Cotton gins play a vital role in processing raw cotton, but their wastewater can harm water systems and aquatic life if not managed properly. Compliance with wastewater regulations, like NPDES permits under the Clean Water Act, is essential to avoid fines, protect ecosystems, and maintain operations. Here’s what cotton gin operators need to know:

- Common Challenges: Controlling pollutants, meeting reporting standards, and investing in costly upgrades.

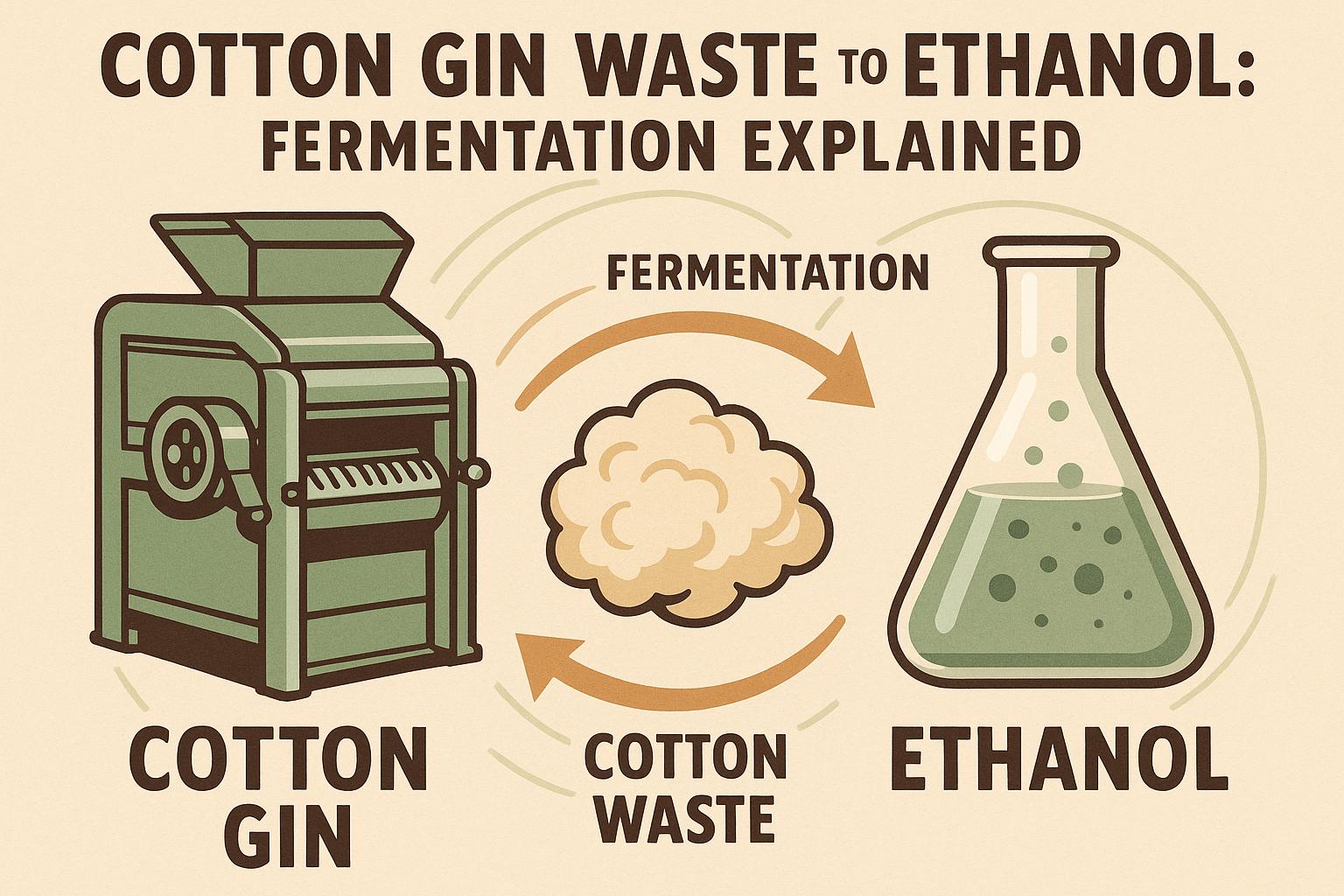

- Key Solutions: Use modern wastewater treatments (biological, filtration, chemical), implement runoff prevention systems, and recycle waste.

