Cotton gin waste is no longer just a disposal problem - it’s a resource for clean energy. By converting agricultural byproducts like cotton burrs and stems into ethanol, ginning operations can reduce waste, lower costs, and create a renewable fuel source. Here’s how it works:

- The Challenge: Cotton gins produce large amounts of waste that are hard to dispose of due to environmental and logistical issues.

- The Solution: Fermentation technology transforms this waste into ethanol, a biofuel made from non-food materials.

- The Process: Waste undergoes pretreatment (like steam explosion or acid treatment) to unlock fermentable sugars, followed by saccharification and fermentation using enzymes and yeast.

- The Benefits: Reduced waste, additional revenue streams, and compliance with renewable fuel standards.

This approach not only addresses waste management concerns but also supports cleaner energy production. With advancements in fermentation methods, cotton gin operators have an opportunity to turn seasonal waste into year-round value.

A Novel Approach to produce Bio- Ethanol &Bio-Gas from Textile Wastes

Cotton Gin Waste: Composition and Potential

Understanding the makeup of cotton gin waste is crucial for turning it into a viable ethanol feedstock. Its intricate lignocellulosic structure makes it a strong candidate for biofuel production through fermentation. Let’s break down the components that make this material suitable for such conversion.

Key Components of Cotton Gin Waste

Cotton fiber is about 95% cellulose, but cotton gin waste contains significantly less - around 31% cellulose. Its holocellulose content, which combines cellulose and hemicellulose, falls between 42% and 50%, offering a substantial source of fermentable sugars. Hemicellulose, including xylan (approximately 9%), further boosts its conversion potential.

In addition to cellulose and hemicellulose, cotton gin waste contains noncellulosic elements like lignin, arabinan, galactan, and acetate, all typical of lignocellulosic biomass. Another advantage is its lower crystallinity - 32.3% compared to the 75.4% found in pure cotton fiber. This lower crystallinity increases the proportion of amorphous cellulose, making it easier for enzymes to access and process during fermentation.

Preparing Cotton Gin Waste for Ethanol Production

Turning cotton gin waste into ethanol starts with breaking down its structure to access fermentable sugars. This process ensures the highest possible sugar yield for efficient ethanol production.

Pretreatment Methods

One effective way to prepare cotton gin waste is through steam explosion. This method uses high-pressure steam, which is then rapidly released, causing the biomass to physically rupture. The sudden release of pressure breaks apart the lignin matrix, exposing the cellulose fibers for enzymatic processing.

Another option is acid pretreatment, which involves using dilute acids like sulfuric or hydrochloric acid. This method dissolves hemicellulose components while leaving most of the cellulose intact for further processing. The process is carefully controlled to modify the biomass structure without damaging it.

Alkaline pretreatment offers a gentler alternative. Using substances like sodium hydroxide or lime, this method focuses on removing lignin by swelling the cellulose structure and breaking the bonds between lignin and carbohydrates. While slower, it produces fewer inhibitors that could interfere with fermentation.

For a milder approach, enzymatic pretreatment uses enzymes such as laccase or manganese peroxidase to break down lignin bonds. Though slower, this method operates under less harsh conditions and creates fewer toxic byproducts.

The choice of pretreatment significantly affects both costs and the release of fermentable sugars, making it a critical step in the process.

Saccharification Process

Once the pretreatment has opened up the cotton gin waste structure, the next step is saccharification, where cellulose is converted into fermentable sugars. This is achieved using cellulase enzymes, which break down cellulose chains into glucose molecules.

Key cellulase enzymes include:

- Endoglucanases: Break internal bonds in cellulose chains.

- Exoglucanases: Work on cellulose ends to release smaller sugar units.

- β-Glucosidases: Convert these smaller units into glucose.

The efficiency of this step depends on the right enzyme loading, which balances sugar yield and cost. Maintaining moderate temperatures and slightly acidic conditions enhances enzyme performance.

A more streamlined option is simultaneous saccharification and fermentation (SSF). This method combines enzyme treatment and yeast fermentation in a single vessel, reducing both processing time and equipment costs. SSF works by maintaining conditions that support both enzymatic activity and yeast fermentation.

The concentration of solids in the saccharification vessel also plays a role. Higher solid loadings can produce more concentrated sugar solutions but may cause mixing issues and reduce enzyme efficiency. Finding the right balance is essential to ensure smooth processing.

