Defoliating cotton is essential for improving yield, fiber quality, and harvest efficiency. The process involves removing leaves to expose bolls, ensuring even drying and reducing contamination. Here’s a quick breakdown of the strategies covered:

- Evaluate Crop Readiness: Use the NACB method (≤4) and knife test to confirm boll maturity.

- Leverage Technology: Satellite imagery and precision tools improve timing and application accuracy.

- Select the Right Defoliant: Match products to crop maturity and weather conditions.

- Timing and Application: Apply when 60–80% of bolls are open, with a 7–14 day gap before harvest.

- Adapt to Weather: Adjust chemical rates based on temperature and humidity.

- Monitor and Adjust: Use real-time data and field checks to refine strategies.

- Coordinate with Harvest: Align defoliation with harvest schedules for best results.

Key Tip: Temperature is critical - defoliants work best above 12°C, with adjustments needed in cooler conditions. Combining traditional methods with modern tools ensures optimal results.

This guide provides actionable steps to streamline the defoliation process while maintaining yield and fiber quality.

Effective Timing of Cotton Defoliation

1. Evaluating Crop Readiness

Properly gauging when crops are ready is key to successful defoliation, ensuring the best timing and results. This process uses multiple techniques to pinpoint the perfect moment to start.

The Nodes Above Cracked Boll (NACB) method and knife test are two widely used approaches. When the NACB count drops to 4 or below - indicating about 60% of bolls are open - it’s a green light for defoliation [5]. The knife test complements this by confirming boll maturity. Key signs include a darkened seed coat, absence of jelly-like material, and noticeable resistance when cutting [5].

Temperature plays a big role in evaluating readiness, as it directly impacts boll maturity [3]. Many farmers now blend traditional methods with tools like satellite imagery to get a clearer picture of field conditions [1].

"Defoliation removes leaves to expose bolls, improving airflow and speeding up drying" [3]

Timing is everything. Starting too early can lower yield and fiber quality, while delaying increases the risk of trash content and staining [1][4]. Satellite imagery, for example, can highlight areas needing different defoliation strategies, helping farmers fine-tune their approach [1].

Once readiness is confirmed, using technology can make defoliation even more precise and effective.

2. Using Technology for Accuracy

Modern tools have revolutionized cotton defoliation, helping farmers fine-tune their strategies. With crop biomass data and satellite imagery, decisions about timing and application methods are now more precise.

How Satellite Imagery Helps

Satellite images give farmers a top-down view of their cotton fields, revealing crop maturity details that might be missed on the ground [1]. This broader perspective allows for targeted defoliation in specific field zones.

Precision Tools in Agriculture

Advanced systems now help farmers calculate the best chemical concentrations and water volumes for defoliation [1]. These tools take into account:

- Crop health and maturity: Ensuring treatments are applied at the right stage.

- Field and environmental conditions: Adapting strategies to the field’s specific needs.

"By making defoliation more precise and efficient, technology can improve harvest efficiency by promoting more even boll opening, reducing trash and staining in harvested cotton, and lowering harvest costs" [1][4].

Blending Technology with Field Practices

Precision platforms don’t replace traditional methods - they enhance them. These tools assist with field scouting, crop tracking, and defoliant selection by:

- Pinpointing areas that need closer inspection.

- Tracking crop maturation patterns.

- Offering data-based recommendations.

- Monitoring environmental factors that affect outcomes.

Balancing these technologies with tried-and-true practices ensures better defoliation results while minimizing risks [1].

Reducing Waste and Runoff

By allowing for more accurate chemical applications, these tools help cut down on waste and runoff. This not only improves harvest efficiency but also aligns with environmental and cost-saving goals [4].

With technology driving better accuracy, the next focus is selecting the ideal defoliant for optimal results.

3. Selecting the Appropriate Defoliant

Choosing the right defoliant is a key step in preparing for a successful cotton harvest. To get the best results, it's important to weigh several factors carefully.

Maturity-Based Selection

The stage of cotton maturity plays a big role in defoliant choice. Herbicidal defoliants work best when about 60% of the bolls are open, while desiccants like sodium chlorate are more effective when 80% of the bolls are open [2]. Tools like satellite imagery can also help by providing a clear view of field conditions and maturity levels [1].