- Steps for Compliance: Regular monitoring, staff training, and creating a Storm Water Pollution Prevention Plan (SWPPP).

NPDES Permit Regulations and Discharge Limitations

Challenges Cotton Gins Face with Wastewater Rules

Cotton gin operators deal with several hurdles, including controlling pollutant levels, meeting strict reporting standards, and investing in expensive infrastructure upgrades. These issues arise from both technical demands and regulatory pressures, directly affecting their daily operations.

How Cotton Gin Wastewater Affects Local Ecosystems

Cotton gin wastewater is loaded with particulate matter (tiny solid particles) and organic compounds (biodegradable materials). These pollutants can significantly lower oxygen levels in water, leading to harm for aquatic life. Research from Pima County, Arizona, highlights how these contaminants can cause lasting damage to ecosystems [3].

The impact of cotton gin wastewater on the environment includes:

- Contaminating drinking water sources with harmful chemicals

- Threatening fish populations due to high pollutant levels

- Reducing soil productivity through the buildup of organic compounds

- Disturbing wildlife habitats, disrupting local ecological balance

Overview of Wastewater Discharge Regulations

Under the Clean Water Act, cotton gins must secure NPDES permits. These permits establish pollutant limits, require regular monitoring, and mandate the development of a Storm Water Pollution Prevention Plan (SWPPP). SWPPPs focus on identifying runoff risks, implementing control measures, and conducting regular water quality tests [4].

State agencies, like the Mississippi Environmental Quality Permit Board, impose strict discharge limits and demand consistent monitoring of wastewater quality [1]. Smaller operations often struggle with these requirements, as they may lack the resources for advanced wastewater treatment systems. This leaves them balancing the need for costly upgrades against staying competitive.

For cotton gin operators, understanding these regulations is key to staying compliant and reducing environmental impact. While the challenges are real, there are practical strategies and emerging technologies available to help manage wastewater more effectively - topics we’ll dive into next.

Steps Cotton Gins Can Take to Follow the Rules

Managing Cotton Gin Waste Effectively

Cotton gin operators can minimize risks by using covered storage systems to stop runoff contamination. These measures help tackle issues like runoff and organic pollution caused by cotton gin wastewater.

To manage waste efficiently, operators can focus on:

- Windrow composting: Regularly turning and monitoring moisture levels to ensure proper breakdown.

- Closed conveyors: Enclosed systems reduce exposure to the environment during waste transport.

- Runoff prevention: Installing drainage systems and barriers to keep runoff under control.

Advanced Solutions for Wastewater Treatment

Modern wastewater treatment methods make it easier to meet regulations without overspending. Biological treatments, for example, use natural processes to break down contaminants effectively.

| Treatment Type | Benefits | Application |

|---|---|---|

| Biological Treatment | Eco-friendly, cost-saving | Removes organic waste |

| Filtration Systems | Eliminates solids, reusable water | Initial treatment |

| Chemical Treatment | Quick and adaptable | Secondary treatment |

Beyond adopting these technologies, operators should focus on building systems that ensure ongoing compliance with regulations.

Staying Compliant in the Long Run

Long-term compliance requires planning and consistent efforts. Cotton gin operators should create a monitoring system to regularly check water quality.

Key steps for sustained compliance include:

- Staff Training Programs: Regularly train employees on waste management practices and how to operate new treatment equipment.

- Environmental Monitoring: Implement routine water quality checks to ensure continuous compliance with regulations [1].