To cut costs, enzyme recycling can be implemented, though it requires additional processing steps.

The result of saccharification is a glucose-rich solution, ready for ethanol fermentation.

sbb-itb-0e617ca

Fermentation Processes and Applications

After pretreatment and saccharification, selecting the right fermentation strategy is crucial for converting cotton gin waste sugars into ethanol in a cost-effective way.

Comparison of Fermentation Methods

When it comes to turning cotton gin waste into ethanol, there are three main fermentation methods. Each strikes a balance between yield, processing time, and overall cost.

Separate Hydrolysis and Fermentation (SHF) involves keeping the saccharification and fermentation steps completely separate. First, cellulase enzymes break down cellulose into glucose. After this, the temperature is lowered to around 86°F to 95°F, and yeast is introduced to ferment the sugars into ethanol.

This separation allows both processes to occur under their ideal conditions, leading to higher sugar conversion rates. However, SHF comes with downsides: it requires more equipment, takes longer, and increases both capital and operational expenses.

Simultaneous Saccharification and Fermentation (SSF) combines saccharification and fermentation in a single vessel. As cellulase enzymes break down cellulose, yeast simultaneously converts the released glucose into ethanol. This method operates at a compromise temperature, typically between 95°F and 104°F.

The biggest advantage of SSF is that it prevents glucose from building up, which could otherwise inhibit enzyme activity. While the temperature may not be ideal for the enzymes, this approach often results in better overall efficiency.

Semi-Simultaneous Saccharification and Fermentation (SSSF) takes a hybrid approach. It starts with a short saccharification phase (4 to 12 hours) before yeast is added to begin fermentation. This gives the enzymes a head start on breaking down cellulose before fermentation kicks in.

| Method | Processing Time | Equipment Needs | Temperature Control | Ethanol Yield | Capital Cost |

|---|---|---|---|---|---|

| SHF | 72-96 hours | Multiple vessels | Precise control needed | High | Highest |

| SSF | 48-72 hours | Single vessel | Moderate control | Very high | Lowest |

| SSSF | 60-84 hours | Single vessel | Moderate control | High | Low |

Each method has its pros and cons, but the choice depends on the specific goals and resources of the operation.

Optimizing Fermentation Conditions

Beyond picking the right method, fine-tuning fermentation conditions can significantly improve ethanol yield. Success depends on using robust yeast strains and maintaining the right environment.

Saccharomyces cerevisiae is the go-to yeast for ethanol fermentation. Standard strains can produce ethanol concentrations of 12% to 15% by volume, but specialized strains can handle up to 18%–20%. These high-tolerance strains are especially useful when working with concentrated sugar solutions derived from cotton gin waste.

Temperature control is critical. Most yeast strains thrive between 86°F and 95°F, with a pH range of 4.0 to 5.0. Temperatures exceeding 104°F can harm or kill the yeast, while temperatures below 77°F slow fermentation, increasing the risk of bacterial contamination. The slightly acidic pH not only supports yeast activity but also discourages bacteria.

Adding nutrients can also make a big difference. Cotton gin waste may lack essential nutrients, so supplementing with nitrogen sources like ammonium sulfate or yeast extract can speed up fermentation and increase ethanol output.

Oxygen management is another key factor. Yeast requires some oxygen early on for cell growth, but too much oxygen during active fermentation can shift sugar metabolism away from ethanol production. Most commercial systems aerate the mixture initially, then maintain anaerobic conditions during fermentation.

The solid content of the fermentation mixture matters too. Higher solid concentrations can lead to more concentrated ethanol but may cause mixing issues or incomplete fermentation. A solid content of 15% to 25% by weight is generally optimal for maintaining efficiency.

Modern fermentation systems often include automated sensors to monitor sugar consumption and ethanol production in real time. These systems help operators quickly identify and fix issues, ensuring the process stays on track.

Integration and Benefits for the Cotton Industry

Transforming cotton gin waste into ethanol offers a smart way to tackle disposal issues while creating a valuable resource. Achieving this requires careful planning, technical upgrades, and collaboration.

Integrating Ethanol Production into Cotton Gins

Adding ethanol production to cotton gins starts with assessing the facility's space, infrastructure, and processing capabilities. Modular fermentation and distillation systems are a practical choice, as they can be adapted to fit existing setups. Timing is also key - aligning ethanol production with the periods when waste is most abundant ensures efficiency. For cost savings and smoother operations, joint processing facilities can be a great option, as they help reduce upfront investment and simplify logistics.