Weather Considerations

Temperature is a major factor in how well defoliants perform. These products work best when temperatures are above 12°C. Standard application rates are effective at temperatures over 25.6°C, but cooler conditions (11.3–25.6°C) may require higher rates. For temperatures below 11.3°C, alternative products might be necessary [3].

Boosting Effectiveness

Adjuvants can make a big difference by improving canopy coverage and minimizing spray drift, especially in dense foliage or challenging weather [1]. Temperature also impacts defoliant performance, with higher rates often needed in cooler conditions. In fields with regrowth after rain, combining chemicals like ethephon and thidiazuron can enhance leaf drop [3].

Sustainable Options

For those looking for environmentally friendly solutions, organic and electric defoliation methods are becoming more common [4]. These options offer effective results while being mindful of environmental impact.

Once the right defoliant is selected, timing and application methods will play a crucial role in achieving the best results.

4. Timing and Methods of Application

Choosing the right defoliant is just the beginning. To get the best results, you also need to focus on timing and how you apply it.

Finding the Best Timing

The success of defoliation largely depends on crop maturity and weather conditions. Herbicidal defoliants perform best when 60% of the bolls are open, while desiccants like sodium chlorate are more effective at 80% open bolls [2]. Key indicators like NACB ≤ 4, as mentioned earlier, are helpful for determining the right time [5].

How Temperature and Weather Play a Role

Temperature has a direct impact on how well defoliants work:

- Above 25.6°C: Standard application rates are effective.

- Between 11.3–25.6°C: You may need to increase the application rate.

- Below 11.3°C: Consider delaying the application or switching to alternative products.

In cooler conditions (11.3–25.6°C), higher rates or combining defoliants with ethephon can help improve boll opening [3].

Best Practices for Application

Getting thorough coverage is essential. Adjuvants like InterLock can make a big difference by reducing spray drift and improving canopy penetration [1]. Using tools like satellite imagery can also help by identifying areas in the field with different maturity levels, ensuring a more uniform application [1].

Timing Before Harvest

Plan for a 7–14 day gap between defoliation and harvest to achieve the best results [5]. Small delays usually don’t disrupt the overall schedule [3].

While timing and application methods are critical, remember that external factors like weather can also heavily influence defoliation outcomes.

sbb-itb-0e617ca

5. Dealing with Weather and Other Factors

Temperature plays a major role in how effective defoliation is. When it drops below 12°C, plant metabolism slows down, making harvest aids less effective [3]. Here's a quick guide for adjusting defoliant rates based on temperature: stick to standard rates when it's above 25.6°C, increase rates for temperatures between 11.3–25.6°C, and consider alternative methods if it dips below 11.3°C.

Humidity and rain can also complicate things. High humidity slows drying, while rain encourages regrowth. To combat this, consider using weather-resistant adjuvants like InterLock, StrikeLock, or PowerLock to improve coverage and reduce the risk of wash-off [1][4].

Modern tools like satellite imagery make it easier to manage weather-related challenges. These images can pinpoint moisture variations, show differences in crop maturity, and identify areas that might need customized defoliation strategies [1].

