Cotton fiber length, or staple length, is one of the most critical factors in determining yarn quality and strength. Longer fibers improve inter-fiber bonding, making yarn stronger, smoother, and more durable. Shorter fibers, however, lead to weaker yarns with more irregularities, such as thick and thin spots, and are prone to breaking during processing. Here's what you need to know:

- Longer Fibers: Create stronger, smoother yarns with fewer imperfections. They require less twist during spinning, increasing production efficiency.

- Shorter Fibers: Result in weaker yarns with more breakage points, higher hairiness, and issues like pilling in fabrics.

- Measurement Methods: Tools like High Volume Instrument (HVI) and Advanced Fiber Information System (AFIS) are used to assess fiber length and uniformity.

- Improving Fiber Length: Choosing the right cotton variety, managing water during growth, and careful ginning practices are key to preserving fiber length.

Long-staple cotton (over 1.1 inches) outperforms short-staple cotton in strength, durability, and fabric quality, making it ideal for high-end products like luxury bedding and fine clothing. Short-staple cotton is more suited for items like denim and blends due to its lower cost.

To improve yarn quality, focus on selecting long-fiber varieties, maintaining proper growing conditions, and reducing damage during processing.

"Thread Therapy with Dr. Bob" Cotton Staples & Fiber Explained

Cotton Fiber Length: Measurement and Importance

Cotton fiber length, often referred to as staple length in the industry, represents the average upper-half-mean fiber length. This measurement plays a crucial role in determining how cotton performs during spinning and impacts the strength and quality of the final yarn.

Longer fibers create better inter-fiber connections, improving cohesion and tensile strength. They also require less twist during spinning, resulting in softer, more flexible yarns and reducing problems like pilling. This makes fiber length a fundamental factor for assessing cotton's processing potential.

Why Fiber Length Matters in Cotton Processing

Fiber length has a direct influence on yarn performance. Shorter fibers with lower elongation are more prone to breaking during processing, which can lead to yarns with 32.3% lower work-to-break values compared to those made from high-quality fibers. Additionally, these yarns may develop as many as 46 extra thick and thin spots per kilometer.

"Longer fibers are preferred because they produce stronger and smoother yarn, resulting in higher-quality fabrics." – Cotton Brazil

The Uniformity Index, which measures the ratio between the mean fiber length and the upper-half-mean length, ensures consistent yarn thickness and smooth processing. In Brazil, 100% of cotton undergoes High Volume Instrument (HVI) analysis across 12 specialized laboratories, providing reliable and transparent quality data.

Methods for Measuring Fiber Length

HVI testing is the industry standard for measuring fiber length. It quickly determines the Upper Half Mean Length and the Uniformity Index using photoelectric sensors. Both Brazilian and U.S. cotton are fully analyzed using this method.

For a more detailed fiber analysis, the Advanced Fiber Information System (AFIS) measures Short Fiber Content (SFCn), Mean Length (Ln), and the 5% longest fibers (L5%) by sampling 3,000 fibers across 40 bins of 1.27 mm each. While slower and more expensive than HVI testing, AFIS provides deeper insights into fiber variation, which is essential for breeding better cotton varieties.

To ensure accurate measurements, cotton lint must be conditioned at 70°F ± 2°F and 65% ± 2% relative humidity for at least two days to reach moisture equilibrium. Following USDA-standard procedures ensures consistent and reproducible data. Understanding these measurement techniques is critical for selecting the best fibers and refining processing methods.

How Fiber Length Affects Yarn Strength and Durability

Now that we've examined fiber length assessments, let's dive into how this characteristic directly impacts yarn strength and durability. Longer fibers tend to create stronger, more reliable connections within the yarn, while shorter fibers introduce weak points. This explains why staple length is such a critical factor in cotton processing.

Fiber Length and Inter-Fiber Bonding

Yarn strength doesn't come from the individual fibers themselves but from the friction and bonding between them. Longer cotton fibers provide a greater contact area, which enhances adherence through friction and improves the mechanical interlocking of fibers within the yarn.

"Longer and finer fibers result in stronger yarns due to the increased number of fibers within the cross-section of a yarn as well as the increased surface area of contact among fibers, which increases the adherence among fibers due to friction." – Journal of Cotton Research

This improved contact allows for better stress distribution across the yarn when tension is applied. When fibers overlap more extensively, the load spreads across multiple connection points, reducing the likelihood of failure at any single weak spot. As a result, the yarn becomes more resistant to breaking during both processing and regular use. These dynamics highlight how fiber alignment plays a pivotal role in maintaining yarn integrity. However, while longer fibers enhance bonding and strength, the presence of numerous fiber ends can counteract these benefits.

