Railroads play a crucial role in moving cotton across the U.S., connecting production areas to mills and ports. Covering 140,000 miles, the network is efficient, cost-effective, and environmentally friendly. Here's why rail is a smart choice for cotton shipping:

- Cost Savings: Rail costs about $70 per ton versus $214 per ton for trucks, saving up to 67% on long-distance shipments.

- Efficiency: Trains can move one ton of cotton 470 miles per gallon, four times more fuel-efficient than trucks.

- Security: Sealed containers and reinforced tarps protect cotton from theft and damage.

- Reliability: Fixed schedules and infrastructure investments ensure consistent transit times.

- Lower Emissions: Rail contributes only 2% of transportation-related greenhouse gas emissions, handling one-third of U.S. intercity freight.

For cotton gin operators, rail offers a practical solution for long hauls, especially for distances over 500 miles. Combining rail with intermodal options allows for flexible delivery while cutting costs and emissions.

Rock Island Rail: The Mississippi Division (Overview)

Economic Benefits of Rail for Cotton Shipping

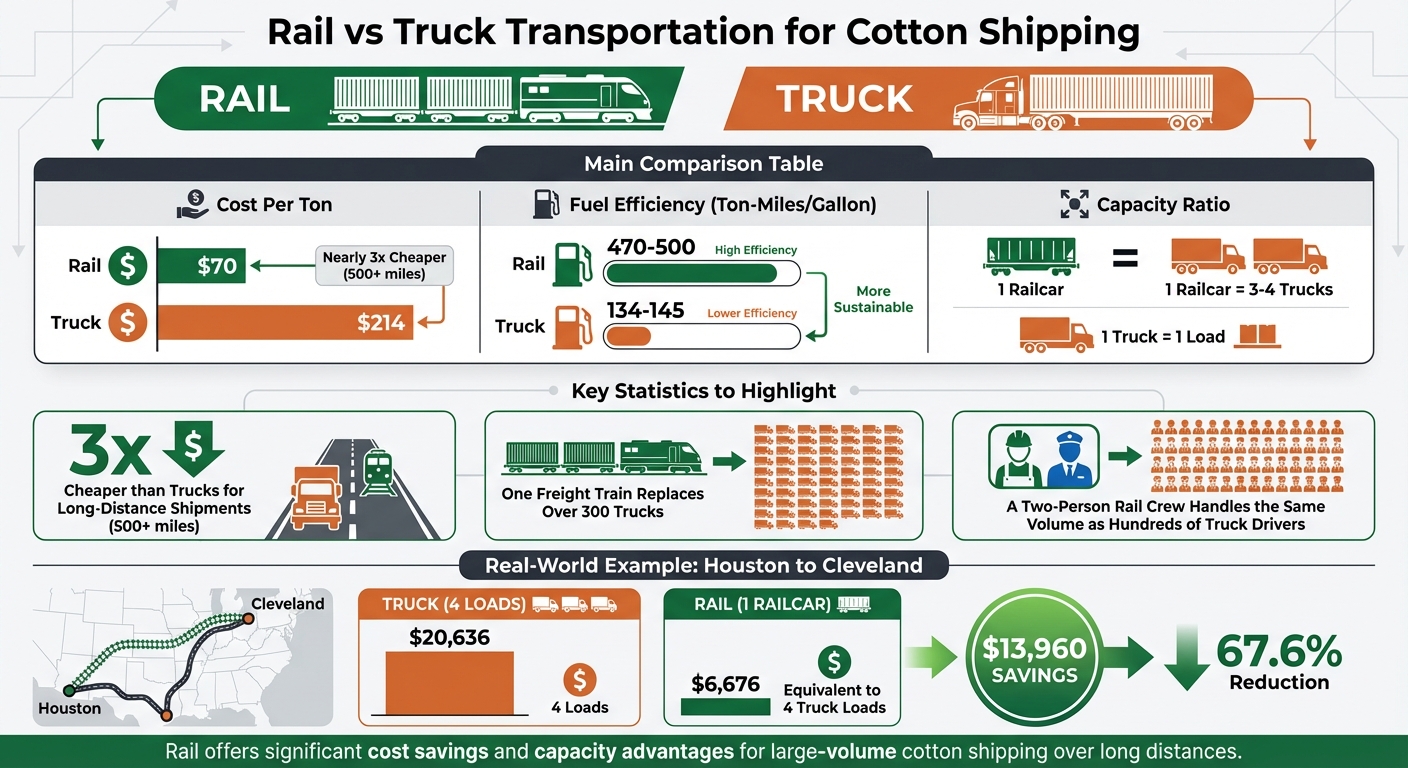

Rail vs Truck Transportation for Cotton: Cost and Efficiency Comparison

Cost Savings for Long-Distance Shipments

When it comes to shipping cotton over long distances - 500 miles or more - rail transportation offers a significant cost advantage. Shipping by rail costs around $70 per ton, compared to $214 per ton for trucks. That’s nearly three times cheaper. This cost difference is largely due to the efficiency of steel wheels, which reduce rolling friction, and the streamlined design of connected railcars, which minimizes air resistance.

