Cotton contamination is a major issue that affects fiber quality, manufacturing efficiency, and market value. Contaminants like plastic, metal, and organic debris are introduced during harvesting, handling, and processing. These materials can damage machinery, reduce product quality, and lead to financial losses across the supply chain.

Key points:

- Common contaminants: Plastic (e.g., bale ties), metal fragments, and organic debris (e.g., bark, leaves).

- Sources: Harvesting equipment, transportation, storage, and bale wrapping errors.

- Detection methods: Manual sorting, mechanical separation, and advanced technologies like High Volume Instrument (HVI) systems, optical scanning, and pneumatic ejection.

- Impacts: Equipment damage, reduced yarn quality, increased waste, and financial losses.

- Solutions: Rigorous quality control, USDA standards, and resources like cottongins.org to identify facilities with effective contaminant removal processes.

Removing contaminants early in the supply chain is critical to maintaining cotton quality, protecting equipment, and meeting consumer expectations.

Module Wraps and U.S. Clean Cotton

Contaminant Types and Sources

Pinpointing the origins of contaminants is crucial for implementing effective removal methods. Here's a closer look at where these contaminants come from within the cotton supply chain.

Common Cotton Contaminants

Plastic materials are one of the leading contaminants in cotton processing. Items like polypropylene strips from bale ties, plastic bags, and synthetic debris from harvesting equipment can wreak havoc on textile machinery. These contaminants are particularly tricky to detect because they often blend in with cotton fibers, sharing similar colors.

Metal fragments pose another significant risk. Pieces of wire, bolts, screws, and other parts from machinery can break spinning equipment, leading to costly delays. These typically arise from maintenance issues with harvesting machinery or mishandling during transportation.

Colored fibers are another issue. Whether it's naturally colored cotton mixed with white cotton, synthetic fibers from clothing or equipment covers, or dyed materials, these contaminants can cause visible flaws in light-colored fabrics.

Field debris, while not as mechanically damaging, can reduce the visual quality of cotton.

Bale wrap contamination is another challenge. Packaging materials, especially traditional dark-colored wraps, can embed in cotton bales. Small fragments are particularly hard to spot when they blend with cotton fibers.

With these contaminants identified, let’s explore how they enter the cotton handling process.

Where Contamination Occurs

Many contaminants make their way into cotton during harvesting. Plastic mulch, irrigation tubing, and field debris are commonly collected during this stage. Equipment maintenance problems can also introduce metal fragments, while workers' personal items, tools, and clothing can contribute colored fibers or other foreign materials.

Transportation is another vulnerable stage. Without proper preparation, truck beds can add metal fragments, and inadequate covering allows wind-blown debris to mix with the cotton. Cross-contamination is also a risk if vehicles are not thoroughly cleaned after hauling other agricultural products.

Even though ginning facilities are designed to clean cotton, poor maintenance or inadequate pre-cleaning can introduce contaminants like metal fragments or oil stains. Bale wrapping errors can also embed packaging materials into the cotton.

Storage environments can be another source of contamination. Poorly maintained warehouses may contribute debris, rodent nesting materials, or deteriorating building fragments. Additionally, improper inventory rotation can expose cotton to environmental contaminants for extended periods.

The USDA evaluates cotton quality based on several factors, including the presence of extraneous matter, as determined by certified cotton classers.

Regional and Supply Chain Factors

Contamination levels and types can vary widely based on geographic and supply chain factors. For instance, regions with high winds may see more field debris, while areas reliant on plastic mulch face greater challenges with synthetic materials. Older harvesting equipment in certain regions often results in higher rates of metal fragment contamination.

Farm size and management practices also play a role. Larger farms with modern equipment and standardized procedures tend to experience fewer contamination issues. Smaller farms, on the other hand, may face more frequent problems, such as metal fragments, due to difficulties in maintaining equipment.

Seasonal conditions also influence contamination patterns. Early-season cotton often contains more moisture-related debris, while late-season harvests may have increased field trash from prolonged exposure to weather. Processing facilities must adapt to these variations based on harvest timing and local conditions.