How Fiber Ends Reduce Yarn Strength

Fiber ends are a weak link in the yarn structure. Shorter fibers lead to a higher density of fiber ends per unit length, which diminishes the overall strength of the yarn. These fiber ends can't transmit tension as effectively as the continuous body of the fiber, creating breaks in the structure that compromise durability.

"The failure of a yarn made by spinning staple fibers is normally due to fiber slippage and not fibers breaking within the yarn." – Journal of Cotton Research

Yarns made from fibers with lower elongation - those that break more easily during processing - often result in shorter segments, which further reduce the yarn's work-to-break values and increase irregularities. Each additional fiber end increases the risk of slippage, weakening both the strength and uniformity of the final product.

Fiber Length and Spinning Efficiency

Fiber length plays a critical role in spinning efficiency. It directly impacts yarn strength, consistency, production speed, and manufacturing costs.

Twist Level and Fiber Length

Longer fibers naturally require less twist during the spinning process. This is because they create better friction and interlocking, resulting in cleaner and more consistent yarn. This improved yarn quality enhances the overall efficiency of production.

"Staple length of cotton affects yarn strength, evenness, and efficiency of the spinning process." – CottonWorks

On the other hand, shorter fibers demand a higher twist to make up for their reduced interlocking ability. While this added twist strengthens the yarn, it also increases production time and reduces flexibility. Ring spinning, in particular, is highly sensitive to fiber quality. Mills producing fine-count, ring-spun yarns need to prioritize longer fibers to ensure efficiency and reduce fiber breakage. These factors significantly influence production costs.

Balancing Fiber Length and Production Costs

Selecting the right fiber length is a balancing act between achieving high-quality yarn and managing costs. Long-staple cotton, which includes fibers longer than 1.1 inches, typically commands higher prices. For instance, the base loan rate for upland cotton is approximately $0.52 per pound, but longer fibers fetch a premium in the market. While this higher cost may seem steep, it often pays off by reducing waste and ensuring smoother production processes.

To further streamline operations, mills can use tools like High Volume Instrument (HVI) data and MILLNet™ to create consistent laydowns - a uniform mix of cotton bales that helps control raw material costs. Additionally, maintaining length uniformity ratios between 80.0% and 81.9% is considered a baseline quality standard. Targeting even higher uniformity levels can minimize processing challenges and boost spinning efficiency.