The capacity of rail transport further magnifies these savings. A single railcar can carry the equivalent of three to four truckloads, and one freight train can replace the work of over 300 trucks. For cotton gin operators managing large shipments to mills or ports, this consolidation can dramatically cut costs per bale. Remarkably, a two-person rail crew can handle the same volume that would require hundreds of truck drivers.

These efficiencies make rail an attractive option for reducing shipping expenses compared to trucking.

Rail vs. Truck Rate Comparison

Let’s break it down with a real-world example. On the shipping route from Houston, TX to Cleveland, OH, moving a load by truck costs $5,159. Since one railcar can carry the equivalent of four truckloads, using trucks for the same volume would total $20,636. By contrast, a single railcar costs $6,676, creating a savings of $13,960 - about 67.6% less than trucking.

Here’s a quick comparison:

| Transport Mode | Cost Per Ton | Fuel Efficiency (Ton-Miles/Gallon) | Capacity Ratio |

|---|---|---|---|

| Rail | $70 | 470-500 | 1 Railcar = 3-4 Trucks |

| Truck | $214 | 134-145 | 1 Truck = 1 Load |

Cotton gin operators with dual-served facilities - those served by more than one railroad - can negotiate even better rates. For facilities that lack direct rail access, transloading provides a practical workaround. This hybrid approach combines rail for the long haul with trucks for the final delivery, capturing most of the rail cost savings.

Fuel costs also play a role in pricing. Since fuel expenses account for 15% to 20% of railroad operating costs, keeping an eye on monthly fuel surcharges can help operators anticipate changes in rates.

Security and Reliability in Rail Transport

Rail transport isn’t just about saving money or being environmentally friendly - it’s also a standout choice for secure and reliable shipping.

Secure Containerized Handling

One of the key advantages of rail transport is its ability to keep shipments safe with sealed containers that stay closed from start to finish. This approach significantly reduces the risk of theft or tampering. As NTG Freight highlights:

"The use of standardized shipping containers in intermodal freight shipping significantly reduces the risk of theft and damage. These containers remain sealed throughout the entire transportation process, minimizing opportunities for unauthorized access or tampering, thus providing an added layer of security for the cargo."

In addition to sealed containers, reinforced tarps provide extra protection against harsh weather while also concealing cargo to deter theft. These measures ensure that cotton shipments remain secure and intact throughout their journey.

Consistent Transit Times

Rail services are known for their reliability, operating on fixed schedules along dedicated tracks that avoid common traffic delays. The rail industry’s significant investment - nearly $25 billion annually - in infrastructure upgrades has further boosted this dependability. Advanced technologies like Positive Train Control (PTC), now fully implemented across all Class I railroad route-miles, play a critical role in preventing human error. Since 2005, these advancements have contributed to a 64% decline in rail-related fatalities.

For cotton gin operators, this reliability is a game-changer. Unlike ocean freight, which often faces port congestion or unpredictable weather delays, rail transport offers consistent delivery times. This predictability helps streamline inventory management and ensures you can meet mill deadlines without unnecessary stress.

Environmental Benefits of Rail Transportation

Building on rail's economic and security advantages, its environmental benefits make it an even stronger choice for transporting cotton efficiently. Rail stands out as a fuel-efficient and low-emission option for moving cotton over long distances.

Lower Carbon Emissions

Freight trains are about four times more fuel-efficient than trucks, resulting in significantly lower greenhouse gas emissions. Even though trains handle nearly one-third of U.S. intercity freight, they contribute only 2.0% of transportation-related greenhouse gas emissions. For medium- to long-distance shipments, switching from trucks to rail can slash carbon emissions by up to 80%. This reduction allows cotton gin operators to significantly lower their carbon footprint, aligning with greener logistics practices and supporting more sustainable transport solutions.

