Certification for cotton gin suppliers isn't just a badge - it's a game-changer. It builds trust, improves transparency, and opens doors to high-value markets. Certified equipment suppliers play a crucial role in maintaining cotton quality and meeting industry demands. Here's why certification matters:

- Credibility: Certification signals a commitment to quality, earning trust from mills and merchants.

- Traceability: Detailed records ensure transparency across the supply chain, reducing risks like fraud.

- Premium Access: Certified suppliers gain entry to high-value markets and long-term partnerships.

- Compliance: Certification aligns with regulations, minimizing liability and ensuring smooth operations.

- Competitive Edge: Certified suppliers stand out, securing better contracts and stronger customer loyalty.

Certification isn't just about meeting standards - it's about thriving in a market that values quality and reliability. Suppliers who embrace certification are better equipped to meet the growing demands of the cotton industry.

1. Builds Credibility and Market Trust

When suppliers pursue certification, they make a visible commitment to quality that resonates throughout the cotton gin industry. Certification sends a clear message to mills and buyers worldwide: these suppliers adhere to good ginning practices, which instantly builds trust.

Certified gins show they comply with top-tier processing standards, helping buyers decide which bales to purchase. For equipment suppliers, their machinery becomes a key part of a trusted system valued by mills. By demonstrating that their equipment supports certification requirements - such as protecting fiber quality through specific features - suppliers gain a distinct edge in market recognition. This credibility boosts their visibility across the industry.

For mills, quality consistency is non-negotiable - it directly impacts production and profitability. Certified gins ensure this consistency by implementing proper moisture management techniques.

The certification framework itself offers strategic perks. Its tiered rating system allows suppliers to highlight particular strengths, like gentle drying methods or seed cotton conditioning. This shifts the focus from price alone to proven performance metrics. It also helps suppliers carve out niches of expertise, enabling them to market their products to specific segments.

Operational advantages further solidify trust. Certified gins, when optimized, can enhance the value of cotton for both farmers and textile mills. Suppliers can emphasize tangible benefits like reduced energy costs, faster production speeds, higher turnouts, and improved cotton grades - outcomes that stem from avoiding harmful practices. These measurable results reinforce a supplier's reputation with every successful installation.

Certification also fosters long-term partnerships. Mills and merchants often stick with certified suppliers because they can count on consistent bale quality, quicker processing, and reduced waste. Suppliers who can prove their equipment contributes to these benefits become essential partners, rather than just another vendor.

Taking it a step further, pursuing higher certifications beyond the Primary Certification distinguishes suppliers even more. Achieving multiple advanced certifications creates a hierarchy of trustworthiness, offering buyers independent proof of quality they can rely on.

2. Improves Traceability and Supply Chain Transparency

Traceability has become a cornerstone of the modern cotton supply chain. Certified suppliers maintain detailed, verifiable records that follow cotton from the farm, through every stage of processing, to its final form. These records provide mills and merchants with the clarity they need to make well-informed purchasing decisions, creating a solid base for advanced tracking methods.

Digital tracking systems have taken this transparency to the next level. For instance, DATT technology tracks cotton from raw fiber to finished bale, assigning each stage a digital passport. This creates an unchangeable record, ensuring stakeholders have a reliable reference throughout the supply chain, effectively closing any gaps in documentation.

The Certified Cotton Gin Program further supports this effort by helping merchants and mills identify gins that prioritize high-quality processing for textile mills. This level of transparency directly ties into the trust built through certification standards.

For suppliers aiming to meet GOTS certification standards, traceability requirements are even more rigorous. GOTS mandates independent verification to confirm that materials entering the supply chain are authentic and traceable back to their source - whether organic farms or farm groups. This is particularly critical at the ginning stage, where the risk of contamination or mixing with non-certified material is highest. Certification bodies conduct annual audits, assessing both the input capacity for raw cotton and the output capacity for lint cotton to ensure that all documentation aligns with actual operations.

Transparency also brings practical benefits beyond fraud prevention. Certified gins consistently produce higher-quality bales through proper moisture management. On average, these bales outperform those from non-certified gins. This consistency allows mills to plan their production processes with confidence, avoiding unexpected disruptions or wasted resources caused by variable cotton quality.

Certified suppliers maintain comprehensive documentation systems that establish a complete chain of custody. When GOTS-certified gins receive raw cotton from farms or farm groups, all certifications are uploaded to a centralized registry. This centralization simplifies compliance checks for international buyers and regulatory bodies, reducing administrative overhead and streamlining verification processes.

Equipment suppliers also benefit when their machinery supports transparent and verifiable operations. Machines that help maintain proper moisture levels or prevent fiber contamination become essential to a traceable system valued by mills. Suppliers can showcase how their equipment contributes to the consistent quality achieved by certified gins, gaining a competitive edge in markets where transparency is non-negotiable.