- Waste Recycling: Recycle waste into soil or plants to cut down on wastewater while adding value [2].

Operators can also benefit from connecting with industry platforms like cottongins.org. Networking with peers and staying updated on the latest practices and regulatory changes can provide helpful insights for maintaining compliance and finding new solutions.

sbb-itb-0e617ca

Examples of Cotton Gins Solving Wastewater Issues

What Leading Cotton Gins Are Doing Right

Waste Water Solutions LLC stands out as a prime example of achieving permit compliance through consistent monitoring and detailed reporting [1]. Their approach not only meets regulatory requirements but also sets a standard for others aiming to tackle wastewater challenges effectively.

Many cotton gins are adopting advanced technologies to reduce their environmental footprint:

| Technology | How It's Used | Environmental Impact |

|---|---|---|

| Covered Storage and Transport Systems | Enclosed storage with moisture control | Reduces runoff, dust emissions, and wind-blown particles |

| Water Management Systems | Automated sprinklers | Lowers dust and fire risks while optimizing water use |

Lessons from Successful Compliance Stories

The most effective cotton gins show that staying compliant takes a well-rounded approach to waste management [2]. Their strategies reveal a few critical practices:

- Monitoring and Adjusting: Regular water quality tests and process updates help facilities stay on track. Adapting to new regulations by revising permits and practices ensures continued compliance [1].

- Using Available Resources: Operators working with organizations like the LSU AgCenter implement proven methods, such as composting cotton gin waste or using it as a soil amendment [2].

These examples show actionable steps that cotton gins can take to meet regulations and get ready for future environmental demands.

Resources to Help Cotton Gins Meet Wastewater Rules

cottongins.org: A Hub for Cotton Gin Operators

Cottongins.org serves as a meeting point for cotton gin operators across the U.S., offering a space to exchange strategies and share success stories related to compliance. By tapping into this network, operators can discover practical solutions for managing wastewater. The platform also allows facilities to highlight their efforts in wastewater management through sponsorships, encouraging collaboration within the industry.

Guidelines and Support from Authorities

The Environmental Protection Agency (EPA) and state agencies provide clear resources to guide operators in meeting wastewater standards. Federal frameworks like the EPA's NPDES guidelines and 40 CFR regulations outline the necessary steps for compliance.

Federal Resources:

- NPDES permit program guidelines

- Federal wastewater rules under 40 CFR standards [3]

State Resources: Agencies like the Mississippi Department of Environmental Quality offer state-specific guidance, including detailed compliance rules and permit application support [1].

Operators should regularly review these resources to stay updated on evolving environmental regulations. By using these tools effectively, cotton gin operators can maintain compliance while demonstrating leadership in environmental responsibility [5].

Conclusion: Meeting Wastewater Rules for a Better Future

Managing wastewater effectively in cotton ginning is about balancing environmental care with smooth operations. By using advanced treatment methods and well-thought-out waste strategies, cotton gins can safeguard ecosystems while staying profitable.

Planning ahead, using modern systems, and sticking to compliance measures help ensure long-term success. These steps not only address challenges like infrastructure upgrades and reporting but also reinforce operational stability.

Cottongins.org serves as a hub for operators to exchange ideas and keep up with changing regulations. Paired with expert guidance and regulatory updates, these tools make it easier to implement practical wastewater solutions. With regular monitoring and adjustments to meet new requirements [5], cotton gins can continue to protect the environment while staying efficient.

The industry's evolving approach to wastewater management highlights its shift toward more sustainable practices. By aligning business goals with environmental care, cotton gins set an example for sustainable agriculture.

Key Steps for Success:

- Regularly review and improve wastewater strategies

- Invest in modern treatment technologies

- Stay connected with industry updates and resources

- Keep detailed records of compliance and environmental efforts

This balanced approach shows that meeting environmental standards strengthens both ecological protection and business success. By staying committed, the cotton ginning industry secures its role in sustainable agriculture while preserving water resources for the future.