Efficient Intermodal Solutions

Intermodal transportation combines the strengths of rail and trucking, using trains for the long-haul portion and trucks for short-distance "first and last mile" deliveries. This approach not only reduces fuel consumption but also cuts emissions by relying less on trucks. Intermodal operations now make up 48% of rail freight carloads, with double-stack container systems maximizing cargo capacity and minimizing environmental impact. The smooth transfer of containers between rail, truck, and ship ensures efficient delivery while keeping environmental effects to a minimum.

sbb-itb-0e617ca

Rail Strategies for Cotton Gin Operators

Cotton gin operators can benefit from tailored rail services that align with their shipment volumes and distances. These approaches build on the logistical advantages, cost savings, and reliability discussed earlier.

Using Micro-Bridge and Shuttle Train Services

Micro-Bridge and shuttle train services are ideal for managing large, consistent shipments. These trains are dedicated to carrying a single, substantial load without splitting cargo, which speeds up delivery and minimizes handling. Unlike trucking, these trains operate on Sundays and holidays, ensuring uninterrupted movement of cotton bales.

For shipments traveling over 300 miles, rail becomes a game-changer. A single freight train can replace up to 52 trucks, consolidating multiple bales into one shipment and significantly cutting costs. By focusing on long-haul routes - typically those exceeding 300 miles - operators can achieve better cost efficiency per unit. Additionally, the energy efficiency of trains offers more stable pricing, avoiding the fuel surcharges and driver shortages that often affect trucking.

Partnering with Rail Providers

Collaborating with Third-Party Logistics (3PL) providers can simplify the complexities of freight booking, route planning, and paperwork, allowing cotton gin operators to concentrate on core operations. Partnering with intermodal providers like RailGateway or NOSTA opens access to major Class I freight corridors, such as CN or CPKC, enabling smooth cross-border shipping.

Packaging plays a crucial role in rail efficiency. Cotton bales should be loaded into containers or trailers compatible with intermodal systems to avoid delays during transfers. This approach maximizes rail's load capacity, as one rail car can transport the equivalent of 3–4 truckloads. Moreover, rail terminals offer enhanced security compared to roadside truck stops, reducing the risk of theft and safeguarding high-value shipments.

Adding Rail to Cotton Gin Supply Chains

Integrating rail into your cotton gin's supply chain can bring even more efficiency to your operations, building on the cost and logistical benefits rail transport already offers. However, making this shift requires careful planning. The U.S. freight rail network, spanning 140,000 miles, connects rural cotton-growing areas to domestic mills and export hubs. To make the most of this, operators must determine whether their facility is served by a Class I, regional, or short-line railroad. For gins without direct rail connections, intermodal options can bridge the gap by combining initial truck transport with rail for long-distance shipping.

When considering rail, it’s important to assess both shipment distance and volume. Rail transport is especially cost-effective for long hauls, with many agricultural products traveling over 1,500 miles. Larger shipments - those with 75 or more railcars - help achieve economies of scale, significantly lowering per-ton costs. Additionally, maintaining at least a 70% utilization rate is key to spreading out fixed costs like staffing and infrastructure investments. Once these factors are evaluated, operators can explore tools designed to make rail integration smoother.