Reducing risk is another key advantage. Mills can trust that they’re not purchasing damaged cotton, ensuring smoother processing and less waste. For suppliers, this builds stronger customer relationships based on verified performance rather than unsubstantiated claims. Transparency also safeguards their reputations by preventing ties to non-compliant practices.

This level of traceability proves that certified systems are both practical and achievable, opening doors to a growing market segment that prioritizes documented compliance and transparent sourcing.

3. Opens Access to Premium Market Segments

Certification unlocks doors to high-value market segments that uncertified suppliers simply can't access. Textile mills and merchants often see certified cotton gins as a hallmark of quality and reliability. For suppliers, meeting these rigorous standards translates into real business advantages and new opportunities to tap into specialized markets.

Certified cotton gins consistently deliver bales with better yields and higher grades compared to their non-certified counterparts. This directly boosts production efficiency and profitability. Equipment suppliers who can prove their machinery contributes to these results become indispensable partners in the success of certified gins.

Take GOTS certification, for example. It requires ginners to adopt specific processing protocols and advanced technology systems, driving ongoing demand for compliant machinery. This isn't a one-and-done scenario - certified gins need regular equipment upgrades to maintain compliance.

The certification structure also allows gins to carve out niches with unique specializations, each requiring tailored equipment. For instance, a gin pursuing Gentle Drying certification needs machinery that carefully manages moisture levels while preventing fiber damage. These specialized machines ensure consistent quality, as outlined in certification standards. Suppliers who focus on these niche needs can position themselves as experts, commanding premium prices for their solutions.

Building a strong reputation for supporting certified operations can significantly boost a supplier's credibility with mills and merchants. This creates a ripple effect, generating more business opportunities beyond just one customer. Additionally, the focus on avoiding fiber damage and maintaining strict temperature limits for heaters ensures a steady demand for advanced, high-performance equipment.

Efficiency is another key selling point. Certified gins often lower energy costs and speed up production, giving them a competitive edge in the marketplace. Suppliers who can demonstrate how their machinery drives these efficiencies shift the conversation from cost to value, helping gins improve profit margins and fostering long-term relationships.

Certification also opens up global opportunities. International buyers increasingly demand certified sourcing and compliance documentation. By supporting these standards, equipment suppliers can connect with export-focused operations. These customers typically have bigger budgets and plan further ahead, offering opportunities for long-term contracts that provide consistent revenue and growth.

Certification also boosts visibility. For example, suppliers may gain exposure through platforms like cottongins.org, a directory highlighting U.S. cotton gins committed to quality processing. This additional exposure helps suppliers connect with top-tier operations across the United States, further expanding their reach and solidifying their place in premium market segments.

sbb-itb-0e617ca

4. Ensures Compliance and Reduces Risk

Certification plays a crucial role in demonstrating compliance, helping suppliers safeguard themselves against liability claims. By providing machinery that meets certified standards and supports customers in maintaining compliance, suppliers create a solid record of due diligence aligned with established best practices.

The cotton gin industry operates within a complex web of regulations, and certification programs offer clear pathways to meet these requirements. For instance, the Certified Cotton Gin Program mandates strict adherence to standards like avoiding lint reclaimers and setting high-temperature limits on heaters to prevent fiber damage. These measures not only protect equipment performance but also ensure the quality of the final product, reducing risks for suppliers.

Different certification programs are tailored to address specific compliance needs. GOTS certification, for example, requires independent verification of ginners and traceability back to organic farms, reducing the risk of fraud during the ginning process. Similarly, BCI ginner certification spans three years and includes regular audits, driving demand for reliable and consistently performing equipment.

This diverse certification landscape encourages suppliers to design equipment that meets precise regulatory demands. Digital systems like DATT, which provide a digital passport for each process step, enhance transparency. Such technologies enable gins to build robust audit trails that satisfy both regulatory requirements and customer expectations.

The financial implications of non-compliance can be severe. Certification programs often include unannounced audits and ongoing monitoring, which help identify and mitigate hazards before they escalate into accidents or injuries. Suppliers who maintain certification and assist their customers in achieving it reduce their exposure to regulatory fines and penalties.

The widespread adoption of certification programs also creates a stable market for suppliers capable of delivering certified equipment.

Certification prepares suppliers for evolving regulations as well. When environmental or safety standards change, certified suppliers are often better positioned to update equipment specifications and documentation. This proactive approach minimizes disruptions, keeping both suppliers and their customers ahead of compliance deadlines.

Beyond legal compliance, certification ensures consistent bale quality and minimizes equipment-related issues for customers. Certified gins, for example, are recognized for maintaining proper moisture management, which helps mills reduce complaints and product returns.