The structure of the supply chain impacts contamination control as well. Vertically integrated operations, where farms and mills work closely together, usually maintain stricter quality standards. In contrast, supply chains with multiple intermediaries face higher risks of contamination due to inconsistent handling practices.

Resources like cottongins.org provide valuable tools for reducing contamination. This directory helps cotton producers identify gins that follow best practices for contaminant removal, ensuring consistent quality across regions and supply chains.

While contamination can significantly impact cotton quality, rigorous quality control measures remain critical. For example, in 1989, less than 0.1% of upland cotton was downgraded due to preparation issues, though contamination still presents a risk to quality.

Detection and Removal Methods

Effective contaminant removal is crucial for ensuring cotton quality, and these methods build on established practices to keep the supply chain clean. Cotton quality control combines traditional manual techniques with cutting-edge technology to detect and eliminate contaminants. A multi-step approach, beginning at the ginning stage, is essential for maintaining fiber quality while controlling costs.

Manual and Basic Methods

Hand sorting remains a cornerstone of quality control, especially for spotting contaminants that automated systems might miss. Operators visually inspect cotton samples for issues like colored fibers, plastic fragments, and other foreign materials.

Mechanical separation methods add another layer of protection. Techniques like gravity separation and magnetic removal target heavy particles and ferrous materials, safeguarding equipment and ensuring cleaner final products.

While these basic methods are effective for removing visible contaminants, advanced technologies take precision to the next level.

Advanced Detection Technologies

Modern facilities are increasingly adopting advanced electronic systems that can detect even the smallest contaminants. High Volume Instrument (HVI) systems, for instance, analyze fiber properties - such as length, strength, and micronaire - while also identifying foreign matter using optical scanning.

Vision-based systems equipped with high-resolution cameras and specialized lighting excel at detecting subtle color differences and contaminants at speeds far beyond manual inspection. Real-time data analytics and process monitoring further enhance these systems, allowing facilities to address contamination issues before they escalate.

Pneumatic ejection technologies complement optical detection by using high-pressure air jets to remove identified contaminants with precision, leaving surrounding fibers untouched. Near-infrared imaging, when paired with AI, achieves detection rates exceeding 99%, requiring minimal human intervention.

Method Comparison

Each detection and removal method has its own strengths, and the choice often depends on a facility's specific needs, budget, and quality standards. Here's a closer look at how these methods stack up:

| Method | Accuracy | Cost | Efficiency | Labor |

|---|---|---|---|---|

| Manual Sorting | Moderate | Low-Medium | Low-Moderate | High |

| Mechanical Removal | Moderate-High | Medium | High | Low |

| HVI/Advanced Vision | High | High | Very High | Low |

| Pneumatic Ejection | High | High | Very High | Low |

| Chemical Processing | High (organics) | Medium-High | High | Low |

Manual sorting offers flexibility for catching unusual contaminants, though it demands significant labor and can produce inconsistent results. Mechanical removal, on the other hand, is a reliable option for common contaminants, balancing performance and cost for high-volume operations. Advanced vision systems and pneumatic ejection technologies provide unmatched accuracy and speed but come with higher upfront and maintenance costs.

This comparison helps processors weigh their options and choose the right mix of methods to achieve the best balance of cost, efficiency, and accuracy.

sbb-itb-0e617ca

How Contaminants Affect Cotton Processing

Detecting and removing contaminants in cotton is not just a minor detail - it's a major factor that can make or break processing efficiency and financial outcomes. Even small amounts of contamination can ripple through the entire production chain, causing operational headaches and significant monetary losses. By understanding these impacts, processors can make smarter choices about quality control and operational strategies.

Ginning Performance Issues

Contaminants, especially plastic fragments from module wrapping, wreak havoc on ginning operations. These materials can jam saws and force shutdowns, grinding productivity to a halt.

For example, a large cotton gin in Texas saw the disastrous effects of plastic contamination firsthand. Module wrapping materials repeatedly jammed saws, leading to frequent shutdowns. Over two weeks, the gin’s daily output dropped by 25%, resulting in $50,000 in lost revenue. Once the facility installed the VIPR Detection System, plastic-related downtime decreased by 90%, allowing operations to return to normal levels.