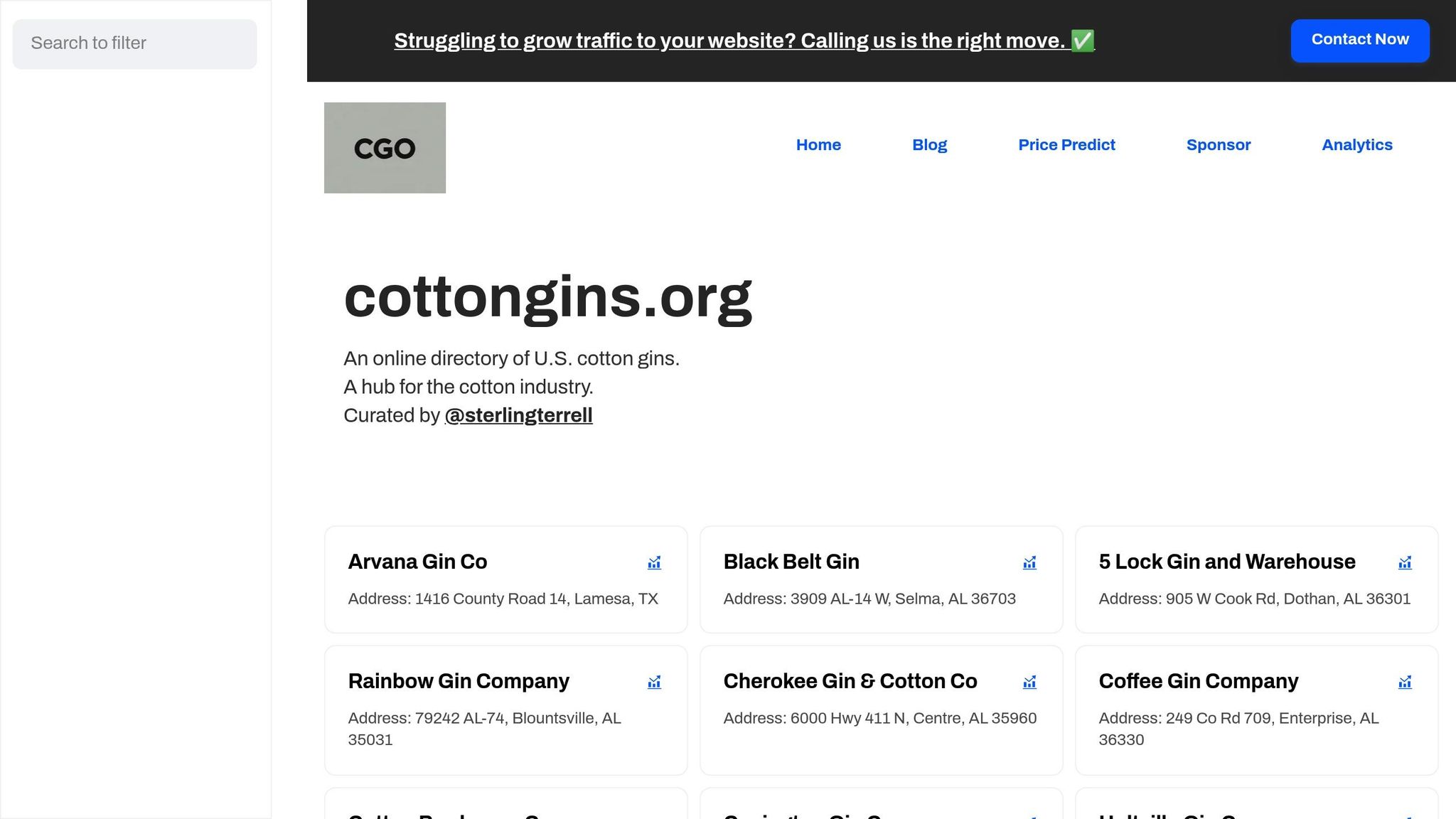

Using Tools on cottongins.org

The cottongins.org directory is a valuable resource for connecting with rail-compatible gins across cotton-producing areas. It provides a detailed, county-by-county listing, making it easier to identify potential partners. Facilities can also use the website’s submission form to update their transportation capabilities, ensuring they remain visible to collaborators. Another handy feature is the Cotton Module Transport Calculator, which helps ginners weigh the benefits of traveling farther to access rail. By boosting overall utilization, this can lower per-bale costs, even if the initial haul is longer.

Promoting Rail Logistics via Sponsorships

Cotton gins that successfully integrate rail transportation can highlight their achievements through sponsorship opportunities on cottongins.org. These sponsorships not only enhance visibility but also showcase rail partnerships and infrastructure investments. Here’s how:

- Sponsored Posts ($200 per post): These posts stay pinned to the top of the site for a day and are shared across social media.

- Official Sponsor Package ($200 per month): Includes logo placement and a backlink in the site’s main page footer, plus a free Sponsored Post for annual commitments.

- Featured Sponsor Tier ($400 per month): Offers top-tier visibility with premium logo placement and two free Sponsored Posts annually.

These sponsorships allow operators to underline their commitment to efficient, rail-integrated logistics, aligning with broader goals of cost savings and streamlined supply chain management.

Case Studies: Cotton Rail Corridors in the U.S.

Texas to West Coast Micro-Bridge

The Cotton Belt Route, originally known as the St. Louis Southwestern Railway, has long been a key player in moving large volumes of Texas cotton to major hubs and West Coast ports. Dubbed the "Cotton Belt Route", it gained its name when St. Louis interests leveraged it for cotton shipments between Texas and the Gateway City. This corridor was purpose-built to handle the heavy flow of cotton from Texas production areas to strategic locations like St. Louis and, eventually, ports on the West Coast.

