his costs per truck and driver settlements right at his fingertips". By streamlining operations, these tools help cut down on overhead and improve profit margins.

Local solutions also play a critical role. Resources like cottongins.org, which helps locate nearby facilities, offer growers practical ways to optimize their logistics. Shorter routes mean reduced fuel costs and less strain on trucking resources. Additionally, tools that calculate hauling thresholds and track per-mile profitability allow growers to make smarter, data-driven decisions that safeguard their earnings.

While infrastructure challenges in cotton transport are unlikely to vanish quickly, a combination of these broad and localized strategies equips growers to tackle the obstacles head-on. By adopting these approaches, growers can build operations that are not only efficient but also resilient in the face of evolving demands.

FAQs

What are the benefits of using intermodal transport for cotton growers?

Intermodal transport offers cotton growers a practical way to move their crops by combining trucks, trains, and sometimes ships - all while keeping the cotton in the same container. This approach can bring down transportation costs since trains are often more economical than trucks for long hauls. Plus, it uses less fuel, making it an efficient choice, particularly during periods of truck driver shortages.

By integrating rail into their supply chain, growers can reduce the number of miles traveled by trucks. This not only alleviates road congestion but also frees up much-needed driver capacity. Fewer transfers between transport modes mean a lower chance of damage to the cotton, helping to preserve the quality of the fibers. Intermodal transport also adds a layer of flexibility and dependability, enabling growers to navigate challenges like weather disruptions or port delays without derailing their schedules.

Modern intermodal services come equipped with digital tools such as GPS tracking and real-time updates. These features provide growers with full visibility into their shipments, helping them streamline inventory management, improve scheduling, and ultimately boost profitability.

How does real-time tracking improve cotton transportation?

Real-time tracking offers cotton growers and shippers a clear window into the entire transportation process, turning it into a smoother and more efficient operation. With tools like GPS tracking and live updates, growers can pinpoint the exact location of their shipments, spot potential issues like traffic jams or bad weather, and adjust routes or schedules before minor hiccups turn into major problems.

This tech isn't just about logistics - it also safeguards the quality of the cotton. Alerts can notify growers if shipments encounter unexpected conditions, like extreme heat or high humidity, giving them the chance to take quick action, such as rerouting to climate-controlled storage. On top of that, real-time tracking minimizes idle time, makes fuel use more efficient, and improves coordination at loading docks and ports. The result? Lower costs, more reliable deliveries, and the peace of mind that comes with knowing deadlines can still be met, even when logistical challenges arise.

Why is it important for cotton growers to work with dependable carriers?

Partnering with reliable carriers is crucial for cotton growers, as it ensures their crops are transported on time and in good condition. This not only helps preserve the quality of the cotton lint but also prevents costly delays that could disrupt operations. Reliable transportation partners also help growers avoid issues like fiber degradation during long transit times and unexpected trucking rate hikes caused by driver shortages or other supply chain challenges.

A dependable carrier often provides real-time tracking and route optimization tools, giving growers more control over their schedules. These tools help reduce idle time, streamline operations, and improve overall efficiency. By working with such carriers, growers can better manage costs and safeguard their profitability, especially in a market where logistical hiccups can quickly eat into margins.