Cotton fiber testing ensures high-quality yarn and fabric production by analyzing key properties like fiber length, strength, uniformity, micronaire, and color grade. These properties directly impact textile durability, appearance, and processing efficiency. Modern methods such as High Volume Instrument (HVI) and Advanced Fiber Information System (AFIS) provide fast and precise results, helping manufacturers optimize production and meet market standards.

Key Takeaways:

- HVI Testing: Measures staple length, strength, micronaire, and color for quick quality assessment.

- AFIS Analysis: Offers detailed insights into fiber maturity, fineness, and trash content.

- Colorimeters: Evaluate brightness and yellowness for grading cotton.

- Results guide textile production, ensure fair market pricing, and improve global trade efficiency.

Accurate testing is critical for maintaining quality in an industry producing over 117 million bales globally (2020/21). Learn how these methods optimize production and ensure consistent cotton classification.

High Volume Instrument (HVI) Cotton Fiber Testing System

Methods for Testing Cotton Fiber

Modern cotton fiber testing uses advanced instruments to accurately measure fiber properties, ensuring consistent quality evaluations.

High Volume Instrument (HVI) Testing Overview

HVI systems are the go-to method for quick and detailed fiber analysis. These machines use video cameras and sensors to measure multiple fiber properties at once. Key measurements include:

| Property | Measurement Range | Industry Standard |

|---|---|---|

| Fiber Length | 0.5-2.0 inches | Determined by staple length |

| Strength | 15-45 grams/tex | Higher values indicate stronger fibers |

| Micronaire | 2.4-7.5 | Ideal range: 3.5-4.9 |

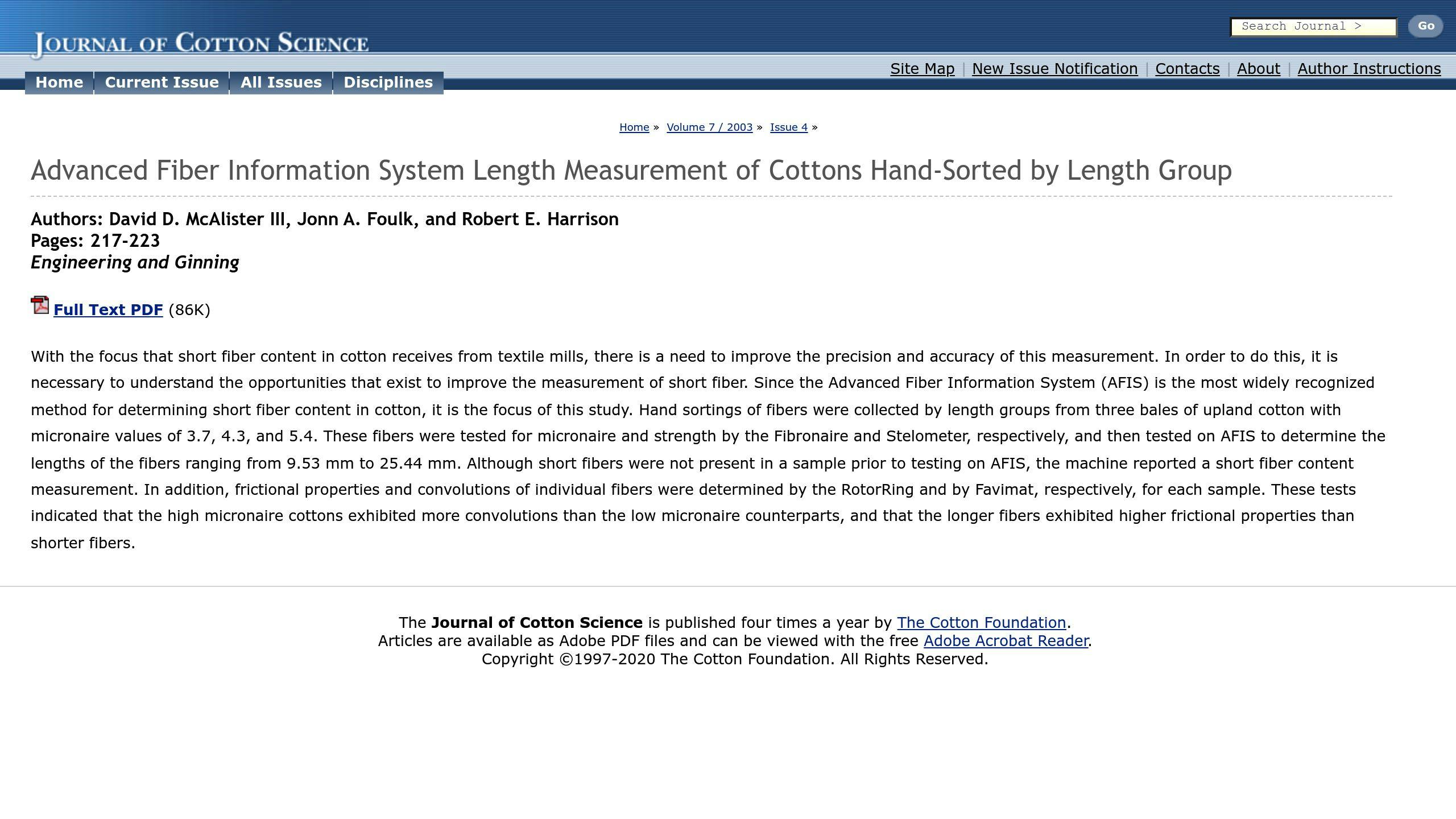

Advanced Fiber Information System (AFIS) Features

AFIS offers a deeper, more detailed analysis of individual fiber characteristics compared to HVI. It identifies small variations that can impact yarn quality and production efficiency. Key metrics include:

- Fiber maturity distribution

- Individual fiber fineness

- Nep content and size

- Percentage of short fibers

- Trash particle size and spread

This detailed data helps manufacturers fine-tune spinning processes and avoid production issues. While AFIS primarily focuses on individual fiber traits, it also evaluates visual and physical quality through trash and color analysis.

Measuring Color and Trash Content

Specialized tools, like colorimeters and image processing software, are used to assess cotton's color and trash levels.

"Color is measured using a cotton colorimeter, which determines the degrees of reflectance (Rd) and yellowness (+b)" [1]

Colorimeters measure brightness (Rd) and yellowness (+b), which are key for cotton grading. Image analysis systems further evaluate trash size and distribution.

To maintain accuracy, regular calibration is essential. Manufacturers recommend daily calibration checks and periodic comprehensive recalibrations [3]. When combined with HVI and AFIS data, these measurements provide a full picture of cotton quality, meeting global trade and industry standards.

Detailed Explanation of Cotton Fiber Quality Factors

Fiber Length and Uniformity

Fiber length and how evenly it's distributed are key to yarn and fabric quality. The High Volume Instrument (HVI) measures the upper-half-mean length from a length fibrogram, providing essential data for textile production. Uniformity indicates the consistency of fiber lengths within a sample. Low uniformity can weaken yarns, leading to lower-quality fabrics and uneven results during spinning.

Fiber Strength and Elongation

Strength and elongation are just as important as length and uniformity for ensuring durability during processing and in the final fabric. Fiber strength, measured in grams per tex, is a key factor in creating long-lasting textiles.

"Fiber strength is largely influenced by genetics, growth environment, and crop management" [4]

Elongation measures how much a fiber can stretch under stress, which is especially important during weaving. Together, strength and elongation determine how well cotton fibers perform during manufacturing. Alongside these, fineness and maturity also significantly impact cotton's overall performance and market value.