Today, the Cotton Belt Route operates under Union Pacific, continuing its role as a crucial freight artery for Texas. The route links critical hubs such as St. Louis, Texarkana, Dallas, Fort Worth, and Waco, giving cotton gin operators seamless access to both Midwestern processing centers and export gateways on the West Coast. With modern intermodal capabilities, the corridor has become even more efficient. These historical innovations laid the groundwork for the ongoing advancements that keep rail transport competitive.

Infrastructure Improvements Supporting Rail

The Cotton Belt Route's efficiency has been shaped by significant infrastructure upgrades over the years. One remarkable achievement occurred in 1886 when 419 miles of track were re-gauged in a single day, shifting from narrow-gauge to standard-gauge to improve network connectivity. This change eliminated bottlenecks, allowing cotton shipments to move more swiftly through the rail system.

Another transformative milestone was the completion of the Thebes Bridge in 1905. This collaborative effort between the St. Louis Southwestern, Missouri Pacific, and other rail lines established a permanent crossing over the Mississippi River. By replacing car ferries, the bridge dramatically reduced transit times for cotton moving from the South to Midwestern hubs. Today, ongoing investments ensure the corridor can handle heavy, long-distance shipments. These examples highlight how a combination of historical progress and modern upgrades has solidified rail as a cornerstone of efficient cotton transportation.

Conclusion

Rail transportation provides a cost-effective, secure, and eco-friendly shipping option for cotton gin operations. Known for its unmatched fuel efficiency, rail offers a significant advantage in both cost and environmental impact. Even though rail handles about one-third of the U.S. intercity freight volume, it accounts for just 2.0% of transportation-related greenhouse gas emissions - a testament to its efficiency and sustainability.

For shipments exceeding 500 miles, rail becomes an even smarter choice, maximizing cost savings and operational efficiency. By adopting intermodal containerized solutions, cotton gin operators can combine rail's long-haul capabilities with trucks' flexibility for first-mile and last-mile delivery. Additionally, working with the 584 local and short-line railroads can connect rural ginning facilities to the larger Class I rail network, ensuring seamless logistics.

Incorporating rail into your operations not only reduces costs but also boosts security and supports sustainability goals. Tools available on cottongins.org can help operators identify rail-loading locations, optimize routes, and explore sponsorship opportunities to highlight their rail logistics capabilities. These resources make it easier to implement the strategies discussed in this guide. Ongoing multi-billion-dollar investments in rail infrastructure ensure that capacity remains strong and reliable.

The partnership between the cotton industry and rail transportation continues to evolve, driven by innovation and shared goals. Shifting heavy, long-distance shipments from highways to rail not only lowers logistics costs but also enhances shipment security and aligns your operations with the sustainability priorities of today’s textile buyers and consumers.

FAQs

How does rail transportation help reduce shipping costs for cotton?

Rail transportation offers a budget-friendly solution for moving large amounts of cotton across long distances. Compared to trucks or air freight, rail typically has lower per-ton-mile rates, which can result in substantial savings for shippers. By cutting down the cost per bale, rail ensures a balance between affordability and dependable service.

What sets rail apart is its ability to handle high-capacity loads. Cotton producers can consolidate shipments, which helps reduce overall logistics expenses even further. This makes rail an efficient and cost-effective option for managing large-scale cotton supply chains.

How is cotton kept secure during rail transportation?

Transporting cotton by rail involves a mix of physical safeguards and modern technology to keep shipments secure. Typically, cotton is loaded into sealed intermodal containers that are locked and closely monitored throughout the journey. This setup minimizes risks like theft or tampering. At rail yards, additional security measures are in place, including video surveillance, controlled access gates, and routine inspections to protect the cargo during transfers or while it’s being staged.

On top of that, advanced tracking tools like IoT sensors and blockchain systems play a key role. These technologies offer real-time updates on a shipment’s location, temperature, and handling conditions. They also create a transparent, tamper-resistant log of the entire journey, making it easier to detect and address any potential problems. Together, these efforts ensure that cotton shipments reach their destination safely and in perfect condition.

How does rail transportation support environmental sustainability in the cotton industry?

Rail transportation offers a much cleaner alternative for moving cotton, slashing freight-related greenhouse gas emissions by up to 75% compared to trucking. In fact, it contributes to only about 2% of total U.S. transportation emissions, highlighting its role as an environmentally friendly option.

Beyond reducing emissions, rail systems are incredibly fuel-efficient, which helps lower the overall carbon footprint tied to cotton logistics. Opting for rail allows the cotton industry to balance cost-effectiveness with a commitment to reducing environmental impact.