Other contaminants, like seed coat fragments, bring their own challenges. They accelerate wear and tear on equipment, requiring more frequent maintenance and shortening the lifespan of expensive machinery. Additionally, clearing jams caused by these fragments forces constant stop-and-start operations, which strain motors and drive systems.

Some processors in Mississippi have tackled this issue by manually presorting cotton modules before ginning. This hands-on approach has proven effective, reducing equipment damage and improving efficiency. It’s a prime example of how addressing contamination early can prevent costly problems later in the process.

These disruptions at the ginning stage inevitably carry over into the spinning phase, where they further complicate operations.

Yarn Quality Problems

Contaminated cotton creates serious challenges for spinning operations. For starters, neps - tiny clusters of tangled fibers - lead to visible flaws in finished fabrics. Meanwhile, seed coat fragments weaken yarn, causing frequent breakage during weaving or knitting.

The fallout can be significant. Contaminated batches often result in up to 15% more waste, which translates to both material losses and higher labor costs for managing rejected products.

Yarn breakage is another persistent issue. Foreign materials disrupt the spinning process, causing frequent stops and producing yarn that lacks the strength and uniformity needed for premium textiles.

A textile mill in North Carolina experienced this firsthand. After processing a contaminated batch, the mill saw a 20% spike in customer complaints. The defects in the finished textiles - holes, weak spots, and uneven dyeing - led to expensive recalls and rework efforts. The incident highlighted the steep costs of contamination, both in terms of money and reputation.

Financial Impact on Supply Chain

The operational challenges caused by contaminants don’t just stop at the mill - they cascade into significant financial losses across the entire supply chain. For starters, contaminated cotton often receives lower grades, which directly reduce its market value and cut into farm-level profits.

Rejected shipments add another layer of cost. Sellers are forced to find new buyers at discounted prices, while also absorbing the logistics expenses of rehandling and reshipping the rejected goods.

Operational delays compound these costs. Cleaning and repairing equipment eats into throughput, while overtime hours inflate labor expenses. These delays can also strain relationships with customers and even lead to penalties for failing to meet contractual obligations.

The USDA classification system underscores the financial stakes, as more than 97% of the U.S. cotton crop undergoes formal grading, which directly determines pricing.

Mills also face added expenses from manufacturing waste loss. Removing non-lint content and other foreign materials before processing creates waste that not only costs money but also comes with environmental compliance obligations.

As mills increasingly adopt automated bale opening systems, controlling contamination earlier in the process has become even more critical. These systems limit opportunities for manual inspection, meaning any contaminants that slip through earlier stages can cause even bigger problems downstream.

Standards and Industry Practices

Maintaining cotton cleanliness standards goes beyond meeting regulatory requirements - it's about safeguarding the reputation and global competitiveness of the U.S. cotton industry. With strict benchmarks and a focus on consumer expectations, the industry has established advanced systems to ensure consistent quality from the farm to the final product.

Cotton Cleanliness Standards

Contaminant removal is a cornerstone of U.S. cotton standards. The USDA enforces these benchmarks through the Universal Cotton Standards and HVI (High Volume Instrument) testing, supported by ICA Bremen-certified Quality Management Programs. These systems are critical for detecting and addressing contamination, which protects both processing equipment and consumer trust.

The Universal Cotton Standards and precise HVI testing ensure that every bale meets consistent quality requirements. This reliability has positioned the U.S. as one of the most trusted producers of high-grade cotton worldwide.

To stay competitive globally, the USDA continually updates its classification system with cutting-edge technology and methods. Even seemingly minor factors, like the preparation of cotton (the uniformity and alignment of lint), are closely monitored. For example, in 1989, less than 0.1% of upland cotton was downgraded due to poor preparation - a testament to the industry’s rigorous standards.

Consumer Expectations

Today’s consumers expect cotton that is not only free of contaminants but also traceable and ethically sourced. Visible flaws or inferior fiber properties can harm trust and reduce market value.

Invisible issues, such as poor fiber uniformity or weakened strength, may not be immediately apparent but can lead to problems like premature wear or fading. These shortcomings erode consumer confidence and have financial consequences: cotton that falls short of cleanliness standards is graded lower, directly affecting its market value and profitability across the supply chain. When shipments are rejected, sellers often face additional costs for rehandling, reshipping, and selling at discounted prices.