The multi-category structure of certification programs also allows suppliers to address diverse compliance priorities. Whether focusing on Gentle Drying, Seed Cotton Conditioning, or other specialized areas, suppliers can demonstrate their expertise in meeting specific regulatory needs relevant to their customers' operations. This targeted approach simplifies compliance management while addressing critical operational risks.

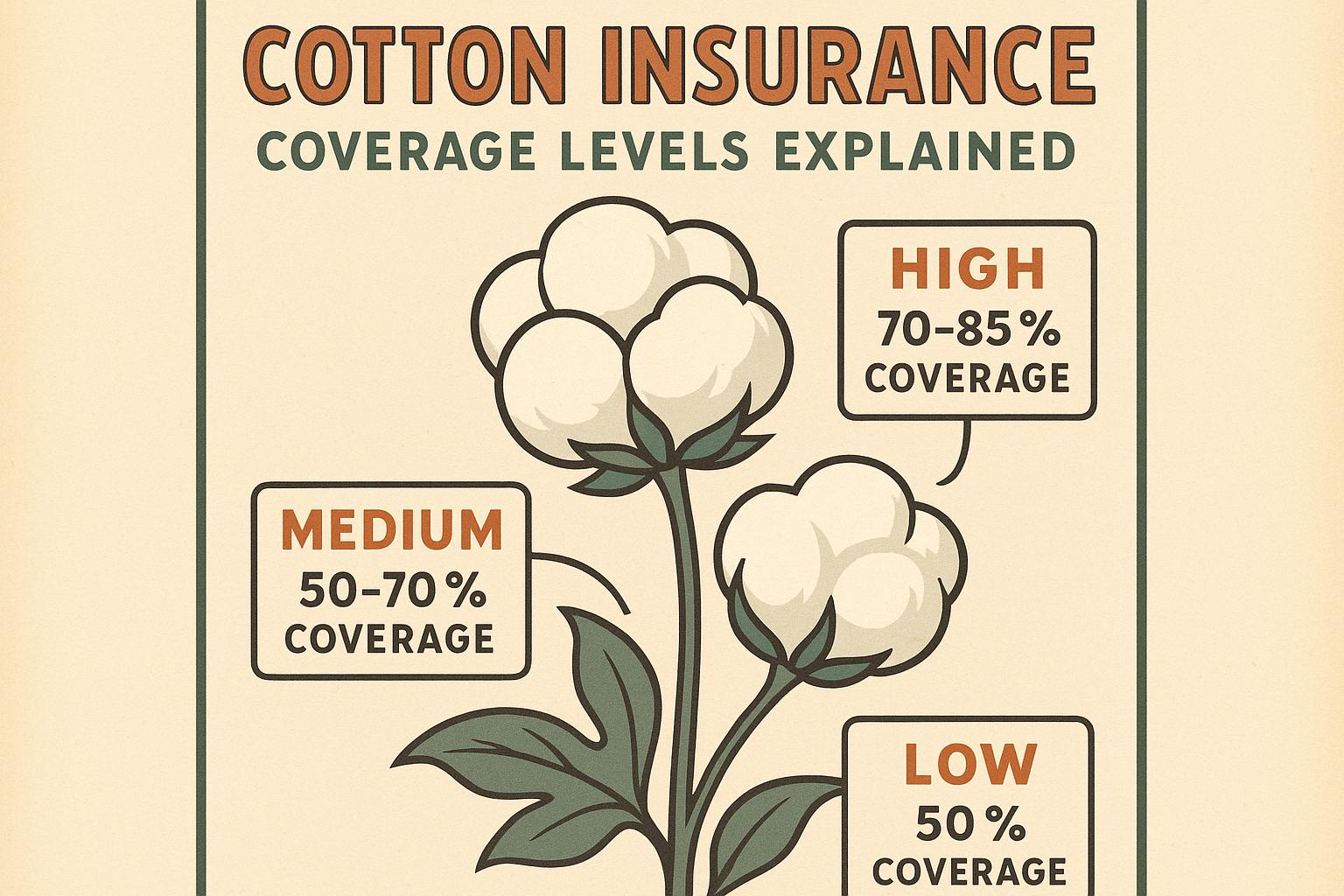

Certification can even lead to financial benefits, such as lower insurance costs. Suppliers with documented compliance often secure better insurance rates and terms, as insurers recognize the reduced risk associated with certified operations. This added cost efficiency boosts both profitability and risk management.

5. Provides Competitive Advantage in Equipment Sourcing

Certification sets suppliers apart by showcasing their commitment to high-quality standards. Cotton gins actively seek partners who share their rigorous certification goals, giving certified suppliers a clear edge in the market.