sbb-itb-0e617ca

Short-Staple vs. Long-Staple Cotton: Performance Comparison

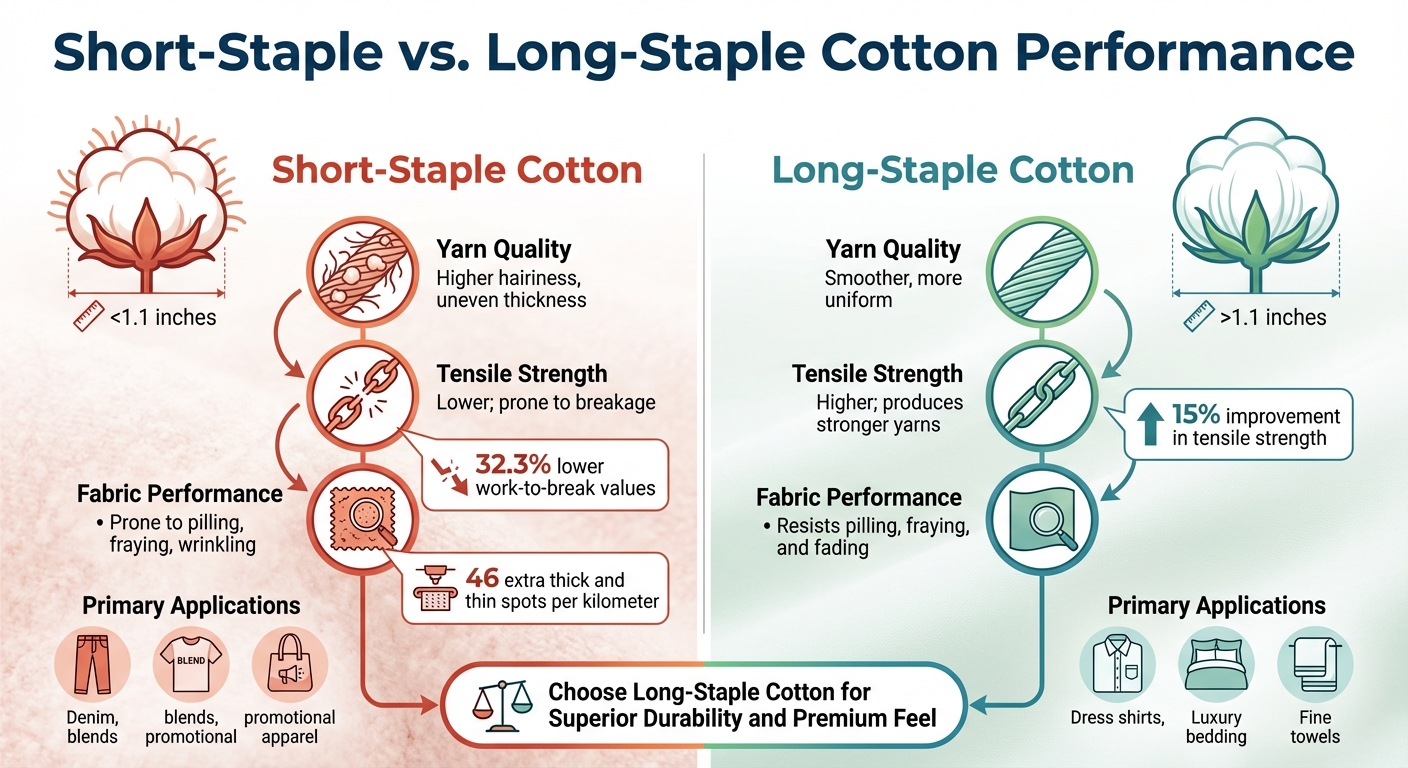

Short-Staple vs Long-Staple Cotton: Performance Comparison Chart

The performance of cotton fibers varies significantly depending on their length, with short-staple and long-staple cotton offering distinct advantages and challenges in yarn production and fabric quality.

Short-Staple Cotton Performance Metrics

Short-staple cotton, defined as fibers measuring less than 1.1 inches, presents notable challenges in yarn production. The shorter fibers lead to increased hairiness and uneven thickness in the yarn. This results in weaker tensile strength and a higher likelihood of breakage during spinning, as the reduced fiber length limits inter-fiber bonding during processing.

When it comes to fabrics, short-staple cotton is more prone to pilling, the formation of small fiber balls on the surface after wear and washing. These fabrics are also more likely to fray, wrinkle, and fade over time compared to those made from longer fibers. Despite these drawbacks, short-staple cotton, such as upland cotton, is commonly used in products like denim, blends, and promotional apparel. Its textured appearance is acceptable for these applications but falls short for higher-end uses.

Long-staple cotton, on the other hand, addresses many of these limitations.

Long-Staple Cotton Benefits in Yarn Production

Long-staple cotton, with fibers longer than 1.1 inches, delivers a range of benefits. Premium varieties such as Pima and Egyptian cotton produce smoother, more uniform yarns with significantly greater tensile strength. The increased fiber length creates more bonding points between fibers, resulting in stronger and more durable yarn.

"The longer the cotton fiber, the stronger, softer, and more durable the resulting fabric." – PimaCott

One industrial case study highlights the advantages of long-staple cotton. A textile mill compared standard-length cotton (approximately 1.0 inch or 25 mm) with long-staple cotton (approximately 1.4 inches or 35 mm). By employing advanced combing and carding techniques, the mill achieved a 15% improvement in tensile strength with the long-staple yarn. Fabrics made from this yarn exhibited reduced hairiness, better uniformity, and significantly less pilling after laundering. These qualities make long-staple cotton ideal for premium products like high-quality dress shirts and luxury bedding, where durability and a refined finish justify the higher cost.

The table below highlights the key differences between short- and long-staple cotton:

| Feature | Short-Staple Cotton | Long-Staple Cotton |

|---|---|---|

| Fiber Length | <1.1 inches | >1.1 inches |

| Yarn Quality | Higher hairiness, uneven thickness | Smoother, more uniform |

| Tensile Strength | Lower; prone to breakage | Higher; produces stronger yarns |

| Fabric Performance | Prone to pilling, fraying, wrinkling | Resists pilling, fraying, and fading |

| Primary Applications | Denim, blends, promotional apparel | Dress shirts, luxury bedding |

These differences emphasize why fiber length plays a crucial role in determining the quality and performance of yarns and fabrics.

How to Improve Cotton Fiber Length for Better Yarn Quality

Did you know that genetics play a massive role - over 80% - in determining cotton fiber length? While genetic factors set the stage, smart environmental management and careful processing ensure fibers reach their full potential. Here’s how to make the most of these advantages.

Growing Practices for Longer Cotton Fibers

Choosing the right cotton variety is step one. Varieties like Acala are well-known for their naturally longer and stronger fibers. Modern breeding techniques, like recurrent selection, are also pushing the boundaries of fiber length improvement.

Water management is another big piece of the puzzle. During the critical first 16–25 days of boll development, consistent irrigation is key to maximizing fiber length. Jeffrey C. Silvertooth, an Extension Agronomist at the University of Arizona, puts it plainly:

"Besides variety, water management and maintaining good plant-water relations during fiber development is probably the most important factor affecting fiber length".