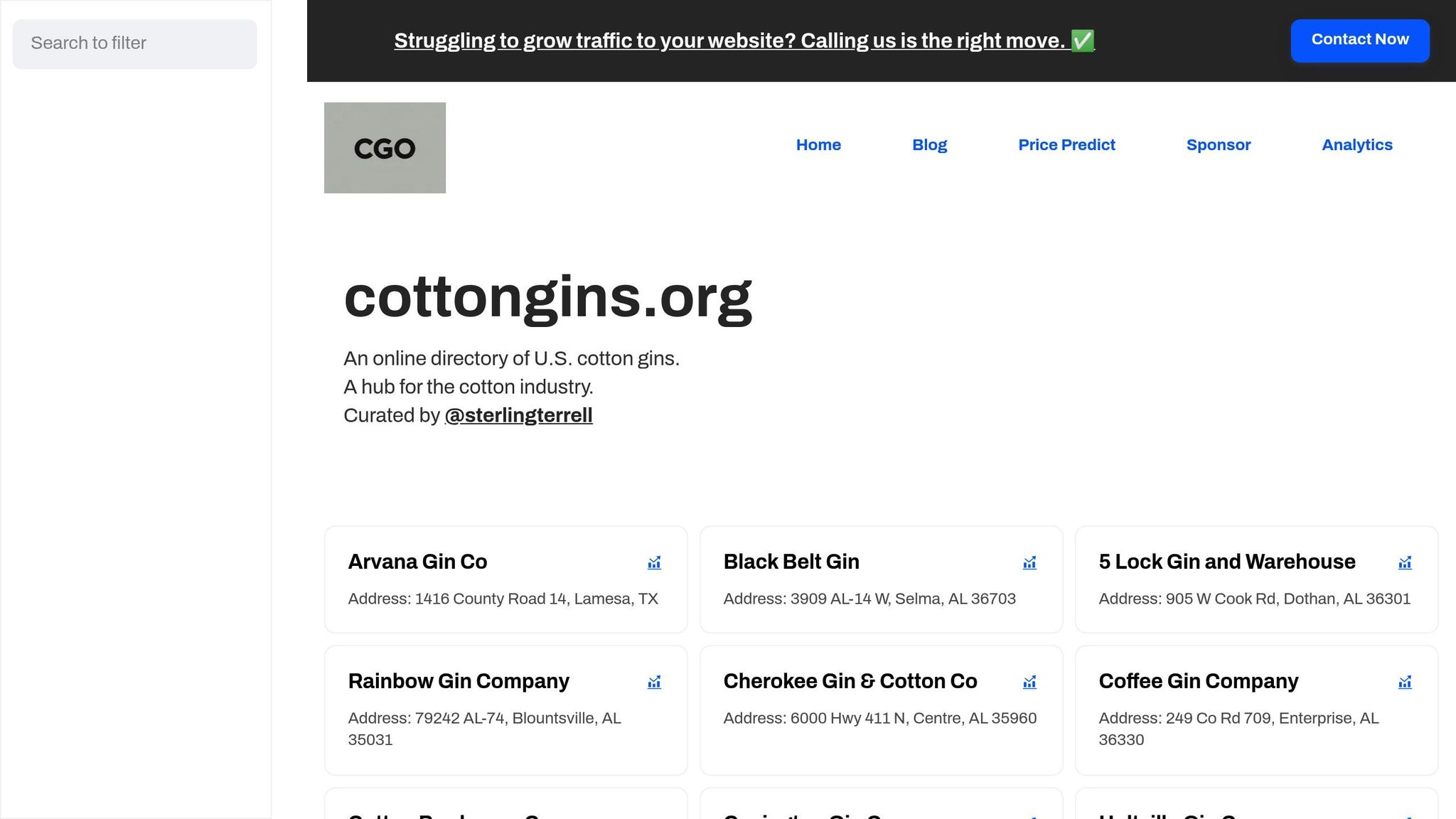

How cottongins.org Supports Quality Control

To uphold these high standards, cottongins.org plays a vital role in promoting transparency and quality assurance within the industry. This comprehensive U.S. cotton gin directory connects processors with facilities that adhere to strict quality control measures and USDA testing standards.