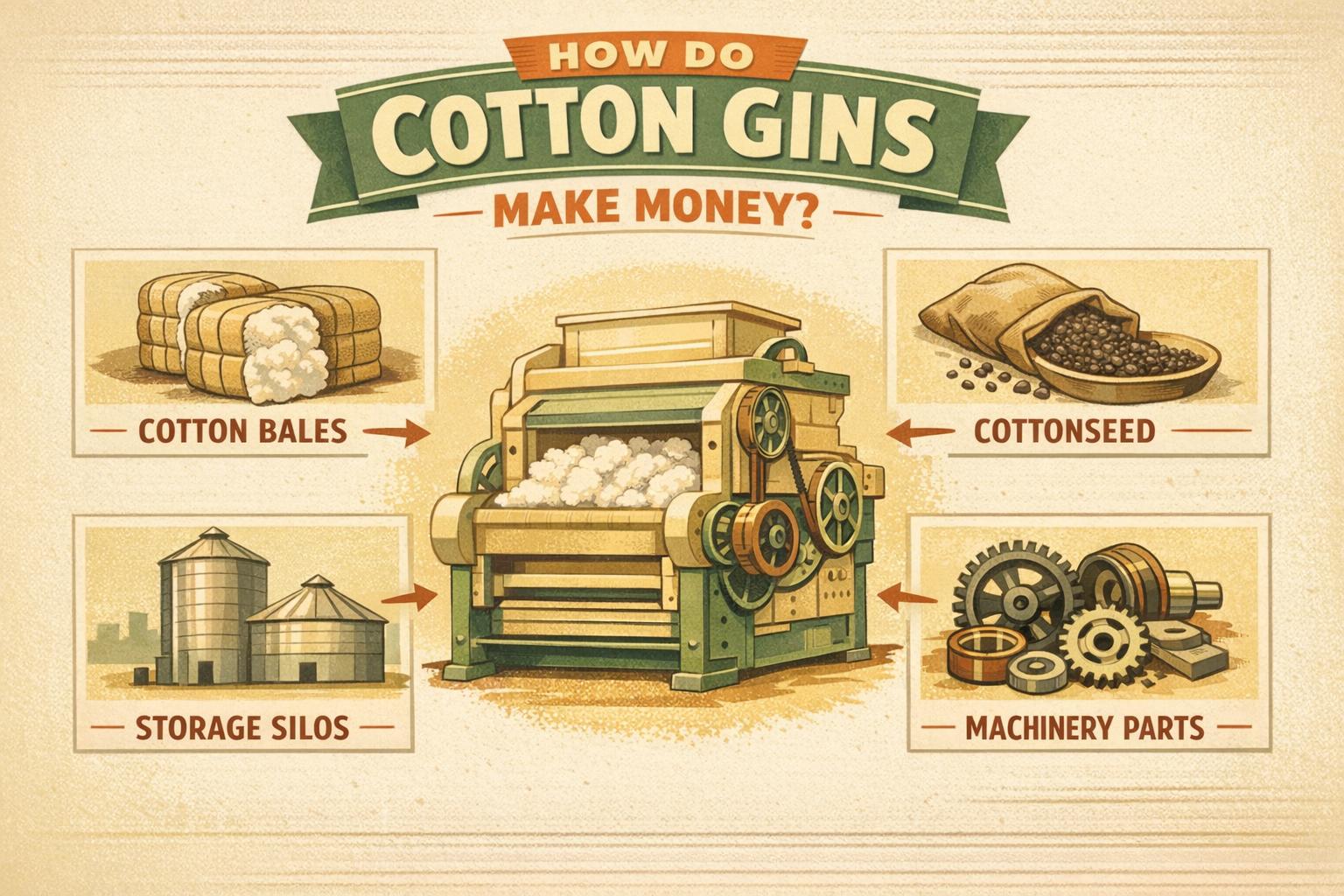

Economic and Regulatory Impact

Turning cotton gin waste into ethanol doesn’t just cut disposal costs - it opens up new revenue opportunities. Plus, it positions operators to take advantage of government programs aimed at supporting renewable energy, which can ease regulatory requirements and provide financial incentives. By meeting renewable fuel standards, cotton gins can reduce their environmental impact and streamline the permitting process, making this shift even more appealing.

