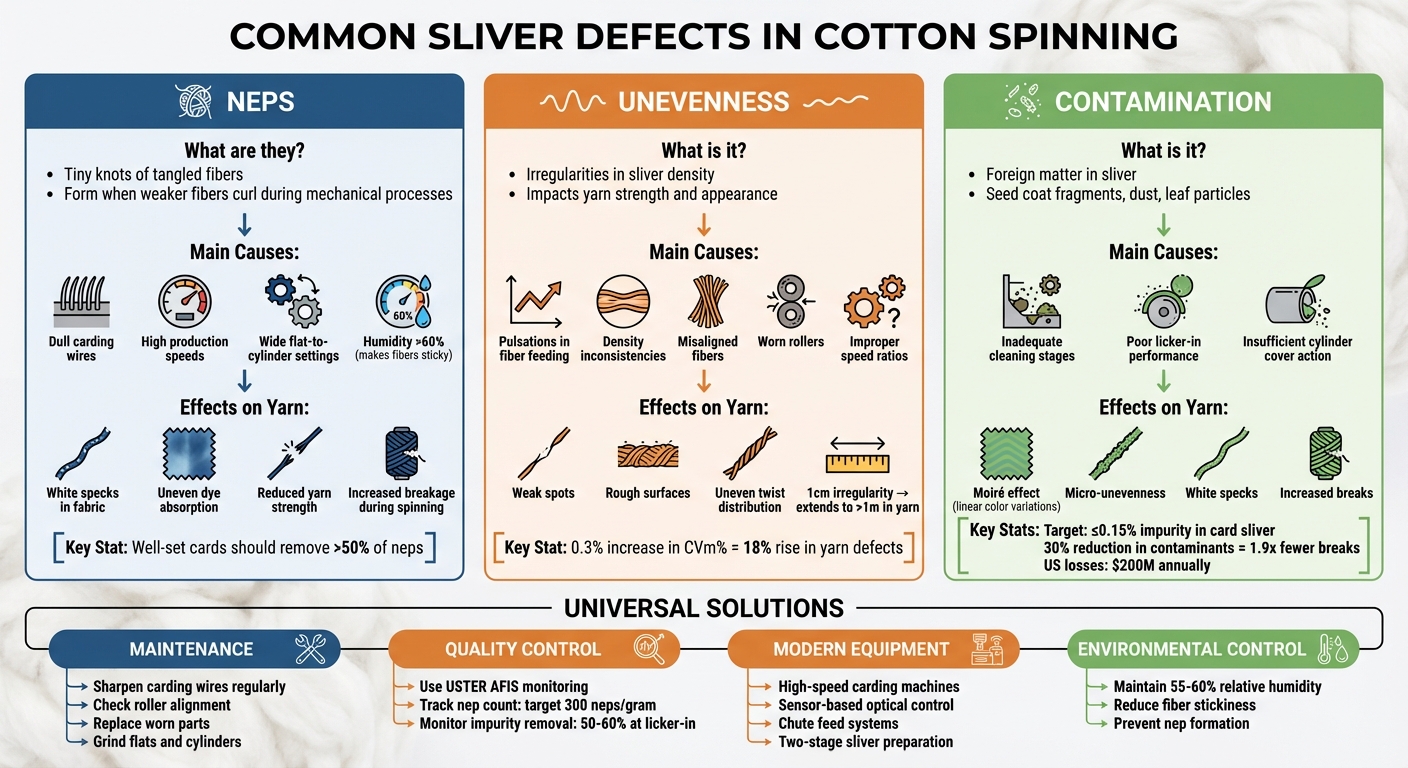

Sliver defects can significantly impact yarn quality, production efficiency, and costs in cotton spinning. Common issues include neps (tiny fiber knots), unevenness, and contamination. These defects often arise from improper machine settings, poor maintenance, or inconsistent feeding during carding and drawing. Even small sliver imperfections can multiply into larger defects in finished yarn, leading to weaker strength, higher breakage rates, and visible flaws in fabrics.

Key Takeaways:

- Neps: Caused by tangled fibers due to dull carding wires, high speeds, or excessive humidity.

- Unevenness: Results from density inconsistencies, misaligned fibers, or worn rollers.