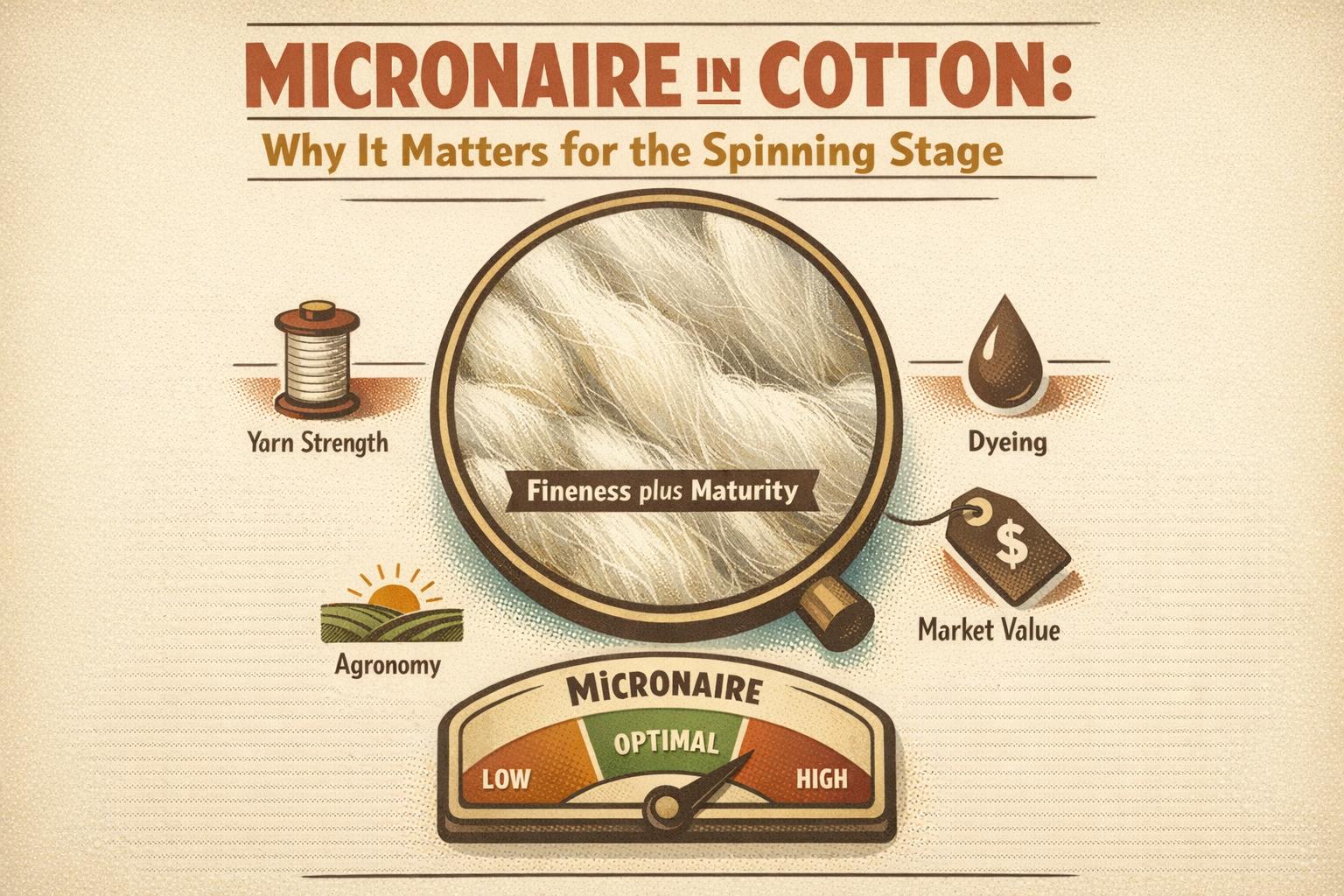

Micronaire and Fiber Maturity

Micronaire values, which range from 2.4 to 7.5, are crucial for assessing cotton quality. For upland cotton varieties, the ideal range is between 3.5 and 4.9 [2]. These values help manufacturers:

- Optimize machinery settings

- Predict how fibers will perform during processing

- Evaluate fiber maturity

- Ensure the quality of the final product

Micronaire readings are heavily influenced by growing conditions [2][4]. Fibers with readings below 3.0 require careful handling to prevent damage, while those above 5.0 can negatively affect the fabric's texture and appearance.

sbb-itb-0e617ca

Uses of Cotton Fiber Testing Results

Optimizing Textile Production

Fiber testing data is essential for improving spinning processes in textile production. For example, strong fiber test results allow manufacturers to increase spinning speeds without sacrificing quality. On the other hand, weaker fibers require slower machinery speeds to avoid breakages and maintain consistent output.