To keep fibers growing, avoid letting more than 50% of plant-available soil-water deplete between irrigation cycles. This ensures the plants have the moisture they need during this sensitive growth phase.

Timely harvesting is equally important. Delaying harvest can expose fibers to weathering, which shortens them before they even reach the gin. Maintaining proper soil potassium levels also plays a role, as potassium deficiencies can stunt fiber elongation and weaken the overall quality.

Processing Methods That Preserve Fiber Length

Field practices set the foundation, but processing methods are just as crucial for protecting fiber length. Ginning, for example, can be a make-or-break step. Keeping lint moisture between 6% and 8% during ginning is essential. If moisture drops below 5%, fibers lose about 1/100 inch in length for every percentage point decrease. That’s a significant loss due to mechanical breakage.

Additionally, minimize cleaning to only what’s necessary for removing trash. While industrial lint cleaners are effective at removing debris, overly aggressive cleaning can damage fibers, creating breakage and neps (tangled fibers) that hurt both length and spinning performance.

Fiber elongation properties also matter. High-elongation fibers, which can stretch between 9.9% and 11% before breaking, handle ginning and spinning stresses far better than low-elongation fibers (7.7% to 8.8%). In fact, yarns made from low-elongation fibers can have a work-to-break value that’s up to 32.3% lower than their high-elongation counterparts. This makes elongation a critical consideration for both breeding and processing.

Conclusion

The length of cotton fibers plays a key role in determining the quality and strength of yarn. It influences how fibers bond, the presence of weak points, and the overall efficiency of the spinning process - a connection that has been extensively studied and documented.

Longer fibers offer more surface area for inter-fiber friction, which enhances the strength and durability of yarn. They also reduce the likelihood of break points, increasing tensile strength by as much as 15%.

However, achieving top-notch yarn quality isn’t just about fiber length. Uniformity and elongation are equally important. Cotton with inconsistent fiber lengths can complicate processing, while fibers with higher elongation are less prone to breaking. This leads to better work-to-break performance and fewer imperfections in the final yarn.

To ensure high-quality output, growers and manufacturers should focus on selecting cotton varieties with strong genetic fiber traits, carefully managing water and nutrients, and avoiding damage during processing by reducing the use of harsh cleaning methods.

FAQs

How does the length of cotton fibers affect yarn quality and the spinning process?

The length of cotton fibers is a key factor in determining the quality of yarn and the efficiency of the spinning process. Longer fibers, often called long or extra-long staple cotton, are much easier to align and twist into continuous yarn. This results in yarns that are stronger, smoother, and more consistent. Plus, these fibers are less prone to breakage during spinning, which means machines can run faster with fewer interruptions - saving both time and money.

On the other hand, short fibers - typically under 0.5 inches - can create challenges. They tend to cause irregularities in the yarn, increase breakage, and slow down the spinning process. Short fibers also lead to more defects, which require extra time and effort to correct. For modern spinning technologies, maintaining a uniform fiber length is critical, as even minor inconsistencies can disrupt production.

To ensure smooth operations and high-quality yarn, cotton growers and manufacturers prioritize achieving longer and more uniform fibers. This focus not only enhances spinning efficiency but also leads to stronger yarns and better results in fabric production.

How can cotton fiber length be improved during growth and processing?

Improving the length of cotton fibers begins with choosing the right genetics. Modern breeding methods use cutting-edge tools to pinpoint and develop cotton varieties that naturally produce longer and more consistent fibers. This process often involves utilizing genetic markers and data-driven selection techniques. Beyond genetics, effective farming practices play a crucial role. Balanced nutrient management, maintaining optimal planting density, and avoiding early defoliation are all essential for encouraging fiber elongation during the growth phase.

When it comes to processing, gentle handling is critical. For instance, using roller gins instead of saw gins can help preserve fiber length since roller gins are less abrasive and maintain better uniformity. Adjustments during lint cleaning, like reducing cylinder speeds and briefly reintroducing moisture before cleaning, also help minimize fiber damage. By combining advanced genetics, thoughtful farming strategies, and careful processing techniques, growers and manufacturers can produce longer fibers that contribute to stronger, higher-quality yarn.

Why is long-staple cotton used in premium textiles?

Long-staple cotton stands out as the go-to choice for premium textiles, thanks to its longer fibers that produce smoother, stronger, and more durable yarn. With fewer short fibers in the mix, the yarn achieves better consistency, fewer imperfections, and enhanced strength - key qualities for crafting luxury fabrics. On top of that, textiles made from long-staple cotton offer exceptional softness and comfort while maintaining their look and durability, even with regular use.