Managing cotton inventory is complex due to the need for bale-level tracking of fiber properties like length, strength, and moisture. Errors in tracking or quality control can lead to pricing issues, shipping delays, or regulatory penalties. The U.S. cotton industry uses Permanent Bale Identification (PBI) tags and USDA databases to ensure traceability, but challenges remain in data consistency, storage, and quality monitoring.

Key points:

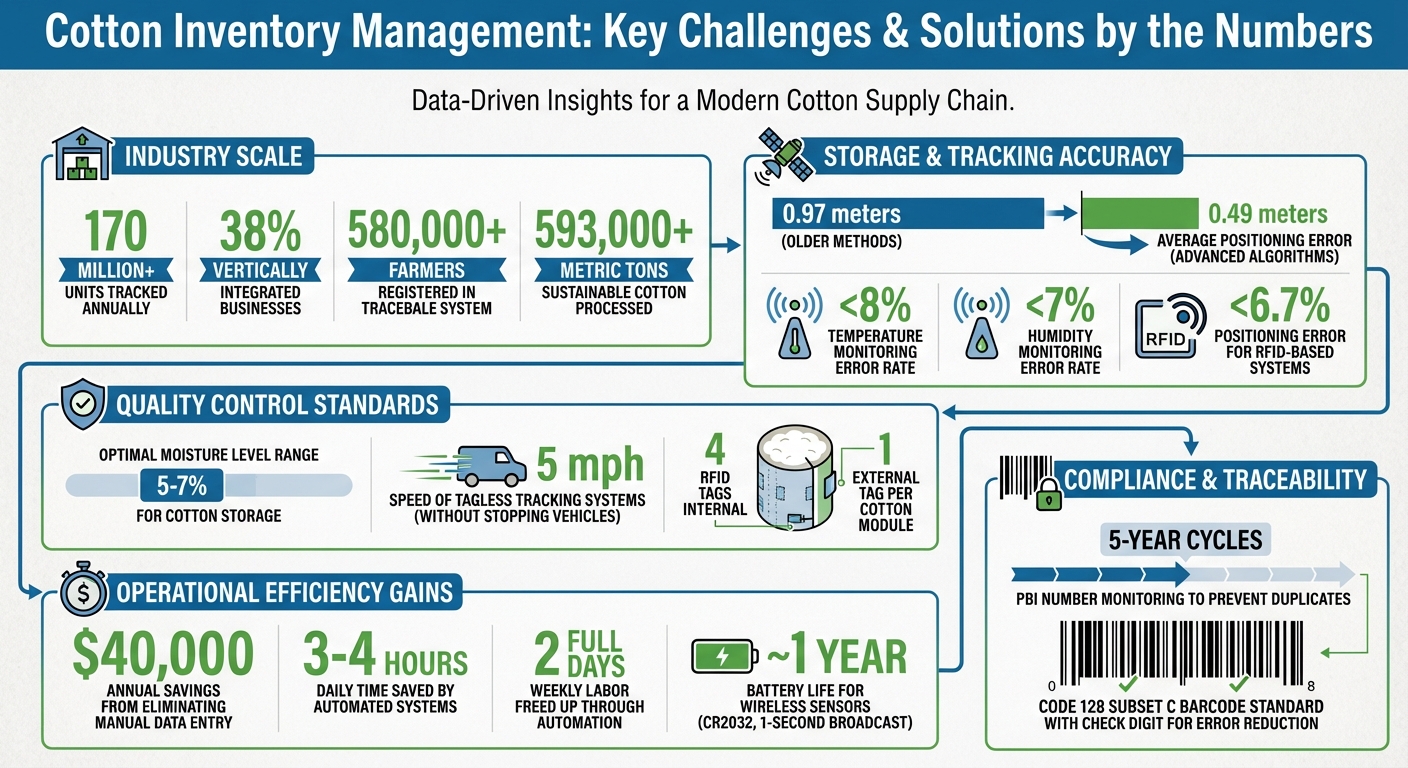

- Storage risks: Fire, mildew, and theft are common issues. Advanced positioning tools now improve bale location accuracy within 0.49 meters.

- Data accuracy: Manual errors in tracking over 170M units annually can disrupt supply chains. Automated systems like MILLNet and CommOS minimize these issues.