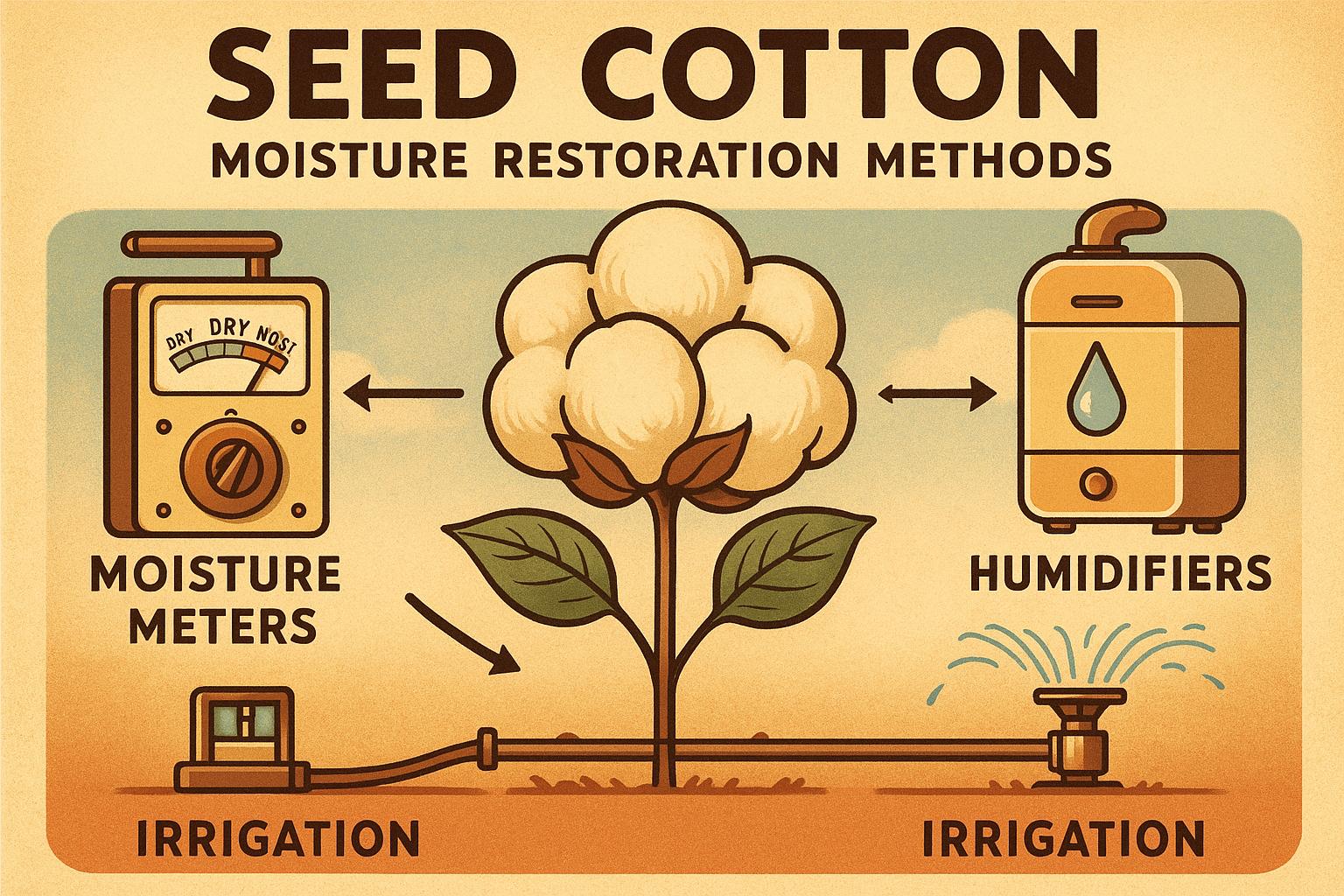

Soil moisture is another critical factor. Too much moisture can lead to regrowth, while too little stresses plants and reduces the effectiveness of defoliants [1][2]. Regularly checking soil moisture levels can help you fine-tune irrigation schedules for better results.

"Ensuring the efficacy of harvest aid products will help maximise harvested yield and reduce leaf trash contamination in modules." - CottonInfo, Defoliation Booklet 2023 [3]

If regrowth occurs after rain, products like thidiazuron and ethephon can help with leaf drop [3]. The key is to stay on top of changing conditions. Use weather forecasting tools and the latest technology to make informed decisions about when and how to apply defoliants for the best outcomes.

6. Adjusting Strategies as Needed

Successful defoliation relies on adjusting approaches to match changing field conditions. Tools like satellite imagery and biomass measurements can help fine-tune treatments across different zones.

Frequent field checks are key to ensuring strategies align with crop maturity indicators, such as NACB and open boll percentages. Satellite tools provide real-time data, making it easier to refine plans as conditions evolve.