- Contamination: Includes seed coat fragments, dust, and other impurities missed during cleaning.

Solutions:

- Maintenance: Regularly sharpen carding wires, check roller alignment, and replace worn parts.

- Quality Control: Use systems like USTER AFIS to monitor neps, impurities, and fiber consistency.

- Modern Equipment: High-speed carding machines and chute feed systems improve sliver quality.

- Environmental Control: Maintain 55–60% relative humidity to reduce fiber stickiness and nep formation.

By addressing these issues early, mills can improve yarn strength, reduce waste, and enhance production efficiency.

Common Cotton Sliver Defects: Causes, Effects, and Prevention Methods

Common Sliver Defects in Cotton Spinning

Uneven Sliver

Even minor irregularities in sliver density can heavily influence yarn strength and its overall appearance. These issues often arise from pulsations in fiber feeding, density inconsistencies, and misaligned fibers. Factors like improper speed ratios, incorrect roller spacing, and worn-out carding elements can amplify these defects throughout the spinning process.

In ring spinning, where draft ratios typically range from 80 to 100x, even a 1 cm irregularity in the sliver can extend to over 1 m of yarn, impacting its quality. Moreover, increasing the CVm% (coefficient of variation of mass) of the sliver by just 0.3% can lead to an 18% rise in yarn defects.

"Any pulsation in fiber feeding during the ring spinning process increases surface roughness in the yarn, and demonstrated that this effect originates from micro-irregularities present in the sliver" - G. Grosberg

Variations in sliver density lead to uneven twist distribution, creating weak spots, rough surfaces, and indistinct segments in the yarn. Typically, the Uster unevenness index for yarns made from clean slivers falls between 12–15%, but contaminated slivers can push this figure above 18%.

Next, let’s delve into the formation of neps and their impact on yarn quality.

Neps in Sliver

Neps are tiny knots of tangled fibers that form when weaker fibers curl or roll during mechanical processes. These fibers, often lacking rigidity, are especially prone to tangling under the beating and rubbing actions of carding machinery.

Dull carding wires exacerbate the issue by failing to control fiber movement, which leads to rolling and tangling. Other contributing factors include high production speeds and wide flat-to-cylinder settings. Environmental conditions also play a role - humidity levels above 60% make fibers more pliable and sticky, increasing the likelihood of neps forming.

"A well set card with good mechanical condition should remove more than 50% of the neps presented to it." - Bhavdip Paldiya, Dept. of Textile Technology, Sarvajanik College of Engineering & Technology

The effects of neps are visible in the final product, causing white specks, uneven dye absorption, reduced yarn strength, and increased breakage during spinning. In ring spinning, the number of defects per kilometer of yarn is directly tied to the number of neps in the sliver.

Now, let’s examine how contaminants further compromise yarn integrity.

Contamination and Foreign Matter

Contaminants like seed coat fragments, leaf particles, dust, and oily residues disrupt the spinning process by creating micro-unevenness and causing the "moiré effect" - visible linear color variations on the yarn surface.

"Moiré effect - linear color variations on the yarn surface caused by contaminants - is a visual indicator of quality deterioration." - H. Stalder

Impurity removal occurs at various stages of processing. The licker-in section of the carding machine removes 50–60% of impurities, targeting sterile seeds and stiff cotton, while the cylinder cover section eliminates 3–10%, focusing on finer impurities and neps. For card sliver, the target impurity content is generally kept at 0.15% or less.

The impact of contamination is significant. Yarns made from slivers with a 30% reduction in neps and dust particles experience nearly 1.9 times fewer breaks compared to those from unregulated slivers. In the U.S., financial losses from "white speck" neps - often caused by immature fibers or biological contaminants - are estimated to reach $200 million annually.

sbb-itb-0e617ca

Carding faults l Sliver defects l Reasons

How to Prevent and Fix Sliver Defects

Preventing sliver defects involves a mix of consistent maintenance, up-to-date technology, and systematic quality checks. The key is addressing issues at their source before they escalate into costly yarn problems.