- Quality control: Monitoring moisture (5-7%) and preventing contamination are critical. Wireless sensors track conditions with high precision.

- Regulations: Mills face strict traceability laws, especially in the EU, requiring farm-to-mill tracking and sustainability reporting.

Solutions include inventory software, RFID tagging, and wireless monitoring tools. These systems integrate data, reduce manual errors, and ensure compliance with global standards, saving time and costs for gins and mills.

Cotton Inventory Management: Key Challenges and Solutions Statistics

SAP For Cotton Ginning Industries

sbb-itb-0e617ca

Main Challenges in Cotton Inventory Management

Successfully tackling these challenges can help improve operations and prevent costly delays.

Storage Limits and Space Use

Cotton warehouses face a host of storage risks, including mildew, fire, and theft. Traditional warehouses relying on manual searches can waste hours, leading to inventory losses and shipment delays. However, advanced positioning algorithms now reduce the average positioning error to 0.49 meters, a significant improvement over the 0.97 meters seen with older location methods. This level of precision is essential when managing thousands of bales spread across multiple storage zones, especially during the busy ginning season. While efficient storage is critical, accurate tracking plays an equally important role in streamlining operations.

Tracking and Record Accuracy

For operations handling over 170 million units annually, manual record-keeping errors are not an option. Vertically integrated businesses, responsible for producing 38% of these units, face the risk of widespread disruptions if inventory and production records don’t align. As noted in a statement by Kontoor Brands in their SEC filing:

We believe our vertically integrated operations in combination with inventory and supply-demand reconciliation processes allow us to excel in meeting our retail customers' rapid order requirements.

Without accurate tracking, these businesses lose the agility needed to shift manufacturing across facilities and meet fast-changing customer demands. But tracking isn’t the only issue - ensuring consistent quality adds another layer of complexity.

Quality Control Difficulties

Preserving cotton quality involves monitoring multiple variables like moisture levels, foreign matter, temperature, and contamination risks. Manual inspections in large warehouses often fail to catch real-time issues. For instance, moisture variations can affect grade, value, and lint yield, while poor temperature control raises the risk of spontaneous combustion. Modern wireless systems can track humidity and temperature with errors of less than 8% and 7%, respectively. Yet, fragmented data from HVI and manual classing files makes it harder to evaluate individual bales and calculate premiums accurately. This lack of integration in quality data remains a critical hurdle.

Tools for Cotton Inventory Management

Modern software platforms are tackling long-standing issues in cotton tracking and quality control by addressing manual errors and gaps in oversight. Tools like the Engineered Fiber Selection (EFS) System, which includes MILLNet for bale management and Cotton Communicator for electronic data exchange, are provided free to support the exchange of fiber quality data. Similarly, CommOS from Gen10 creates "virtual lots" to represent physical goods, automating workflows and integrating bale-level quality tracking with High Volume Instrument (HVI) data. For those prioritizing supply chain transparency, TraceBale by CottonConnect has registered over 580,000 farmers and processed more than 593,000 metric tons of sustainable cotton. As of February 2026, Primark uses TraceBale to track cotton from farms to spinners in countries like India, Pakistan, Bangladesh, and Turkey, aligning with their goal of sourcing 100% sustainable cotton by 2027. Below, we explore how software, tagging systems, and sensor tools are streamlining inventory management.

Inventory Management Software

Modern inventory software simplifies the tracking of thousands of cotton bales while linking quality data to pricing and production decisions. For example, MILLNet helps prevent issues like "underspinning" or "overspinning" by matching specific fiber properties to the lowest-cost raw materials that meet product requirements. Johnny Mauney, Cotton Quality Manager at Gildan Yarns, LLC, highlights the importance of EFS:

"EFS is critical to helping us interpret the cotton properties that we're getting into our facilities and how we can better utilize those materials to make the best end product that can be made from the quality standpoint."

CommOS offers a live view of physical inventory while its Formula.Engine tool removes guesswork from pricing by automatically calculating premiums and discounts.