Temperature plays a big role in defoliant effectiveness. Here’s how to adjust rates based on the weather:

| Temperature Range | Adjustment Recommendation |

|---|---|

| Above 25.6°C | Use standard defoliant rates |

| 11.3-25.6°C | Increase defoliant rates |

| Below 11.3°C | Explore alternative methods |

If unexpected rain or regrowth occurs, combining ethephon with thidiazuron can help maintain progress under tough conditions [3].

Satellite imagery is especially useful for identifying areas that need specific treatments, such as:

- Adjusting defoliant rates in moisture-retaining zones

- Timing treatments for uneven crop maturity

- Modifying approaches for varying senescence levels

"The largest improvement in boll opening occurred when post-application temperatures were cool (mean 11.3°C min and 25.6°C max)" [3]

Using real-time data ensures defoliation stays effective, protecting both yield and fiber quality under a variety of conditions [1][4]. Collaborating with local agricultural extension services can also provide helpful region-specific advice.

Inspect results within 7-10 days and, if needed, apply follow-up treatments with alternative products or methods [2][5]. Coordinating these adjustments with harvest timing will help achieve the best efficiency and quality.

7. Coordinating Defoliation with Harvest

The final step in preparing for a successful cotton harvest is aligning defoliation with harvest operations. Timing is everything - defoliants are typically applied when about 60% of the bolls are open [2][5].

Temperature plays a key role in this process. Defoliants work best when morning temperatures are around 11.3°C and midday temperatures reach up to 25.6°C. Nighttime temperatures should stay above 12°C to keep the plants active and responsive to the chemicals [3].

Checking boll maturity is another important step. The knife method, which involves inspecting the seed coat's color and firmness, helps confirm readiness. Mature bolls will have darker seed coats, signaling they’re ready for defoliation [2].

Farmers can also use tools like cottongins.org to coordinate with local gins, ensuring harvest schedules align with gin availability and avoiding unnecessary delays. In cooler weather, mixing defoliants can help maintain their effectiveness [3].

"The largest improvement in boll opening occurred when post-application temperatures were cool (mean 11.3°C min and 25.6°C max), and the addition of ethephon had little influence in warmer conditions (17.7°C min and 31.4°C max)" [3]

Satellite imagery offers another layer of precision, helping farmers identify maturity zones and plan defoliation patterns. This technology also aids in syncing equipment movements with field conditions, reducing weather-related risks [1].

The window between defoliation and harvest is typically 7-10 days. During this time, regular field checks ensure the defoliation process is working as expected [2][5]. Proper timing safeguards fiber quality and maximizes profitability, which are key goals for any cotton producer.

Careful planning and coordination make the transition from defoliation to harvest smooth, ensuring both yield and quality are optimized.

Conclusion

Timing, accurate chemical use, and the integration of modern tools are key to effective cotton defoliation. These practices help maintain fiber quality and streamline harvest operations. Success hinges on careful execution and adjusting to field conditions, with temperature playing a major role in achieving the best results.

By combining methods like NACB counting with advanced tools such as satellite imagery, farmers can achieve more precise defoliation. Modern technology complements established practices, offering better accuracy in managing the process [1][4]. This blend of techniques enables farmers to make informed decisions while honoring proven methods.

To achieve the best outcomes, farmers should:

- Keep a close eye on field conditions and temperature

- Leverage technology for accurate applications

- Work with local resources to align harvest timing

- Adjust strategies as conditions evolve

Integrating traditional practices with modern tools represents the future of cotton defoliation. These strategies provide a clear path to producing high-quality cotton while improving harvest efficiency. By combining scientific insights with hands-on experience, farmers can boost both yield quality and operational performance.

FAQs

When to defoliate cotton?

Timing cotton defoliation is a key step in the harvest process. Generally, defoliants are applied when about 60% of the bolls are open [2]. Several factors play a role in determining the right moment:

- Temperature: Defoliants work best when minimum temperatures are above 12°C. Cooler conditions can reduce their effectiveness [3].

- Weather Forecast: Ideal weather conditions are crucial for optimal results [5].

Defoliants usually take 7-14 days to take effect, but this depends on the weather and the specific product used [5]. Applying too early may cause immature bolls to shed, while waiting too long can expose the crop to bad weather [3]. Timing it right helps align with harvest operations and supports better yield and fiber quality.