Using cottongins.org for Collaboration

The platform cottongins.org is a valuable tool for cotton gin operators looking to collaborate on ethanol production projects.

With the "Cotton Gins Near Me" feature, operators can locate nearby facilities to explore joint ventures. Adding facilities to the directory through the "Submit A Gin" function increases visibility and builds a stronger network for potential partnerships. Subscribers also gain access to updates on the latest technologies and best practices in ethanol production.

The directory simplifies regional coordination for shared transportation and marketing efforts. For larger-scale initiatives, state-level listings help equipment suppliers and service providers identify high-density areas of cotton gins, leading to better pricing and improved technical support for these projects.

Conclusion: Advancing Cotton Ginning Practices

Turning cotton gin waste into ethanol offers a game-changing opportunity for the cotton industry. This approach not only transforms waste into a profitable resource but also addresses two pressing challenges: cutting waste management costs and producing a renewable fuel source.

With advancements in pretreatment methods and fermentation techniques, the process has become both practical and efficient. Properly storing cellulose-rich waste ensures that production can continue throughout the year. The real challenge lies in finding the right mix of pretreatment strategies and fermentation conditions to maximize ethanol output while keeping costs in check.

The financial benefits go well beyond waste reduction. Cotton gin operators can tap into new revenue streams and may also qualify for renewable energy incentives or tax breaks. Thanks to the modular design of modern fermentation systems, facilities of all sizes can adopt this technology - whether through individual setups or collaborative efforts. This creates a ripple effect, encouraging partnerships and fostering growth across the industry.

Collaboration within the cotton ginning community holds immense promise. Shared processing facilities can reduce upfront costs and take advantage of economies of scale. Regional coordination improves transportation efficiency and helps establish reliable supply chains for ethanol distribution. Platforms like cottongins.org provide spaces for operators to connect with local partners, share resources, and streamline their operations.

Beyond the financial advantages, converting waste into ethanol underscores a commitment to environmental responsibility. By producing clean-burning ethanol, cotton gins can lower their carbon emissions and contribute to national renewable energy goals, reinforcing the industry's role in tackling sustainability challenges.

To succeed, operators need strategic planning, technical know-how, and a willingness to collaborate. Those who adopt this technology today position themselves as leaders in sustainable agriculture, paving the way for diversified and resilient business models.

This shift not only redefines cotton ginning operations but also creates long-term value for the entire industry.

FAQs

How is cotton gin waste turned into ethanol through fermentation, and what are the main steps in the process?

Cotton gin waste can be turned into ethanol through a process known as fermentation. This involves three key steps:

- Pretreatment: The waste material undergoes preparation to break down its rigid lignocellulosic structure. Techniques like steam explosion or ultrasonication are employed to release fermentable sugars from the material.

- Saccharification: Enzymes are introduced to convert the complex carbohydrates in the waste into simple sugars, making them suitable for fermentation.

- Fermentation: Microorganisms like yeast or bacteria ferment these sugars into ethanol. Sometimes, this step is combined with saccharification in a process called simultaneous saccharification and fermentation (SSF), which streamlines the process.

This approach not only helps manage waste effectively but also produces a renewable fuel, offering solutions to challenges in both energy production and waste reduction.

What makes cotton gin waste a good option for producing ethanol compared to other biomass materials?

Cotton gin waste stands out as a smart option for ethanol production thanks to its availability and potential to reduce waste. As a byproduct of processing cotton, it’s plentiful and often overlooked, making it both cost-effective and a solution to waste management issues.

Rich in lignocellulosic material, this waste is well-suited for fermentation, which is key to producing ethanol efficiently. Unlike crops like corn, it doesn’t compete with food supplies, offering a more eco-friendly alternative for bioethanol production. Plus, turning this waste into a valuable resource could open up new revenue opportunities for the cotton industry.

What are the economic and regulatory advantages of producing ethanol from cotton gin waste?

Turning cotton gin waste into ethanol isn't just about managing waste - it's about unlocking new revenue opportunities while cutting down on disposal expenses. By transforming these byproducts, operators can effectively turn what was once a challenge into a financial win.

On the regulatory side, ethanol production can open doors to government incentives and help lower the costs associated with waste management and environmental compliance. Plus, it aligns with broader eco-friendly initiatives, boosting a company's public image and showing commitment to sustainability.

These benefits go beyond just financial gains. They also position cotton gin operators to thrive in a market that's increasingly focused on sustainable practices and environmental responsibility.