Lot Numbering and Bale Tagging Systems

RFID technology has revolutionized bale tracking, eliminating the need for manual spray paint or physical tags. Round cotton modules now typically include four internal RFID tags and one external tag for unique identification. The tCotton system from TSW Automation provides "tagless" tracking, capturing data like yield, weight, and moisture at speeds of up to 5 mph without requiring vehicles to stop. Additionally, PBI tags feature a Code 128 subset C barcode with a check digit to reduce scanning errors. To avoid duplicate numbering across crop years, AMS monitors PBI numbers in five-year cycles, ensuring gins do not repeat numbering within that timeframe.

Production and Storage Monitoring Tools

Beyond tracking and tagging, advanced sensor technologies play a key role in ensuring safe storage and operational efficiency. Wireless sensor networks help prevent issues like mildew, fire, or quality degradation by monitoring environmental conditions. For example, in December 2020, Baoding YIN XIANG Cotton Industry Co., LTD. in Hebei Province implemented an RFID-based inspection system with 10 card readers and wireless sensors placed within cotton stacks. This system achieved a relative error of less than 8% for temperature, under 7% for humidity, and positioning errors below 6.7%. The SHT20 chip monitors temperature and humidity in real time, while LIS3DH three-axis acceleration sensors detect physical movement or shifts in stacks. These sensors can operate for about a year on a single CR2032 battery with a 1-second broadcast interval.

For module traceability, John Deere's round module harvesters incorporate RFID tags, enabling seamless tracking from the field to the gin. Tools like the "CottonHarvestFileDownload" executable allow gins to automatically retrieve Harvest Identification files, ensuring smooth data integration.

Best Practices for Cotton Inventory Management

Managing cotton inventory comes with its fair share of challenges, including limited storage space, tracking errors, and maintaining consistent quality. The following practices can help streamline operations and address these hurdles effectively.

Maximizing Space and Reducing Waste

One of the first steps to efficient cotton inventory management is ensuring proper storage. Covered storage facilities are essential to shield cotton modules from rain and excess moisture, which can lead to mold and degrade quality. As M.B. McKee Company, Inc. highlights:

"Covered storage facilities protect cotton from exposure to rain and excessive moisture, preserving its quality until it can be processed at the gin."

Incorporating weather forecasting into your planning, along with maintaining strict storage protocols and routine equipment upkeep, helps safeguard cotton quality. These measures also minimize processing delays that might arise due to unexpected weather conditions. Flexible scheduling can further adapt operations to changing weather patterns, ensuring smooth workflows. By combining these strategies with seasonal planning, you can enhance operational efficiency and maintain consistent quality.

Planning for Seasonal Volume Changes

Peak production periods demand equipment and systems that align with the ginning plant’s capacity. The Cotton Ginners Handbook emphasizes the importance of this:

"The bale press, condenser, and hydraulic systems must be sized to match the design capacity of the ginning plant in order to maximize capacity."

Additionally, using bale coverings and ties approved by the Joint Cotton Industry Bale Packaging Committee ensures compliance with standards required for eligibility in the Commodity Credit Corporation loan program. Preparing separate workflows for domestic and international shipments - such as warehouse release notes for local sales and export packing orders for global shipments - helps manage high-volume periods more efficiently. Centralized systems that automate data sharing with banks, insurance providers, and freight companies further streamline the process, reducing delays and errors.

Training Staff for Consistent Operations

Modernizing inventory management with automated, cloud-based systems can significantly reduce manual errors and save time. For instance, a system that eliminated up to 3–4 hours of manual data entry daily resulted in annual savings of $40,000. However, adopting advanced technology requires skilled personnel. Cross-training staff ensures that operations remain productive during seasonal spikes or unexpected challenges. Professional onboarding services and expert implementation partners can also help teams get up to speed with new systems, minimizing errors during the transition.

Case Studies: Successful Inventory Management in Cotton Operations

Real-world examples highlight how cotton operations have improved inventory management by adopting advanced technology and refining their processes. These examples provide actionable insights for gins and mills looking to achieve similar results.

Better Tracking Through Software Integration

TSW Automation, Inc.'s tCotton system showcases the power of RFID technology in eliminating the inefficiencies of manual tracking. By integrating this technology into inventory management software, the system significantly reduces human error. It tracks modules, rounds, and bales in real time - from the field to the gin yard - replacing outdated paper-based methods. The system also automates the capture of key data like weight, yield, and producer information, and syncs seamlessly with third-party accounting software to prevent duplicate data entry. As TSW Automation, Inc. explains:

Track modules, rounds and bales in real-time. Record farm, field, supplier information and much more with the use of RFID technology.