By offering contact details for gins that meet these high standards, cottongins.org helps stakeholders find partners that align with their specific quality requirements. The directory is particularly beneficial for those seeking ginning facilities that use HVI testing and participate in USDA Quality Management Programs - both key indicators of regulatory and consumer compliance.

The platform also allows gins to submit their information, increasing their visibility to potential clients who prioritize quality services. For processors focused on maintaining high standards, cottongins.org simplifies the search for partners who ensure proper instrument calibration and provide ongoing staff training - both essential for maintaining accurate cotton classification and cleanliness.

Additionally, the USDA supports transparency in the supply chain by sharing official data on cotton classification, volume, and pricing. Resources like CottonWorks™ highlight the importance of proper sampling techniques and maintaining optimal laboratory air quality for reliable testing. Through its directory, cottongins.org strengthens industry-wide efforts to maintain high standards, ensuring that U.S. cotton remains a trusted choice in the global market.

Conclusion

Quality control is the cornerstone of the U.S. cotton industry's strong global reputation. By using a comprehensive approach to identify and eliminate contaminants - from the farm to the final product - the industry ensures that American cotton continues to be a trusted source of premium fiber worldwide.

Strict standards, like those outlined in the Universal Cotton Standards, play a key role in maintaining this reputation, consistently resulting in minimal downgrades. These high standards are supported by advanced systems and practices that prioritize precision.

The integration of real-time data analytics has transformed quality management. These tools allow programs to track trends and address potential issues before they escalate, protecting processing equipment and avoiding expensive disruptions. This forward-thinking strategy strengthens both efficiency and product reliability.

By combining advanced analytics with layered detection systems, the industry has built a strong defense against contamination. This ensures smoother operations and upholds the integrity of the final product.

Industry resources further bolster these efforts. For example, cottongins.org connects stakeholders to facilities that emphasize contamination control and adhere to USDA's stringent standards. This platform's directory promotes transparency and reinforces the quality assurance that both consumers and international markets expect from U.S. cotton.

As consumer demands increasingly shift toward traceability and ethical sourcing, maintaining rigorous quality control becomes even more critical. Continued investments in training, equipment calibration, and verification processes ensure that U.S. cotton not only meets high standards but also sustains its global reputation for excellence.

FAQs

What are the best technologies for identifying and removing contaminants in cotton?

To meet consumer expectations for high-quality cotton, cutting-edge technologies play a crucial role in identifying and eliminating contaminants. Optical sensors and machine vision systems are among the tools commonly used to detect foreign materials like plastic, leaves, or dirt. These systems rely on high-speed cameras and AI to sort out impurities with impressive efficiency.

In addition to these detection systems, air-jet separators and vacuum systems are widely utilized in cotton processing facilities. These tools physically remove debris, ensuring the cotton remains clean and pure. Together, these technologies help maintain the quality standards demanded by both consumers and manufacturers.

How do regional and supply chain factors affect cotton contamination levels?

Regional and supply chain dynamics play a big role in determining the type and extent of contamination in cotton. Factors like soil quality, weather conditions, and farming methods in different areas can lead to specific impurities such as dirt, seeds, or bits of plant material. Beyond that, how cotton is handled during harvesting, transportation, and ginning can also introduce contamination if these processes aren't carefully managed.

Ensuring cotton meets consumer quality expectations requires strict oversight at every step of the supply chain. This means conducting regular inspections, using advanced cleaning methods, and relying on modern equipment to identify and remove contaminants effectively.

How does cottongins.org support cotton producers in maintaining high-quality standards?

cottongins.org serves as a key resource for cotton producers by offering a detailed directory of cotton gins throughout the United States. This directory makes it easier for producers to locate nearby gins, streamlining the processing of cotton and minimizing the chances of contaminants entering the supply chain.

The platform also encourages user participation by allowing submissions of new gin entries and offering sponsorship opportunities. These features promote collaboration within the industry, helping producers prioritize delivering clean, top-notch cotton that aligns with consumer demands.