One major advantage is better market access. According to industry data, more than 50 cotton gins currently meet the Certified Cotton Gin Program's primary certification requirements, collectively processing over 2 million bales annually. These certified gins prioritize working with equipment suppliers who can support their certification efforts. Suppliers with verified credentials often receive preferential treatment, gaining not only access to these opportunities but also the ability to secure premium pricing. Their deep understanding of certification requirements strengthens their position as trusted vendors.

For example, when a gin requires equipment capable of maintaining strict temperature limits on heaters or managing moisture levels effectively, certified suppliers are uniquely equipped to meet these demands. This expertise, backed by measurable performance metrics, often leads to stronger contract negotiations and higher pricing power.

Certified gins also produce higher-quality bales and achieve consistent moisture management, which boosts production efficiency and enhances their reputation. For equipment suppliers, this translates into repeat business, referrals, and a spot on preferred vendor lists - further solidifying their competitive position.

The certification framework itself opens additional doors. The Certified Cotton Gin Program allows gins to focus on specific certification categories that align with their operational goals and buyer needs. Suppliers who understand these varied pathways can customize their offerings, distinguishing themselves not only from non-certified competitors but even from other certified suppliers.

Certified gins benefit from cost savings, such as lower energy expenses and faster production times, which often lead to long-term partnerships with their equipment suppliers.

In terms of marketing, certified suppliers leverage industry directories to highlight their credentials. By showcasing their ability to meet strict certification standards, they reinforce their reputation for quality and reliability. Listings on platforms like cottongins.org help connect these suppliers with gins that prioritize quality, enabling targeted outreach to the right audience.

With nearly two decades of proven results, certification has become a sustainable competitive advantage. As more gins seek dependable, quality-focused partners, certified suppliers are well-positioned to capture a growing share of the market.

Conclusion

Certification plays a crucial role in strengthening the market position of cotton gin equipment suppliers while supporting long-term growth. The five key benefits discussed - boosting credibility, improving traceability, opening doors to premium markets, ensuring compliance, and gaining a competitive edge - combine to provide significant value in an industry increasingly focused on quality and transparency.

With over 50 certified gins processing 2 million bales annually, certification serves as a stamp of approval for best practices. It connects suppliers to a global network of quality-driven businesses, building trust with cotton mills and merchants in a market that values reliability and precision.

Suppliers who achieve certification demonstrate their ability to meet rigorous standards, which directly appeals to mills and textile manufacturers looking for consistent quality and reduced waste. By implementing systems that ensure consistent moisture management and operational reliability, certified suppliers not only secure repeat business but also earn preferred vendor status. This kind of trust and reliability opens the door to higher-value contracts and premium market opportunities where buyers prioritize dependable performance.

Investing in certification also prepares suppliers for the future. As supply chain transparency becomes increasingly important and digital verification technologies evolve, certified suppliers are better positioned to stay ahead of industry shifts. The three-year certification cycle, which includes regular audits, ensures standards remain up-to-date and aligned with the latest industry demands.

For suppliers aiming to lead in quality and innovation, certification offers a pathway to join a network of businesses focused on excellence. With distinct certification ratings highlighting their strengths, suppliers can strategically target buyer priorities and stand out in a competitive marketplace. Ultimately, certification is both a flexible and forward-thinking strategy for those committed to meeting the evolving needs of the cotton industry.

FAQs

What are the benefits of certification for cotton gin equipment suppliers?

Certification plays a key role for cotton gin equipment suppliers by showcasing their dedication to quality standards and reliable practices. This not only strengthens their reputation but also reassures customers that their products and services meet established industry benchmarks, boosting confidence in their offerings.

On top of that, certification can give suppliers a leg up in the market, creating opportunities for new business and partnerships. Suppliers with certification are often viewed as dependable and professional, making them a go-to choice for cotton gin operators who prioritize efficiency and top-notch quality in their operations.

What traceability technologies are discussed in the article, and how do they enhance the cotton gin supply chain?

Traceability technologies like barcode systems, RFID tags, and blockchain tracking play a key role in maintaining transparency and accountability across the supply chain. These tools make it possible to monitor every step, from manufacturing equipment to final delivery.

With these systems in place, suppliers can offer precise tracking details, improve quality control processes, and strengthen customer trust. They also help simplify operations while ensuring adherence to industry standards - a win for both suppliers and cotton gin operators.

How does certification help cotton gin suppliers access premium market opportunities?

Certification plays a key role in boosting a cotton gin supplier's reputation and market presence. By aligning with established industry standards, suppliers showcase their dedication to delivering quality, safety, and reliability - qualities that resonate with high-value clients and premium markets.

Businesses often favor certified suppliers because certification signals reduced risks and adherence to industry regulations. This can pave the way for exclusive contracts, larger projects, and enduring partnerships that might not be accessible otherwise.