This advanced tracking capability allows managers to sort by factors like moisture content or producer, which helps optimize ginning schedules during peak harvest times. When paired with space optimization strategies in high-volume mills, this approach delivers even greater efficiency.

Space Optimization in High-Volume Mills

High-volume mills face challenges like limited storage space and handling seasonal surges, but module-based systems have proven to be an effective solution. Since their introduction in 1972, seed-cotton modules have become essential for large-scale operations. These modules enable gins to separate harvesting from ginning, making it easier to handle seasonal peaks while extending the ginning season. This approach increases operational hours and reduces costly downtime. Additionally, interactive mapping software enhances storage and retrieval processes, improving logistics planning.

Combining these practices with moisture-based sorting upon arrival further boosts ginning efficiency while maintaining cotton quality during extended storage periods. As Cotton.org emphasizes:

Modules allow gins to handle seed-cotton more efficiently, to help extend the ginning season and to operate more hours each year without expensive down time.

Well-constructed modules also protect against harsh weather, minimizing lint and seed loss during storage. These strategies collectively streamline operations, ensuring both efficiency and quality preservation.

Conclusion

Managing cotton inventory effectively means leaving behind outdated manual methods. Shifting from spreadsheets and paper-based tracking to automated systems significantly reduces the risk of data entry mistakes. For example, in 2026, Cotton Gin Operations Manager Daniel Pantaleo reported saving $40,000 annually in wasted time after adopting automated inventory software. The system also freed up two full days of labor every week. Cotton operations can achieve similar results by embracing modern tools.

As outlined earlier, modern integration offers real-time accuracy and operational efficiency. Automated RFID tagging and inventory software play a key role in this shift. When paired with bale-level tracking, these tools provide real-time insights into stock levels, locations, and quality attributes. This creates a unified source of truth, seamlessly connecting inventory data with accounting, logistics, and quality control systems. By eliminating redundant data entry, operations become more consistent and streamlined. Mike Woods, Fixed Asset Market Manager at Camcode, emphasizes this point:

An inventory management system, combining technology, processes, and procedures, is crucial for efficiently monitoring and maintaining stocked products, ensuring the right amount of inventory is available at the right time and of the right quality.

Automated workflows further enhance efficiency by generating shipping documents, packing lists, and quality reports. However, technology alone isn’t enough. Success depends on clear policies, optimized storage designs, and thorough staff training to ensure systems are used properly. Implementing unique IDs for every bale, leveraging barcode scanning, and establishing company-wide labeling and documentation procedures lay the groundwork for dependable inventory management.

FAQs

What’s the best first step to move from spreadsheets to bale-level tracking?

The ideal first step is switching to a digital inventory management system that allows for unique bale identification. Tools like the Permanent Bale ID Tag can help assign and track a unique ID for every bale. This approach not only streamlines tracking but also makes the move from spreadsheets to a more efficient, bale-specific digital system much easier.

How do I choose between barcodes, PBI tags, and RFID for tracking bales?

When deciding on tracking methods, it's essential to align them with your operation's specific needs.

- Barcodes: These are budget-friendly and work well for straightforward tracking tasks. They rely on line-of-sight scanning, making them ideal for smaller-scale operations or those with less complex requirements.

- PBI tags: Known for their durability, these tags are a trusted choice across industries. They provide reliable long-term traceability, making them suitable for environments where resilience is key.

- RFID: This option offers cutting-edge tracking capabilities, including real-time updates and automation. However, it comes with higher initial setup costs, which may be a factor for businesses with tighter budgets.

Evaluate factors like your budget, the scale of your operations, and your traceability requirements to determine the best fit for your supply chain.

What data should I capture to meet traceability and sustainability rules?

To meet traceability and compliance requirements in cotton inventory management, it's essential to gather data that confirms the origin, handling, and farming practices of the cotton. This includes farm-level details (such as the location where the cotton was grown), shipment records, bale identification numbers, and supplier information.

Advanced tracking systems can also monitor certifications like Better Cotton Initiative (BCI) or Global Organic Textile Standard (GOTS). Additionally, they may document farming practices, including how water and soil are managed. Collecting this data not only ensures transparency but also helps businesses align with regulatory and sustainability requirements.