Maintenance and Operating Procedures

Regular maintenance is the backbone of defect prevention. The "Four Fronts and One Accurate" rule ensures that the licker-in roller, cylinder, cover plate, and doffer needle teeth remain sharp, while maintaining precise spacings. This approach helps avoid fiber hang-ups and the twisting that leads to new neps during processing.

"The card is the heart of spinning mill." - Mazharul Islam Kiron, Founder & Editor of Textile Learner

Routine grinding of flats and cylinders prevents patchy webs, and worn wire points must be replaced immediately to avoid creating holes in the web. Polishing surfaces with '00' emery paper and a paste of French chalk and turpentine ensures smooth fiber-contact surfaces, reducing fiber buildup on key components.

Check coiler and table calendar rollers for eccentricity, wobbling, or worn gears, as these can cause uneven sliver percentages. Trumpets should also be inspected for burrs or oblong wear, and replacing them with properly sized ones ensures consistent sliver thickness. Adjust the tension draft gradually to stabilize frequent sliver breaks.

Environmental conditions play a vital role too. Maintaining relative humidity between 55% and 60% in the carding area minimizes fiber stickiness, which can lead to nep formation. Light and even feeding reduces cylinder loading, enhancing the removal of neps. By combining equipment care with controlled environmental factors, mills can create a strong foundation for further technological advancements.

Modern Spinning Technology

Adopting sensor-based optical control systems allows real-time detection of neps, mass irregularities, and contaminants in the sliver. These systems catch defects early, preventing them from reaching the finished yarn.

High-speed carding machines with tight gauges improve fiber separation and nep removal by increasing contact between fibers and needle teeth.

"The tight spacing makes the needle teeth have more contact with the fibers... which enhances the carding effect and makes neps easy to remove." - TradeTextile

Chute feed systems eliminate manual lap feeding, reducing feed variation and improving sliver consistency. Apron-doff systems enhance web collection, minimizing breakages during material transfer. Mills that use two-stage sliver preparation achieve better fiber alignment and cleanliness compared to single-stage setups.

Properly maintained carding machines can eliminate 70% to 90% of neps, while combing machines remove an additional 50% to 60%. Opening and cleaning lines reduce trash content by about 30%, with carding machines removing up to 85% more. Advanced technology ensures minimal defects during production, while robust quality checks confirm ongoing improvements.

Quality Control Methods

The USTER AFIS system offers reliable monitoring by measuring individual fiber characteristics such as neps, trash, and maturity - details that bundle testing often misses. This single-fiber testing method provides insight throughout the spinning process.

Tracking nep count variations between carding machines helps identify units needing maintenance, such as those with dull needles or improper spacing. Aim for an impurity removal efficiency of 50–60% at the licker-in and 3–10% at the cylinder cover, keeping the card sliver impurity rate below 0.15%.

| Quality Parameter | Measurement Tool | Control Target |

|---|---|---|

| Neps & Seed Coat Neps | USTER AFIS | 300 neps/gram (50% benchmark for 28mm fiber) |

| Impurity Content | Visual/AFIS | ≤0.15% in card sliver |

| Short Fiber Content | USTER AFIS | Predict sliver strength; compare to mill standards |

| Maturity Ratio | USTER AFIS | IFC <6% (very high) to >15% (very low) |

Benchmarking against USTER STATISTICS helps mills determine if fiber fineness, trash levels, and maturity meet global production standards. By analyzing equipment performance and quality output, mills can quickly address irregularities. Since raw materials account for more than 50% of total manufacturing costs in spinning mills, these quality control measures reduce waste and improve efficiency, ultimately boosting yarn strength and consistency.

Other Common Sliver Defects: Patchiness, Bulkiness, and Breaks

Beyond unevenness, neps, and contamination, issues like patchiness, bulkiness, and breaks can also compromise sliver quality. These problems can be addressed with specific mechanical tweaks and environmental adjustments to improve overall performance.

Fixing Patchy Webs

Patchy webs happen when fibers fail to distribute evenly. The main culprits? Cylinder loading, damaged wires, or waste buildup in the cylinder undercasing. Air currents or incorrect calendar-shell roller tension can also create patches.