Manufacturers rely on fiber testing data to:

- Adjust carding equipment based on fiber length and uniformity

- Use micronaire values to prevent damage during processing

- Monitor fiber properties to maintain consistent quality and avoid production issues

"The quality of the cotton fibers directly impacts the quality of the final product, and thus, accurate testing is crucial for maintaining consistent quality and efficiency in production."

In addition to production improvements, fiber testing results are critical for determining cotton's market value and classification.

Cotton Classification and Market Value

The USDA uses fiber testing data to grade cotton quality, ensuring fair pricing and transparency in the market. High Volume Instrument (HVI) and Advanced Fiber Information System (AFIS) data provide consistent metrics that guide classification and pricing.

Here’s how key quality parameters affect cotton’s value and use:

| Quality Parameter | Impact on Value and Use |

|---|---|

| Fiber Length | Determines grade and spinning potential |

| Strength | Influences quality rating and end-product applications |

| Micronaire | Affects value ranges and processing needs |

Standardized testing protocols, like those from the USDA, have transformed cotton marketing by:

- Offering reliable quality benchmarks

- Ensuring precise pricing

- Supporting fair negotiations

- Streamlining international trade

For cotton processors, accurate testing ensures they meet buyer requirements and choose the best processing methods. This standardized system not only guarantees product quality but also enhances global trade efficiency - vital in an industry that produced around 117 million bales in 2020/21 [1].

Conclusion

Testing Methods Overview

Modern textile machinery relies on precise fiber testing, especially for strength and consistency, to meet the demands of high-speed production. Tools like High Volume Instrument (HVI) and Advanced Fiber Information System (AFIS) testing play a key role in maintaining quality control. Here's how they contribute:

| Testing Method | Purpose in the Industry |

|---|---|

| HVI Testing | Core quality assessment and classification |

| AFIS Analysis | In-depth evaluation of fiber properties |

| Combined Use | Enhances production processes and market positioning |

Advancements in Fiber Testing

Artificial intelligence and machine learning are reshaping fiber testing, making it faster and more accurate. These technologies can predict performance better and improve calibration processes. Meanwhile, automated testing systems boost efficiency and precision. As these advancements continue, they will further cement fiber testing as a cornerstone of global cotton quality and industry competitiveness.

"The accuracy of cotton fiber testing is crucial for the textile industry as it directly affects the quality of yarns and fabrics produced."

Additional Resources: cottongins.org

As fiber testing evolves, staying connected with processing facilities is vital. Platforms like cottongins.org provide a directory of U.S. cotton gins, helping industry professionals collaborate and maintain quality standards. This resource supports the alignment of testing protocols and quality control efforts across the cotton processing sector.

FAQs

How to measure staple length of cotton?

Staple length, a key factor in cotton quality, is measured using High Volume Instrument (HVI) technology. This method aligns the fibers and calculates the upper-half-mean length, which is the average length of the longer half of the fibers. This approach delivers precise and consistent results for assessing cotton quality.

"The accuracy of staple length measurement is crucial for determining the quality of cotton fibers and their suitability for textile production" [1][4][5]

To get reliable results, it's important to properly condition the cotton sample before testing. Modern HVI systems have replaced the older "hand stapling" method, offering more consistent and accurate measurements across the industry.

The process includes:

- Preparing and conditioning the cotton sample

- Aligning fibers through combing

- Using the HVI system for automated length calculation

Measuring staple length is a critical step in ensuring cotton fibers meet the standards required for textile production. Alongside other fiber quality metrics, it plays a central role in cotton classification and helps ensure high performance in manufacturing.