Roller adhesion, often caused by high humidity or too much soft waste, can lead to visible defects like patches or "singles". To fix this, make sure to regularly grind flats and cylinders and replace any damaged wires immediately. Adjust the settings between the cylinder and flats, as well as the cylinder and back plate, to ensure proper alignment. Increasing cage suction and fully opening the mixing before the card can also help reduce patches. If roller adhesion persists, lowering the relative humidity and limiting soft waste in the mix may resolve the issue. These steps work alongside earlier maintenance practices to promote even fiber distribution.

Fixing Bulky Sliver

Bulky sliver is often the result of oversized or damaged trumpets that fail to compress fibers effectively. Low calendar pressure and insufficient tension can make the problem worse.

The solution? Calibrate trumpet sizes to match your sliver hank and replace any trumpets showing signs of wear, burrs, or oblong bores. Boosting calendar roller pressure and fine-tuning rack pressure will also improve sliver compaction. Even minor damage to trumpets can increase unevenness (U%) in the sliver, so regular inspections are critical. These adjustments ensure fibers are compressed tightly and consistently.

Preventing Sliver Breaks

Sliver breaks can disrupt production and often point to issues with tension, fiber transfer, or environmental conditions. Excessive tension between the doffer and calendar roller, poor fiber transfer, air disturbances, worn gears, or undersized trumpets are common causes.

To address this, reduce the tension draft step by step until the breaks stop. Install air barriers near the web area to minimize disturbances. Maintaining relative humidity between 50–60% can prevent fibers from becoming too brittle or sticky. Introducing an apron-doff system can also improve web collection and conversion into sliver. Routine checks of table calendar rollers and gears can catch mechanical issues early, preventing breaks before they occur. These measures align with earlier quality control practices to maintain smooth operations.

| Defect | Primary Causes | Recommended Remedies |

|---|---|---|

| Patchy Web | Cylinder loading, damaged wires, air currents, roller adhesion | Grind/replace wires, adjust settings, increase cage suction, control humidity |

| Bulky Sliver | Oversized trumpets, low calendar pressure | Calibrate trumpet size, increase calendar and rack pressure |

| Sliver Breaks | High tension, poor fiber transfer, air currents, worn components | Reduce tension, install air barriers, maintain 50–60% RH, inspect components |

Conclusion

The strategies highlighted in this article emphasize how maintaining tight control over sliver quality is essential for achieving high-performance cotton spinning. As Rimtex Industries aptly states: "Sliver is the basis of yarn making process; yarn inherits its properties and qualities from sliver".

Practical steps can help ensure consistent sliver quality, as most defects can be avoided with proper measures. Mechanical precision plays a crucial role - keeping licker points sharp and ensuring accurate spacing can eliminate 50% to 60% of impurities at the licker-in stage. Additionally, modern sensor-based systems provide real-time detection of neps and mass irregularities, allowing immediate adjustments. Mills that adopt two-stage carding have seen a remarkable drop in yarn breakage rates - from 0.83 to 0.16 per unit length - resulting in better efficiency and higher-quality output. Furthermore, reducing neps and dust by 30% can lead to nearly twice as few yarn breaks during spinning, significantly boosting productivity. These improvements directly enhance both production efficiency and the overall performance of the yarn.

FAQs

How can I tell if unevenness is coming from carding or drawing?

Unevenness during carding often arises due to problems such as inadequate fiber opening, poor transfer between components, or contamination in the fibers. On the other hand, drawing-related unevenness is typically caused by irregular sliver stretching or drafting inconsistencies. To pinpoint the issue, carefully observe the specific process stage and look for disruptions in the smooth flow of fibers.

What’s the fastest way to cut nep levels without losing output?

To reduce nep levels quickly without affecting output, focus on adjusting process parameters. For example, lowering the beater speed and fine-tuning machine settings can make a big difference. High beater speeds often lead to more fiber breakage and increased nep formation. The goal should be to minimize fiber damage while keeping the process efficient.

Which sliver tests should I track daily to prevent yarn breaks?

To minimize yarn breaks, it's essential to keep a close eye on daily sliver tests like nep count, nep size, fiber cleanliness, and fiber rupture. These factors play a direct role in determining yarn quality and contribute to smoother spinning processes. Consistent monitoring allows for early detection of potential problems and helps maintain uniform product quality.